- Citric acid stabilized iron oxide nanoparticles for battery-type supercapacitor electrode

Seungil Parka, C. Justin Raja, Ramu Manikandanb, Byung Chul Kimb and Kook Hyun Yua,*

aDepartment of Chemistry, Dongguk University, Jung-gu, Seoul-04620, Republic of Korea

bDepartment of Printed Electronics Engineering, Sunchon National University, 255, Jungang-ro, Suncheon-si, Jellanamdo 57922, Republic of Korea

We report the synthesis of citrate

stabilized iron oxide (C-Fe3O4) spherical nanoparticles

for supercapacitor electrodes. The citrate functional group present in the

surface of the Fe3O4 nanoparticles effectively controls

the morphology and the surface area of the nanostructures. The C-Fe3O4

electrodes exhibited a battery-like energy storage properties with a

maximum specific capacity of 146 Cg-1 (242 Fg-1) which is much higher than the specific capacity of

citrate free Fe3O4 electrode (62 Cg-1; 112 Fg-1). Moreover, the C-Fe3O4

electrode showed better cyclic stability (75%) than the citrate free Fe3O4

electrode (~35%) after 1000 charge/discharge cycles.

Keywords: Ion oxide, Nanoparticle, Supercapacitor

Transitional metal oxides (TMOs) are the potential pseudocapacitive

electrode materials as they have multiple valence

states of the metal ions that could enable a fast-faradaic redox reaction near

to the surface region. In the recent past, a variety of TMOs

such as RuO2, MnO2, Co3O4,

NiO, Fe3O4 was studied for their capacitive performance

[1-3]. Among all these transition metal oxides, iron oxides exhibit considerable

attractions due to their low toxicity, natural

abundance, low cost, environmental friendliness and rich redox

chemistry and having multiple applications due to their unique structural, electrical

and magnetic properties [4, 5]. Generally, iron oxides are

promising negative electrode materials for supercapacitors owing to its

excellent electrochemical performance in the negative potential window

with a high theoretical capacitance [6]. However, few researchers have

been reported Fe3O4 as a positive electrode material and

displayed considerable electrochemical performances which are

even comparable or higher than the well-known TMOs like Co3O4,

MnO2, CuO etc., [7, 9].

In general, the metal oxides nanoparticle synthesized

through conventional chemical techniques suffers from the agglomeration of

nanoparticles, which significantly leads to the formation of large-sized

particles with poor surface area and porosity [10]. In order to overcome this

issue, the Fe3O4 surface should be stabilized with citric

acid via the coordination bond which can be acted as a promising catalyst for

the formation of pyrimidine derivative compound. Further, high surface area of

CA anchored Fe3O4 also plays a significant role to determine their

catalytic performance [11]. As the electrochemical

performance of the supercapacitor electrode

highly depends upon the surface area and porous nature of the electroactive materials, it is important

to control the size and modifying the porosity of the nanoparticles to provide

large electroactive surface area for the effective charge-storage process.

Considering these crucial electrochemical factors, we

synthesized water dispersible, citrate stabilized Fe3O4

nanoparticles and utilized for the fabrication of supercapacitor

electrode. The citrate stabilization considerably controls the

particle size, surface area and porosity of the Fe3O4

nanoparticles and the fabricated electrode exhibited an

excellent battery-like charge storage property in the

positive potential window.

The water-dispersible citrate capped iron oxide (C-Fe3O4)

was prepared according to the synthesis procedure reported in our previous work

[12]. In brief, FeCl3·6H2O (0.016 mol) and

FeCl2·4H2O (0.008 mol) were dissolved in 80 ml deionized

(DI) water and reflexed for 30 min at 70 °C under argon atmosphere. Subsequently,

the 20 mL of 28% ammonia solution was added slowly to the mixture until the

formation of a black turbid solution. Then, 4 mL of 2.6 M citric acid solution

was added to the reaction mixture and the temperature was raised to 90 °C under refluxing condition and maintained for 60 min. Finally, the mixture

was cool down to the room temperature and the C-Fe3O4

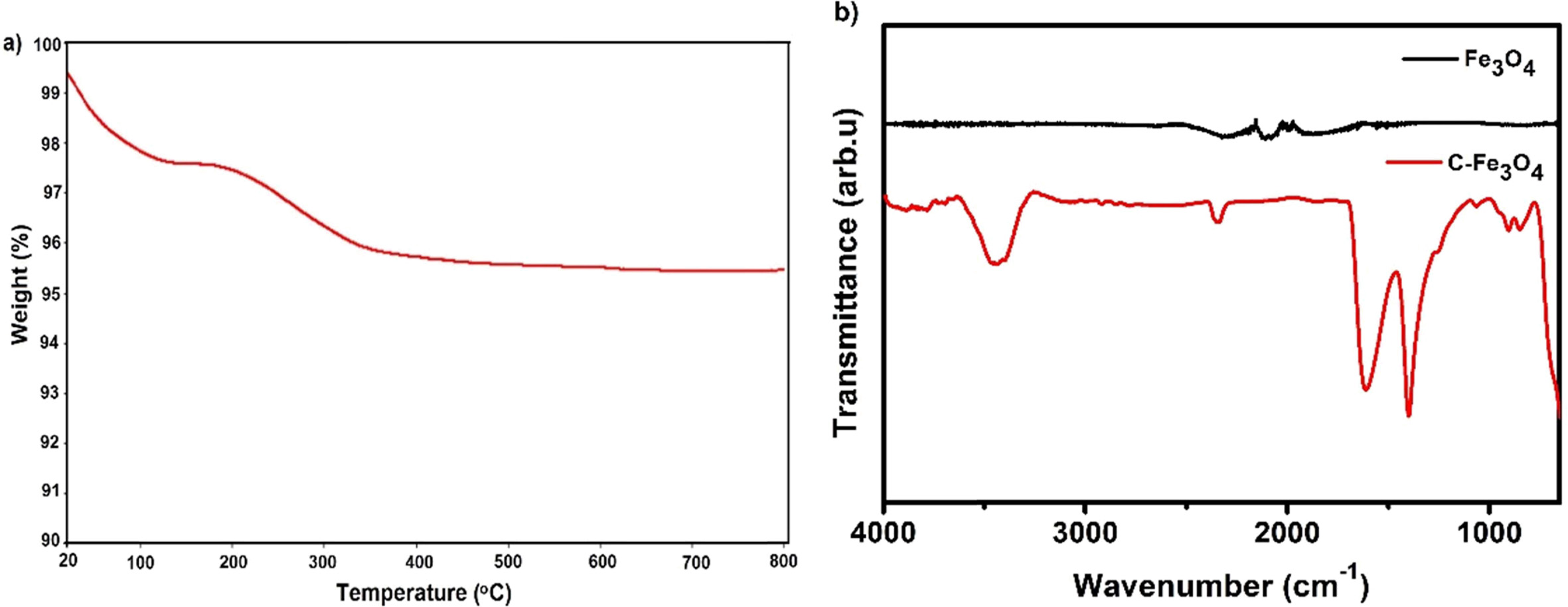

nanoparticles were centrifuged, washed repeatedly and dispersed in DI water. The citrate free Fe3O4

nanoparticles were synthesized by the

heat treatment of the C-Fe3O4 samples at 300 °C for 30 min per the TG curve

(Fig. 1(a)). The FTIR spectra of the samples confirm the

successful removal of citrate functional groups such as OH

stretching (3,439 cm-1),

C=O stretching (1,602 cm-1),

symmetric stretching of COO-

(1,400 cm-1)

groups from the surface of the C-Fe3O4 nanoparticles

[13, 14] (Fig. 1(b)).

The structural properties of the synthesized samples were

identified by powder X-ray diffraction (XRD, Rigaku, Ultima IV) using Ni

filtered Cu Kα radiation (λ = 1.5418 Å) operated at 40 kV and 30

mA in the 2θ range 20°- 80°. Morphological study of the sample was performed

utilizing transmission electron microscopy (TEM) (JEOL

(Japan) model JEM-2100F). The nitrogen adsorption/desorption

measurement was carried out using a Microtrac, BELsorp-mini II surface analyzer

employing the volumetric method. The specific surface area was calculated by

the Brunauer-Emmett-Teller (BET) technique and the pore size distribution was

estimated from the desorption branch of the isotherm by the

Barrett-Joyner-Halenda (BJH) method. Attenuated total

reflectance - Fourier transform Infrared Spectroscopy (ATR-FTIR) measurement was

performed using ATR-FTIR spectrometer (Smiths Detection).

The supercapacitor electrodes were fabricated by mixing the active

materials (C-Fe3O4 or Fe3O4) (75

wt%), acetylene black (20 wt%) and polyvinylidene fluoride (5 wt%) in N-methyl-2-pyrrolidone. The obtained paste was coated over a nickel foam

substrate of exposed geometric area 1×1 cm2 and dried at 100 °C

for 12 h in a vacuum oven. The mass of the active material present in the

electrodes was determined ~3.5 mg.

Electrochemical measurements such as cyclic voltammetry, galvanostatic charge/discharge test and impedance spectroscopy were performed at room

temperature (~25 °C) using a ZIVE-SP2 (Korea) electrochemical workstation. The measurements were

carried out in a three-electrode setup consisting of a working electrode of Ni

foam coated with the active material, a platinum counter electrode and a Hg/HgO

reference electrode in 6M KOH aqueous electrolyte. The electrochemical

impedance spectra (EIS) of the electrodes were measured in the frequency range

of 10 mHz - 100 kHz at equilibrium

open circuit potential 0 V with an AC

perturbation of 5 mV in 6 M KOH electrolyte.

The specific capacity (Qs) value of the

electrodes was calculated using eq. (1).

where, I is the constant

discharge current (A), Dt

is the discharge time (s) and m is the mass of the active material (g)

in the electrodes.

|

Fig. 1 (a) TGA curve of C-Fe3O4 and (b) FTIR spectrum of C-Fe3O4 and Fe3O4 samples. |

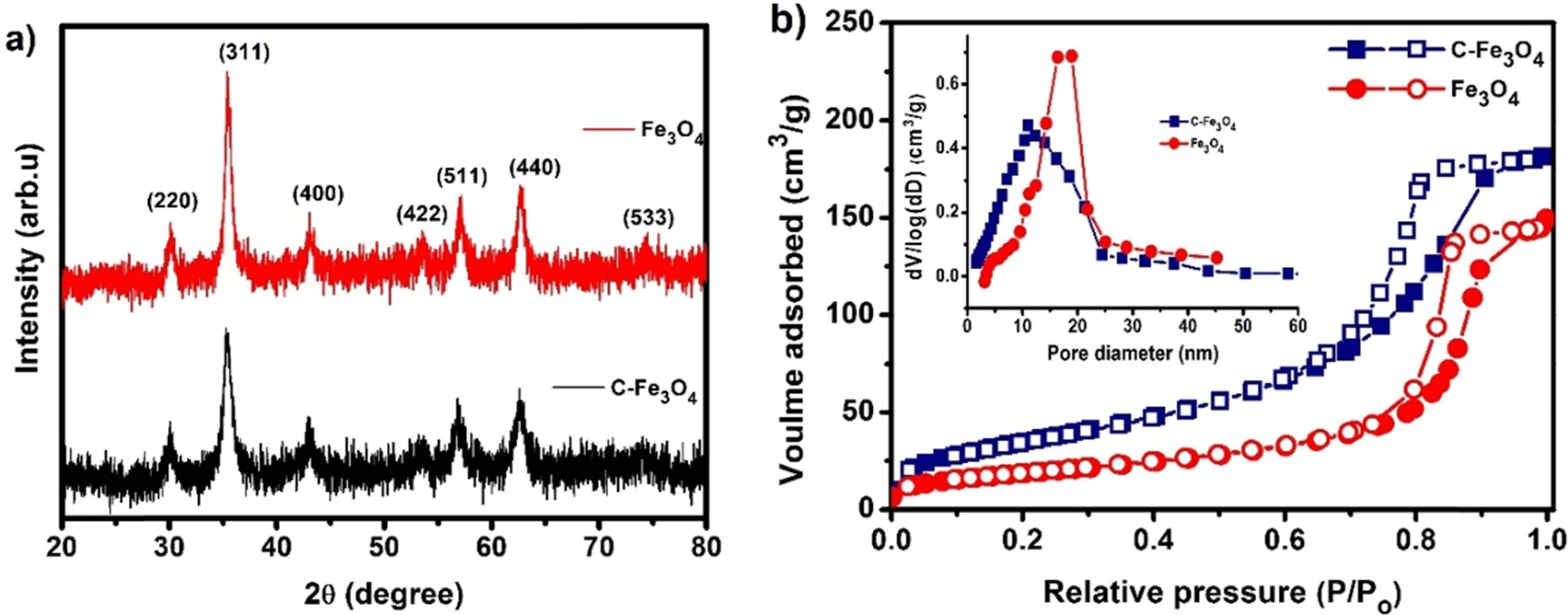

The crystal structures of synthesized samples were studied using XRD

analysis as shown in Fig. 2(a). The XRD patterns show strong and broad

diffraction peaks representing the formation of crystalline Fe3O4

nanostructures and the corresponding peaks

are indexed to a face-centered cubic

lattice of Fe3O4 (JCPDS Card No. 19-0629). From the

diffraction patterns citrate free Fe3O4 exhibited

slightly high intensity than the C-Fe3O4 representing the

crystallinity of the sample increased on heat-treatment. The nitrogen

adsorption/desorption isotherms of the samples are shown in Fig. 2(b) and the

inset show the pore size distribution of the samples. The adsorption/desorption

shows the samples exhibit type-IV

hysteresis loop, that is characteristic of mesoporous materials. The BET surface area of the C-Fe3O4

sample is calculated to be 131.07 m2g-1

and it decreased to 67.39 m2g-1

after the heat-treatment of the sample. These

decrease in BET surface area is mainly attributed to the

removal of surface functionalities to form more agglomerated nanostructure.

Similarly, the total pore volume of the sample also decreases from 0.281 to

0.224 cm3 g-1

for Fe3O4 sample and the estimated average pore diameter

of C-Fe3O4 and Fe3O4 samples are 9

nm and 13 nm respectively, which confirms the mesoporous

distribution of the synthesized nanostructures. Thus, these

samples can offer considerable attaching area between active materials and the

electrolyte for better electrochemical performance [15, 16].

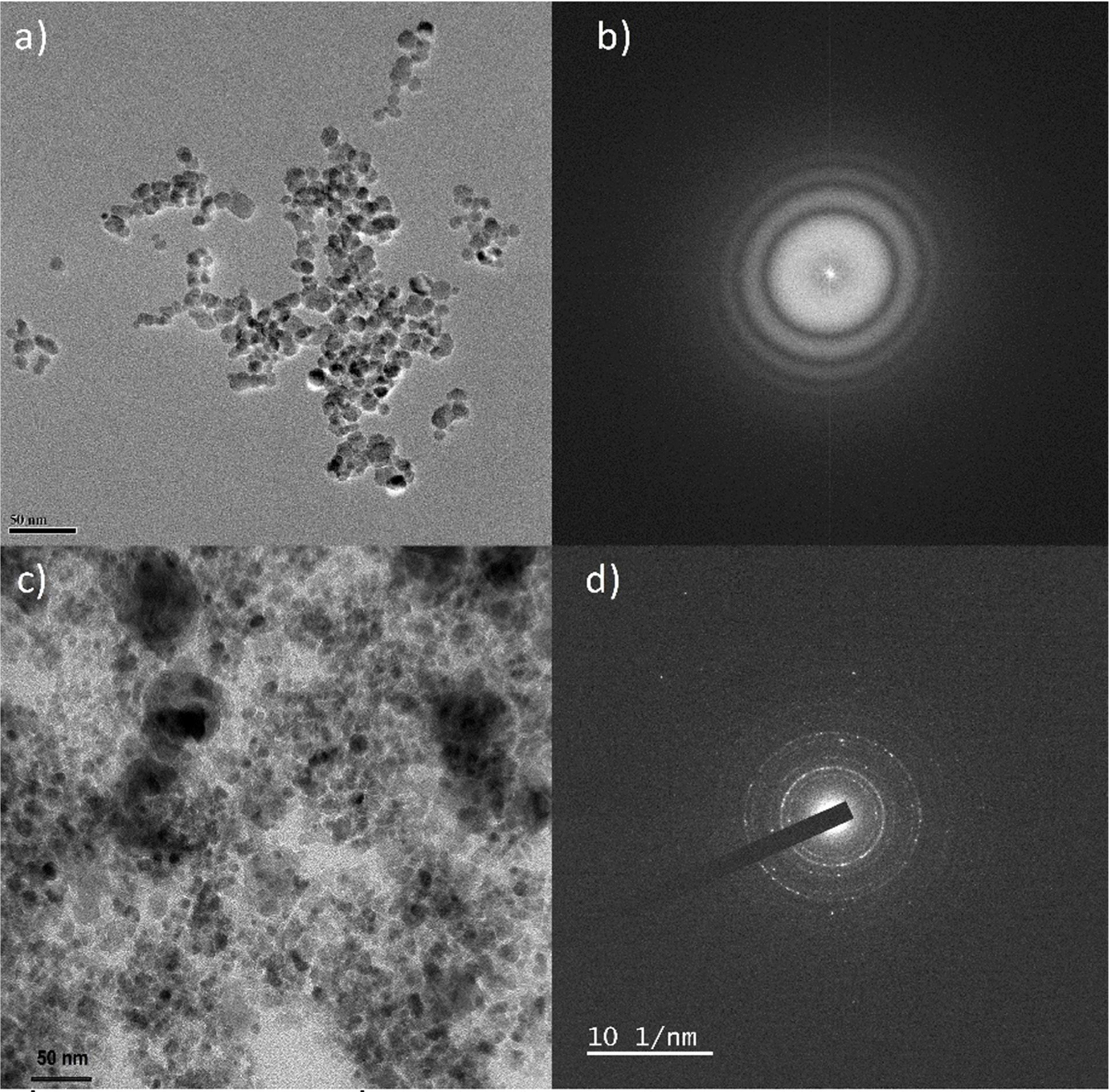

The surface morphology of the C-Fe3O4 and

Fe3O4 samples were examined by TEM analysis. Fig. 3(a)

shows the TEM image of C-Fe3O4 and it displays well-defined

spherical morphology with slightly interconnected nanoparticles

of size ranges from 10-20 nm. Moreover, the sample depicts well-dispersed

nature without much agglomerations of the nanoparticles. But the TEM image (Fig. 3(c)) of the

heat-treated sample (Fe3O4) displays highly agglomerated spherical nanoparticles with few slightly

big sized nanoparticles. Thus, the subsequent heat treatment and removal of

surface citrate groups from the sample highly influence the size of nanoparticles. The corresponding selected area electron

diffraction (SAED) pattern of C-Fe3O4 and Fe3O4

samples are shown in Fig. 3(b) and (d) respectively.

As absorbed in XRD, the SAED pattern of the heat-treated sample is more

crystalline than the citrate stabilized Fe3O4 sample.

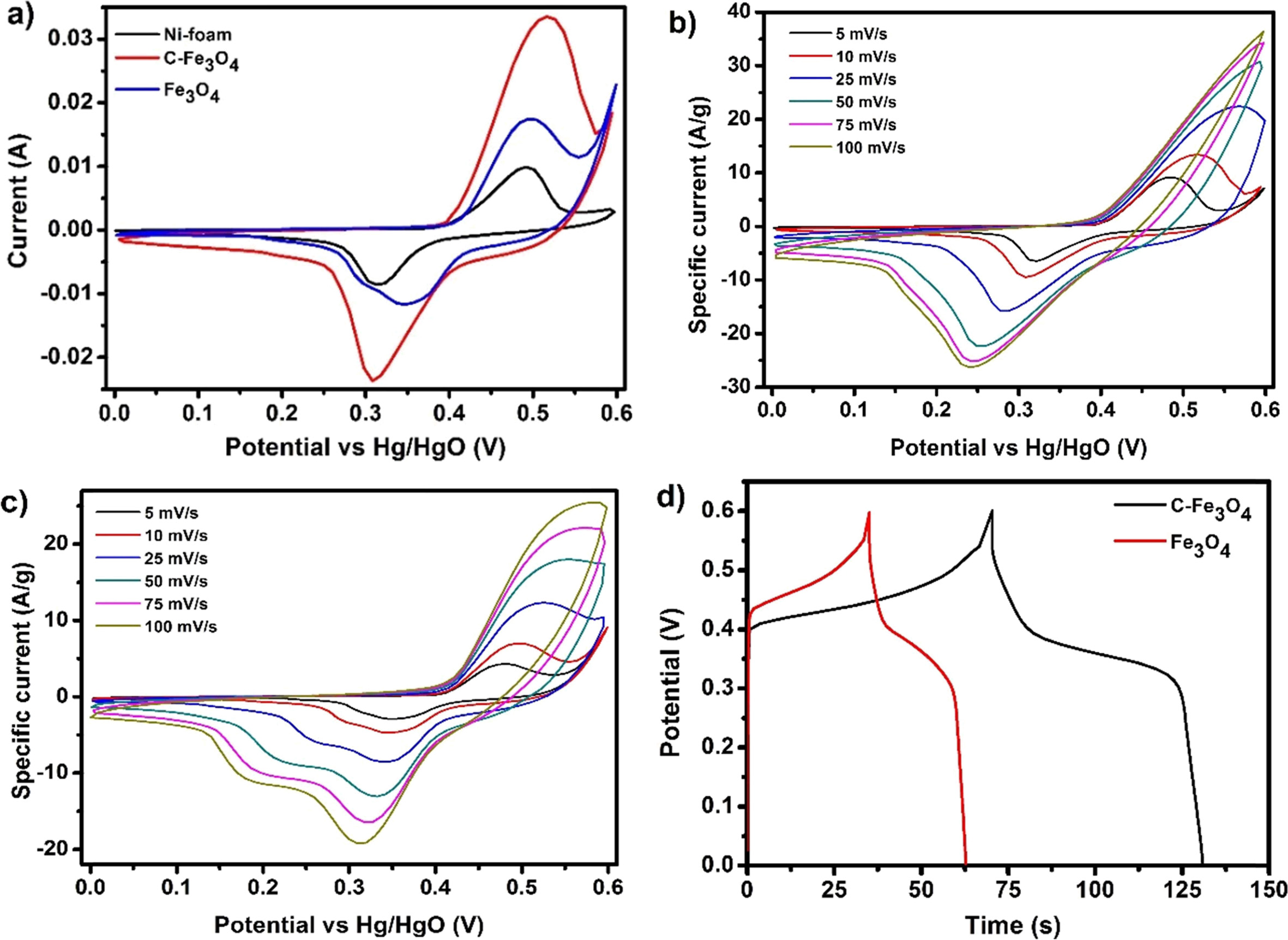

Electrochemical capacitance performances of the C-Fe3O4

and Fe3O4 electrodes were investigated by cyclic voltammetry

(CV), galvanostatic charge/discharge (GCD) test and

electrochemical impedance spectroscopy (EIS) in 6M KOH electrolyte. Fig. 4(a)

shows the CVs of the bare Ni-foam, C-Fe3O4 and Fe3O4

electrodes (~3.5 mg) measured at 10 mVs-1

scan rates. The CV of bare Ni-foam exhibited distinct pair of redox peaks

originated from the Faradaic redox reaction of Ni elemental species

in an alkaline electrolyte and the similar pair of redox peaks

are exhibited in the C-Fe3O4 and Fe3O4

electrodes. However, the citrate free Fe3O4

electrode displays a secondary reduction peak with comparatively broad

oxidation peak than the Ni-foam, which corresponds to the redox

reaction of Fe(II)/Fe(III) redox couple of the electrode

material. The C-Fe3O4 electrode shows a significantly

larger redox peak area represents the overlapping the two peaks observed in Fe3O4

electrode, moreover, the electrode exhibited high background current revealing

superior capacitive performance than the other two electrodes. Moreover, these irregular

shape of the CVs with redox peaks correspond

the non-capacitive faradic or battery-like redox characteristic of the

electrodes [17, 18]. This enhancement in C-Fe3O4 electrode

over Fe3O4 is mainly due to the improved surface area and

pore density of the sample due to the stabilization of citrate functional

groups on the surface. Further, the CVs of the electrodes measured for various

scan rates are displayed in Fig. 4(b) and (c). From these CVs, C-Fe3O4

electrode possesses higher background current and redox peak intensity for all

the measured scan rates. Moreover, the electrodes nearly retain its shapes even

at higher scan rates representing better supercapacitor electrode materials.

The GCD curves of the C-Fe3O4 and Fe3O4

electrodes at 1 Ag-1

specific current is shown in Fig. 4(d) and the curves display a nonlinear

shape, which reveals the non-capacitive faradic reaction that typically

exhibited in the supercapattery electrode materials due to the battery-type

charge storage mechanism [19, 20]. Similar to CVs, the

GCD curve shows a prolonged charge/discharge time for C-Fe3O4

electrode than Fe3O4 electrode representing

better capacitive performance. The specific capacity (Qs)

values of the electrodes were calculated and the C-Fe3O4 electrode

shows maximum specific capacity 146 Cg-1

(242 Fg-1)

at a specific current 1 A g-1,

which is much higher than the Fe3O4 electrode (62 Cg-1;

112 Fg-1).

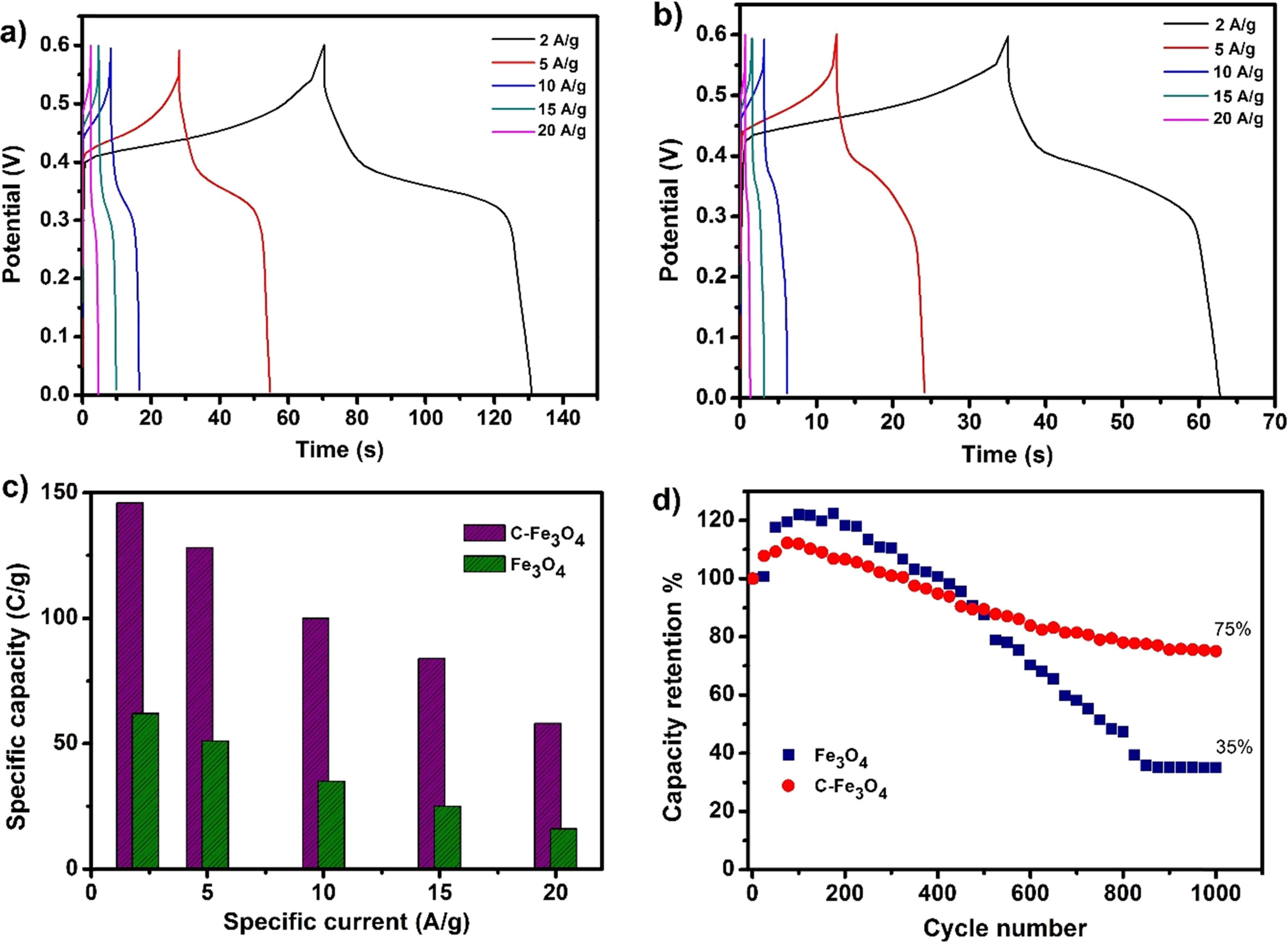

Fig. 5(a) and (b) shows the GCD curves of C-Fe3O4

and Fe3O4 electrodes measured for various specific

currents and Fig. 5(c) displays the variation of specific capacity of the

electrodes for various specific currents. From this, the C-Fe3O4

electrode demonstrates higher specific capacity values for all the

measured specific currents with relatively higher discharge time than the Fe3O4

electrode. Moreover, the specific capacity of the electrodes decreases with the

increase in specific currents due to the increasing IR-drop and the limited

involvement of active material in a redox reaction concerning the increase in

specific currents [21]. Fig. 5(d) shows the cyclic stability of the C-Fe3O4

and Fe3O4 electrodes for 1,000 charge/discharge

cycles at 10 Ag-1.

The C-Fe3O4 electrode shows comparable cyclic stability

with ~75% of the specific capacity retention after 1,000 cycles.

But, the Fe3O4 electrode displays only ~35% specific

capacity retention representing nearly poor stability of the electrode.

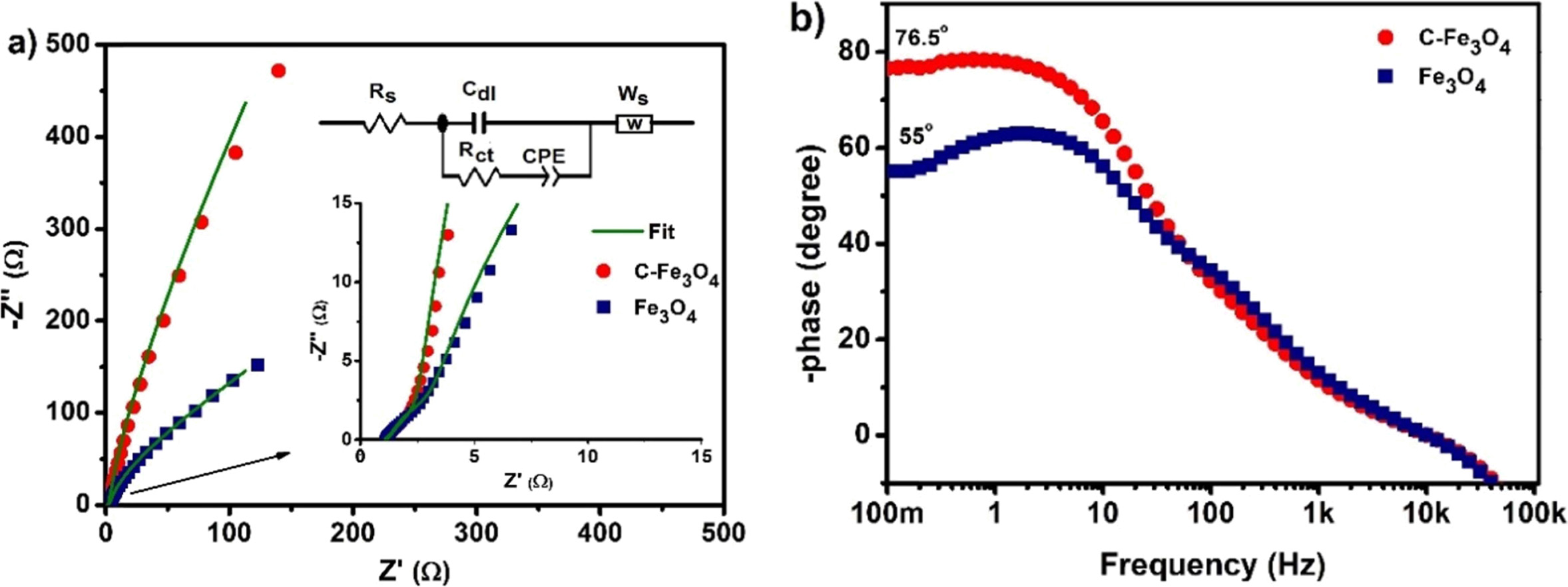

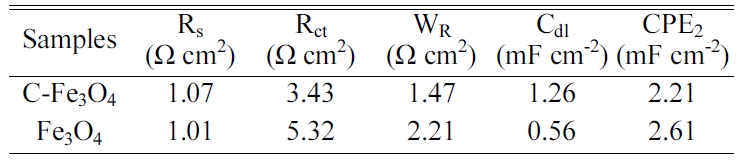

The Nyquist plots of the electrodes are shown in Fig. 6(a)

and the inset shows the magnified portion of the high-frequency region of the

plots. The Nyquist plots were fitted using Zview software with an equivalent

circuit (inset of Fig. 6(a). The circuit consists of a bulk resistance (Rs)

[11, 22, 23] and a parallel combination of resistance Rct and

capacitance (Cdl) represents the charge-transfer resistance

and electric double layer capacitance contribution of the electrodes. The

slight inclined low-frequency slope was fitted with the Warburg element

(Ws) corresponding the diffusion control process

of the electrodes. Additional constant phase elements CPE1 included

in the circuit due to the non-ideal capacitive behavior of the electrodes and

it represents the energy storage process originated from the redox reaction

[24]. The best-fitted results of the electrodes are presented in Table.1. From

these, the Rs value of the electrodes found to be nearly similar,

but the charge transfers resistance Rct value of

C-Fe3O4 electrode lower than the Fe3O4

electrode. This is mainly attributed to high mesoporosity of the

electrode materials may account these better charge-transfer process than the

Fe3O4 electrode [25]. Fig. 6(b) shows the corresponding

Bode phase plots of electrodes with low frequency (100 mHz) phase angle of

-76.5 and 55°. The existence of high phase angle at low frequency (approaches

slightly close to the ideal capacitor, -90°) for C-Fe3O4

electrode denotes the better charge storage properties of the electrode than

the citrate free Fe3O4 electrodes [26]. Table 1

|

Fig. 2 (a) XRD patterns of C-Fe3O4 and Fe3O4 samples, (b) N2 adsorption/desorption isotherms of the C-Fe3O4 and Fe3O4 and the inset pore size distribution of the samples. |

|

Fig. 3 (a) TEM image of C-Fe3O4 nanoparticles, (b) SAED pattern of the C-Fe3O4 nanoparticles, (c) TEM image of Fe3O4 nanoparticles and (d) SAED pattern of the Fe3O4 nanoparticles. |

|

Fig. 4 (a) CVs of bare Ni-foam, C-Fe3O4 and Fe3O4 electrode at 10 mV s−1 scan rate, CVs of bare, (b) C-Fe3O4 and (c) Fe3O4 electrodes measured at various scan rates, and d) the GCD curves of C-Fe3O4 and Fe3O4 electrodes at 1 A g−1. |

|

Fig. 5 Charge/discharge curves of (a) C-Fe3O4 and (b) Fe3O4 electrodes for different specific currents, (c) Variation of specific capacity with various specific currents and (e) Cyclic stability of the electrodes for 1,000 cycles at 10 Ag−1. |

|

Fig. 6 (a) Nyquist plots (the inset shows a magnified part and equivalent circuit) and b) Bode plots of the C-Fe3O4 and Fe3O4 electrodes |

In summary, the synthesized citrate stabilized iron oxide

nanoparticles possess a controlled size, mesoporosity and high

surface area than the citrate free Fe3O4 nanoparticles.

These improved properties demonstrate the C-Fe3O4 nanoparticles

as a promising supercapacitor electrode material with a battery like a charge

storage behavior and excellent electrochemical performances.

The authors R. Manikandan and B.C. Kim acknowledges the Creative Materials

Discovery Program through the National Research Foundation of Korea funded by

the Ministry of Science, ICT and Future (NRF-2015M3D1A1069710); and the Basic

Science Research Program through the National Research Foundation of

Korea funded by the Ministry of Education

(NRF-2014R1A6A1030419), Republic of Korea.

- 1. W. Deng, X. Ji, Q. Chen, C.E. Banks, RSC Adv. 1 (2011) 1171-1178.

-

- 2. M.Y. Cho, S.M. Park, B. H. Choi, J.-W. Lee, K. C. Roh, J. Ceram. Process. Res. 13(S2) (2012) 166-169.

- 3. D. Qiu, X. Ma, J. Zhang, B. Zhao, Z. Lin, Chem. Phys. Lett. 710 (2018) 188-192.

-

- 4. M.P. Kumar, L.M. Lathika, A.P. Mohanachandran, R.B. Rakhi, ChemistrySelect 3 (2018) 3234-3240.

-

- 5. G.V.M. Williams, T. Prakash, J. Kennedy, S.V. Chong, S. Rubanov, J. Magn. Magn. Mater. 460 (2018) 229-233.

-

- 6. V.D. Nithya, N. Sabari Arul, J. Mater. Chem. A 4 (2016) 10767-10778.

-

- 7. S. Mallick, P.P. Jana, C.R. Raj, Chem. Electro. Chem. 5 (2018) 2348-2356.

-

- 8. L. Song, Y. Han, F. Guo, Y. Jiao, Y. Li, Y. Liu, F. Gao, J. Nanomater. 2018 (2018) 1-13.

-

- 9. F. Yang, X. Zhang, Y. Yang, S. Hao, L. Cui, Chem. Phys. Lett. 691 (2018) 366-372.

-

- 10. M. Aghazadeh, I. Karimzadeh, M. Reza Ganjali, Mater. Lett. 209 (2017) 450-454.

-

- 11. L. Li, C. Polanco, A. Ghahreman, J. Electroanal. Chem. 774 (2016) 66-75.

-

- 12. B.-B. Cho, J.H. Park, S.J. Jung, J. Lee, J.H. Lee, M.G. Hur, C. J. Raj, K.-H. Yu, J. Radioanal. Nucl. Chem. 305 (2015) 169-178.

-

- 13. C. Hui, C. Shen, T. Yang, L. Bao, J. Tian, H. Ding, C. Li, H.-J. Gao, J. Phys. Chem. C 112 (2008) 11336-11339.

-

- 14. S. Nigam, K.C. Barick, D. Bahadur, J. Magn. Magn. Mater. 323 (2011) 237-243.

-

- 15. J. Yao, Y. Gong, S. Yang, P. Xiao, Y. Zhang, K. Keyshar, G. Ye, S. Ozden, R. Vajtai, P.M. Ajayan, ACS Appl. Mater. Interfaces 6 (2014) 20414-20422.

-

- 16. Z. Gu, H. Nan, B. Geng, X. Zhang, J. Mater. Chem. A 3 (2015) 12069-12075.

-

- 17. N. Padmanathan, H. Shao, D. McNulty, C. O'Dwyer, K.M. Razeeb, J. Mater. Chem. A 4 (2016) 4820-4830.

-

- 18. B.C. Kim, R. Manikandan, K.H. Yu, M.-S. Park, D.-W. Kim, S.Y. Park, C. J. Raj, J. Alloys Compnd. 789 (2019) 256-265.

-

- 19. H. Chen, S. Chen, Y. Zhu, C. Li, M. Fan, D. Chen, C. Tian, K. Shu, Electrochim. Acta 190 (2016) 57-63.

-

- 20. N. Tang, H. You, M. Li, G.Z. Chen, L. Zhang, Nanoscale 10 (2018) 20526-20532.

-

- 21. R. Manikandan, C. J. Raj, M. Rajesh, B.C. Kim, G. Nagaraju, W.-G. Lee, K.H. Yu, J. Mater. Chem. A 6 (2018) 11390-11404.

-

- 22. S.H. Lee, J.M. Kim, J.R. Yoon, J. Ceram. Process. Res. 18 (2017) 51-54.

- 23. C.J. Raj, M. Rajesh, R. Manikandan, J.Y. Sim, K.H. Yu, S.Y. Park, J.H. Song, B.C. Kim, Electrochim. Acta 247 (2017) 949-957.

-

- 24. F.B. Ajdari, E. Kowsari, A. Ehsani, M. Schorowski, T. Ameri, Electrochim. Acta 292 (2018) 789-804.

-

- 25. H. Liu, P. He, Z. Li, Y. Liu, J. Li, Electrochimica Acta 51 (2006) 1925-1931.

-

- 26. X. Pan, G. Ren, M.N.F. Hoque, S. Bayne, K. Zhu, Z. Fan, Adv. Mater. Interfaces 1 (2014) 1400398.

-

This Article

This Article

-

2020; 21(2): 278-283

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.278

- Received on Dec 23, 2019

- Revised on Jan 23, 2020

- Accepted on Feb 7, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kook Hyun Yu

-

Department of Chemistry, Dongguk University, Jung-gu, Seoul-04620, Republic of Korea

Tel : +82 2 2260 3709 Fax: +82 2 2268 8204 - E-mail: yukook@dongguk.edu

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.