- Mechanical properties and electrical resistivity of SiC-TiC composites with nitrate sintering additives

Sung Min Soa,b, Hee Woong Hwanga,c, Sam Heang Yia,c, Joo Seok Parka,*, Kyoung Hun Kima, Kwang Ho Leed, Jongee Parke and Sung Gap Leec

aKorea Institute of Ceramic Engineering and Technology, Jinju, Korea

bInformation Materials Lab. Materials Engineering, Inha University, Incheon, Korea

cCeramic Engineering Department, Gyougsang National University, Jinju, Korea

dBooil Technology co., Ltd., Gunpo, Korea

eDepartment of Metallurgical and Materials Engineering, ATILIM University, Ankara, Turkey

We fabricated SiC-TiC

composites by hot-press sintering with aluminum and yttrium nitrate additive

and evaluated crystal phase, relative density, microstructure, electrical

resistivity and mechanical properties of the sintered body. And the effect of

nitrate additive on the densification of SiC-TiC composites was compared with

that of Al2O3 and Y2O3 additives.

Because nitrate additives were uniformly dispersed in SiC and TiC mixture, it

inhibited the growth of crystal grain between each other and formed fine and

uniform microstructure, thereby improving mechanical properties and electrical

resistivity. The electrical resistivity and flexural strength of the SiC-TiC

composite with aluminum and yttrium nitrate additive were 2.3 Ω·cm and 652.3

MPa respectively.

Keywords: SiC-TiC, Composites, Mechanical properties, Electrical resistivity, Nitrate additive

Silicon carbide (SiC) forms tetrahedron basic structure

by sp3 hybrid orbital function of carbon (C) and silicon (Si), and

strong covalent non-oxide having σ-bond between C and

Si. It is a ceramic material with excellent mechanical

properties such as hardness, strength, elastic modulus, and

abrasion resistance compared to other ceramic materials and additionally has

high thermal conductivity and stable properties to various acids and bases

[1-5]. As a result, it is applied as a core component in

various industries such as abrasives, heating elements, high

temperature structural materials, heat exchangers, mechanical

seals, bulletproof materials, and semiconductor manufacturing

process parts [6-9]. SiC can be classified into β-SiC

of cubic structure and α-SiC of a hexagonal and rhombohedral structure

according to the crystal structure. The α-SiC has different polytypes according

to the stacking sequences such as 4H, 6H, 15R, etc., and it is known that

various physical and electrical properties are expressed by this crystal

structure [10]. High purity SiC has a low electrical conductivity close to the

insulator, but recently, there has been a growing interest in

the application of SiC materials to the devices used

in extreme environments such as high temperature, high power,

and high frequency by controlling electric conductivity or an electrodischarge

machining for the processing of semiconductor process equipment parts or

complex shaped parts that require various electrical conductivity [11-13].

The electrical resistance of SiC can be lowered by doping

nitrogen (N) atoms in the SiC lattice, sintering with liquid phase additives

such as Al2O3, Y2O3, Sc2O3,

etc. in nitrogen atmosphere, or adding conductive additives such as TiN, ZrN,

TiC, TiB2 which helps to improve electrical conductivity [14-16].

Among them, TiC has the highest hardness, modulus of elasticity, coefficient of

thermal expansion, and lower electrical resistance

than SiC. Therefore, when forming a composite with SiC it

is expected to lower the electrical resistance and to improve mechanical

properties compared to SiC monoliths through particle strengthening effect

[17]. SiC-TiC composites can be prepared through liquid phase sintering with

the addition of oxide sintering aids such as Y2O3,

Al2O3-Y2O3, or reaction sintering

through a reduction of TiO2 added in SiC [18, 19]. In

addition, pressure sintering methods such as hot press sintering and spark

plasma sintering are used to manufacture products that are dense and have

excellent mechanical properties [20].

The study of SiC-TiC composites has been mainly focused

on improving mechanical properties such as fracture toughness through particle

strengthening mechanism. It is known that residual

stress due to mismatch of thermal expansion coefficient of TiC (α =

7.4 × 10-6 K-1)

particles uniformly dispersed in the SiC matrix (α = 4.5 × 10-6 K-1)

suppress the progress of cracks, thereby increasing the fracture toughness and

strength. Furthermore, Wei and Becher reported that the fracture toughness

increased by 50% when the TiC content in the SiC-TiC composite was 24.6 vol%

[21-24]. On the other hand, researches on the electrical properties of SiC-TiC

composites are rare. M. Khodaei et al. prepared a SiC-TiC composite

showing an electrical resistance of 2.2 × 105

Ω·m by the reaction between TiO2 and SiC [25].

Therefore, this study aims to manufacture low-resistance SiC-TiC

composites with excellent mechanical properties using Y3Al5O12

(yttrium aluminum garnet, YAG) as a liquid sintering aid. The electrical

resistance of SiC-TiC composites is greatly influenced by the grain size of the

components constituting the matrix, the amounts of additives,

and the uniform dispersion [26]. Therefore, aluminum

nitrate nonahydrate (Al(NO3)3·9H2O) and

yttrium nitrate hexahydrate Y(NO3)3·6H2O

dissolved in ethanol are used as sintering aids to uniformly control the

microstructure, and accordingly, the electrical resistance and mechanical

properties were investigated.

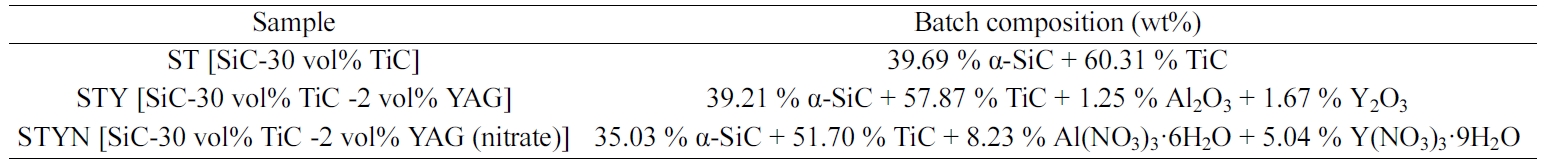

α-SiC powder (0.5 μm, 15C, Saint-Gobain, Norway) and TiC

powder (2-3 μm, Pacific Particulate Materials, Canada) with 6H crystal

structure were used as starting materials to prepare SiC-TiC

composites. Al(NO3)3·9H2O (98%,

Sigma-Aldrich, USA) and Y(NO3)3·6H2O (99.8%,

Sigma-Aldrich, USA) were used as sintering aids. Here, Al2O3

(0.2 μm Sumitomo Chemical, Japan) and Y2O3 (2 μm, high

Purity Chemical, Japan) were used as oxide sintering aids for comparison with

nitrate sintering aids. The raw materials were weighted as shown in Table 1 and

mixed mechanically for 12 h with SiC balls in a polypropylene jar using ethanol

medium. The mixed slurry was dried and passed through

200 mesh sieve to prepare a SiC-TiC mixed powder. The prepared powder was

placed in a graphite mold of 50 × 50 mm, and then sintered at

1,800-1,950 oC for 1 h under 40 MPa pressure in a nitrogen

atmosphere using a hot-press sintering furnace (SHP-30; Samyang Ceratech, South

Korea) to form a SiC-TiC composite.

The density of the prepared SiC-TiC composites was

measured using the Archimedes method, and the crystal phase analysis was

performed using an X-ray diffractometer (Smart Lab, Rigaku, Japan). The SiC-TiC

sintered body was tailored by 3×4×35 mm, and then the bending strength was

measured by 3 point method under span 30 mm and head speed 0.5 mm/s according

to ISO 14704 standard. Fracture toughness was calculated by measuring the

indented crack length using the formula (KIC =

0.018 (E/H) 0.5(P/C1.5) proposed by Miyoshi

et al. [27]. E is the modulus of elasticity, H is the Vickers hardness, P is

the indentation load, and C is half the average crack length. The

microstructure of the sintered body was observed using FE-SEM (JSM-7100F; Jeol,

Japan), and thermal conductivity was calculated by the equation

((k = ρ·Cp·D (k: thermal conductivity, ρ: density, Cp: heat capacity,

D: thermal diffusion

coefficient)) after measuring the thermal diffusion coefficient using a laser flash device (LFA 427, NETZSCH, Germany). The

specific resistance of the SiC-TiC

composites was measured using a resistance measuring instrument (CMT-SR1000N, Advanced Instrument Technology,

USA).

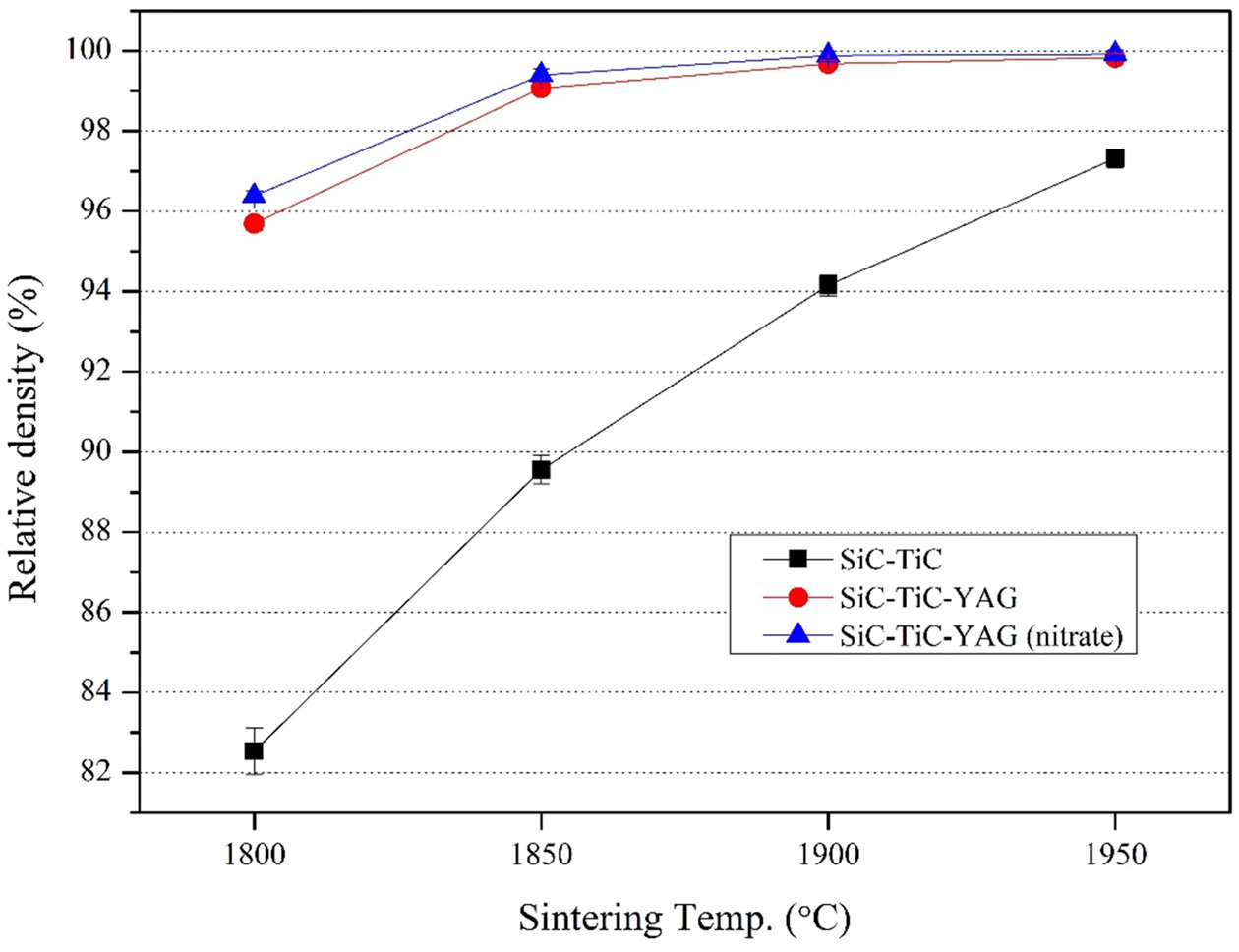

Fig. 1 is a graph showing the relative density of the

composite according to the sintering temperature. The relative density

increased with increasing sintering temperature. Reaching a maximum value at

1,950 oC. ST (SiC-30 vol% TiC) composition without sintering

aid shows a low relative density of about 82.5-97.3% depending on the sintering

temperature. However, STY (SiC-30 vol% TiC-2 vol% YAG) and STYN (SiC-30 vol%

TiC-2 vol% YAG) compositions with the sintering aid show the

relative density of 99% or more at the sintering temperature of 1,850 oC

or higher. Comparing the relative densities of nitrate and oxide sintering

aids, the relative density of STYN was slightly higher than that of STY from

the sintering temperature of 1,800 °C and the relative density of STY was

about 99.1% at 1,850 oC while that of STYN was 99.4%. Through

this result, it was found that nitrate sintering aid acts at a lower

temperature than oxide sintering aid, promotes sintering, and helps to

manufacture a denser sintered body [26].

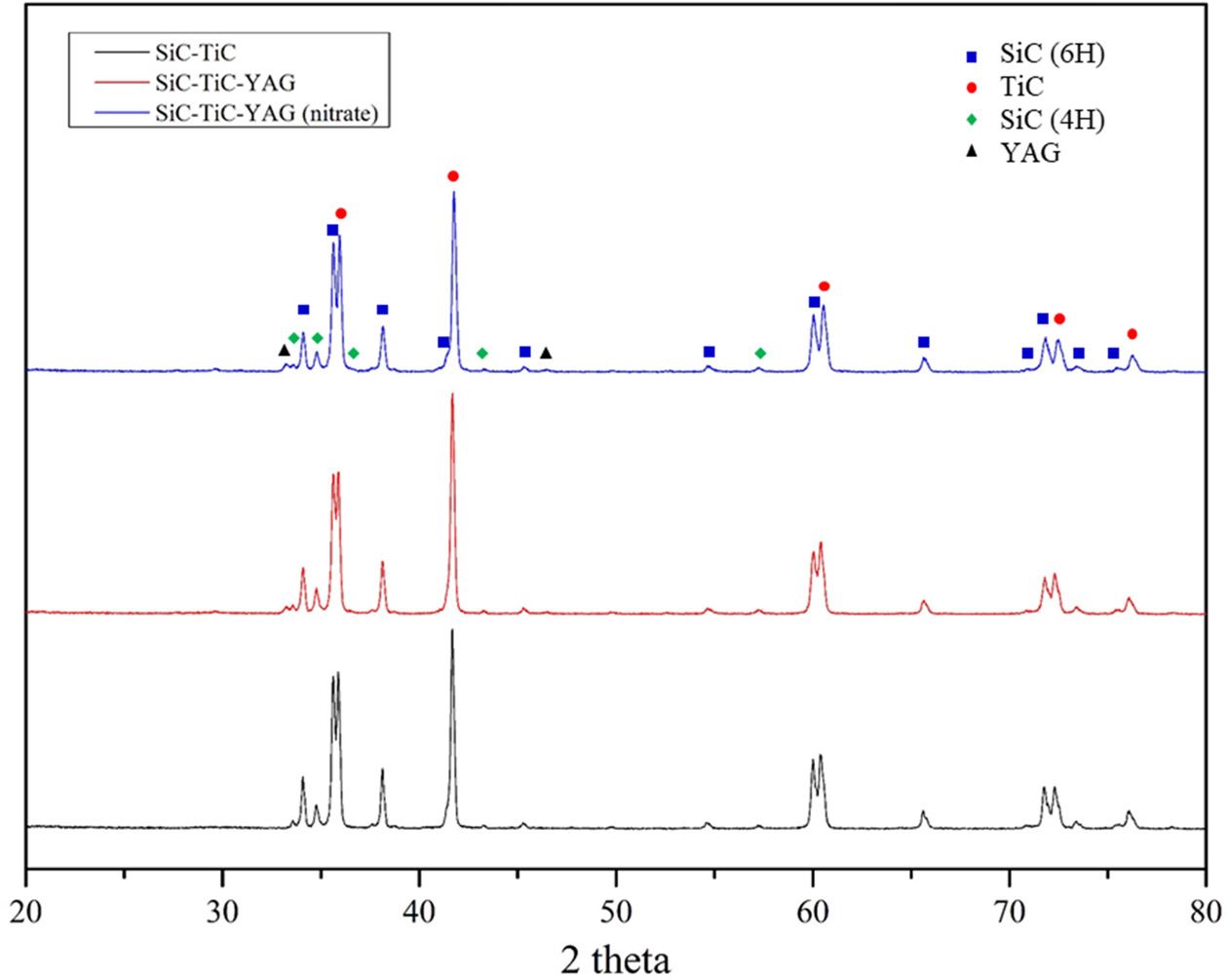

Fig. 2 is the result of crystal phase analysis obtained

through x-ray diffraction analysis. In all specimens, the main crystalline

phases were analyzed by 6H-SiC and TiC, and 4H crystalline phases not included

in the starting material were observed, indicating that SiC was phase-shifted

from 6H to the 4H structure. This phase transition is thought to be caused by

TiC because it occurs even in the composition without the sintering aid. In the

compositions to which the sintering aid was added, the YAG crystal phase was

observed from 1,800 °C, and it was confirmed that the liquid phase was formed

at a low temperature and involved in densification.

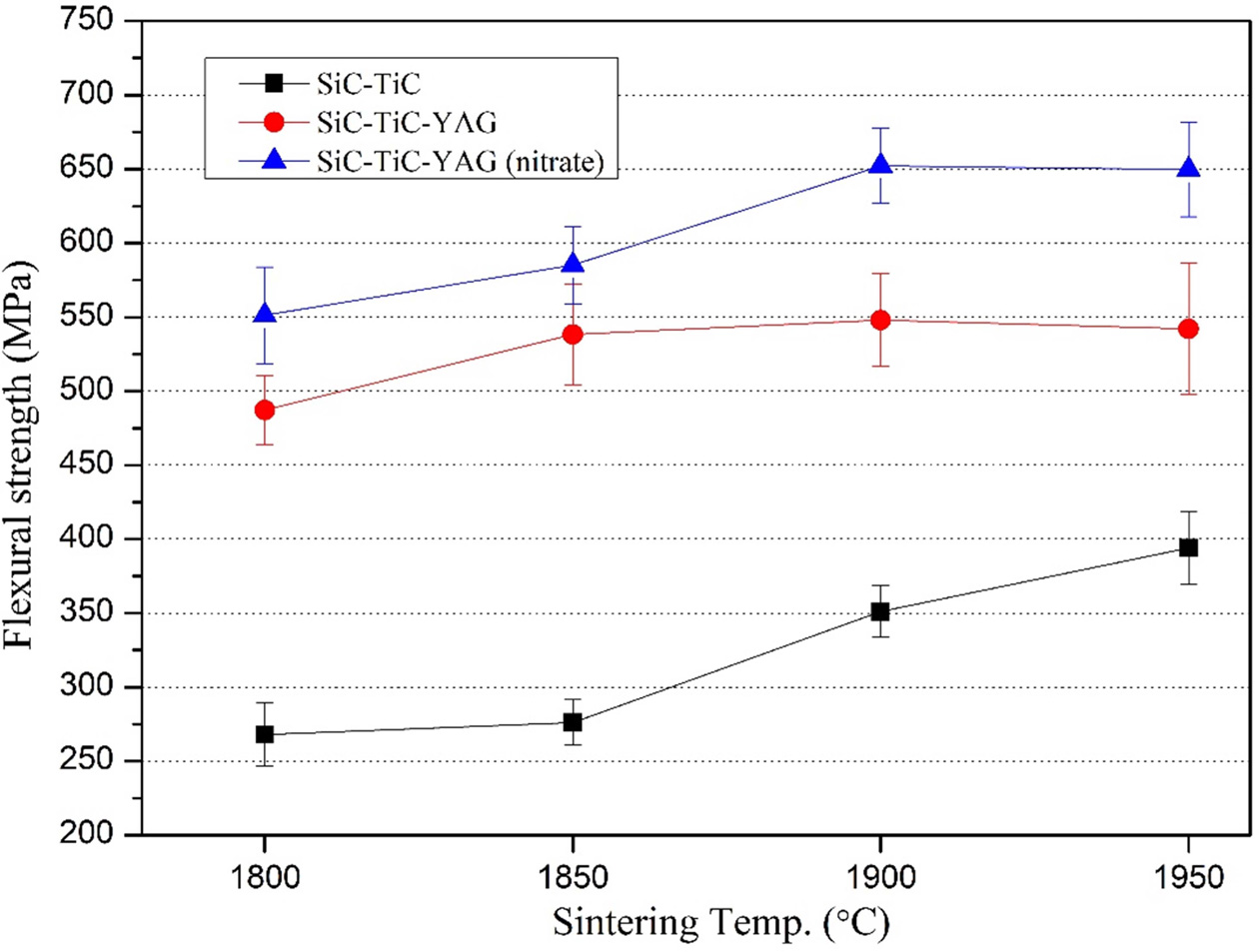

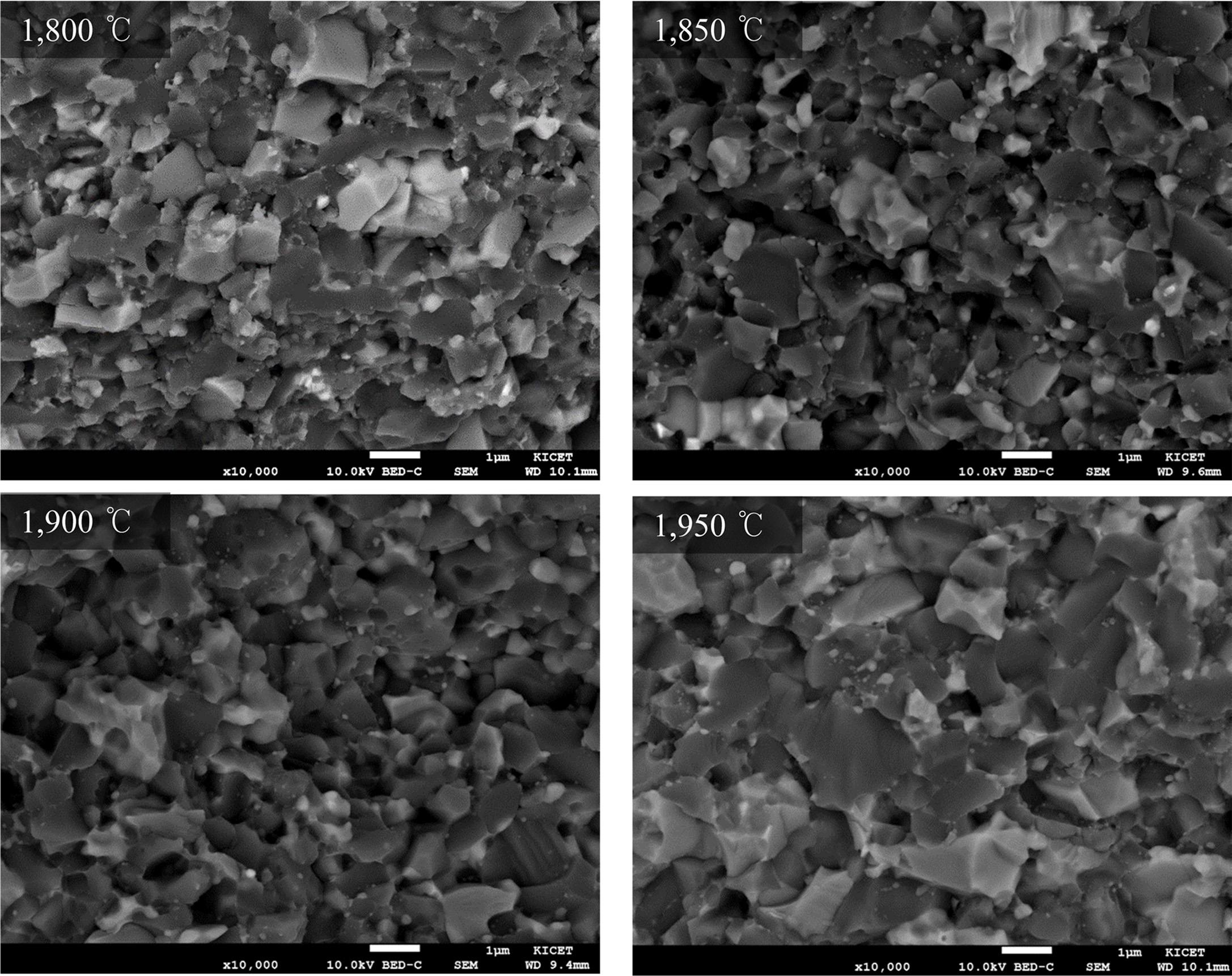

The bending strength results of SiC-TiC composites were

shown in Fig. 3. As the sintering temperature increases, the bending strength

tends to increase, and when the sintering aid is not added, the relative

density is low and the porosity is high, resulting in low strength. However,

the composition with the sintering aid showed a high bending strength due to

the increase of the relative density induced by rapid densification and showed

a maximum value at 1,900 oC. Therefore, it can be seen that the

bending strength of STYN composition is better because the bending strength of STY

is 547.9 MPa while the bending strength of STYN is

652.3 MPa. Also, as the sintering temperature increased from

1,900 oC to 1,950 oC, the bending strength

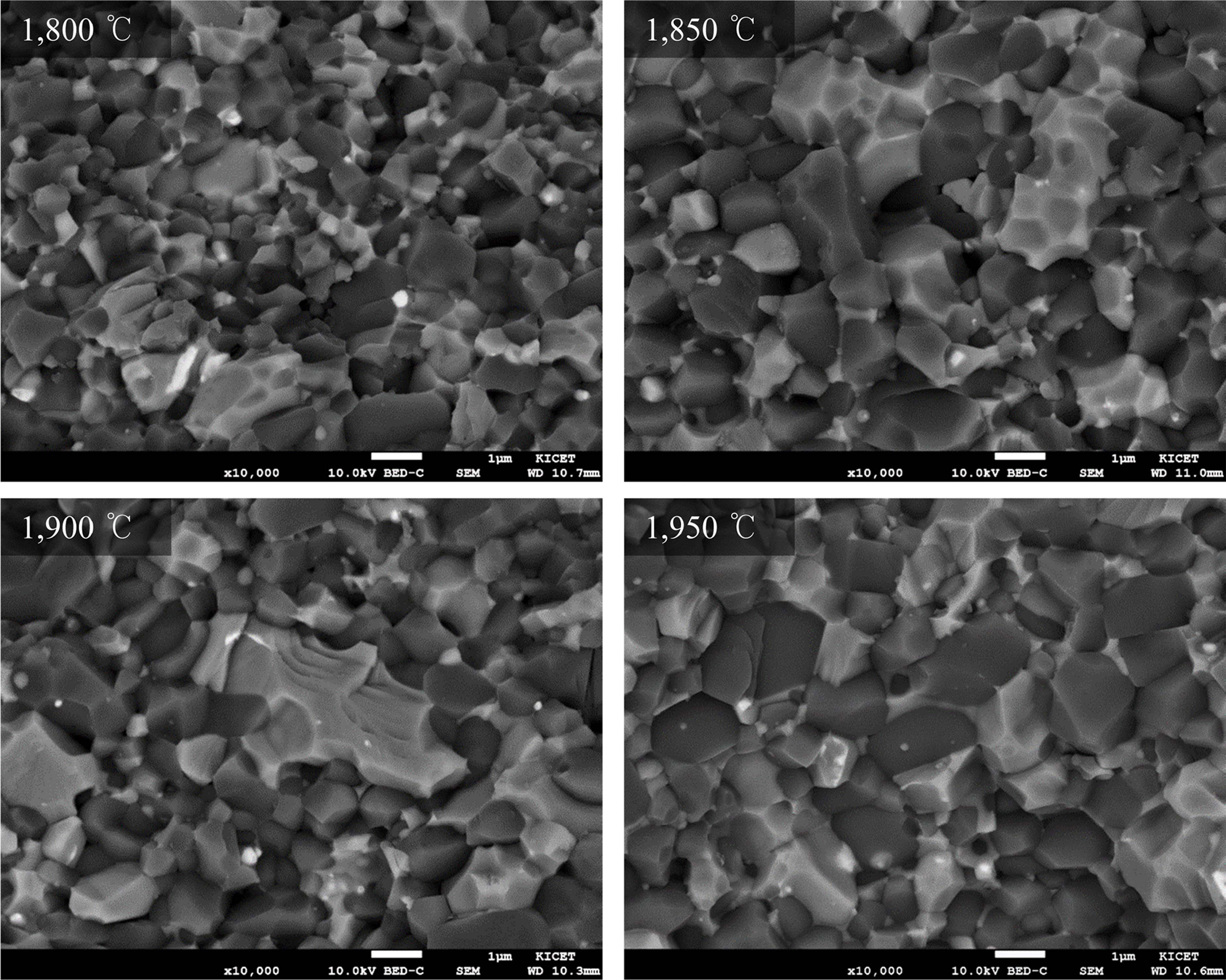

decreased slightly. This is thought to be due to the grain growth

at 1,950 oC sintering temperature, as can be seen from Fig. 3

and 4. The reason why the bending strength is relatively high in the case of

using the sintering aid of nitrate is thought to be that the fracture behavior is

different as well as the influence of the high relative density. As seen in

Fig. 3 and 4 of fractured surface FE-SEM

images, the fracture shape of STY specimens shows more intragranular intergranular while that of STYN

specimens shows both intragranular and intergranular. As such, the intergranular fracture in SiC-TiC composites is due to the

strong interfacial bonds between the grains, and both the strength and fracture

toughness are enhanced because more energy is consumed when cracks propagated through the grains of the composites.

The addition of nitrate sintering aids showed that the YAG crystal size is smaller and more uniformly distributed in the

microstructure than the oxide sintering aids, and as a result, strong

interfacial bonds are formed between grains of the composite [28, 29].

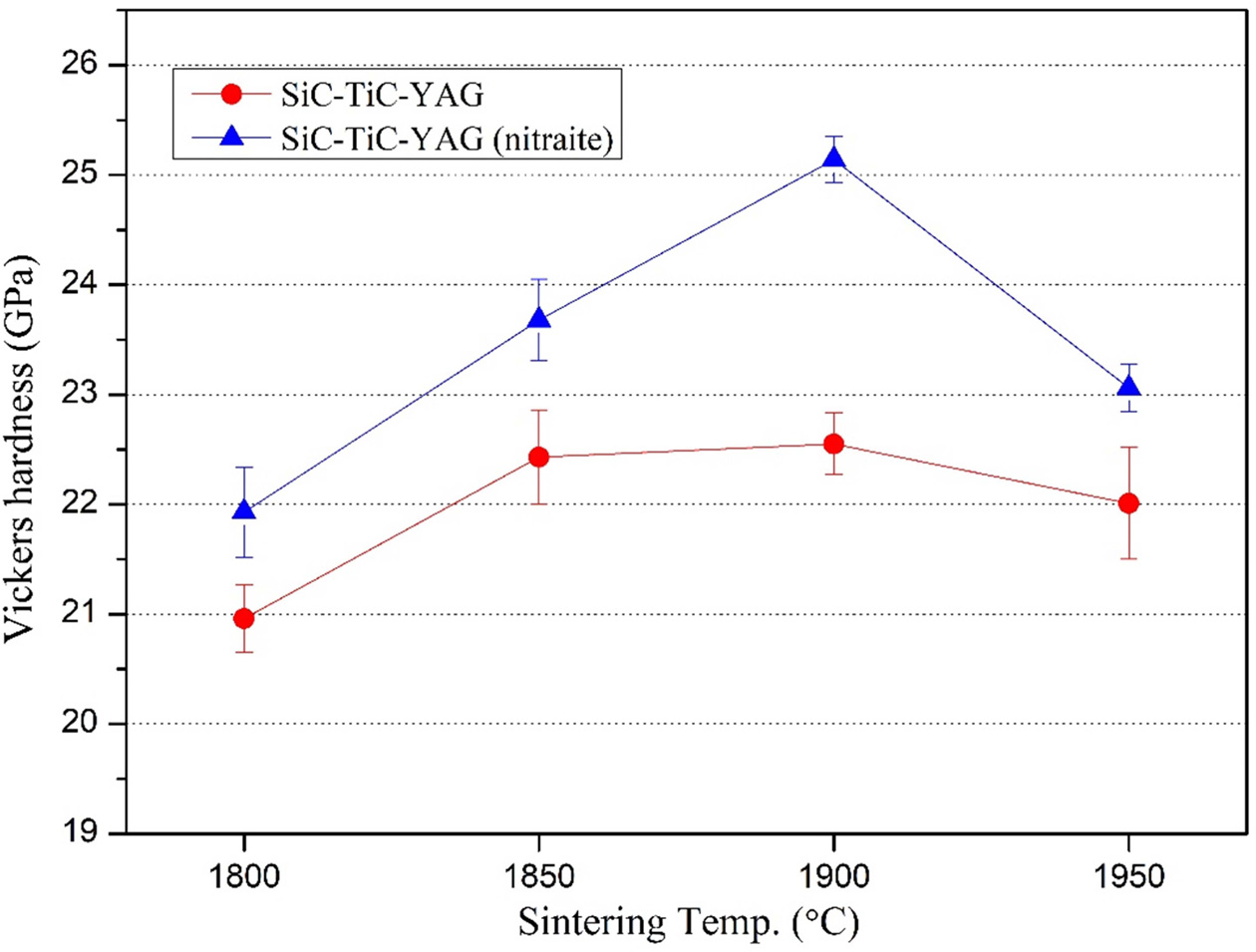

Fig. 6 shows the Vickers hardness results of SiC-TiC

composites according to the sintering temperature. The hardness tends to

increase with increasing the sintering temperature,

which is due to the increase in the sintering density and

similar to the relative density graph (Fig. 1). At 1,900 oC,

the hardness of STY composition was 22.55 GPa and STYN composition was 52.14

GPa, which showed better hardness when nitrate sintering aid was added. The

hardness decreases as the sintering temperature increases to 1,950 oC,

which may be due to grain growth as can be seen in the microstructure photographs

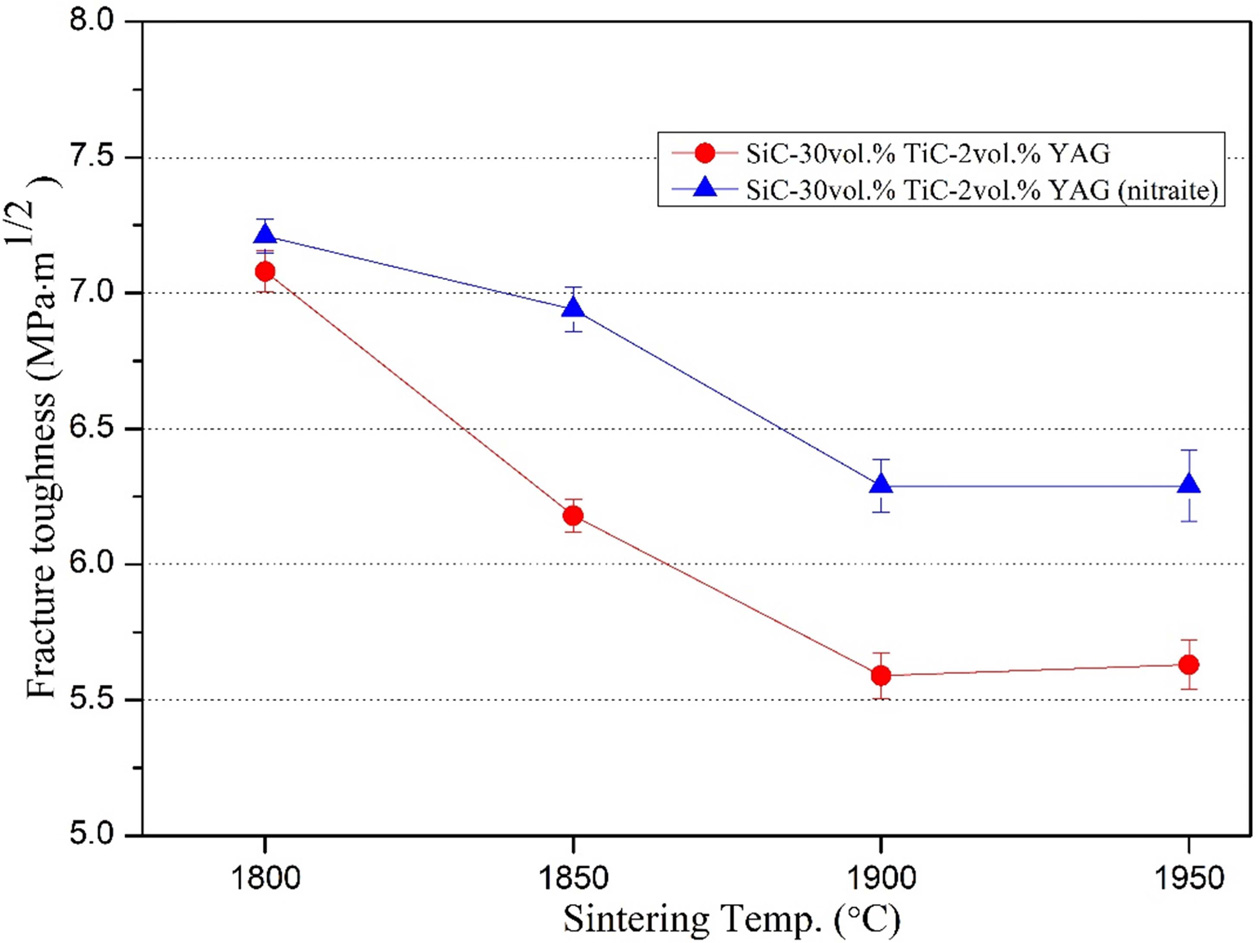

(Fig. 4 and 5). The fracture toughness of composites with sintering temperature

is shown in Fig. 7. Higher fracture toughness results in STYN composition with

a nitrate sintering aid. Fracture toughness in grain-reinforced

ceramic composites is known to be enhanced by residual stresses in thermal

expansion coefficients and elastic modulus differences between the matrix and

dispersed ceramic particles. The fracture toughness is enhanced by the residual

stress on the matrix when the coefficient of thermal expansion of the added

particles is greater than that of the matrix. Therefore, in the SiC-TiC

composites, the thermal expansion coefficients of SiC and TiC are 4.5 × 10-6 K-1

and 7.4 × 10-6 K-1,

respectively, so that compressive residual stress is formed

on the SiC because of the smaller coefficient, and the

toughness is enhanced compared to monolithic SiC [30, 31].

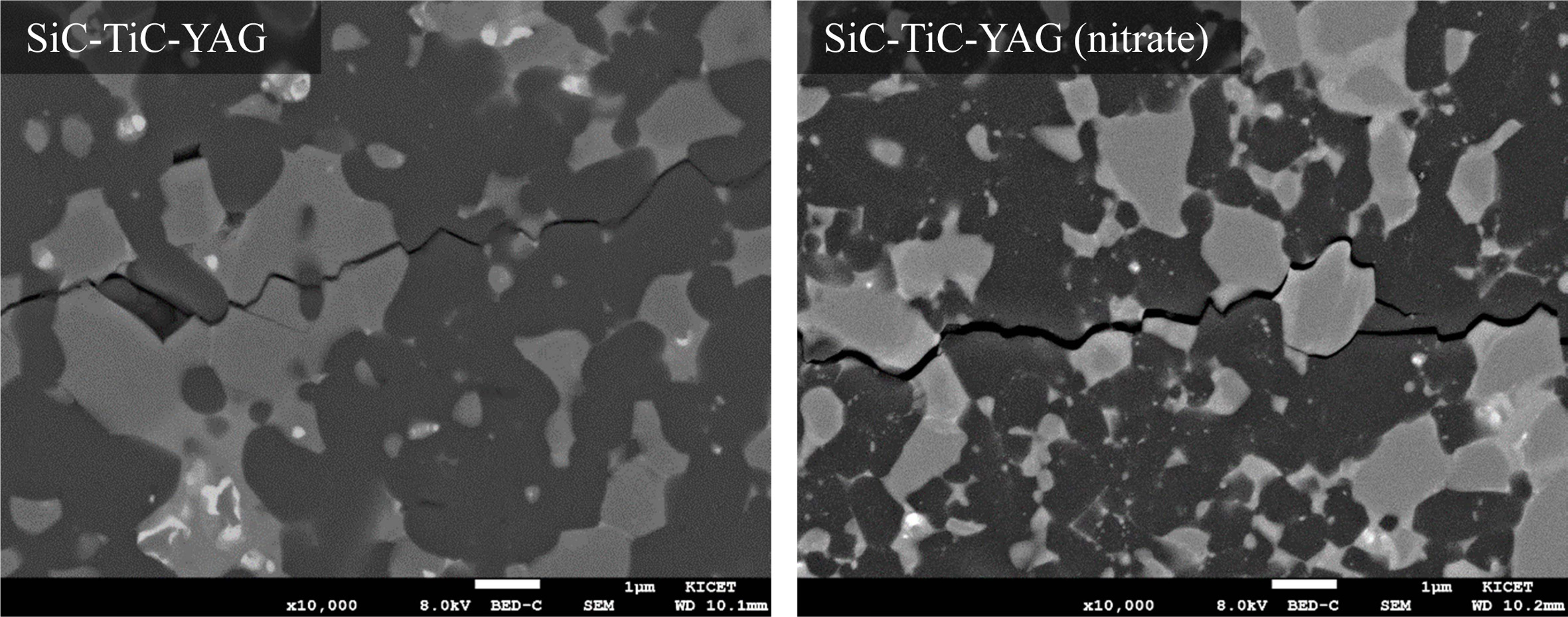

To understand the fracture mode and the strengthening

mechanism of the SiC-TiC composite in more detail, the cracks induced by

Vickers indenters were observed by FE-SEM and shown in Fig. 8. It was confirmed

that crack toughening and branching occurred in all compositions containing

nitrate and oxide sintering aids, which prevented crack propagation and

enhanced fracture toughness [32].

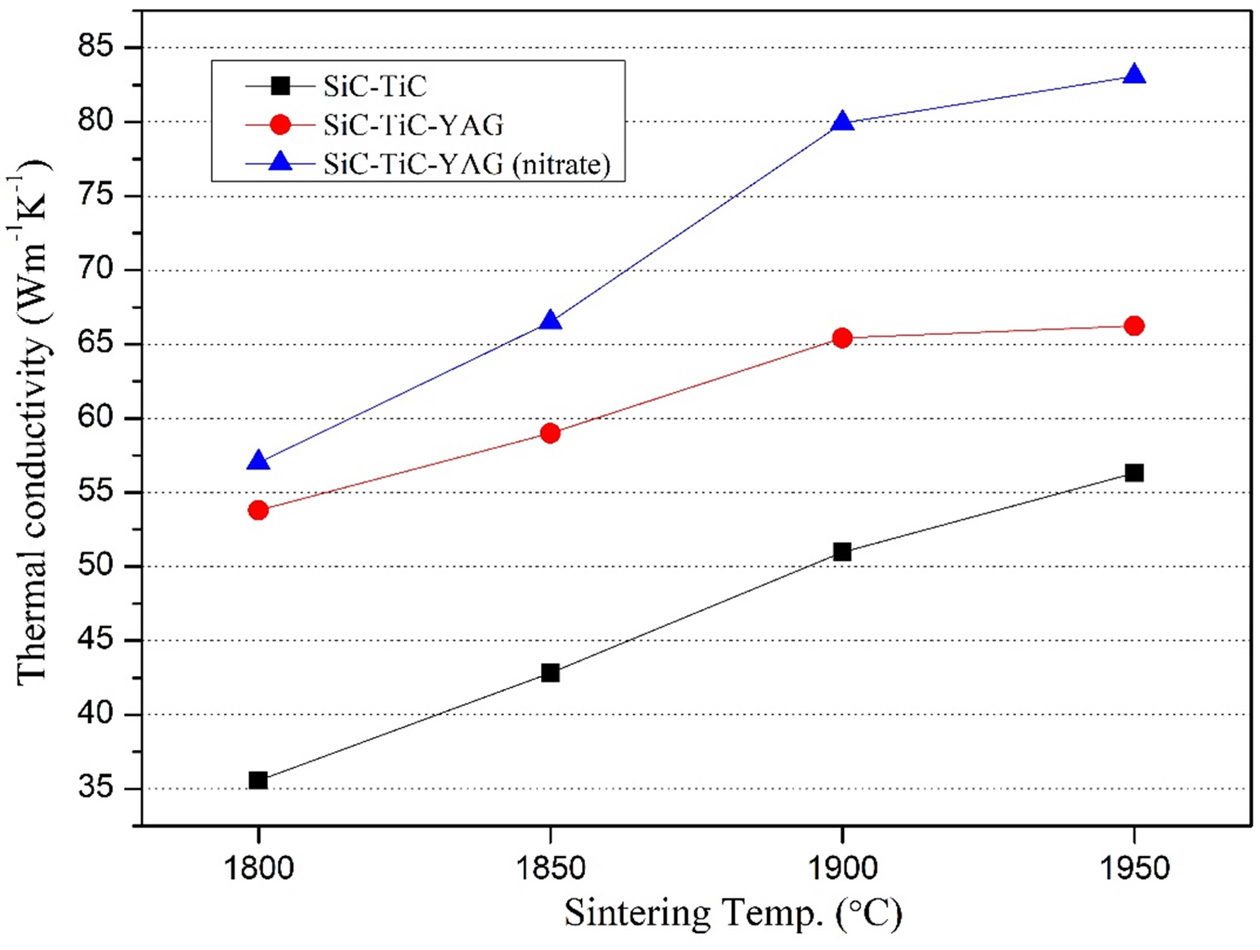

Fig. 9 is the thermal conductivity measurement result of

the SiC-TiC composite. As the sintering temperature increased and densification

proceeded, the thermal conductivity increased. However, the

composite without sintering aid showed low thermal conductivity due

to low density and low porosity inside the specimen.

STYN sample showed the best thermal conductivity as 83

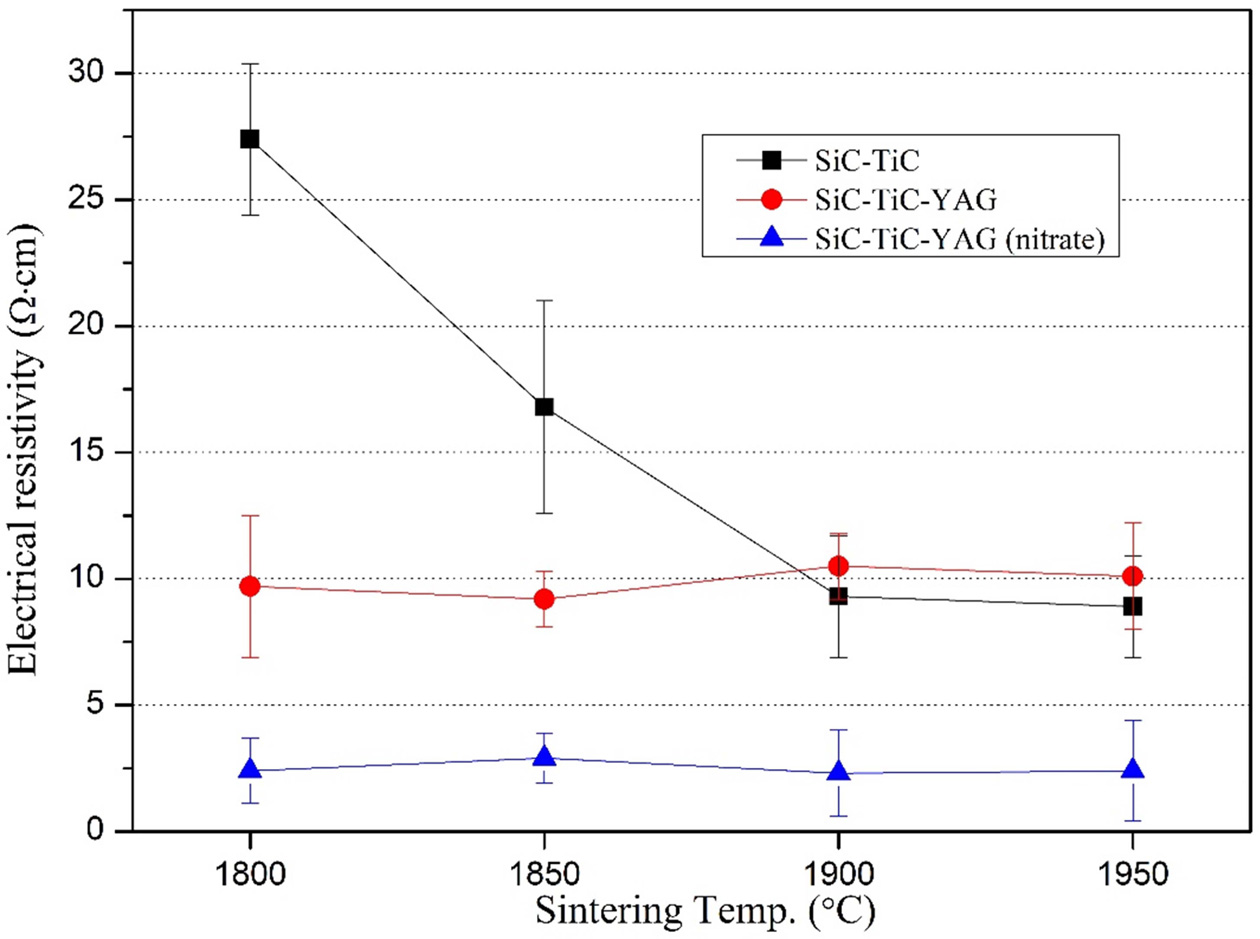

W/mK at sintering temperature of 1,950 oC. Fig. 10 shows the

electrical resistance of the SiC-TiC composite according to the sintering temperature.

In the composition without the sintering aid, the electrical resistance

decreased significantly as the densification progressed. When sintering was

performed at 1,900 and 1,950 oC, the value was lower than that

of the STY composition containing the oxide sintering aid. This may

be because YAG, which has high electrical resistance, is present

at the grain boundaries and triple points of SiC and TiC, thereby lowering the

overall electrical conductivity. On the other hand, in the composition

containing nitrate sintering aid, the YAG phase was found to have the lowest

electrical resistance, because it exists finely and uniformly compared to the

oxide composition, and it was found to have a low electrical resistance of 2.3 Ω·cm

at 1,900 oC.

|

Fig. 1 Variation of relative density of SiC-TiC composites with the sintering temperature. |

|

Fig. 2 XRD patterns of SiC-TiC sintered specimens at 1,950?. |

|

Fig. 3 Variation of flexural strength of SiC-TiC composites with Fig. 2. XRD patterns of SiC-TiC sintered specimens at 1,950?. the sintering temperature. |

|

Fig. 4 Fracture surfaces of SiC-TiC-YAG composite. |

|

Fig. 5 Fracture surfaces of SiC-TiC-YAG (nitrate) composite. |

|

Fig. 6 Variation of Vickers hardness of SiC-TiC composites with the sintering temperature. |

|

Fig. 7 Variation of fracture toughness of SiC-TiC composites with the sintering temperature. |

|

Fig. 8 SEM image of the crack paths of SiC-TiC composites sintered at 1,900 oC. |

|

Fig. 9 Variation of thermal conductivity of SiC-TiC composites with the sintering temperature. |

|

Fig. 10 Variation of electrical resistivity of SiC-TiC composites with the sintering temperature. |

In this study, compact and uniform SiC-30 vol% TiC

composites having a relative density of about 99.9% at 1,900 oC

could be prepared by hot press sintering method adding aluminum nitrate and

yttrium nitrate as sintering aids. Nitrate sintering aid is dissolved in

ethanol and can be uniformly mixed with the raw material, which promotes

densification of SiC-TiC composite at a lower temperature than oxide sintering

aid, and forms a uniform and fine YAG phase to improve mechanical properties of

the sintered body. With sintering at 1,900 oC, the bending

strength was 652.3 MPa, the Vickers hardness was 25.14 GPa, and the fracture

toughness was 6.29 MPa·m1/2. Since the electrical conductivity of

SiC-TiC ceramic composites is greatly influenced by the grain

size of the components constituting the matrix and the

amounts of additives and uniform dispersion, SiC-TiC composites with the

electrical resistance of 2.3 Ω·cm could be prepared at 1,900 oC

sintering temperature with the addition of nitrate.

This work was supported by the Technology Innovation Program

(10067558, Development of functional watches with ceramic

composite) funded by the Ministry of Trade, Industry & Energy (MOTIE,

Korea)

- 1. Y.G. Gogotsi, P. Kofstad, M. Yoshimura, and K.G. Nickel, Diam. Relat. Mater. 5[2] (1996) 151-162.

-

- 2. A. Noviyanto and D. Yoon, Curr. Appl. Phys. 13[1] (2013) 287-292.

-

- 3. O. Lopes, A. Ortiz, F. Guibertuau, and N. Padture, J. Eur. Ceram. Soc. 27[11] (2007) 3351-3357.

-

- 4. S. Prochazka and R. M. Scanlan, J. Am. Ceram. Soc. 58[12] (1975) 72-72.

-

- 5. R.A. Alliegro, L.B. Coffin, and J.R. Tinklepsugh, J. Am. Ceram. Soc. 39[11] (1956) 386-389.

-

- 6. D. Sciti and A. Bellosi, J. Mater. Sci. 35[15] (2000) 3849-3855.

-

- 7. K. Biswas, G. Rixecker, and F. Aldinger, J. Eur. Ceram. Soc. 23[7] (2003) 1099-1104.

-

- 8. M. Balog, P. Šajgalı́k, M. Hnatko, Z. Lenčéš, F. Monteverde, J. Kečkéš, and J.-L. Huang, J. Eur. Ceram. Soc. 25[4] (2005) 529-534.

-

- 9. S. Kaur, R. Riedel, and E. Ionescu, J. Eur. Ceram. Soc. 34[15] (2014) 3571-3578.

-

- 10. H. Harima, Microelectron. Eng. 83[1] (2006) 126-129.

-

- 11. K.J. Kim, S.H. Jang, Y.W. Kim, B.K. Jang, and T. Nishimura, Ceram. Int. 42[15] (2016) 17892-17896.

-

- 12. J.R. Jenny, D.P. Malta, St G. Müller, A.R. Powell, V.F. Tsvetkov, H. McD Hobgood, R. C. Glass, and C. H. Carter Jr., J. Electron. Mater. 32[5] (2003) 432-436.

-

- 13. F. Siegelin, H.J. Kleebe, and L.S. Sigl, J. Mater. Res. 18[11] (2003) 2608-2617.

-

- 14. K.J. Kim, J.H. Eom, Y.W. Kim, W.S. Seo, M.J. Lee, and S.S. Hwang, Ceram. Int. 43[15] (2017) 5343-5346.

-

- 15. G. Augustine, V. Balakrishna, and C.D. Brandt, J. Cryst. Growth 211[1-4] (2000) 339-342.

-

- 16. T.Y. Cho, Y.W. Kim, and K.J. Kim, J. Eur. Ceram. Soc. 36[11] (2016) 2659-2665.

-

- 17. J. Cabrero, F. Audubert, and R. Pailler, J. Eur. Ceram. Soc. 31[3] (2011) 313-320.

-

- 18. M. Khodaei, O. Yaghobizadeh, N. Ehsani, H.R. Baharvandi, and A. Dashti, Ceram. Int. 44[14] (2018) 16535-16542.

-

- 19. O. Agac, M. Gozutok, H.T. Sasmazel, A. Ozturk, and J. Park, Ceram. Int. 43 (2017) 10434-10441.

-

- 20. H. Endo, M. Ueki, and H. Kubo, J. Mater. Sci. 26 (1991) 3769-3774.

-

- 21. D. Ahmoye, D. Bucevac, and V.D. Krstic, Ceram. Int. 44[12] (2018) 14401-14407.

-

- 22. D. Shaoming, J. Dongliang, T. Shouhong and G. Jingkun, J. Mater. Sci. Lett. 15 (1996) 394-396.

-

- 23. H.G. An, Y.W. Kim and J.G. Lee, J. Eur. Ceram. Soc. 21[1] (2001) 93-98.

-

- 24. G.C. Wei and P.F. Becher, J. Am. Ceram. Soc. 67[8] (1984) 571-574.

-

- 25. M. Khodaei, O. Yaghobizadeh, N. Ehsani, and H.R. Baharvandi, Int. J. Refract. Met. Hard Mater. 76 (2018) 141-148.

-

- 26. J.Y. Kim, T. Iseki, and T. Yano, J. Am. Ceram. Soc. 79[10] (1996) 2744-2746.

-

- 27. T. Miyoshi. N. Sagawa, and T. Sasa, J. Jpn. SpC. Mech. Eng. A 51[471] (1985) 2489-2497.

-

- 28. Z. Zhang, X. Du, W. Wang, Z. Fu, and H. Wang, Int. J. Refract. Met. Hard Mater. 41 (2013) 270-275.

-

- 29. Y. Azizian-Kalandaragh, A. Sabahi Namini, Z. Ahmadi, and M. Shahedi Asl, Ceram. Int. 44[16] (2018) 19932-19938.

-

- 30. M. Taya, S. Hayashi, A.S. Kobayashi, and H.S. Yoon, J. Am. Ceram. Soc. 73[5] (1990) 1382-1391.

-

- 31. S.M. So, W.H. Choi, K.H. Kim, J.S. Park, M.S. Kim, J. Park, Y.S. Lim, and H.S. Kim, Ceram. Int. 46[7] (2020) 9575-9581.

-

- 32. M.S. Asl, Z. Ahmadi, A.S. Namini, A. Babapoor, and A. Motallebzadeh, Ceram. Int. 45[16] (2019) 19808-19821.

-

This Article

This Article

-

2020; 21(S1): 16-22

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s16

- Received on Dec 17, 2019

- Revised on Mar 22, 2020

- Accepted on Mar 24, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Joo Seok Park

-

Korea Institute of Ceramic Engineering and Technology, Jinju, Korea

Tel : +82-55-792-2775

Fax: +82-55-792-2796 - E-mail: pjuju@kicet.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.