- Characterization of CuIn1-xGaxSe2 films prepared by spin-coating and co-reduction method

Jing Li, Kegao Liu*, Qilei Sun, Zhigang Wang and Haiyang Wu

School of Materials Science and Engineering, Co-Innovation Center for Green Building of Shandong Province, Shandong Jianzhu University, Fengming Road, Jinan 250101, China

CuIn1-xGaxSe2

film has excellent photovoltaic performance due to its large optical absorption

coefficient and direct-band gap. It was prepared by spin-coating and chemical

co-reduction method which is a simple and easy way with low cost in this work.

The surface morphology of the product film was observed using scanning electron

microscope (SEM). The absorbance curves are measured by visible

spectrophotometer. The phases of the samples were characterized by X-ray

diffraction (XRD). It was found by phase analysis that prolonging the reaction

time and increasing the reaction temperature were beneficial to the sample

crystallization. With the doping concentration increasing, the surface

morphology of CuIn1-xGaxSe2 films changed with

a tendency from spherical crystals to rods. The effect of doping concentration

on the resistivity is not particularly obvious. As the doping concentration

increases, the resistivity will increase slightly; When x=1, the resistivity

changes greatly, which may be due to the poor film continuity. Their estimated

band gaps of CuIn1-xGaxSe2 films are 1.25 eV,

1.3 eV, 1.33 eV, 1.38 eV and 1.4 eV respectively.

Keywords: CuIn1-xGaxSe2, morphology, band gap, photovoltaic, solar cell

The optimal band gap for a single junction solar cell is

about 1.4 eV. Pure CuInSe2 with a gap 1.04 eV has excellent

photoelectric performance [1,2]. Doping is an

important means to regulate the properties of materials [3-5], the

enhancement of the thermoelectric properties of the SrTiO3 by doping

with Zr were investigated [6]. To increase the width of CuInSe2

band gap, indium can be partially replaced by gallium and

then it can obtain the compound of

copper indium gallium diselenide (CIGSe). CIGSe

polycrystalline thin film is recently being developed as an

absorber material for thin-film photovoltaic solar cells, it is a

multi-crystalline semiconductor of p-type with

high-quality characteristics, such as its large optical absorption

coefficient and direct-band gap [7]. Light trapping was studied in ultrathin

CuIn1-xGaxSe2 solar cells by dielectric

nanoparticles [8]. CuInSe2 nanowire arrays with core-shell structure

were electrodeposited at various duty cycles into anodic

alumina templates [9]. The influence of process parameters

were investigated on the gallium composition of a CuIn1-xGaxSe2

solar cell [10]. It reported the effects of substrate

temperatures in the three-stage growth of CuIn1-xGaxSe2

thin films and their photovoltaic performances [11]. The structural

and optical properties of Cu-poor CuIn1-xGaxSe2

films with different gallium contents prepared by co-evaporated technique were studied

[12]. The effect of growth conditions on the

properties of sputtered precursor thin films for CuIn1-xGaxSe2

(CIGS) absorber layers was reported

[13]. Single phase polycrystalline copper indium gallium diselenide thin-films for solar photovoltaic applications were fabricated by an economical

two-stage method of pulsed current

electrodeposition [14]. Other research

works include simulations about CuIn1-xGaxSe2 alloys [15], 3-stage deposition of CuIn1-xGaxSe2

on Mo-coated glass and stainless steel

substrates [16], CuIn1-xGaxSe2 nanopowders or

nanoparticles produced by solvothermal

method [17, 18] and CuIn1-xGaxSe2 prepared by electrodeposition [19]. It has

reported our work about CuInSe2 films prepared from chlorides under

different conditions [20]. Quaternary compound CuIn1-xGaxSe2 was prepared by

spin-coating and chemical

co-reduction method in this work.

The corresponding amounts of raw materials were weighed

according to the stoichiometric ratio of CuIn1-xGaxSe2,

the precursor solution with the highest concentration

was prepared, and the mixture was shaken by the

ultrasonic cleaner to make it uniformly mixed. The CuIn1-xGaxSe2

precursor film was prepared by spin-coating with 3,000 rpm for 10 seconds, and

then the sample was placed in a reaction vessel containing hydrazine hydrate

for heat treatment at a certain temperature. Then the CuIn1-xGaxSe2

film sample was obtained after soaking in ionized water for 24 h and drying at

room temperature. The surface morphology of the product film was observed using

scanning electron microscope (SEM). The absorbance curves are measured by Model

723PC visible spectrophotometer made by Shanghai Precision Instrument Co., Ltd.

According to the light absorption characteristics of the absorbance curve in

the visible light region, the band gap widths of the CuInSe2 film samples

were estimated using extrapolation. The phases of the samples were

characterized by X-ray diffraction (XRD).

CuIn1-xGaxSe2

films were prepared by spin-coating and chemical co-reduction method

The phases of CuIn1-xGaxSe2

films prepared by different reaction time

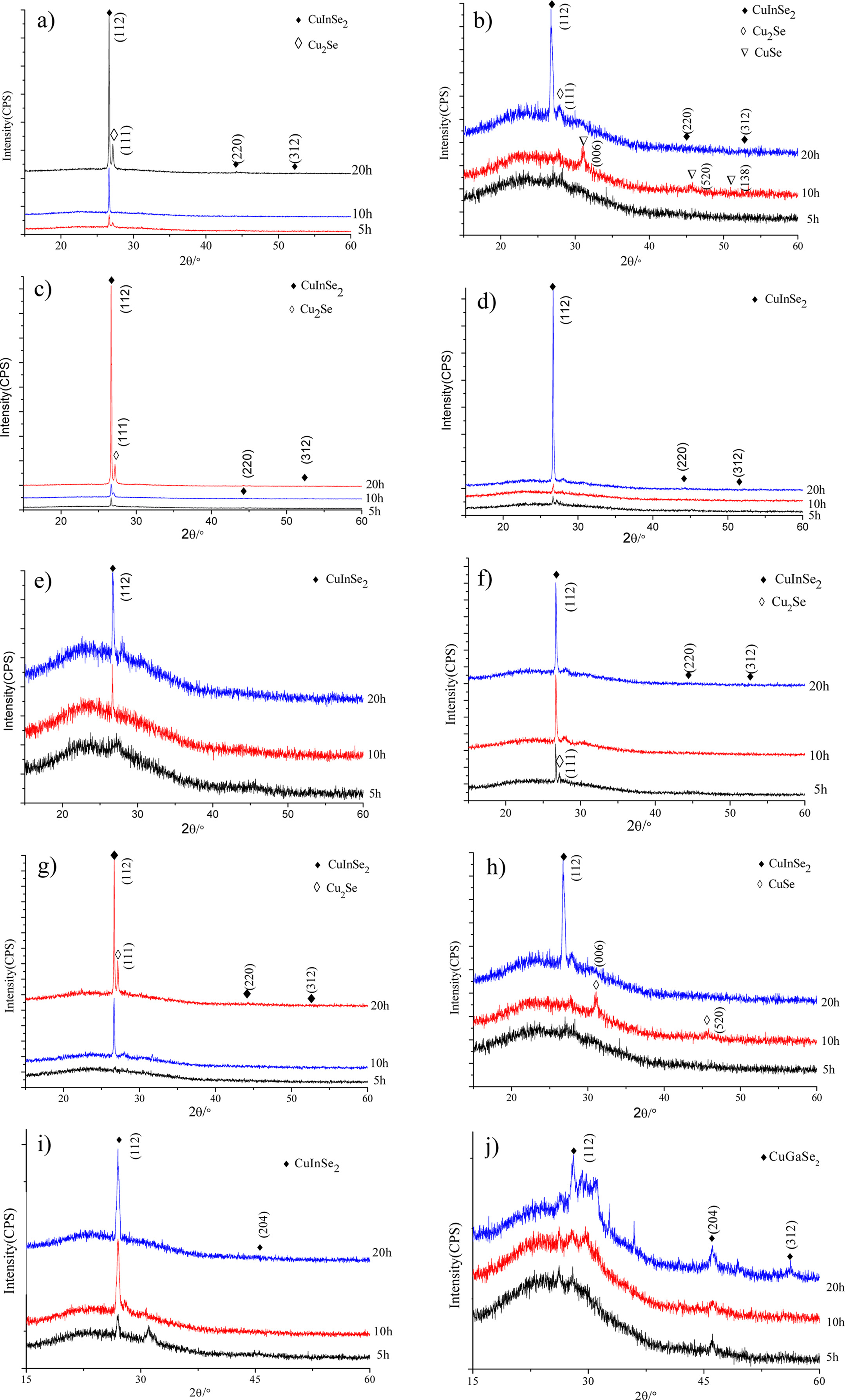

Fig. 1 shows the XRD patterns of CuIn1-xGaxSe2

obtained with different reaction time of 5 h, 10 h and 20 h at 220 °C. It

can be seen that the samples with long reaction time have higher XRD peak

intensities, and the reaction time extension is favorable for the

crystallization of the film samples. Compared with the standard PDF card with

No.89-5649, the XRD patterns of the CuIn0.9Ga0.1Se2

film samples in Fig.1a show three high peaks with 2θ angles at 26.67°, 44.32°

and 52.47° that correspond to the (112), (220) and (312) crystal planes

respectively; According to the standard PDF card with No.88-2043, the XRD peak

of impurity phase Cu2Se appears in Fig. 1(a), where the 2θ angle

27.12° corresponds to the (111) crystal plane. Fig. 1(b) indicates that the

CuIn0.8Ga0.2Se2 film samples reacted with 5 h

and 10 h have no XRD peaks corresponding to the target phase while the XRD

intensity are very low. The target XRD peaks occur in the sample with the

reaction time 20 h; Impurity CuSe appeared in the sample obtained with reaction

time 10 h. Fig. 1(c) and (d) show the XRD patterns of CuIn0.7Ga0.3Se2

and CuIn0.6Ga0.4Se2 film samples, compared

with the standard PDF card with No.89-5649,

the XRD peak positions with 2θ angles are slightly shifted to the right, while

the impurity phase Cu2Se also appeared in the sample reacted for 20

h in Fig. 1(c). It can be seen from Fig. 1(e) that the XRD intensities for the

target phase of the CuIn0.5Ga0.5Se2 sample are

lower than others and increase with the reaction time prolongation. CuIn0.4Ga0.6Se2

film samples with good crystallinity are obtained under different reaction

conditions as shown in Fig. 1(f). It can be seen from Fig. 1(g) that the CuIn0.3Ga0.7Se2

sample with reaction time 5 h has no XRD peaks. As the reaction time increases

to 10 h and 20 h, the CuIn0.3Ga0.7Se2 sample

crystallizes better and better, but impurity phase Cu2Se appeared

when 20 h. Fig. 1(h) shows that the CuIn0.2Ga0.8Se2

samples did not show the XRD peaks of the target phase with the reaction time 5

h and 10 h, and the XRD peak appeared when the reaction time extended to 20 h. Compared

with the standard PDF card No.89-5649 in Fig. 1(i), the 2θ angle positions of

XRD peaks for the CuIn0.1Ga0.9Se2 samples are

shifted to the right as a whole. The XRD peaks of the CuGaSe2 sample

correspond to the standard PDF card with

No.31-456, and the 2θ angles with

27.7°, 46.11° and 54.25° correspond

to (112), (204) and (312) crystal planes of CuGaSe2 respectively as

shown in Fig. 1(j).

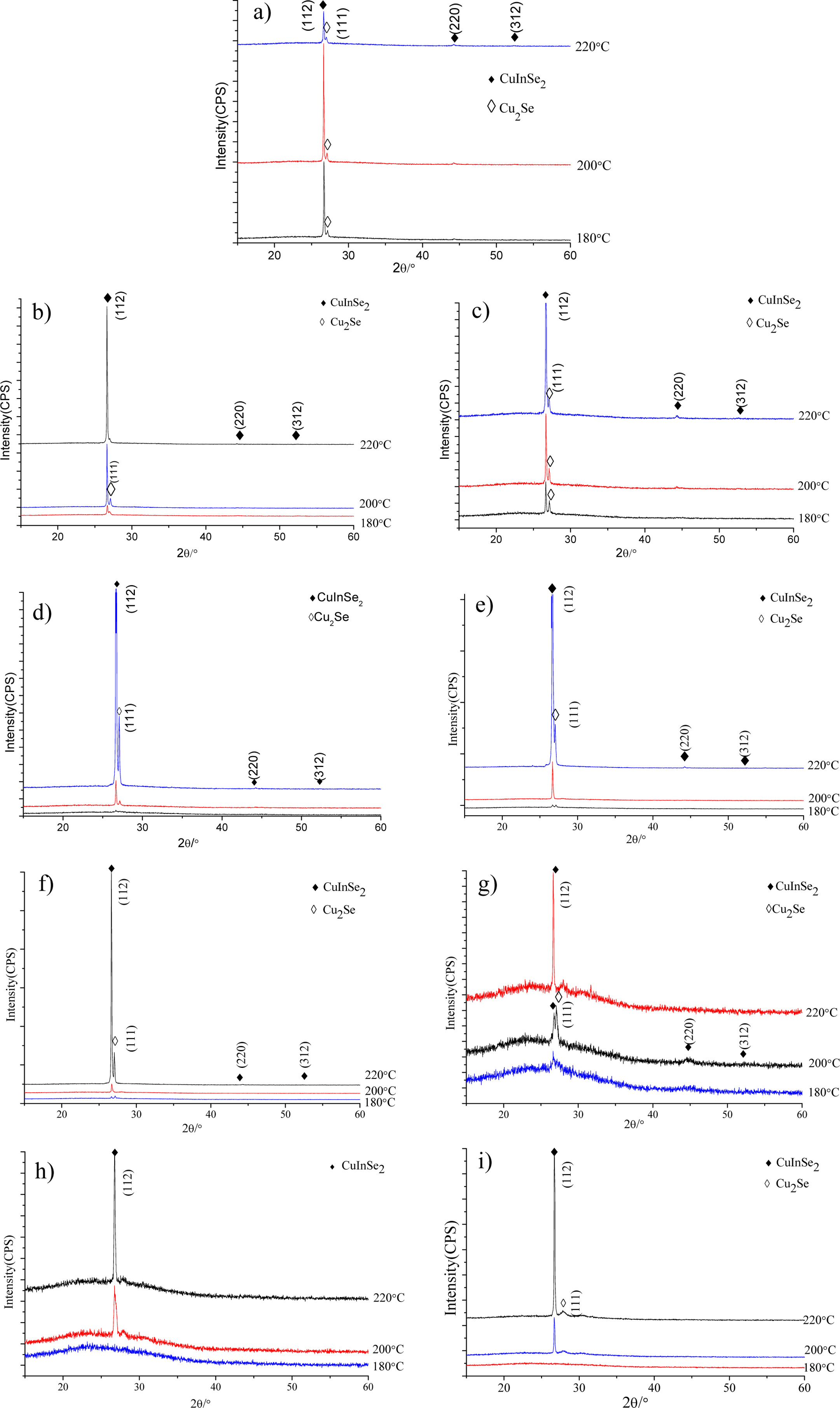

Phases of CuIn1-xGaxSe2

films prepared at different reaction temperatures

Fig. 2 shows the XRD patterns of CuIn1-xGaxSe2

samples reacted at different temperatures for 20 h, compared with

the standard PDF card with No.89-5649, the XRD peaks of 2θ

angles of 26.67°, 44.32° and 52.47° correspond to

(112), (220) and (312) crystal planes respectively. It can be seen

from Fig. 2(a) that CuIn0.9Ga0.1Se2 film samples

are all with better crystallinity obtained at three

temperatures, but impurity phase Cu2Se also appears, among

which CuIn0.9Ga0.1Se2 sample prepared at

200 °C has best crystallinity. Fig. 2(b) indicates that CuIn0.8Ga0.2Se2

film samples have impurity phase Cu2Se while the

sample with best crystallinity was obtained at 220 °C. Fig. 2(c) and Fig.

2(d) show that the XRD peak intensity and sharpness of CuIn0.7Ga0.3Se2

and CuIn0.6Ga0.4Se2 samples prepared at

220 °C are significantly higher than others, but Fig. 2(d) shows a higher

XRD peak for impurity phase Cu2Se. Fig. 2(e) and Fig. 2(f) show that

the XRD peak intensities of CuIn0.5Ga0.5Se2

and CuIn0.4Ga0.6Se2 samples prepared at

220 °C are significantly higher than those obtained at 180 °C

and 200 °C while impurity phase Cu2Se appears

at 220 °C. Fig. 2(g) shows that the XRD intensity of the CuIn0.3Ga0.7Se2

sample prepared at 180 °C is very low and become greatly high for the

sample obtained at 220 °C. Fig. 2(h) shows that there are no obvious XRD

peaks for CuIn0.2Ga0.8Se2 sample prepared at

180 °C, which indicates that no target phase appears, when the reaction

temperatures were raised to 200 °C and 220 °C

respectively, the XRD peaks for target phase appeared, the film

sample prepared at 220 °C has higher XRD peak intensity and better

crystallinity. Fig.2i shows that CuIn0.1Ga0.9Se2

film sample obtained at 220 °C has higher XRD peak intensity and better

crystallinity.

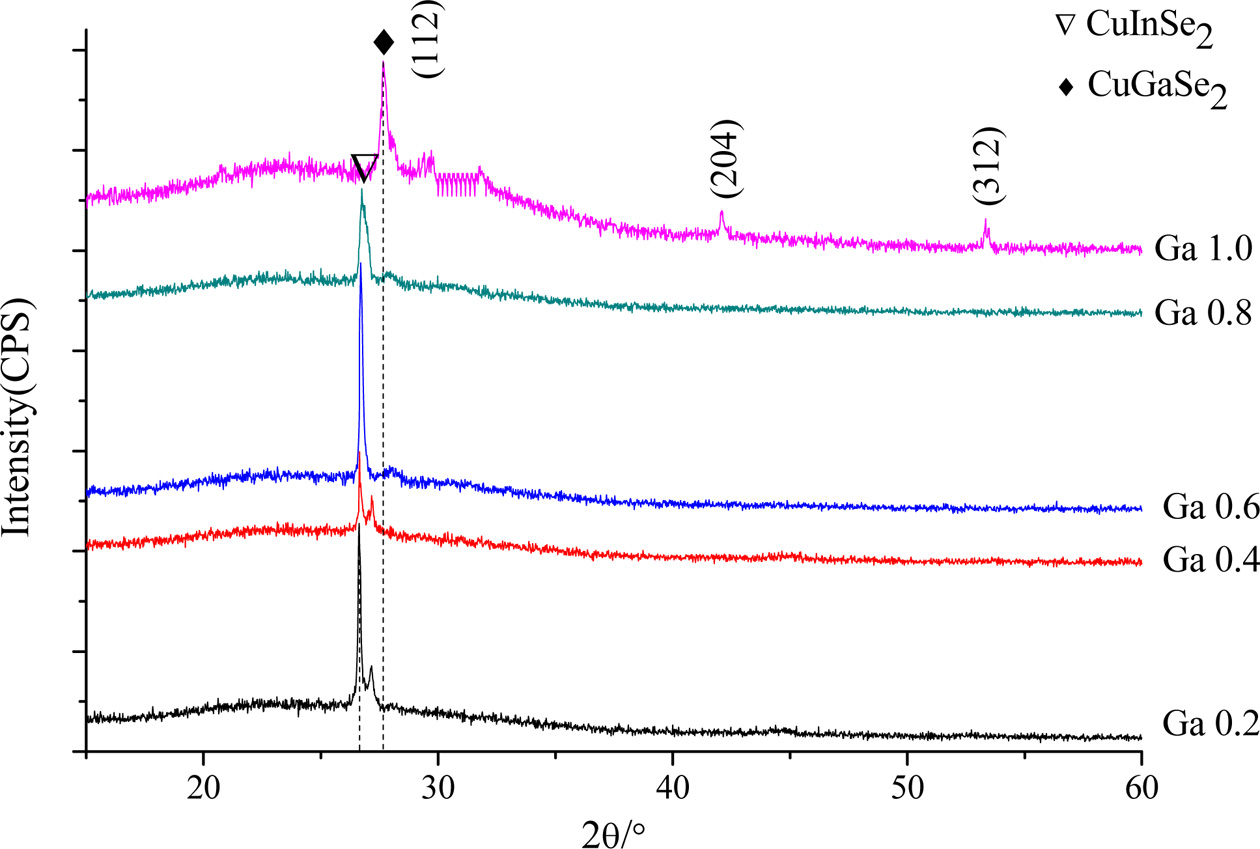

Comparison of XRD patterns of CuIn1-xGaxSe2

prepared at 220 °C for 20 h

Fig. 3 shows the XRD patterns of CuIn1-xGaxSe2

with doping concentrations of 0.2, 0.4, 0.6 and 0.8 and 1.0 prepared at

220 °C for 20 h. It can be seen that, as the Ga doping concentration

increases, the characteristic XRD peaks of the samples gradually shift toward

the large diffraction angles. For example, as shown along the (112) crystal

plane, the 2θ angle of CuGaSe2 is about 0.57° larger than that of

CuIn0.8Ga0.2Se2.

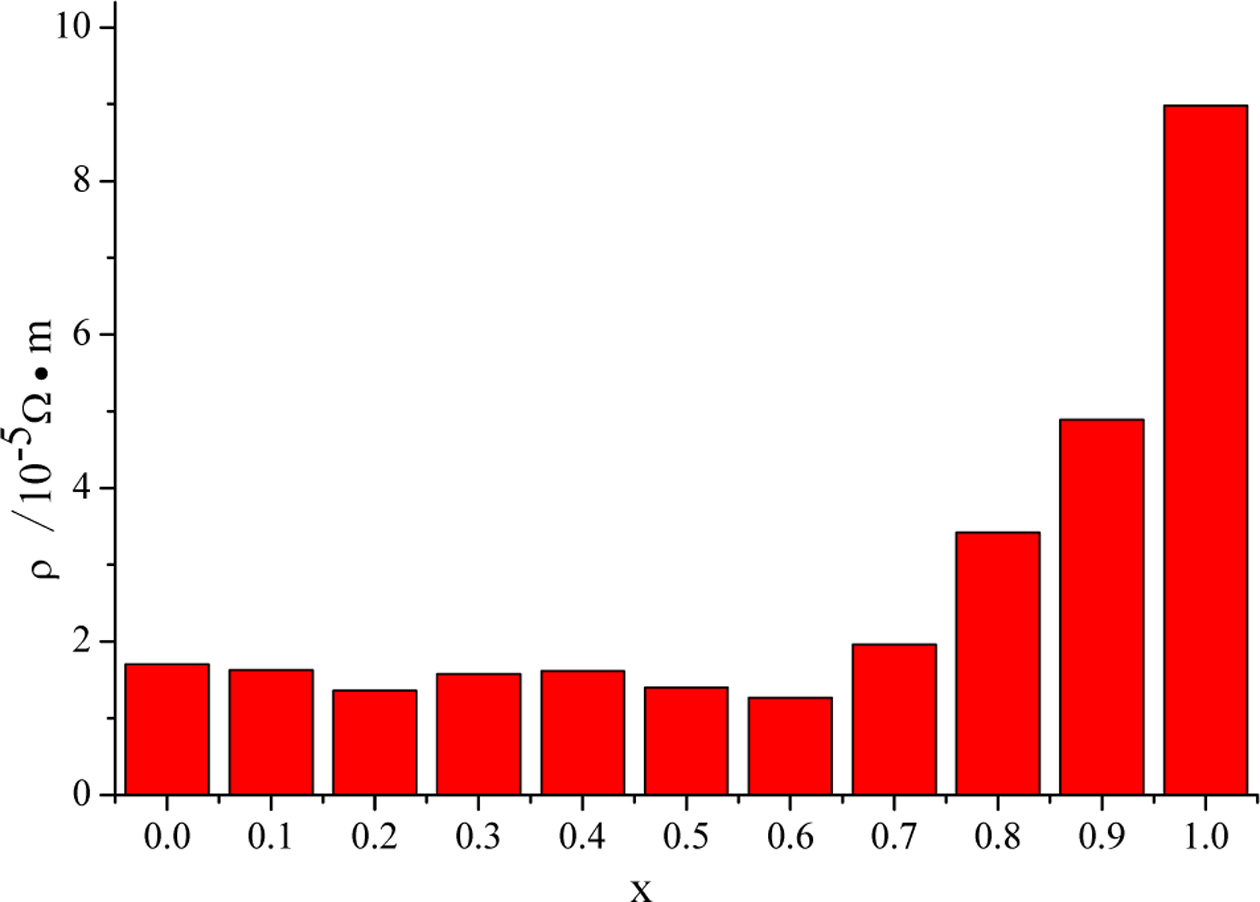

Analysis of electrical properties of CuIn1-xGaxSe2

films

The resistivities of CuIn1-xGaxSe2

films are shown in Fig. 4, and the influence of doping concentration on the

resistivity are not obvious. As the doping concentration increases,

the resistivity will increase slightly, and when x=1, the

resistivity changes greatly, it may be due to poor continuity of the film

sample.

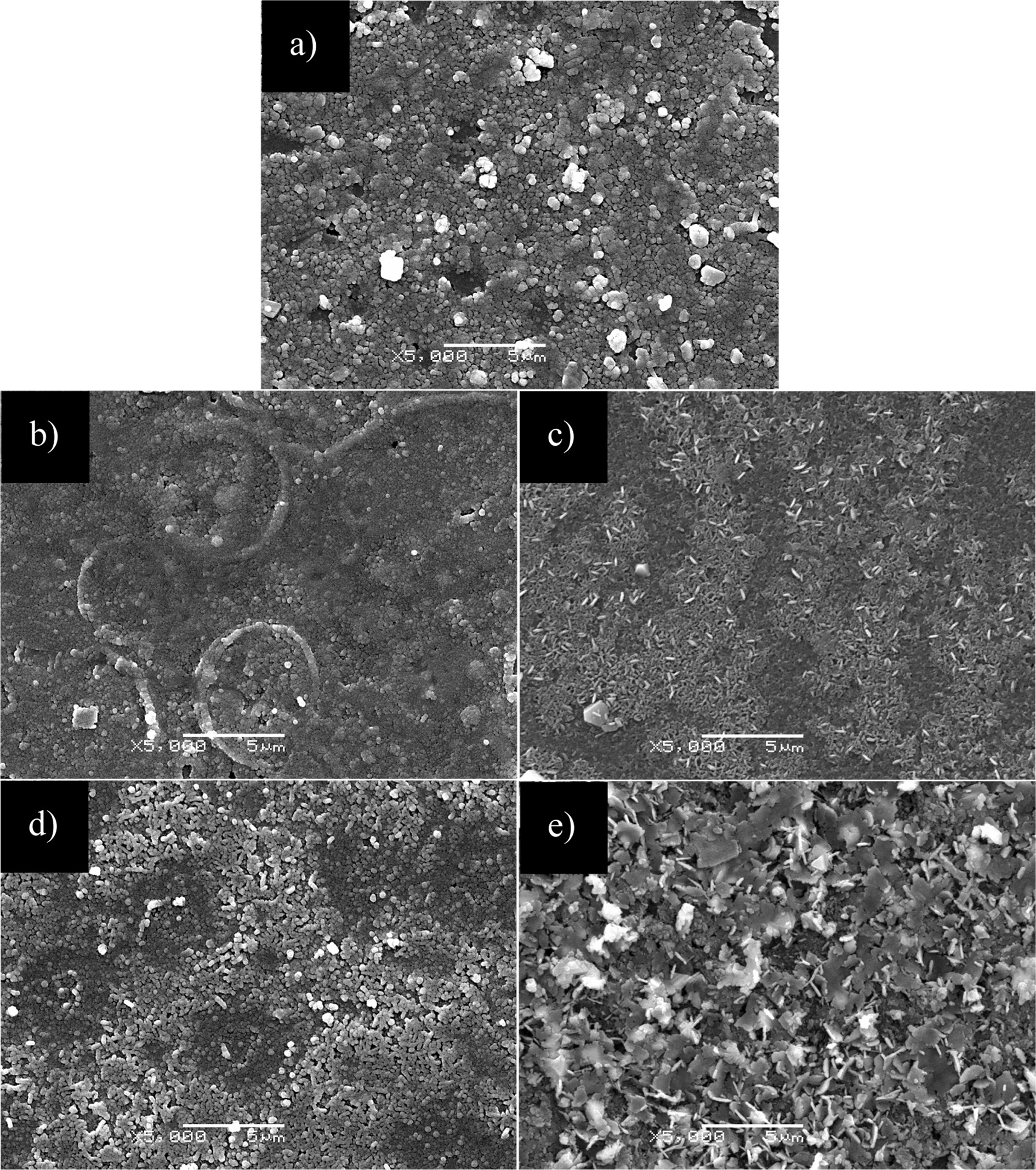

Morphology analysis of CuIn1-xGaxSe2

thin films

Fig. 5 shows the SEM images of CuIn0.8Ga0.2Se2,

CuIn0.6Ga0.4Se2, CuIn0.4Ga0.6Se2,

CuIn0.2Ga0.8Se2 and CuGaSe2 film

samples prepared at 220 °C for 20 h respectively. It can be seen that the

CuIn0.8Ga0.2Se2 and CuIn0.6Ga0.4Se2

films are dense and continuous and composed of spherical crystals with

diameters of about 0.2 to 0.3 μm, CuIn0.6Ga0.4Se2

film has a non-uniform particle size. The CuIn0.4Ga0.6Se2

film is composed of rod-like crystals with lengths of about 0.8 to 1.0 μm, and

its shape is similar to rod shape gathered together with crystal grains. The

CuIn0.2Ga0.8Se2 film consists of small rod-like

crystals with lengths of about 0.3 to 0.5 μm, and its length and size are

smaller than those of the CuIn0.4Ga0.6Se2

film. The CuGaSe2 film is composed of rod-like crystals with lengths

of about 0.8 to 1.0 μm and irregular sheet crystals.

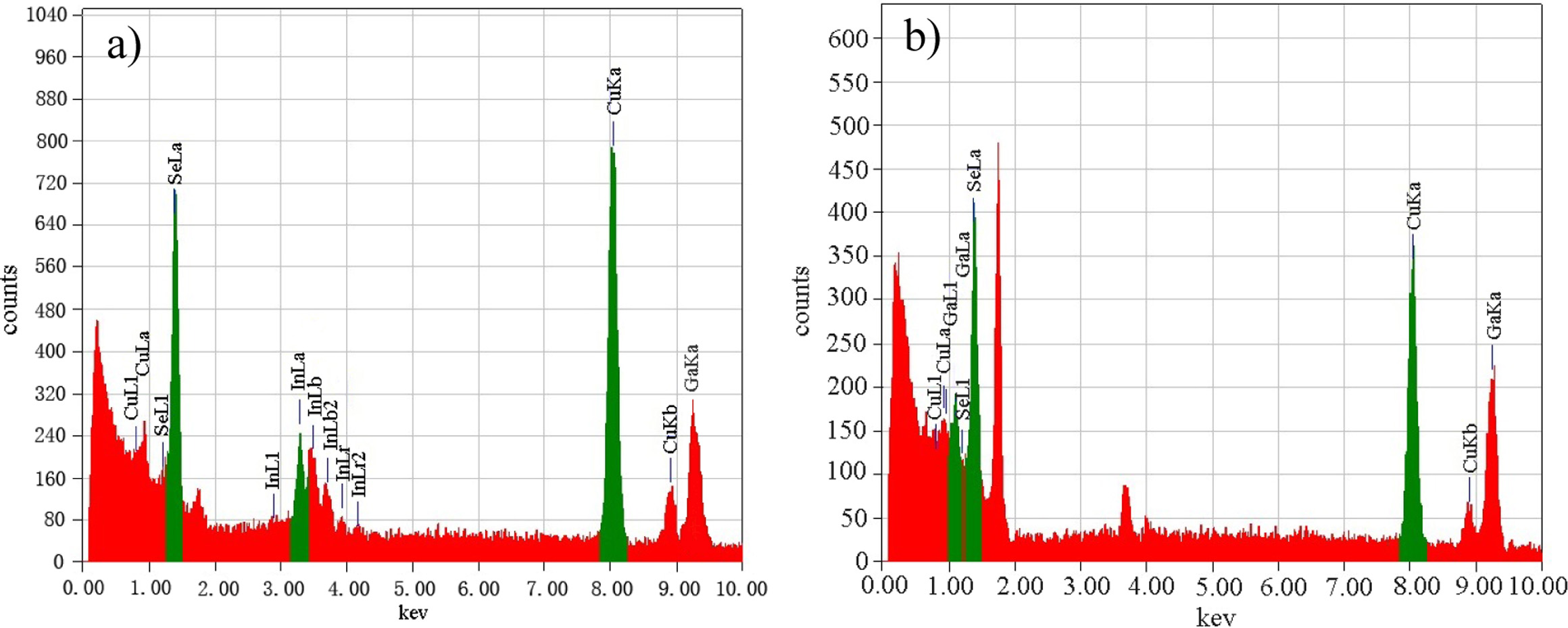

Composition

analysis of CuIn1-xGaxSe2 film by EDS

Fig. 6 shows the EDS spectrums of CuIn0.2Ga0.8Se2

film and CuGaSe2 film prepared by spin-coating and co-reduction

method. It can be seen from Fig. 6(a) that Cu, Se, In and Ga elements appear

from left to right, it confirmed

that the above four elements are contained in the product

film, although the element ratio is not necessarily stoichiometric. Fig. 6(b)

indicates that CuGaSe2 film sample consists of Cu, Se and Ga elements.

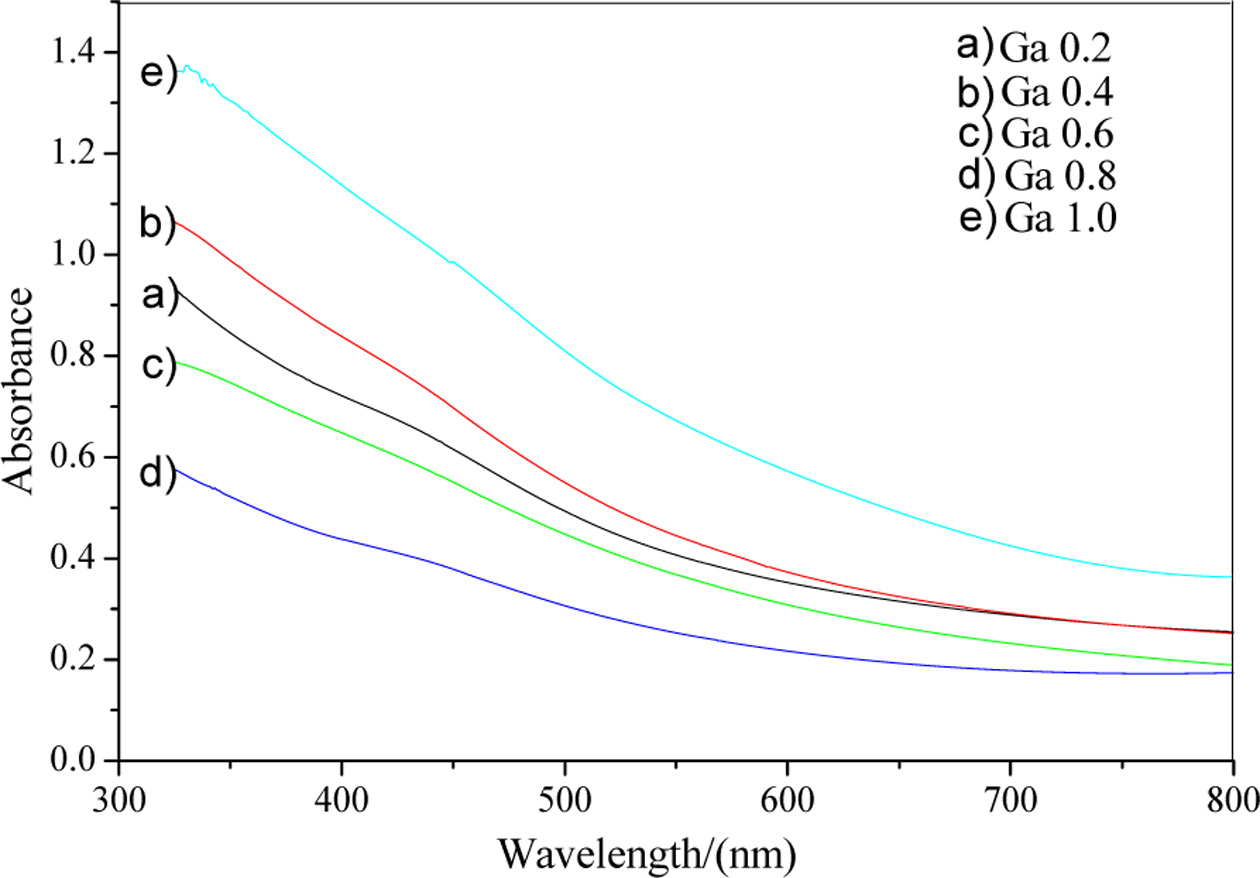

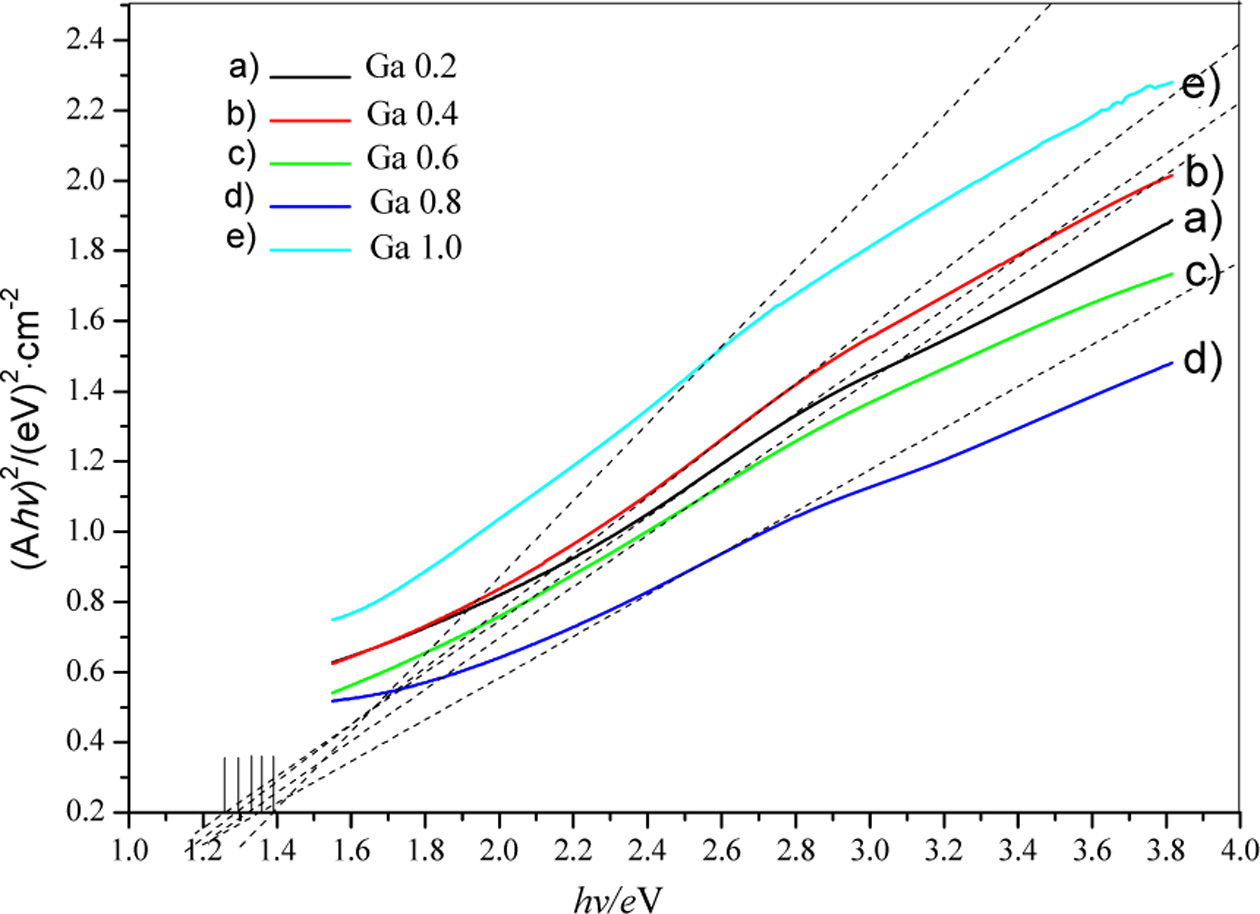

Estimation

of the band gaps of CuIn1-xGaxSe2 thin films

The absorption spectrums of the film samples were tested using

a UV-Vis method on a visible spectrophotometer. Fig. 7 shows

the absorbance of CuIn1-xGaxSe2 films with

different doping concentrations prepared at 220 °C for 20 h. The band gaps

of the film samples were then estimated by extrapolation as shown in Fig. 8. It

can be seen that the estimated band gaps of CuIn0.8Ga0.2Se2,

CuIn0.6Ga0.4Se2, CuIn0.4Ga0.6Se2,

CuIn0.2Ga0.8Se2 and CuGaSe2 films

are 1.25 eV, 1.3 eV, 1.33 eV, 1.38 eV and 1.4 eV, respectively.

|

Fig. 1 XRD patterns of CuIn1-xGaxSe2 prepared at 220 °C for different reaction time. (a) CuIn0.9Ga0.1Se2, (b) CuIn0.8Ga0.2Se2, (c) CuIn0.7Ga0.3Se2, (d) CuIn0.6Ga0.4Se2, e) CuIn0.5Ga0.5Se2, (f) CuIn0.4Ga0.6Se2, (j) CuIn0.3Ga0.7Se2, (h) CuIn0.2Ga0.8Se2, (i) CuIn0.1Ga0.9Se2, (j) CuGaSe2. |

|

Fig. 2 XRD patterns of CuIn1-xGaxSe2 reacted at different temperatures for 20 h. (a) CuIn0.9Ga0.1Se2, (b) CuIn0.8Ga0.2Se2, (c) CuIn0.7Ga0.3Se2, (d) CuIn0.6Ga0.4Se2, (e) CuIn0.5Ga0.5Se2, (f) CuIn0.4Ga0.6Se2, (j) CuIn0.3Ga0.7Se2, (h) CuIn0.2Ga0.8Se2, (i) CuIn0.1Ga0.9Se2. |

|

Fig. 3 XRD patterns of CuIn1-xGaxSe2 with different doping concentrations prepared at 220 °C for 20 h. |

|

Fig. 4 The resistivities of CuIn1-xGaxSe2 films with different doping concentrations prepared at 220 °C for 20 h. |

|

Fig. 5 SEM images of CuIn1-xGaxSe2 with different doping concentrations prepared at 220 °C for 20 h. (a) CuIn0.8Ga0.2Se2, (b) CuIn0.6Ga0.4Se2, (c) CuIn0.4Ga0.6Se2, (d) CuIn0.2Ga0.8Se2, (e) CuGaSe2. |

|

Fig. 6 EDS spectrums of CuIn0.2Ga0.8Se2 and CuIn0.2Ga0.8Se2 films reacted at 220 °C for 20 h. Target products: (a) CuIn0.2Ga0.8Se2, (b) CuGaSe2. |

|

Fig. 7 UV-Vis spectrums of CuIn1-xGaxSe2 with different doping concentrations at 220 °C for 20 h. |

|

Fig. 8 Estimation of band gaps of CuIn1-xGaxSe2 with different doping concentrations at 220 °C for 20 h. |

The CuIn1-xGaxSe2 films

were prepared by spin-coating and co-reduction method. It was

found by phase analysis that longer reaction time and higher reaction temperature

were beneficial to the sample crystallization, the

better experimental conditions for preparing CuIn1-xGaxSe2

films are at 220 °C for 20 h. With the increase of

doping concentration, the surface morphology of

CuIn1-xGaxSe2 films changed with a tendency

from spherical

crystals to rods. The effect of doping concentration

on the resistivity is not particularly obvious. As the doping concentration increases, the resistivity will increase slightly. When x=1, the resistivity

changes greatly, which may be due to

the poor continuity of the film. According to the absorbance of CuIn1-xGaxSe2

films, their estimated band gaps are 1.25 eV, 1.3 eV, 1.33 eV, 1.38 eV and 1.4

eV, respectively.

This work was financially

supported by the National Natural Science Foundation of China (No.51272140) and

the Innovation Team of the Co-Innovation Center for Green Building of Shandong

Province in Shandong Jianzhu University

- 1. R. Bouferra, G. Marín, S. Amhil, S. M. Wasim, and L. Essaleh, Physica B. 565 (2019) 14-17.

-

- 2. S.M. Chauhan, S.H. Chaki, M. P. Deshpande, J.P. Tailor, and A.J. Khimani, Mat. Sci. Semicon. Proc. 74 (2018) 329-335.

-

- 3. Y.J. Park, S.W. Kim, K. Sugimoto, T. Hasegawa, K. Tanima, K. Uematsu, K. Toda, and M. Sato, J. Ceram. Process. Res. 20[5] (2019) 460-463.

-

- 4. T. Kato, N. Kawaguchi, and T. Yanagida, J. Ceram. Process. Res. 20[5] (2019) 449-454.

-

- 5. H. Fukushima, D. Nakauchi, N. Kawaguchi, and T.Yanagida, J. Ceram. Process. Res. 20[3] (2019) 211-215.

-

- 6. T.T. Khan and S.C. Ur, J. Ceram. Process. Res. 19[4] (2018) 327-331.

- 7. A. Aissata and M. Fathib, J.P. Vilcotc, Energy Procedia 18 (2012) 197-204.

-

- 8. G. Yin and P. Manley, M. Schmid, Sol. Energy 163 (2018) 443-452.

-

- 9. Y.-S. Cheng, N.-F. Wang, Y.-Z. Tsai, J.-J. Lin, and M.-P. Houng, Appl. Surf. Sci. 396 (2017) 631-636.

-

- 10. C.-S. Chiou and H.-C. Peng, Sol. Energy 146 (2017) 436-442.

-

- 11. B. Noikaew and S. Chatraphorn, Surf. Coat. Tech. 307 (2016) 547-553.

-

- 12. Y.-F. Wu, H.-P. Hsu, and H.-I. Chen, J. Lumin. 142 (2013) 81-85.

-

- 13. M. Behr, M. Sharma, S. Sprague, N. Shinkel, J. Kerbleski, C. Alvey, S. Rozeveld, T. Hasan, C. Wintland, M. Mushrush, and A. Wall, Thin Solid Films 665 (2018) 36-45.

-

- 14. S. Mandati, B.V.Sarada, S.R. Dey, and S.V. Joshi, Mater. Lett. 118 (2014) 158-160.

-

- 15. H.T. Xue, F.L. Tang, F.Z. Zhang, W.J. Lu, and Y.D. Feng, Mater. Lett. 164 (2016) 169-171.

-

- 16. S. Sunkoju, S. Schujman, D. Dixit, A. Diebold, J. Li, R. Collins, and P. Haldar, Thin Solid Films 606 (2016) 113-119.

-

- 17. A. Khanaki, H. Abdizadeh, and M.R. Golobostanfard, Mat. Sci. Semicon. Proc. 16 (2013) 1397-1404.

-

- 18. A.B. Marai, J.B. Belgacem, Z.B. Ayadi, K. Djessas, and S. Alaya, J. Alloy Compd. 658 (2016) 961-966.

-

- 19. R.-W. You, K.K. Lew, and Y.-P. Fu, Mater. Res. Bull. 96 (2017) 183-187.

-

- 20. K.G. Liu, Y. Xu, Q.L. Sun, H.P. Li, and H.Y. Wu, Results in Physics, 12 (2019) 766-770.

-

This Article

This Article

-

2020; 21(2): 226-232

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.226

- Received on Nov 23, 2019

- Revised on Jan 13, 2020

- Accepted on Jan 17, 2020

Services

Services

- Abstract

introduction

experimental

preparation and characterization of cuin1-xgaxse2films

summary

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jing Li, Kegao Liu

-

School of Materials Science and Engineering, Co-Innovation Center for Green Building of Shandong Province, Shandong Jianzhu University, Fengming Road, Jinan 250101, China

Tel : +86-15610183153 - E-mail: liukg163@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.