- Investigation of the electrical properties of Ag/n-Si schottky diode obtained by two different methods

Vagif Nevruzoglu*, Melih Manir and Gizem Ozturk

Department of Energy Systems Engineering, Recep Tayyip Erdogan University, 53100 Rize, Turkey

In present study, Ag/n-Si Schottky

diodes were produced by vacuum evaporation method at two different substrate

temperatures (200 K and 300 K) and structural, optical, electrical properties

were investigated. X-ray diffraction studies showed that the textures of the Ag

films are cubic with a strong (111) preferred direction. Field emission

scanning electron microscopy (FESEM) images revealed that the Ag layer coated

at 200 K substrate temperature consisted of nano clusters of equal size (12-15

nm) and the Ag layer consisted of islets of different sizes (80-100 nm) at 300

K substrate temperature. The ideal factor (n), barrier height (φB),

saturation current (I0) and series resistance (RS) for

Schottky diodes 200 K and 300 K substrate temperature produced, obtained by

using I-V measurements respectively 1.11, 0.85 eV, 0.0014 ηA, 3.45 KΩ and 3.68,

0.78 eV, 0.05 ηA, 5.51 KΩ. Donor density (ND) and flat band

potential (EFB) for Schottky diodes 200 K and 300 K

substrate temperature produced, obtained by using C-V measurements respectively

1.1 × 1015 cm-3, 0.52 V and 1.4 × 1016

cm-3, 0.34 V. When the characteristic properties of Schottky diodes

are examined, it is understood that the differences depending on the method are

caused by the distribution of homogeneous and equal sized nano clusters on the

Si surface of the Ag layer produced at 200 K substrate temperature.

Keywords: Cold substrate, Thin film, Schottky diode

Metal-semiconductor contacts (Schottky diodes) are

indispensable component of the electronics industry. Compared to P-N junction,

these devices have some advantages such as low series resistance, high power capacity

and high switching speed at low voltage values [1, 2].

The electrical parameters of an ideal Schottky diode are determined by the

properties of the metal-semiconductor interface region [3, 4]. In this

direction, metal layers are formed by different methods and an intermediate

layer is placed in the metal-semiconductor contact area

[5, 6]. Nowadays, Schottky diodes, transistor and solar

cells are produced using different methods such as thermal evaporation, spin

coater and magnetron sputtering [7-9]. Micro and nano structured materials are

becoming increasingly important in technology [10].

Ag / SiO2 / n-Si Schottky diode was produced

and examined by with vacuum evaporation technique. The electrical

characteristics of the metal-insulator-semiconductor diode and

the interface state density were evaluated by I-V and impedance spectroscopy.

They calculated the barrier height as 0.62 eV, the ideality factor as 1.91 and

the average series resistance as 975.8 Ω [11].

Bates et al. (2007) showed that Ag atoms have deposited on

the surface of n-Si at 400 and 550 oC by using magnetron sputtering

technique. They found that Ag grain size at 400 oC from TEM

images was 5 nm and 10 nm at 550 oC. In Schottky diode produced

at 400 oC, carrier density is smaller than

550 oC. However, resistance and mobility values of

Ag layer produced at 400 oC were higher than 550 oC

[12]. Mahmood et al. (2018) examined Ag / n-Si diodes by creating some of the

characteristics of these diodes with the organic interface layer and

non-interface layer. The ideality factor of the structures with non-interface

layer and the organic interface layer was 1.42 and 1.83 respectively. The size

of the barrier height was 0.65 eV for the Ag / n-Si structure and 0.66 eV for

the hybrid structure. The series resistance values of the structures with and

without organic interface layer were 7,839 Ω and 135 respectively. Donor

density was 2.07 × 1014 cm-3 in the Ag / n-Si

structure and 24.8 × 1014 cm-3 in the hybrid

structure [13]. Korosak and Cvikl (1998) used Ionized Cluster Ray (ICB) method

and obtained the Ag / n-Si Schottky structures current voltage

characteristics measured at different temperature ranges (300 K-150

K). In the examples, different current conduction mechanisms

were determined [14].

Clayton et al. (2013) revealed that Ag / n-Si composite

films produced by magnetron sputtering technique at 550 oC on

n-Si (111) substrates were characterized. Films were prepared with a

concentration of 13, 16 and 22% Ag and measured in the 77-500 K temperature

range. A decrease in resistance values was observed between the Ag

nanoparticles formed with increasing Ag concentration due to less grain

boundary. It was found that as Ag concentration increased, grain boundaries

converged and became ineffective. The barrier heights were found to be 0.360

eV, 0.390 eV and 0.470 eV for the films with Ag concentrations of 13%, 16% and

22%, respectively. As can be seen from the studies mentioned above, the

characteristics of Schottky diodes change depending on the production method

[15].

In the study conducted by Yüzüak et al. (2019), Ag layers

were grown by soliton growth mechanism on n-Si (100) substrates by using cold

substrate method [16]. Some characteristics of the diode obtained at 200 K

substrate temperature were compared with those of the diode produced at 300 K

substrate temperature.

As mentioned above, in

literature studies, the studies using cold substrate method exist. However,

based on our best knowledge, there is no a study examining the effect of this

technique on the characteristics of Ag / n-Si Schottky structures which forms

the basis of the study. Present study was realized by making use of this gap.

Recent studies have focused on the surface plasmon resonance (SPR) diffusion

model that occurs in nano size metallic particle systems [14]. This model shows

more effective diffusion of nano sized metallic particles. The advantages and

disadvantages of this model will be revealed in this dual structure we have

discussed.

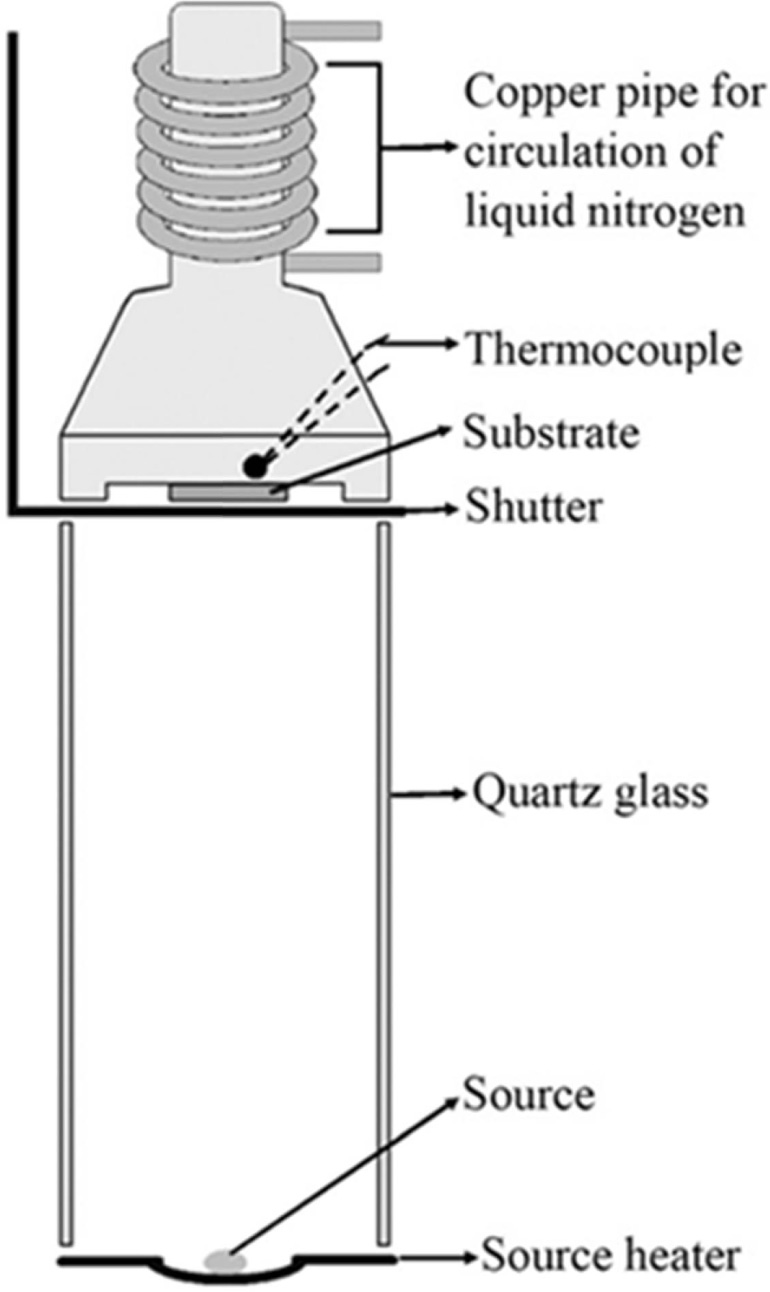

In the experiments, n-Si substrates (100) with resistivity

value of ρ = 1-10 Ω·cm and thickness of d = 375 µm were used. InGa material was

used for ohmic contact on n-Si. Ag/Si binary structures were annealed at room

conditions for 30 min at 300 °C due to the formation of diode

structure. The cold substrate method view of the evaporation apparatus is given

in Fig. 1. Substrate temperature was monitored and controlled using thermocouple. When the pressure reached

1.1 × 10-5

Torr, the substrate was cooled using liquid nitrogen. The Ag thin

films were grown at substrate temperatures of 300 K and

200 K. The shutter is continuously kept open during

deposition. The Ag thin films were deposited by vacuum

evaporation in a quasi-closed volume on n-Si substrates using high purity Ag

wire (99.99%) as the source material [16].

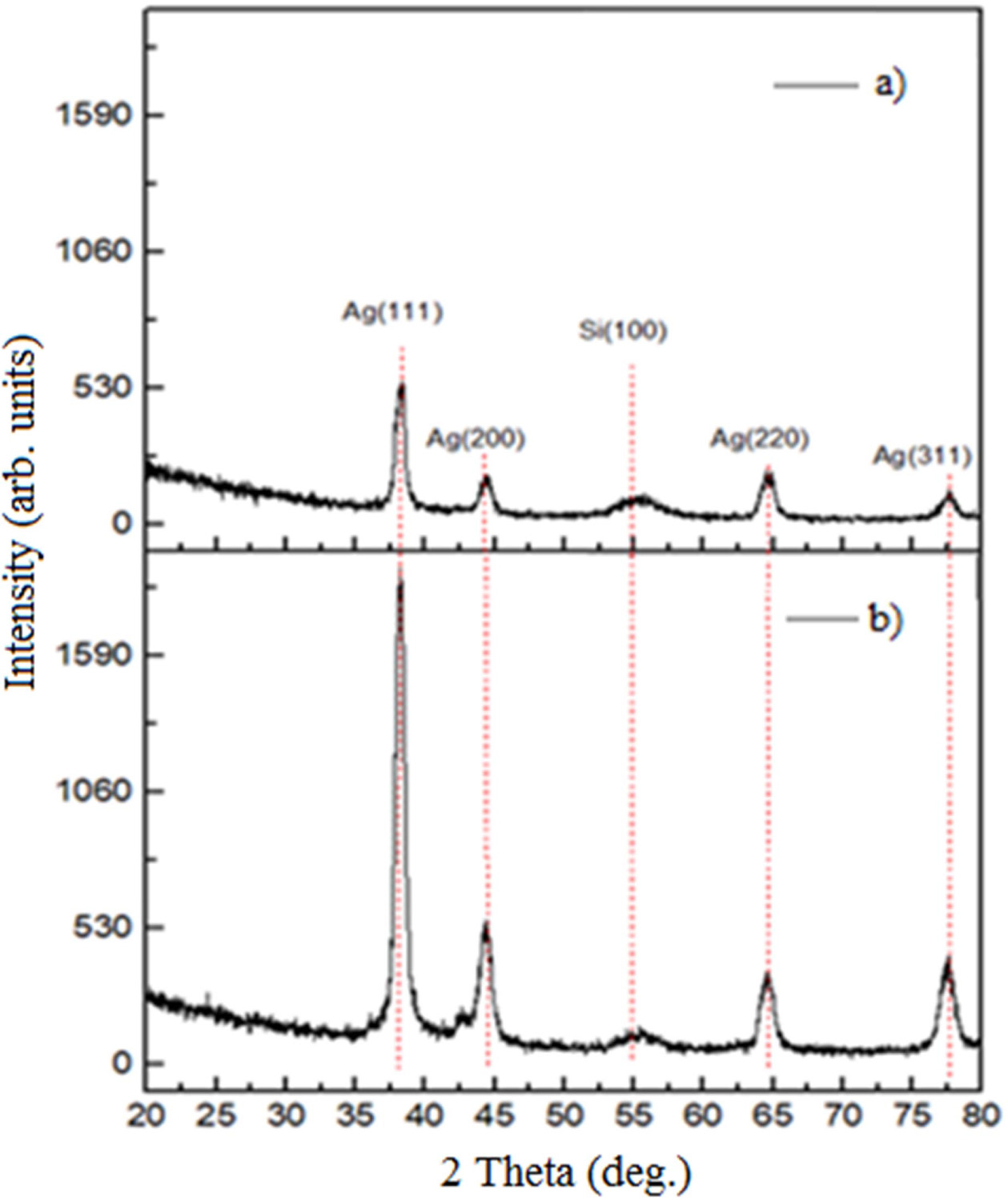

The crystal structure of Ag thin films was studied by X-ray

diffraction (XRD) using Rigaku SmartLab diffractometer with CuKα radiation (λ = 1,5408

Å) over the range 20o ≤2θ ≤ 80o at room temperature.

Electrical measurements of n-Si / Ag Schottky diodes were performed at room

temperature (300K) using the Ivium CompactStat.h10800 electrochemical measuring

device. Zeiss Sigma 300 was used for Field Emission Scanning Electron

Microscopy (FESEM) analysis. Changes in the Photocurrent values versus

wavelength were studied at room temperature in the range of 350-750 nm by

Monora 200 monochramator for Ag layers produced at 200 K and 300 K substrate

temperatures.

|

Fig. 1 A cross-sectional view of the thermal evaporation apparatus. |

The XRD results of the Ag films on n-Si substrates at

temperatures of 300 K and 200 K are shown in Fig. 2. X-ray was sent to the

substrate surface at angle of 1o and reflected from the Ag thin

film. It was found from the XRD patterns that the reflection intensity of the

substrate evaporated in Ag layer at 200 K temperature was higher than substrate

evaporated at 300 K. This phenomenon is due to forming a tight package on the

n-Si surface for the Ag coated substrate at temperature of 200 K. The peaks of

Ag layers at angles 2θ = 38.2o, 44.3o, 64.5o and

77.6o belonged to (111), (200), (220) and (311) planes respectively.

In addition, it was seen that the Ag thin film was in line with the preferred

growth orientation (111) and had a cubic structure [17]. The peaks seen in the

XRD pattern were compared with the PDF Card No: 1100136 data card. However, in

the spectrum 2θ= 55o, Si (100) plane reflection was detected.

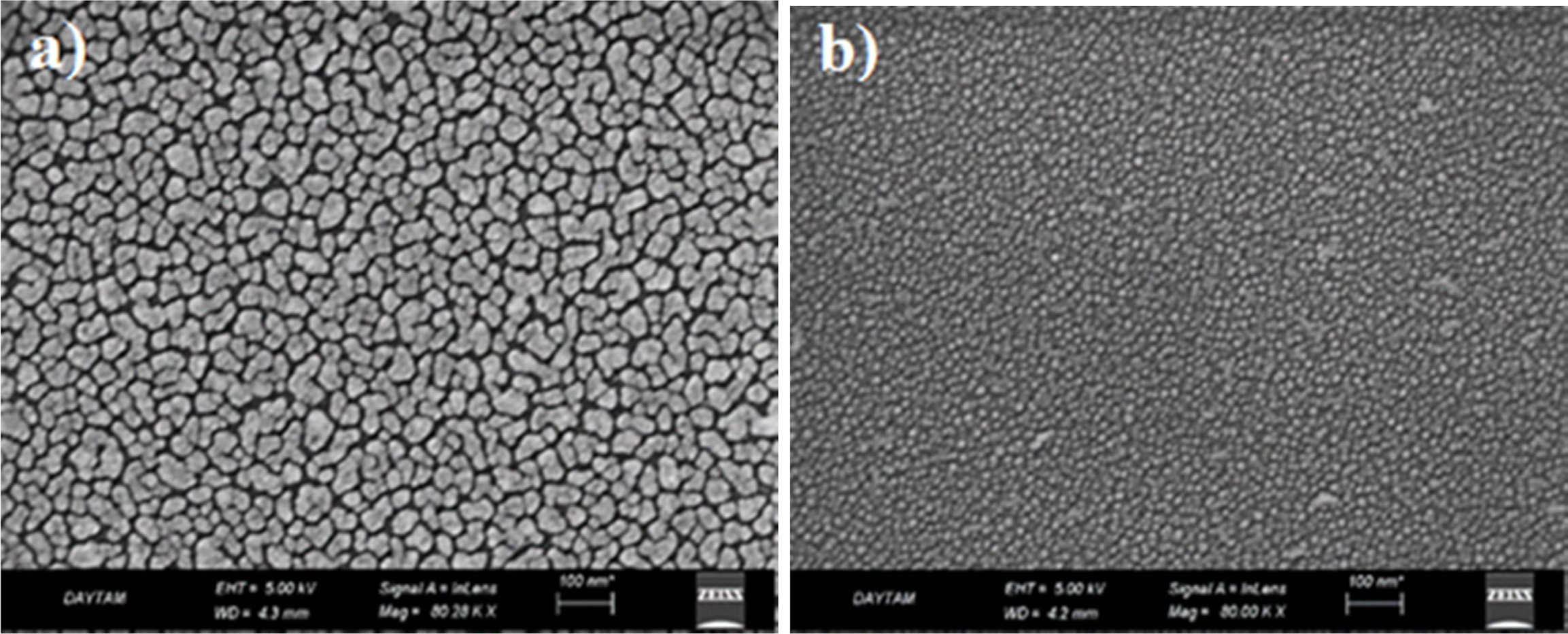

Fig. 3 shows the FESEM image of Ag thin films produced on

a glass surface for substrate temperature at 200 K and 300 K. In Fig. 3(a), at

300 K production temperature, Ag layer is

composed of islets of different sizes and in Fig. 3(b), at 200 K production

temperature, Ag layer is composed of equal sized clusters [18]. This result

shows that the Ag layer at substrate temperature of 200 K is caused by soliton

growth mechanism.

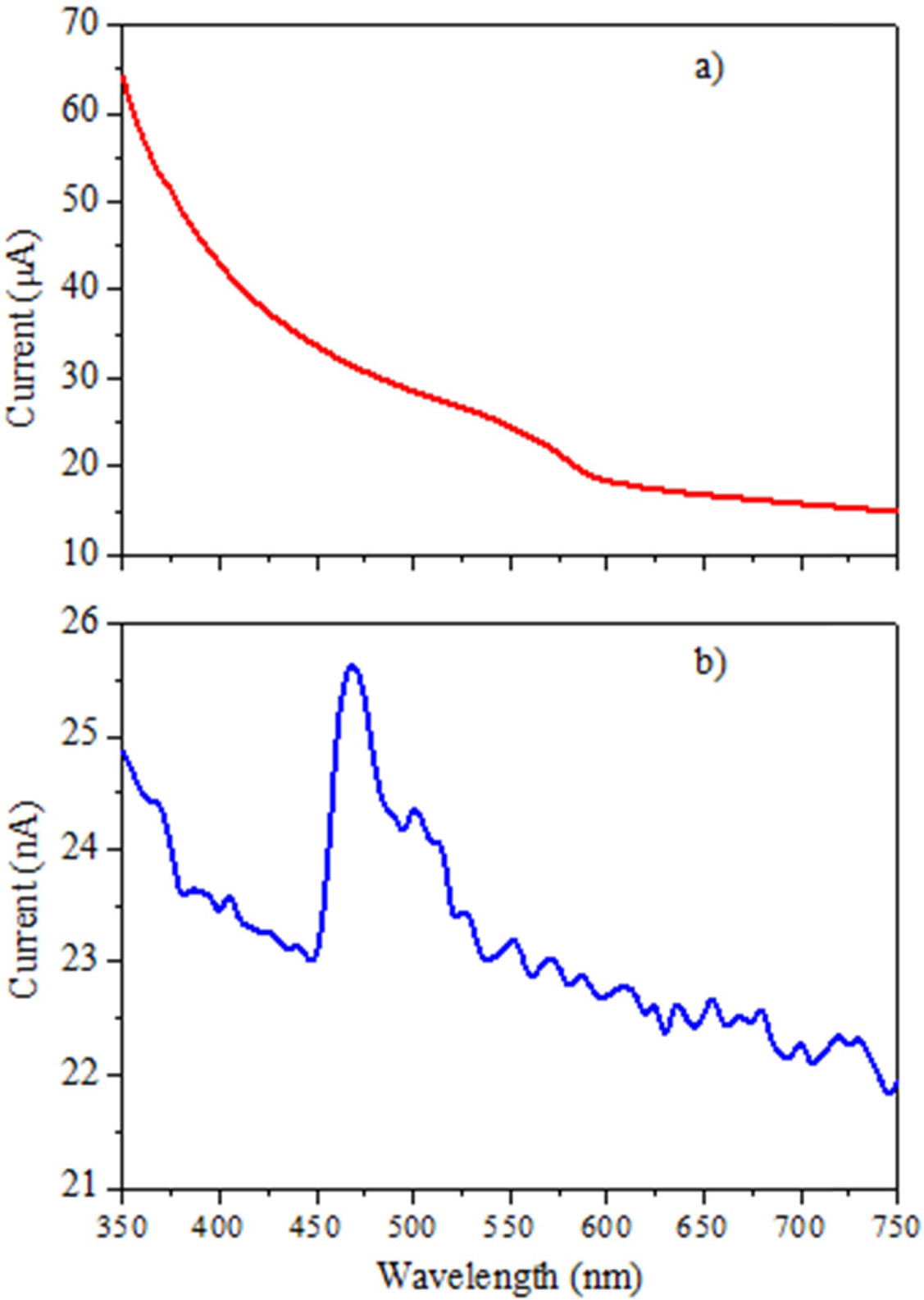

As it is known, superficial plasmon resonance (SPR) event

occurs in nano-sized Ag layers at a certain frequency [19]. In order to

determine this, the changes in the photocurrent values according to the

wavelength of Ag layers formed on the insulating glass surface at 300 K and 200 K

substrate temperatures were examined. Fig. 4

shows the photocurrent value of the Ag film produced at a substrate temperature

of 200 K at a wavelength of 470 nm [19]. The wavelength at which the SPR event

occurs corresponds to 638 THz. It is known from the literature that the SPR

event in the Ag structure has a frequency of 638 THz [14]. At 300 K substrate temperature, there is no interesting

situation in the photocurrent values

with varying wavelengths.

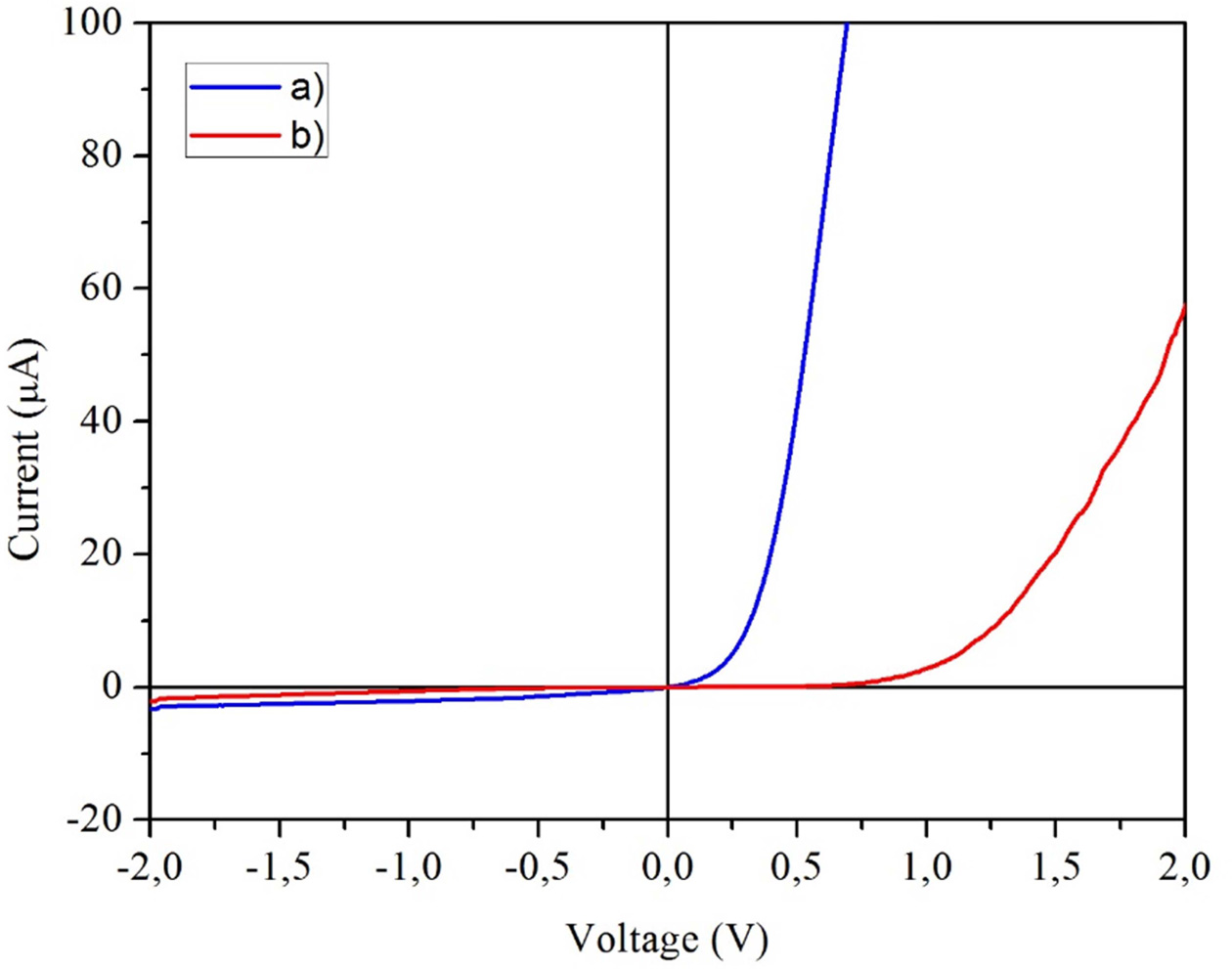

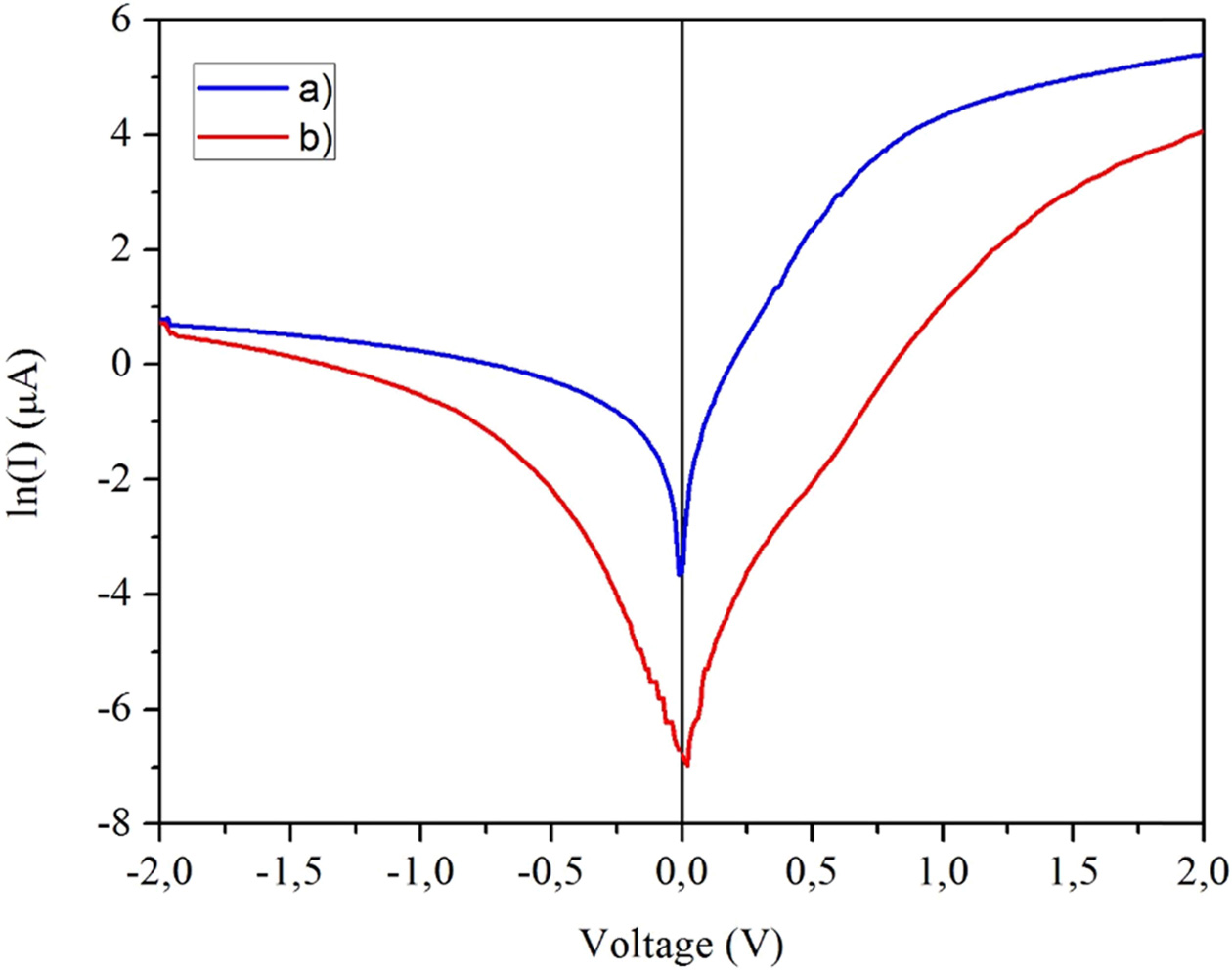

Fig. 5 shows the I - V measurement results of n-Si / Ag

Schottky diodes produced at substrate temperature of 200 K and 300 K. As can be

seen, both examples show rectifier characteristics. The n-Si / Ag Schottky diode

produced at a substrate temperature of 200 K showed sharper rectifier

properties. This was due to reduction in surface state density in the metal-semiconductor

contact region of the diode produced at a substrate temperature of 200 K.

The thermionic emission current-voltage relation of a

Schottky diode is given by [20]

where I0 is the

saturation current, q is the electronic charge, V is the applied

voltage, n is the ideality factor, k is Boltzmann’s constant and T

is the temperature in K. The saturation current I0 is

defined by

where A* is the

theoretical Richardson constant (A* = 112 A/cm2K2 for

n-Si), A is the diode area and fb

is the zero bias barrier height. For V values greater than 3 kT/q, the ideality

factor n can be calculated from the slope of the rectification line region of

the forward bias ln(I)-V plot for each temperature and can be written as

I0 can be

determined by an extrapolation of the forward bias ln(I)-V

curve to V = 0 for each temperature. The zero bias

barrier height (fb)

is calculated by the following formula:

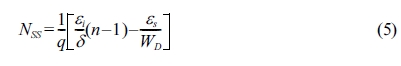

The expression for the interface state density as deduced

by Card and Rhoderick [21] is reduced to

where d is the thickness of

interfacial insulator layer, WD is the width of the space

charge region, εi and εs are the

permittivity of the interfacial insulator layer and the semiconductor,

respectively.

In Fig. 6, the semi-logarithmic I-V graph of n-Si /Ag

Schottky diodes was produced at 200 K and 300 K substrate temperatures. The ln

(I) -V curve of the n-Si / Ag Schottky diode produced at substrate temperature

of 300 K shows a linear behavior between bias voltages of 0.2-1.5 V, while the

diode produced at substrate temperature of 200 K shows a linear variation in

the range of bias voltages of 0-0.7 V [18].

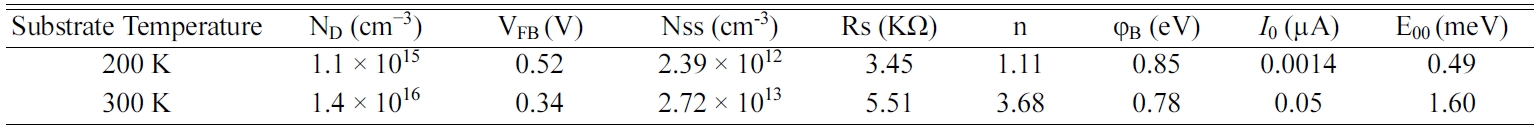

In Table 1, ideality factor (n) and saturation current (I0)

values of n-Si / Ag Schottky diodes produced at 200 K and 300 K substrate

temperatures were calculated from ln (I)-V graph. As can be seen from the Table

1, Schottky diode at 300 K substrate temperature has higher n and I0

values than 200 K substrate temperature production. However, the barrier height

(φB) of the diode at a substrate temperature of 300 K is lower than

that produced at 200 K. As is known, at a substrate temperature of 300 K, the

Si surface Ag layer is coated with islets of different sizes. Thus,

non-homogeneous regions were formed at the interface of the Si / Ag Schottky

barrier [22-25]. This leads to a reduction in the barrier

potential at the metal-semiconductor interface [26, 27].

The ideality factors of the samples are greater than 1,

indicating that there are different current conduction mechanisms in the

diodes.

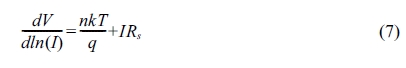

The thermionic emission current-voltage relation of a

Schottky diode with series resistance is given by [20]

where Rs is serial

resistance. Eq. (6) can be differentiated as follows:

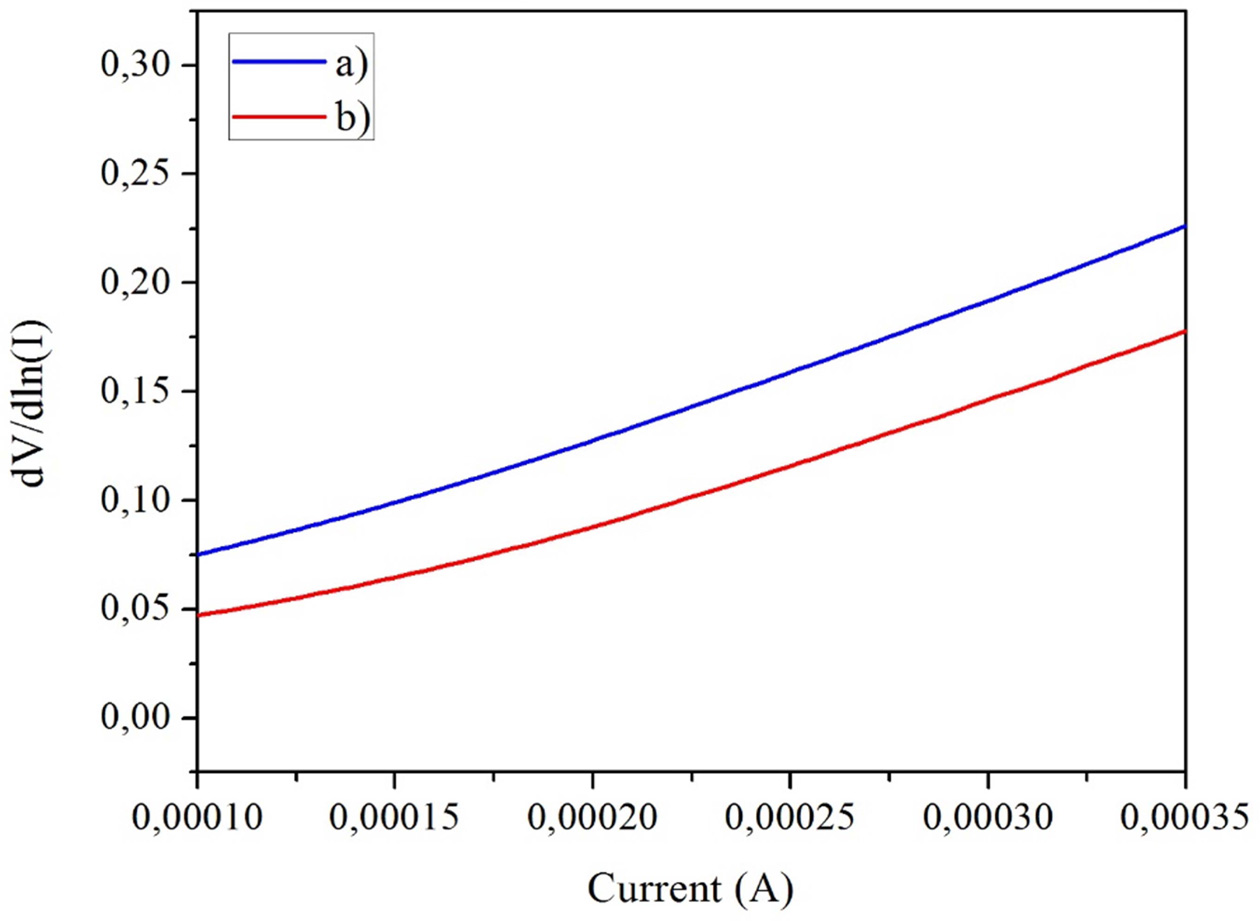

The series resistances are evaluated by using the slopes

of dV/dln(I) versus I curves. Fig. 7 shows dV/dln(I) versus I plots for the

n-Si/Ag (at 200 K and 300 K) Schottky diode.

From the experimental results, series resistance values

of diodes were found. In Table 1, series resistance values are calculated from

dV/dln (I) graph and are given. It is seen in the Table 1 that the diode

prepared at 300 K substrate temperature has higher series resistance values

than the diode prepared at 200 K substrate temperature. Increases in series

resistance values are due to increases in surface state density in the

metal-semiconductor interface area [28, 29].

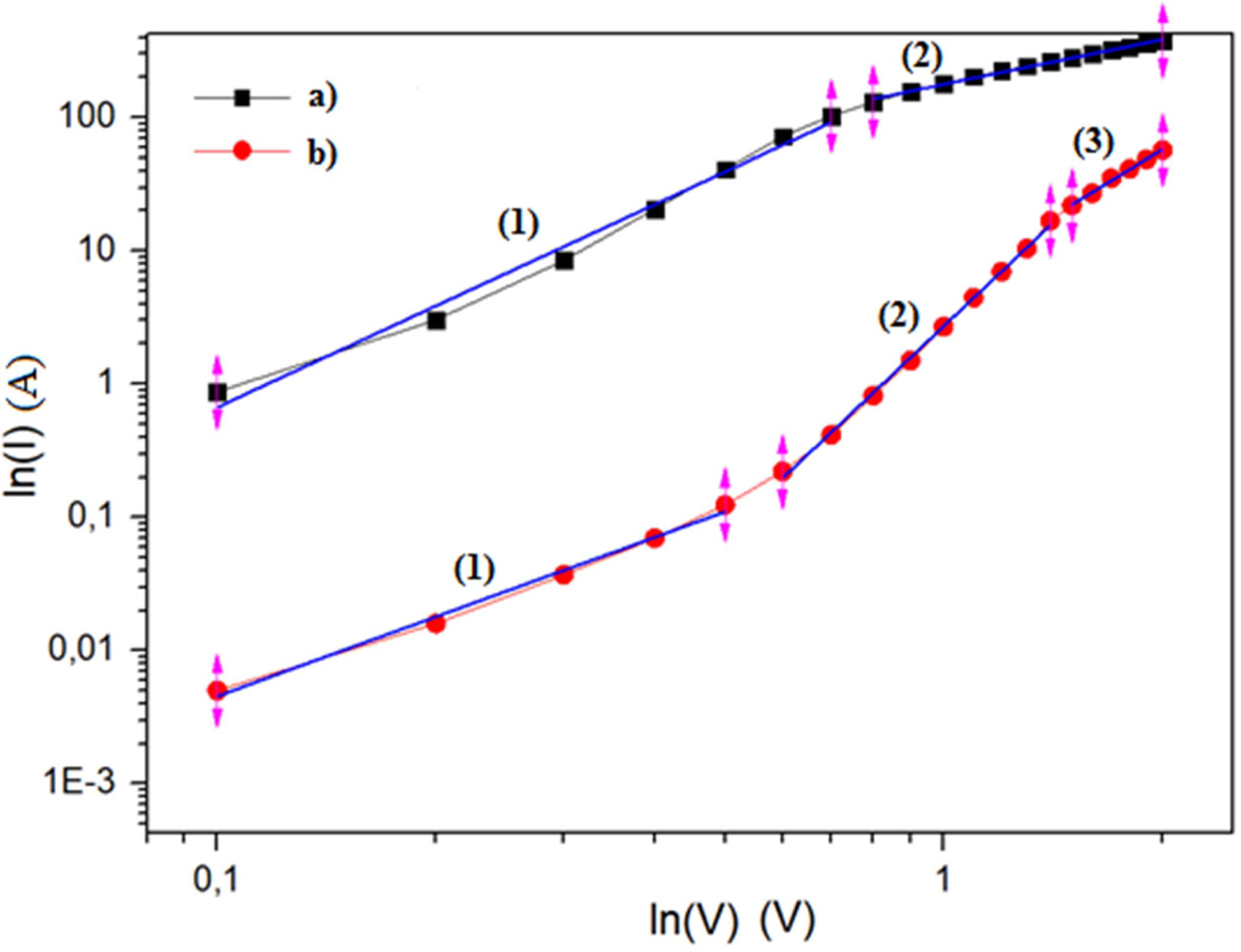

Double Logarithmic I-V graph (Fig. 8) was used to

determine the conduction mechanisms of the produced Si / Ag

Schottky diodes. In Fig 8, Schottky diode produced at

300 K substrate temperature, 3 separate linear regions, two

separate linear regions produced at 200 K substrate temperature were seen.

Since the first region slope (m) of both diodes is greater than 2, the space

charge limited current mechanism (SCLC) is effective in this region. In the

second region, m <2 and omics behavior is exhibited. This shows that the

tunneling current mechanism is dominant in the second region. In the third

region of the Schottky diode produced at a substrate temperature

of 300 K, m > 2, the Space Charge Limited Current

mechanism (SCLC) is effective in this region.

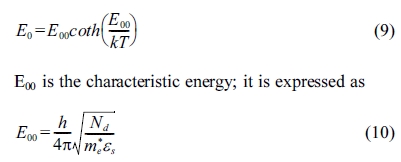

In practice, tunneling mechanism is very significant for

semiconductors that have E00 =10 value or a doping level

higher than ~1 × 1017 cm-3

[10]. The carrier density of Schottky diode at substrate

temperature of 300 K was found to be 1.1 × 1017

cm-3.

Therefore, the tunneling mechanism was investigated for

n-Si/Ag structure. Tunneling mechanism can occur as two mechanisms: (1)

field emission (FE) and (2) thermionic field emission (TFE). TFE

theory is the dominant mechanism in the intermediate temperature and doping

concentration, but FE theory is dominant only at quite low temperatures for the

material having high doping concentrations [23]. Current-voltage relation for

tunneling mechanism is given by [30,31]

Where

According to the theory, if E00 >> kT

is FE dominant, E00 ~ KT is TFE dominant, and E00 << kT

is thermionic emission diffusion mechanism is dominant. In the Si / Ag

Schottky diode produced at 200 K substrate temperature according to E00

values given in Table 1, it is found that the field thermionic emission

diffusion mechanism is dominant. The field emission mechanism is dominant in

the Si-Ag Schottky diode produced at a substrate temperature of 300 K.

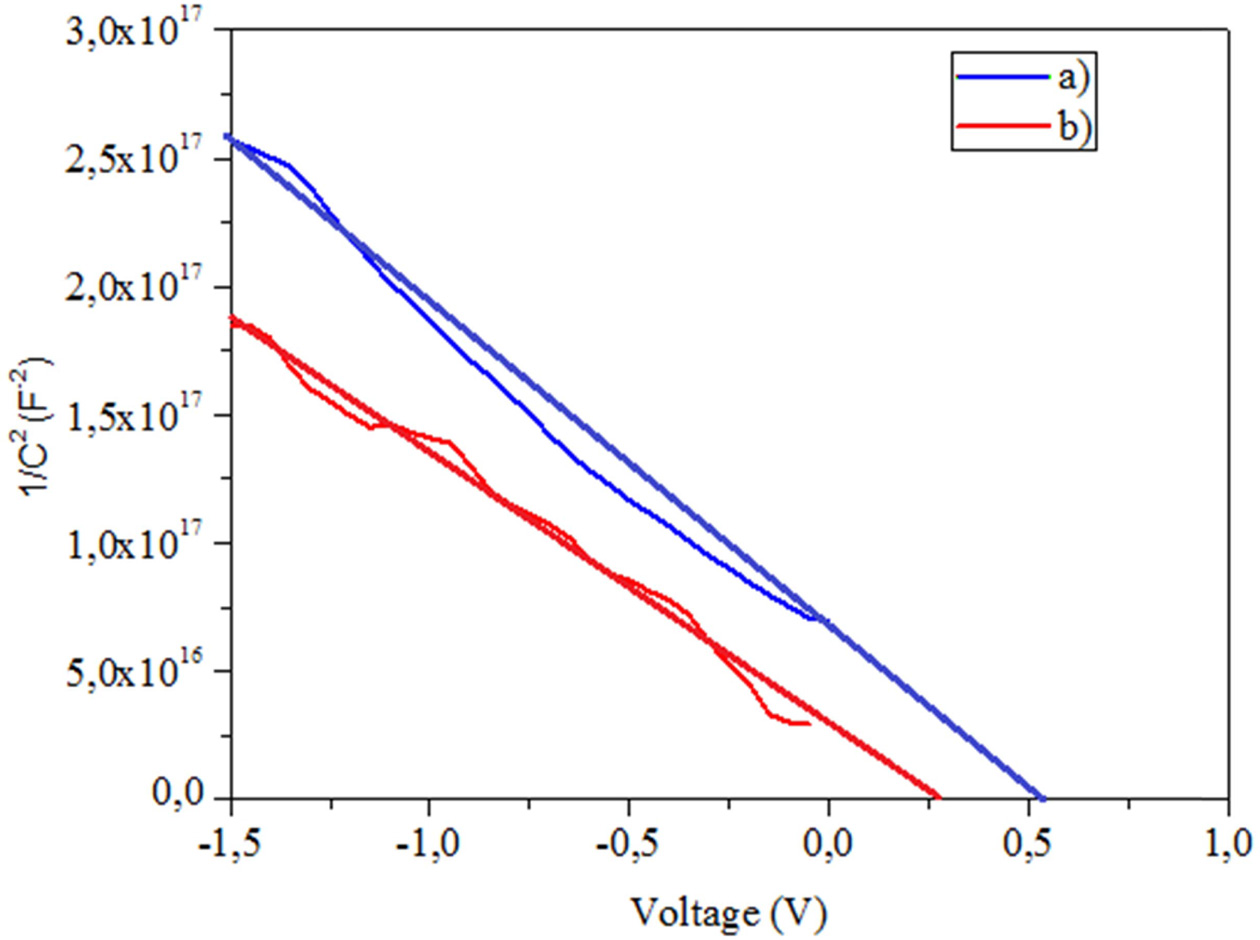

Fig. 9 shows the Mott-Schottky graph measured at 1000 Hz

frequency for Schottky diodes produced at 200 K and 300

K substrate temperatures. Typical results of C/V

measurements for both types of diodes are displayed in Fig. 9. The constant

slopes of the 1/C2 versus V curves indicate uniform doping profiles of the substrates and abrupt interfaces. Ideally, the capacitance (C) of a Schottky barrier is expressed from Eq.

(11) [32, 33].

Where V is the applied potential, S is the active device

area, Nd is the donor concentration, Vd is the diffusion

potential, ε0 is the vacuum dielectric constant and the relative

dielectric constant εs. Where the curve in the graph is 1 / C2 = 0

gives us the flat band potential (VFB). Table 1 shows the VFB

values of Schottky diodes produced at 200 K and 300 K substrate temperatures. Donor

densities in Si/Ag Schottky diodes were determined from linear

regions of Mott Schottky curves.

Table 1 shows ND, VFB and NSS

values calculated from C-V measurements. The donor density was found to be

lower at the 200 K substrate temperature than the 300 K substrate temperature.

The surface state density (NSS) at the

metal-semiconductor interface was calculated to be lower

in the Schottky diode produced at a substrate temperature of 200 K compared to

a substrate temperature of 300 K.

|

Fig. 2 XRD patterns of n-Si/Ag prepared binary structure at (a) 300 K and (b) 200 K. |

|

Fig. 3 FESEM image of glass/Ag thin films (a) 300 K and (b) 200 K. |

|

Fig. 4 Wavelength-current graph at (a) 300 K and (b) 200 K. |

|

Fig. 5 I-V graph of n-Si/Ag Schottky barriers at (a) 200 K and (b) 300 K. |

|

Fig. 6 Semi-logarithmic I-V graph of n-Si/Ag Schottky diode at (a) 200 K and (b) at 300 K. |

|

Fig. 7 Experimental dV/dln(I) versus I plots for the n-Si/Ag Schottky diode at (a) 200 K and (b) 300 K. |

|

Fig. 8 Double logarithmic forward bias I-V plots of a n-Si/Ag Schottky diode at (a) 200 K and (b) 300 K. |

|

Fig. 9 Mott-Schottky graph of Si/Ag Schottky diodes (a) 200 K and (b) 300 K. |

In this study, Schottky diodes were produced by

evaporating Ag onto n-Si using vacuum evaporation technique at 200 K (cold

substrate) and 300 K substrate temperature. It was seen from the FESEM images

that the Ag layer was composed of equal sized nano clusters at 200 K substrate

temperature and that the Ag layer was composed of islets of different size at

300 K substrate temperature. When the photocurrent values were examined

according to wavelength, SPR effect was observed in Ag thin film produced at

200K substrate

temperature at 470 nm wavelength (638 THz).

Si/Ag Schottky diode produced at 200 K substrate temperature from I-V measurements had better rectification properties. In the experiments, n, I0

and Rs values of Schottky diode produced at 300K substrate temperature were

higher than those produced at 200 K substrate temperature. It was understood

from the obtained results that transmission at 200 K and 300 K substrate

temperatures can be controlled by tunneling at low bias voltages and SCLC at

high bias voltages.

- 1. S.M. Sze, in “Semiconductor Devices: Physics and Technology”, (John Wiley & Sons, 2008) p. 84.

- 2. B. Sahin, H. Cetin, and H. Ayyildiz, Solid State Commun. 135 (2005) 490-495.

-

- 3. S. Karatas, Microelectron. Eng. 87 (2010) 1935-1940.

-

- 4. M.E. Aydin, K. Akkilic, and T. Kilicoglu, Physica B. 352 (2004) 312-317.

-

- 5. Z. Ahmad and M.H. Sayyad, Physica E. 41 (2009) 631-634.

-

- 6. S. Guduru, V.P. Singh, S. Rajaputra, S. Mishra, R. Mangu, and St. Omer, Thin Solid Films 518 (2010) 1809-1814.

-

- 7. V. Nevruzoglu, M. Tomakin, E.F. Keskenler, and G. Ozturk, J. Ceram. Process. Res.18 (2017) 494-500.

- 8. F.K. Konana, A. Betiéd, H.J.T. Nkuissib, K. Dakshib, B. Akaa, and B. Hartitib, J. Ceram. Process. Res. 18 (2017) 882-886.

- 9. M. Amuthasurabi, J. Chandradass, V.R. Babu, P.B. Sethupathi, and M.L.J. Martin, J. Ceram. Process. Res. 18 (2017) 815-818.

- 10. E. Bingöl, F. Bozali, E.F. Keskenler, V. Nevruzoğlu, and M. Tomakin, Turk. J. Mater 1 (2016) 19-24.

- 11. M. Okutan and F. Yakuphanoğlu, Microelectron. Eng. 85 (2008) 646-653.

-

- 12. C.W. Bates, J.C. White, and C. Ekeocha, 143 (2007) 38-41.

-

- 13. O.H. Mahmood, A.G. İmer, and A. Korkut, ICSMD-2018, 1 (2019) 47-51.

- 14. D. Korosak and B. Cvikl, ASDAM '98, 1 (1998) 137-140.

-

- 15. W. Clayton, J. Bates, and C. Zhang, Aip Advances 3 (2013) 1-15.

-

- 16. G.D. Yüzüak, E. Yüzüak, V. Nevruzoğlu, and İ. Dinçer, Applied Physics A. 125 (2019) 794-803.

-

- 17. F. Heıdarpour, W.A. Wan, AB Karım Ghanı, F.R. Bın Ahmadun, S. Sobrı, M. Zargar, and M.R. Mozafarıa, Dig. J. Nanomater. Bios. 5 (2010) 787-796.

- 18. M. Tomakin, M. Altunbaş and E. Bacaksız, Physica B. 406 (2011) 4355-4360.

-

- 19. K.C. Lee, S.J. Lin, C.H. Lin, C.S. Tsai, and Y.J. Lu, Surf. Coat. Technol. 202 (2008) 5339-5342.

-

- 20. D.K. Schroder, in “Semiconductor Materials and Device Characterization”, (Wiley, New York, 1990) p. 190.

- 21. H.C. Card and E.H. Rhoderick, J. Phys. D: Appl. Phys. 4 (1971) 1589-1601.

- 22. R.T. Tung, Mater. Sci. Eng. R: Rep. 35 (2001) 1-138.

-

- 23. S. Oktik, G.J. Russell, and J. Woods, Semicond. Sci. Technol. 2l (1987) 661-665.

-

- 24. K. Patel, K.K. Nanda, and S.N. Sahu, J. Appl. Phys. 85 (1999) 3666-3670.

-

- 25. V.V. Kislyuk, M.I. Fedorchenko, P.S. Smertenko, O.P. Dimitriev, and A.A. Pud, J. Phys. D: Appl. Phys. 43 (2010) 185301-185311.

-

- 26. R.T. Tung, Phys. Rev. B 45 (1992) 13509-13523.

-

- 27. J.H. Werner and H.H. Guttler, J. Appl. Phys. 69 (1991) 1522-1533.

-

- 28. A. Keffous, M. Siad, S. Mamma, Y. Belkacem, C.L. Chaouch, H. Menari, A. Dahmani, and W. Chergui, Appl. Surf. Sci. 218 (2003) 336-342.

-

- 29. J.H. Lee, J.S. Yi, K.J. Yang, J.H. Park, and R.D. Oh, Thin Solid Films 431 (2003) 344-348.

-

- 30. F.A. Padovani and R. Stratton, Solid-State Electron 9 (1966) 695-707.

-

- 31. C.R. Crowell and V. L. Rideout, Solid-State Electron 12 (1969) 89-105.

-

- 32. S.M. Sze, in “Physics of Semiconductor Devices” (Wiley Eastern Limited, 3rd edition, 1985) p. 170.

- 33. E.H. Rhoderic and R.H. Williams, in “Metals Semiconductor Contacts” (Oxford University Press, 1988) p. 48.

This Article

This Article

-

2020; 21(2): 256-262

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.256

- Received on Jan 15, 2020

- Revised on Mar 19, 2020

- Accepted on Mar 20, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Vagif Nevruzoglu

-

Department of Energy Systems Engineering, Recep Tayyip Erdogan University, 53100 Rize, Turkey

Tel : +90 464 2237518 Fax: +90 464 2237514 - E-mail: vagif.nevruzoglu@erdogan.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.