- Mechanism of stopping crack propagation in continuous fiber reinforced self-healing ceramic

Jang-Won Leea, Ki-woo Namb and Wataru Nakaoa,*

aFaculty of Engineering, Yokohama National University, 79-5, Tokiwadai, Hodogaya-ku, Yokohama 240-8501, Japan

bDepartment of Materials Science and Engineering, Pukyong National University, 45 Yongso-ro, Nam-gu, Busan 48547, Korea

The self-healing fiber-reinforced

composite (abbreviation: shFRC) was made by adding SiC, a self-healing

material, between an Al2O3 matrix and an Al2O3

continuous fiber. shFRC has the characteristic of healing the reduced strength

by self-healing. The purpose of this study was to evaluate the damage and

healing of new composite material, shFRC, and define new failure criteria. The

test method used in this study was a high temperature creep test. The interface

fracture behavior with time was investigated by analyzing the creep rate. The

creep test conditions were 137 MPa and 150 MPa at 1,000 oC, and

68.5 MPa, 100 MPa, and 137 MPa at 1,200 oC, respectively. As a

result, the crack propagation of 1,000 oC was stopped by

healing, and the creep rate was zero. The crack healing part was higher than

the strength before the crack formation. Due to the rapid hardening of the

interface and the decrease in strength of the fiber, delayed fracture behavior

was not observed at 1,200 oC. If the crack is stopped by

self-healing at a constant load, shFRC can use that load stress as the

allowable stress. However, when the reaction rate of the interface is markedly

rapid, crack propagation is difficult to control.

Keywords: Damage and healing behavior, self-healing, Fiber reinforced ceramics, Crack branching, Creep test, Crack suppression

Ceramics have higher heat resistance and specific strength

than metals. If the nickel alloy, used in the turbine blades of an aircraft jet

engine, is replaced with ceramic, fuel efficiency would be

dramatically increased by non-cooling and weight reduction.

Improved fuel economy has the advantage in that CO2 gas emissions

are reduced, and the acceleration of global warming can be alleviated. However,

their safety is significantly lower in actual operating environments

because ceramics are brittle. Thus, it is not suitable as a

component for an aircraft requiring high reliability. Continuous Fiber

Reinforced Ceramic Matrix Composites (abbreviation: CFCC), represented by

ceramic composite materials, is attracting attention as a countermeasure to

compensate for these problems [1-4]. CFCC has the property in that fiber

absorbs energy when a crack propagates and induces delayed fracture [5-6].

However, there is high risk of a sharp decline in strength after cracking. As a

solution to this problem, we propose a method of adding self-healing to CFCC.

The healing effects of fiber reinforced composites with

self-healing have already been reported in various fields.

Ultra-high-performance fiber reinforced concrete (UHPFRC) have been reported to

recover most of the compressive strength damaged by air and hydration reaction

[7], and hollow fiber-reinforced polymer com- posites have

been reported to recover most of the bending strength lowered by UV

reaction [8]. In addition, it has been reported that the

mechanical and lifetime models of self-healing ceramic matrix composites are

presented, and that the coupling of mechanical and physicochemical mechanisms

should be considered as a key element for predicting self-healing behavior in

oxidizing environment [9]. However, no experimental cases of

self-healing fiber-reinforced composite ceramics have been

reported.

The interface control of CFCC plays a key role because the

bond strength between the fiber and matrix has a major influence on the

fracture strength and behavior [10, 11]. CFCC composite material in which

self-healing material is added to the interface layer facilitates

interface control by oxidation as well as heals the

cracks, thereby restoring the strength weakened after the cracking

to better than the strength before cracking. This new composite material is

called self-healing Fiber Reinforced Ceramics (shFRC). Since shFRC is designed

with the weakest part interface layer, cracks propagate along the interface

layer and healing is manifested by high temperatures after

crack propagation.

The purpose of this study was to secure the high

reliability required at the operating environment by evaluating the fracture

and healing behavior and to establish a new fracture standard for shFRC when damage

and recovery occur simultaneously at high tem-

peratures. High temperature creep tests were performed to

simultaneously produce damage (load) and healing (high temperature).

Spinel-structured γ-phase alumina fibers with high heat resistance, high

chemical stability, and low cost were used. And the α-phase alumina, which can

maintain high strength for a lengthy duration at high

temperature and has excellent chemical stability, was

used as a matrix [12, 13]. SiC, known for its strength recovery by

high temperature oxidation, was used as the interface

layer between the matrix and fiber [14-17].

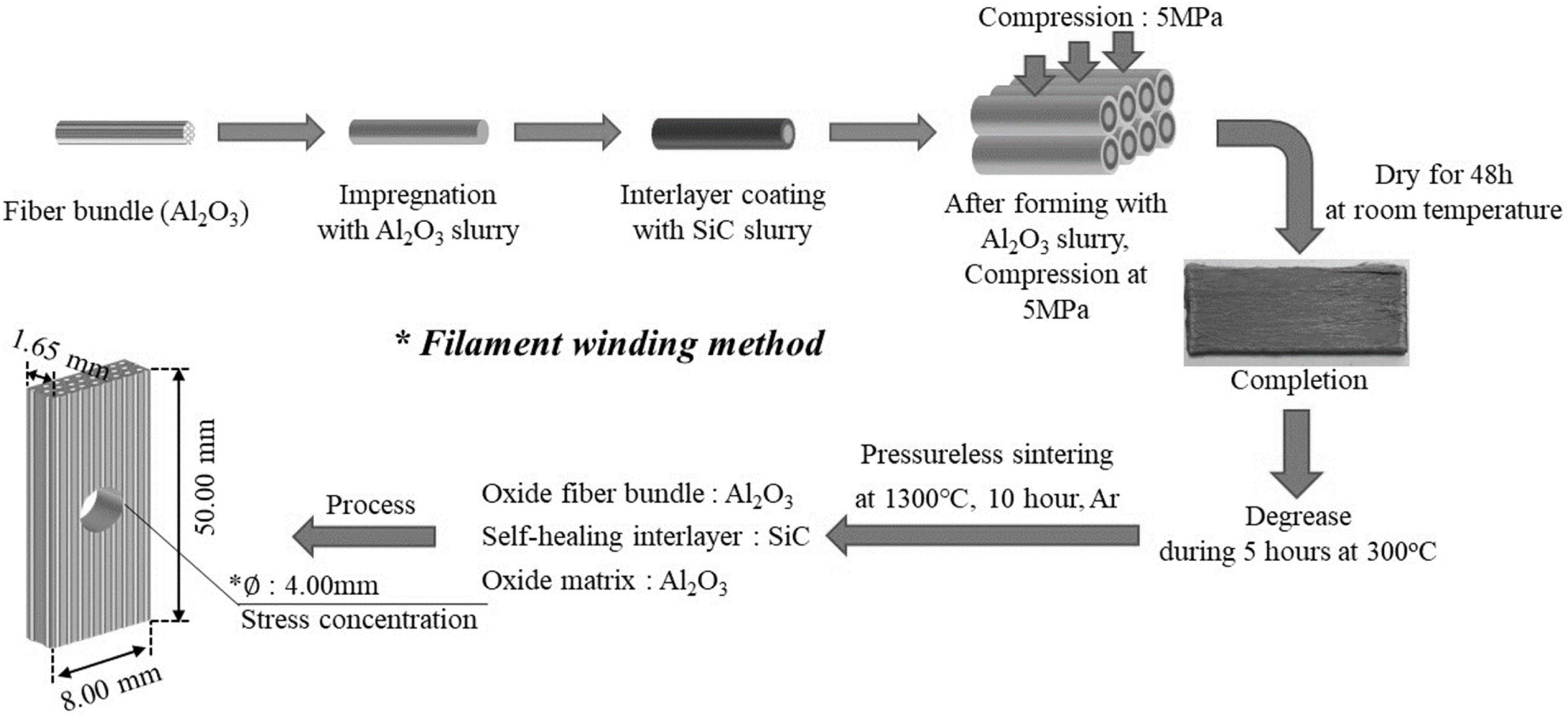

Specimen

The test specimen is an Al2O3f/SiC/Al2O3

composite containing non-oxide SiC in the interface layer of the fiber/matrix.

Continuous fibers (S-640D, γ-phase, Nitivy Co., Ltd.,

Tokyo, Japan) use bundles of twisted bundles of approximately 640 fibers with a

fiber diameter of 7 μm, and the composition is Al2O3 72%,

SiO2 28%. As the matrix (AKP-50, α-phase, Sumitomo Chemical Co.,

Ltd., Tokyo, Japan, Purity over 99.99%), an Al2O3 powder

having an average particle diameter of 0.23 μm is used. The powder used for the

interface layer is SiC (Ultrafine grade, β-phase, Ibiden Co., Ltd., Gifu,

Japan, Purity over 98%) having an average particle diameter of approximately

0.35 μm. The manufacture method used filament winding method to easily control

the thickness of the interface layer and the matrix. The slurry was mixed with

each powder (Al2O3, SiC) with distilled water, a

dispersant (Ammonium poly acrylate, A-30SL, TOAGOSEI CO., LTD., Japan) and a

binder (Acrylic emulsion, #7110, SEKISUI CHEMICAL CO., LTD., Japan) was added

and ball milled for 24 h to complete. Al2O3 continuous

fibers were impregnated into the Al2O3

slurry, and then coated by passing through the drying

furnace with 850 rpm at 90 °C, and the sample was obtained by repeating

the filament winding process three times under the same conditions. The

obtained sample was impregnated on the SiC slurry by the same

methods above with 650 rpm. Sample coated up to SiC was impregnated in Al2O3

slurry and forming on the 60 mm × 60 mm wide plates without drying. The formed

specimen was dried for 48 h at a pressure of 5 MPa. the obtained forming was

heated at 300 oC for five hours to remove dispersant and

binder, and then sintered at 1300 oC

for 10 h. Sintering atmosphere is Ar. The size of the processed specimen is

8.00 mm × 50.00 mm × 1.65 mm and the diameter of the center hole

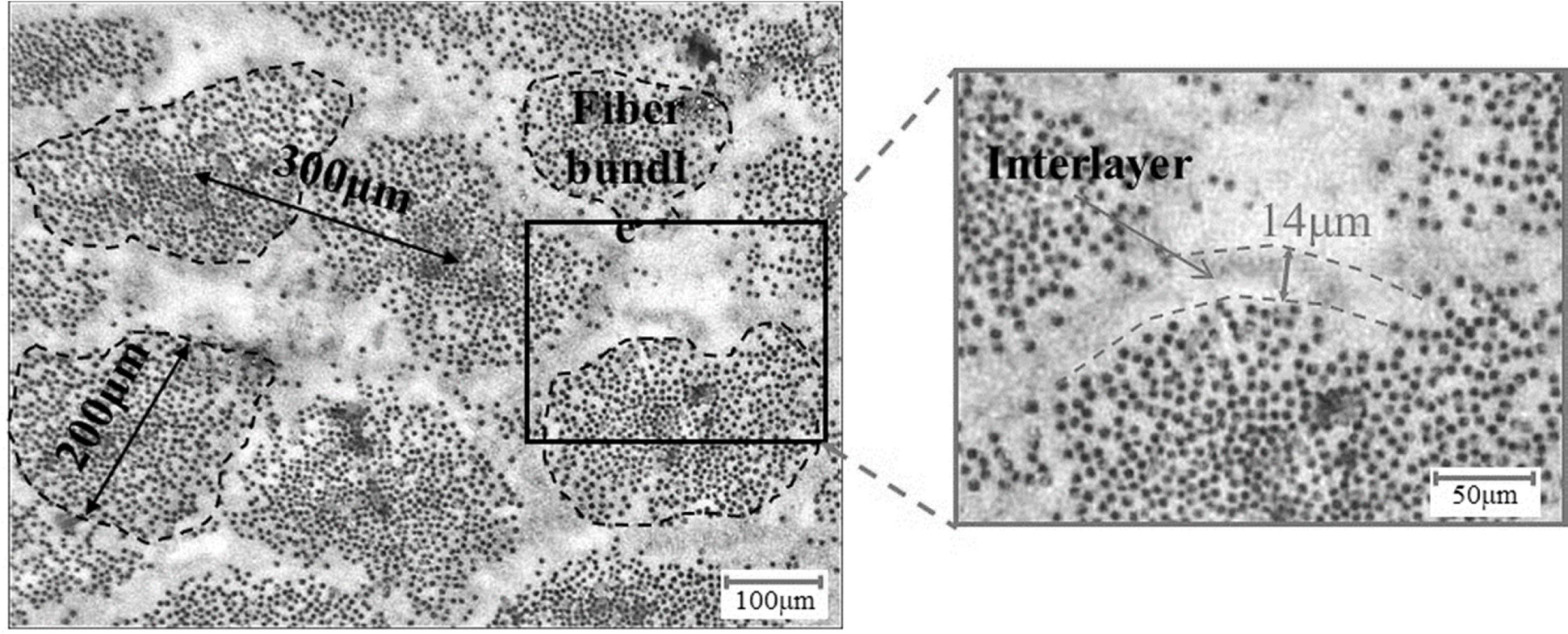

is 4 mm. The interface layer is designed to be the weakest part. The thickness

of the interface layer coated on the fiber is approximately 14 μm and the

spacing between the fiber bundles is about 300 μm. The average diameter of the

fiber bundles is 200 μm. And the average density of the specimen is 2.3 g/cm3.

The test specimen contains

approximately 60 Vol.% of fiber, 9

Vol.% of interfacial layer, and 31 Vol.% of parent metal. Also, fiber

orientation is one axis. Fig. 2 shows the internal structure of the completed

test specimen.

Experimental

set-up

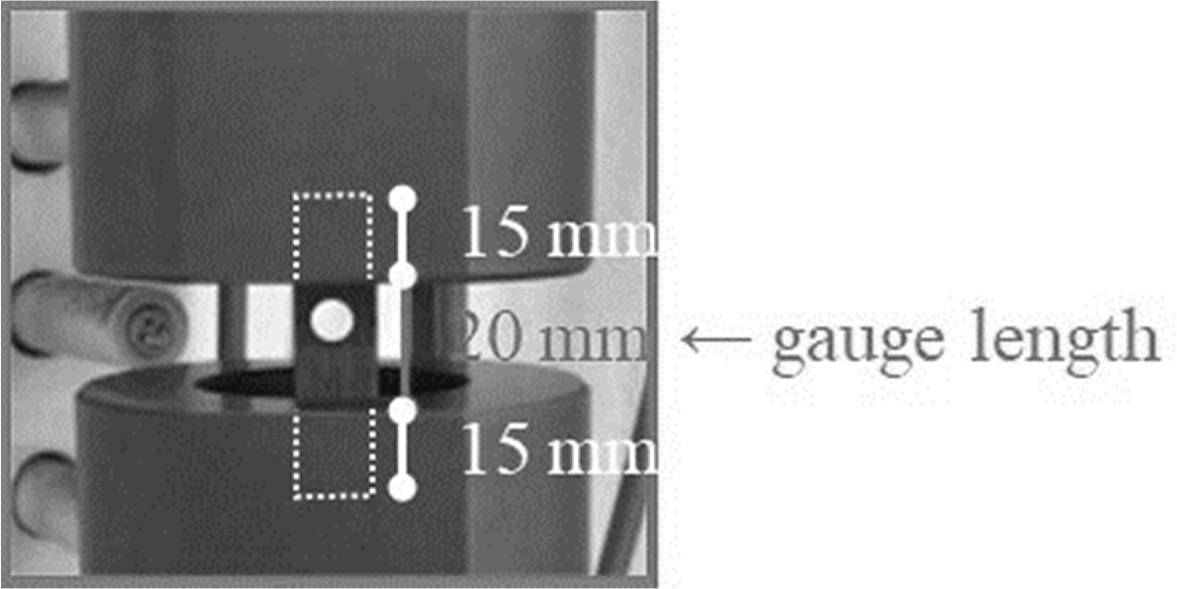

When the ratio 2ρ/2b of the diameter of the hole to the

width of the specimen is less than 0.5, the Howland method is regarded as

highly accurate [18]. Since 2ρ/2b is 0.5 in the specimen, the

stress concentration coefficient was

calculated using Equation (1) proposed by Howland.

Wherein ρ (mm) is the radius of the hole, b (mm) is half

the width of the specimen, and α is the stress concentration coefficient. The

test apparatus used a universal testing machine (EHF-FB5KN, SHIMADZU CO., LTD.,

Japan) which can control a crosshead and a load by the lower hydraulic pump.

The heating rate and the crosshead speed were set to 10oC/minute and

10 N/second with reference to JIS R1723:2015 standard, respectively.

The jig was manufactured using SiC having a

relatively low thermal expansion rate even at high temperatures. The gauge

length of the test specimen was 20 mm, and the strain was calculated to use the

gauge length. The maximum stress was calculated by equations (2) and (3)

considering stress concentrations.

Wherein A (mm2) is the cross-sectional area, P

(N) is the load, σ0 (MPa) is the load per unit area, and σmax

(MPa) is the maximum normal stress to which the stress concentration factor is

applied. The stress used in the test data was σmax (MPa), and the

cross-sectional area A was calculated by subtracting the diameter of the hole 4

mm since it was calculated in the region where stress concentration occurred.

Fig. 3 shows the mounting of the specimen.

High temperature tensile test to determine creep

stress conditions

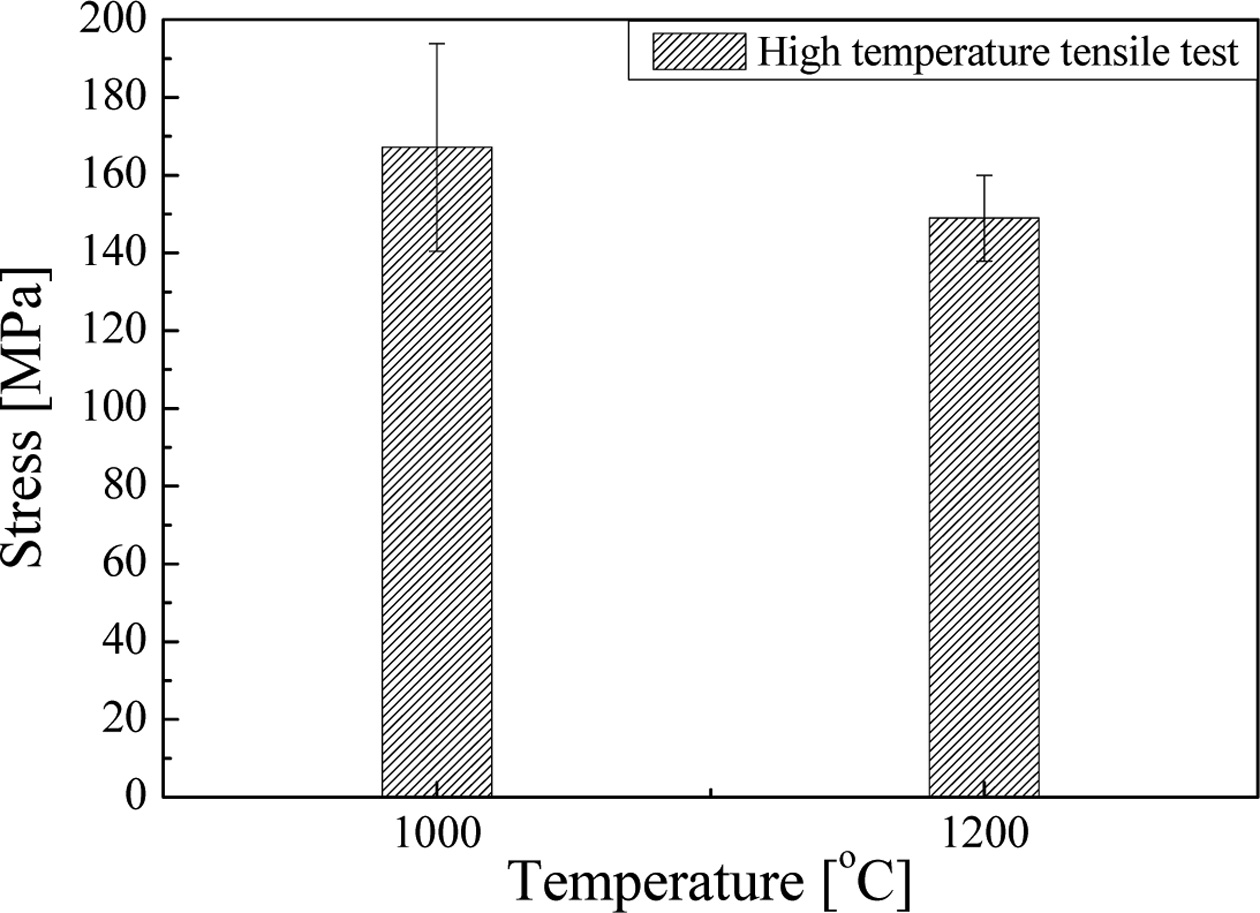

A high temperature tensile test was performed to determine

creep stress conditions. In the fiber reinforced composite

ceramics, the internal structure was not uniform due to internal defects and

voids during the compounding and sintering process. Thus, the average value

of tensile failure stress was calculated by performing the tensile

test three times [19, 20]. The temperature condition was set at 1,000 oC,

which is relatively slow, and 1,200 oC, which

is rapidly accelerating, considering the healing reaction rate of

SiC at atmospheric pressure in the air [21]. The heating rate and

the crosshead speed were 10 oC/minute and 0.5 mm/minute, respectively, referring to the standards of JIS R 1687: 2009.

The results of the high temperature tensile test are shown in Fig. 4. Tensile

fracture stress at 1,000 oC was 147.9 MPa, 197.6 MPa, and 156

MPa, respectively and the average fracture stress was 167 MPa. Tensile fracture

stress at 1,200 oC was 161.7 MPa, 143.2 MPa, and 142 MPa,

respectively and the average fracture stress was 148 MPa. The temperature

conditions of the high temperature creep test were determined by the average

tensile stress. Creep stress conditions are 150 MPa, and 137 MPa respectively

at 1,000 °C. and 137 MPa, 100 MPa, and 68.5 MPa, respectively at 1,200°C. Fig. 1

|

Fig. 1 The manufacturing process of specimen. |

|

Fig. 2 Completed actual structure of self-healing fiber reinforced ceramics (by digital microscope). |

|

Fig. 3 Mounting of the test specimen. |

|

Fig. 4 High tensile strength at 1,000 oC, and 1,200 oC, respectively. |

Effect

of competition between damage and recovery on crack branching behavior

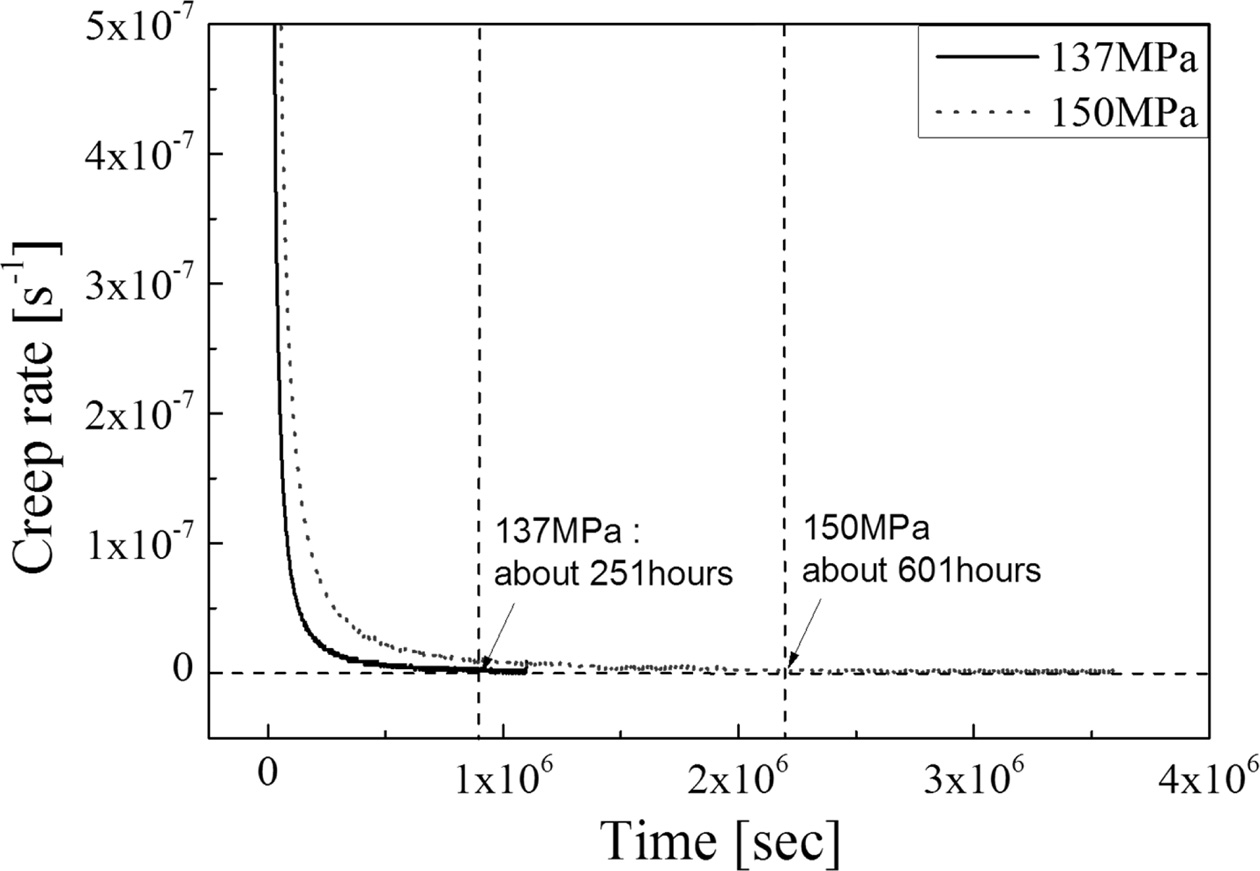

The creep test results at 1,000 oC are

shown in Fig. 5. Both creep rates converged to zero at the conditions of 150

MPa and 137 MPa, respectively. The creep rate converged to zero was 601 h at

150 MPa and 251 h at 137 MPa, respectively. From the fact that the creep rate

converges to 0, it can be observed that the crack propagation is suppressed by

the self-healing effect even though it is continuously damaged by the external

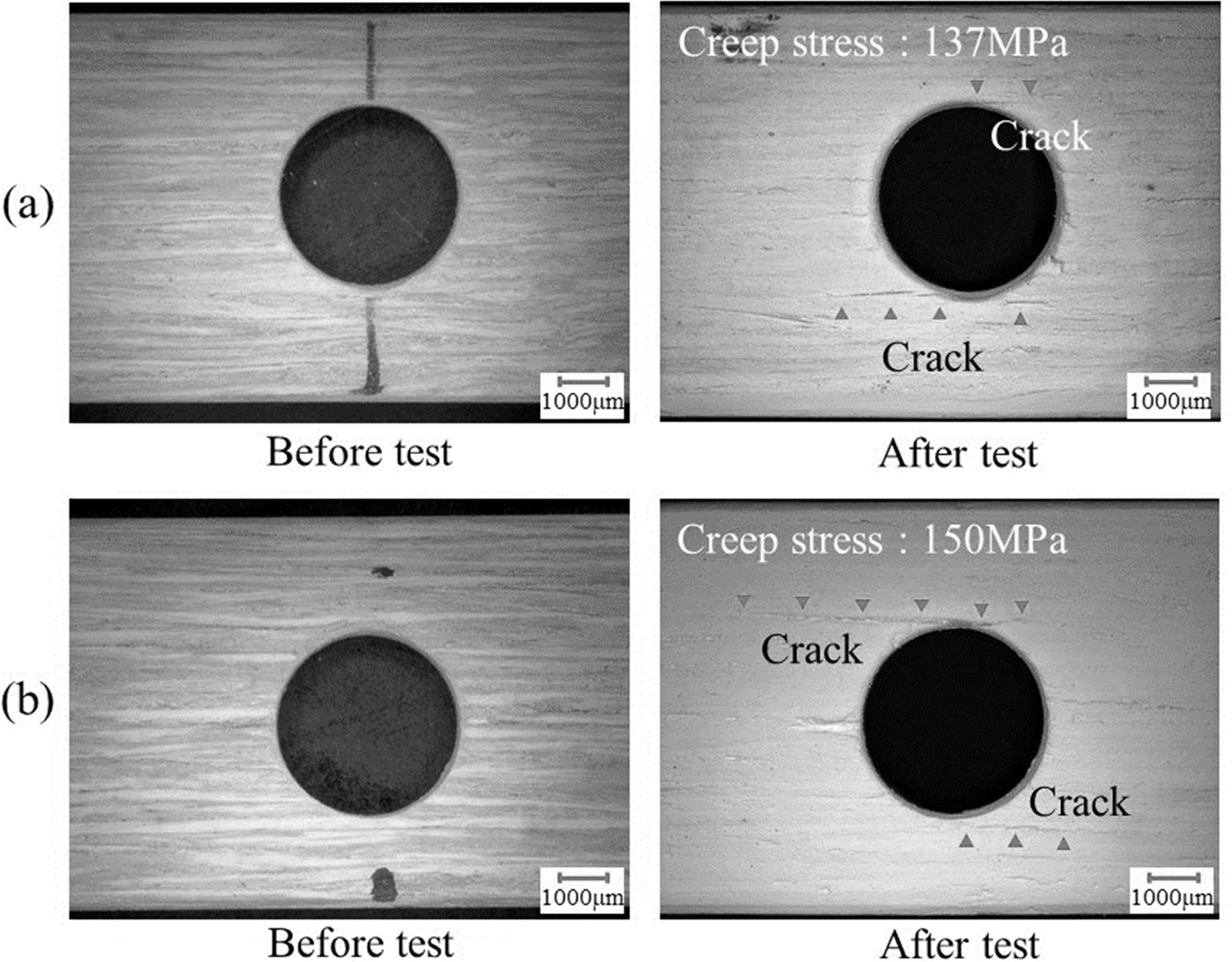

force. Fig. 6 shows the observation of the surface before and after each test

specimen. After the test of Fig. 6(a) and Fig. 6(b), the crack healed on the

surface of the specimen was observed. The crack healing length in Fig. 6(a) was

shorter than the crack healing length in Fig. 6(b). It can be observed that the

crack propagation length depends on the stress and the crack healing length

depends on the time when the creep rate converges to zero.

Strength

recovery effect by self-healing

Ozaki et al. set the standard for self-healing that the

strength of the healed part should be equal to or higher than the strength

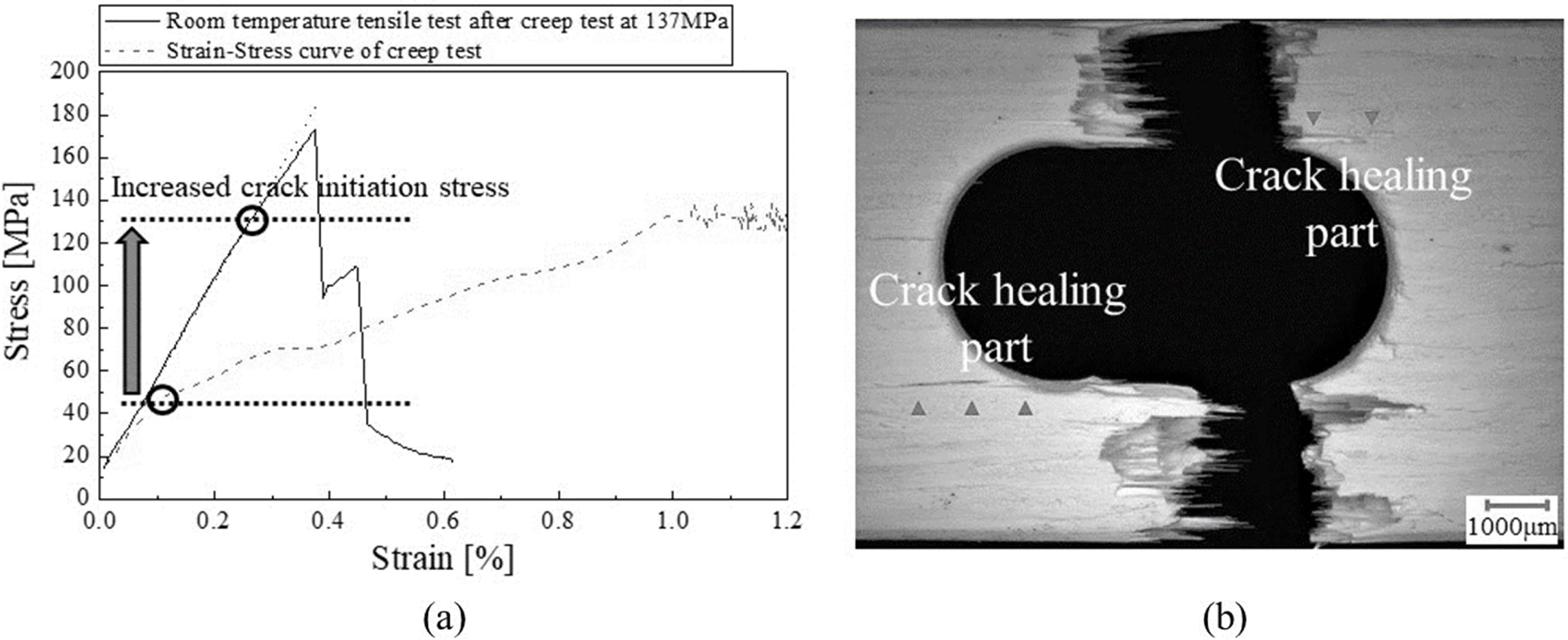

before the crack began [22]. Tensile tests were performed at room temperature

on the specimens conducted at a stress of 137 MPa, and the results are shown in

Fig. 7. Fig. 7(a) shows the stress rise section of the creep test and the

stress-strain curve at room temperature tensile test. The crack initiation

stress and strain increased. However, the slope after cracking was higher than

that before the test. It is considered that this is because the crack branching

at the weakest interface is made difficult by the self-healing

reaction of the interface layer. Fig. 7(b) shows a photograph

of the surface fractured by room temperature tension. The

specimen was last fractured but no more cracks propagated at the healed crack

part. This is because the interfacial layer designed with the weakest part

designed was cured by high temperature oxidation in the process of healing the

crack.

From the results in Fig. 7, it can be observed that the

ductility is lowered and the fracture toughness and crack

initiation stress are increased by interfacial curing. Additionally,

the reduced strength after the initiation of the crack is recovered by

self-healing, it was confirmed macroscopically that the

crack no longer occurs in the healing part even when the fracture stress is

loaded.

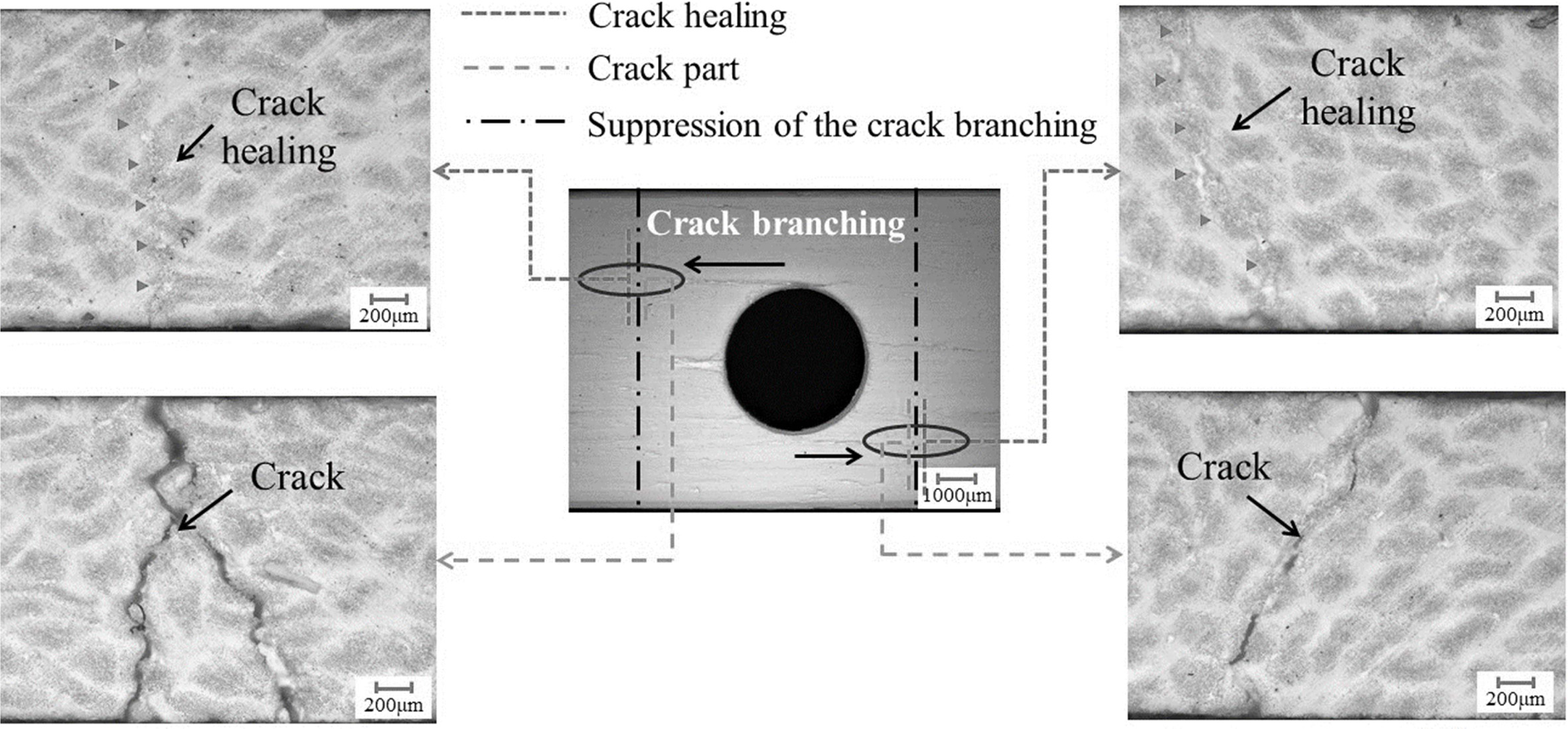

Fig. 8 shows an internal cross-sectional picture of

stopped crack part after the high temperature creep test at 150 MPa. The part

where the crack propagation stopped was confirmed macroscopically. It can be

observed that at 150 MPa, the crack did not propagate again for 400 h after 601

h when the crack propagation stopped. In other words, it is suggested that the

constant load stress at which the crack is stopped by self-healing can be

designed to the allowable stress.

Effect

of oxidation of interface layer on fracture behavior

Because of the hardening by oxidation of the interface

layer, cracks become markedly difficult to propagate to the interface layer and

most of the load is applied to the fibers. The creep tests were performed at

1,200 °C to investigate the influence of fracture behavior due to rapid

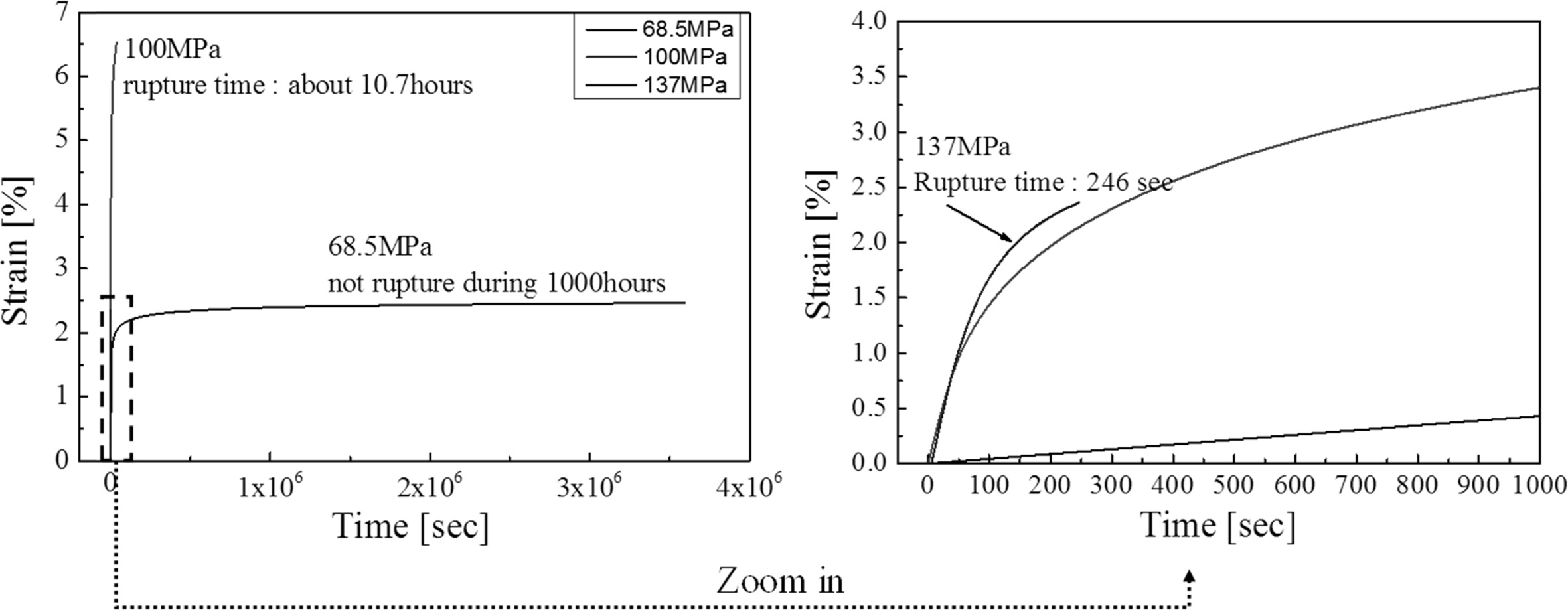

oxidation of the interfacial layer. Fig. 9 shows creep curves at 68.5 MPa, 100

MPa, and 137 MPa, respectively. The fractured time at 100 MPa was 10.7 h, and

the fractured time at 137 MPa was 246 seconds. In contrast, 68.5 MPa was not

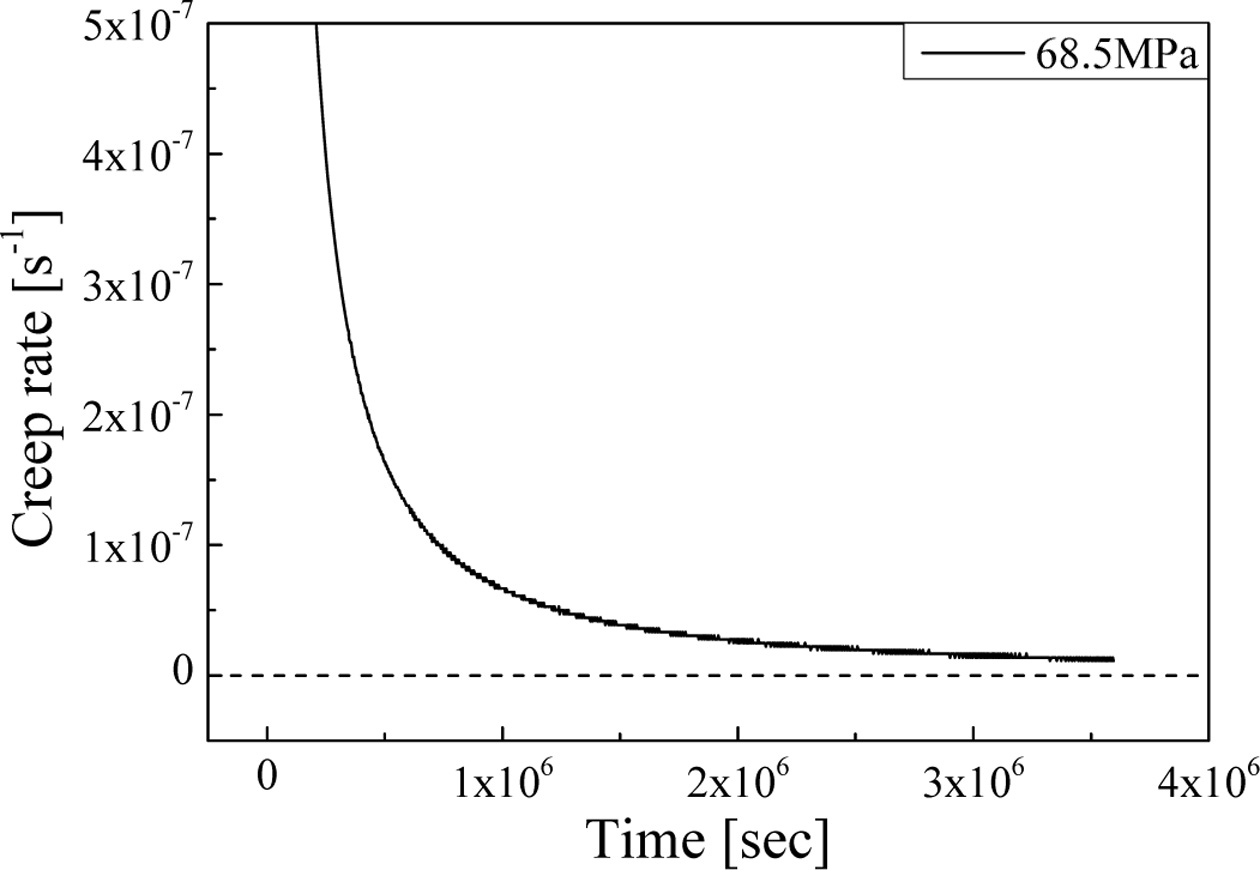

fractured for 1,000 h. Fig. 10 shows the time-creep rate curves for the creep tests conducted at 68.5 MPa. Fig. 10

shows the time-creep rate curves for the creep tests conducted at 68.5

MPa. Unlike the test results performed at 1,000 °C, the creep rate did not

converge to zero for 1,000 h. However, it was confirmed that the creep rate continuously slowed. This is because interface

hardening occurred by rapid oxidation before the crack propagated along the

interface layer by the hardened interface.

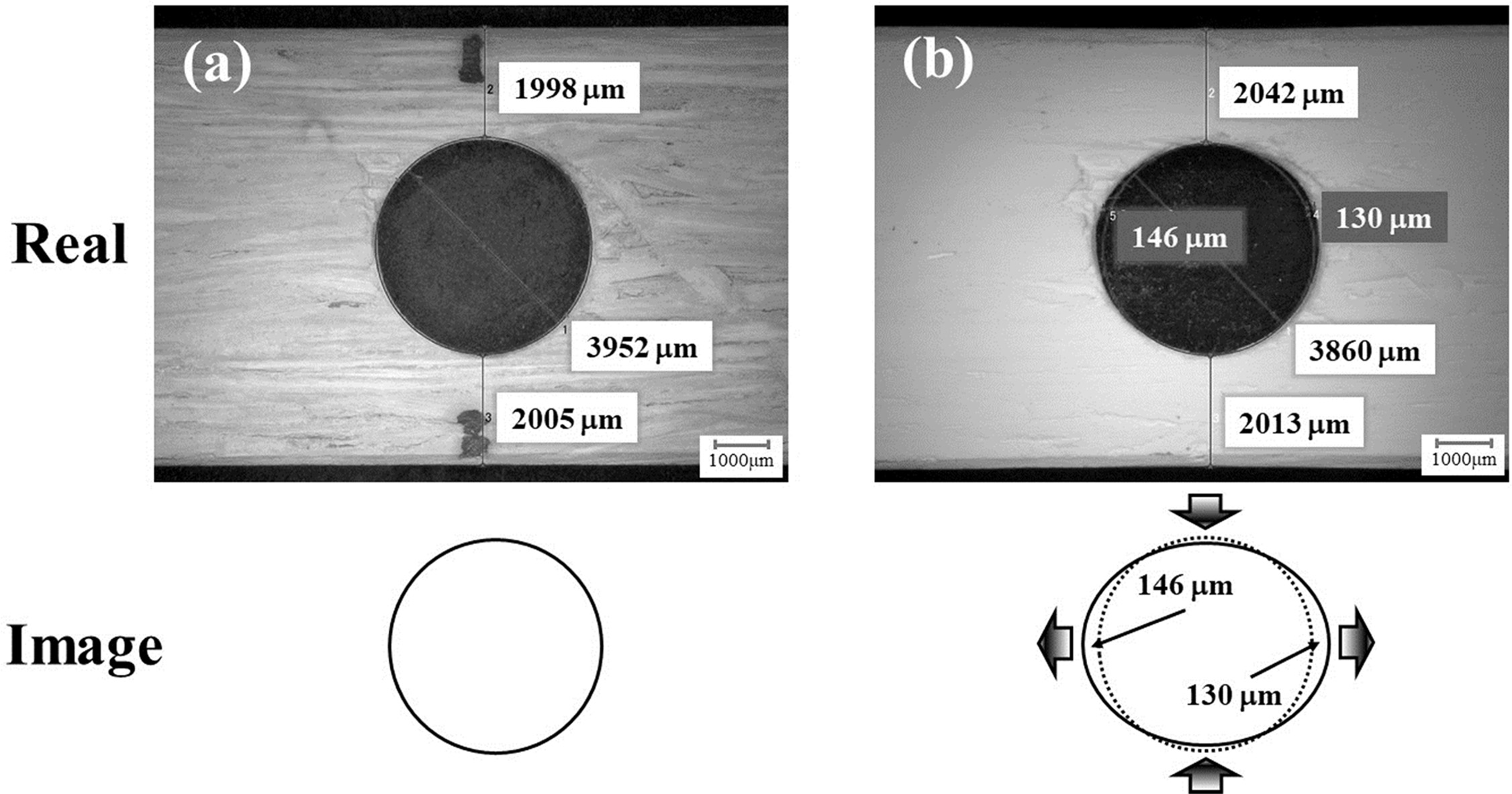

Fig. 11 shows the surface photographs of before the test

and after the test of the specimens performed at 1,000 h 68.5 MPa. No crack was

observed on the surface after the test, but it was confirmed that the hole was

extended by approximately 0.2 mm in the load direction. The matrix exhibits

Nabarro-Herring creep behavior in which atoms are diffused by prolonged

high-temperature exposure at relatively low stress, and reinforcing fibers (γ-phase)

are expected to drastically decrease in strength due to grain

growth as the amorphous phase is transferred to the α-phase

[23]. For this reason, it is thought that the fiber existing inside the test

piece first fractured due to the decrease in strength of the fiber.

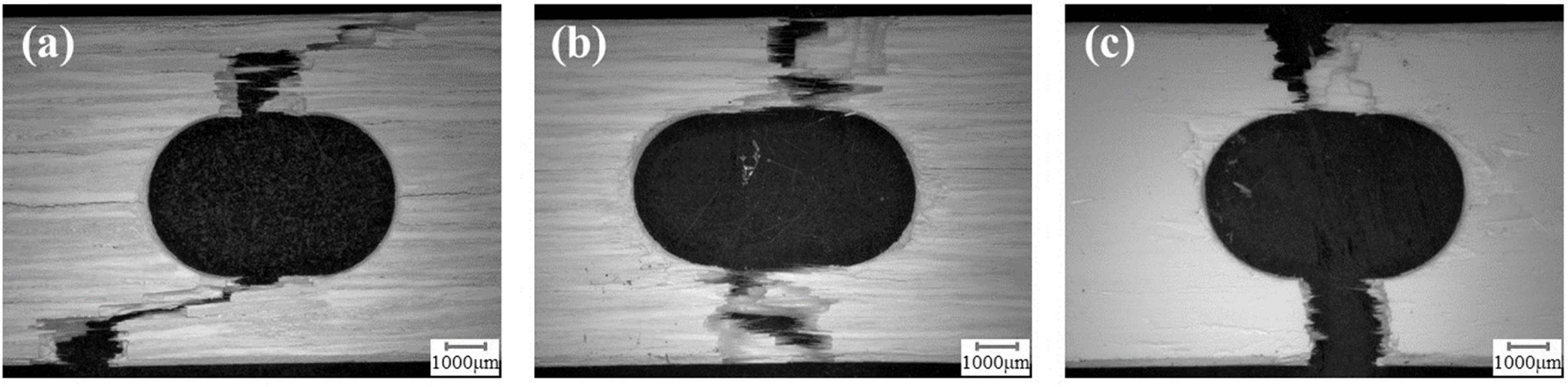

Fig. 12(a) and 12(b) show creep fracture surfaces of 137

MPa and 100 MPa, respectively. Fig. 12(c) shows the room temperature tensile

fracture surface of a specimen subjected to creep test at 68.5 MPa for 1,000 h.

It was confirmed that most of the interface layer was oxidized and the entire surface

was white. Oriented fibers are not observed due to the thick oxide layer on the

surface. This is because all of the SiC introduced into the interface layer was

oxidized to SiO2. And the pull-out length of the fiber is markedly

short, and almost no interface fracture occurs compared to Fig. 12(a) and Fig.

12(b). From the surface observation results, it has become clear that the

above-mentioned decrease in strength of the fibers and the diffusion

creep behavior of the base material appeared. Therefore, it is

difficult to expect the delayed fracture by the fiber at 1,200 oC.

|

Fig. 5 Creep rate curve of the shFRC at 1,000 °C. |

|

Fig. 6 Picture of specimen surface before and after the creep test (a) 137 MPa, (b) 150 MPa. |

|

Fig. 7 (a) Comparative analysis of crack initiation stress before and after the creep test at 137 MPa, (b) Tensile fracture behavior observation after creep test. |

|

Fig. 8 Internal cross section of test specimen for 1,000 h at 1,000 oC, 150 MPa. |

|

Fig. 9 Time-strain curve of the shFRC at 68.5 MPa, 100 MPa, and 137 MPa, respectively. |

|

Fig. 10 Time-creep rate curve at 68.5 MPa, 1,000 h. |

|

Fig. 11 Surface of the specimen of 68.5 MPa, 1,000 h condition (a) before the test (b) after the test. |

|

Fig. 12 Tensile fracture surface with stress condition (a) at 137 MPa, (b) at 100 MPa, (c) Tensile fracture surface of the specimen after the test at 68.5 MPa for 1,000 h. |

In this study, we evaluated the crack propagation behavior

when Al2O3/SiC/Al2O3f damage and

healing behavior occurred simultaneously. The results are as follow.

In the 1,000 oC creep test, the time when

the creep rate

converged to zero was 601 h at 150 MPa and 251 h at 137 MPa, respectively. The

higher the load stress, the longer the propagated crack length. Therefore, the

crack propagation length of Al2O3/SiC/Al2O3f

depends on the stress and the crack healing length depends on the time when the

creep rate converges to zero.

Since Al2O3/SiC/Al2O3f

makes it difficult to crack at the weakest interface layer by the self-healing

reaction of the interface layer at 1,000 oC, the

fracture toughness and the crack initiation stress increases.

At

1,000oC, when crack propagation is suppressed at a constant load and

completely stops, cracks no longer propagates. Thus, it is suggested that creep

stress higher than the crack initiation stress can be an allowable stress.

When the oxidation reaction rate of the interfacial layer

is markedly rapid and the load stress is low (1,200 oC, 68.5

MPa), the matrix shows diffusion creep behavior and the fiber shows a sharp

decrease in strength due to phase transformation. And the

interfacial layer makes it difficult for cracks propagation since all

SiC is oxidized to SiO2 before cracks are initiated. Thus,

the fiber is first fracture inside. In this reason, it is difficult

to expect a delayed fracture by fiber reinforcement.

At

1200 oC, stopping and suppression of crack pro-

pagation is no observed, but at 1,000 oC, a behavior is

confirmed in which damage and healing occur simulta- neously. Therefore, the suitable

operating temperature of Al2O3/SiC/Al2O3f

is 1,000oC.

This work has been supported

by the Advanced Low Carbon Technology Research and

Development Program (ALCA), JST, Japan

- 1. L. Li, Mater Sci Eng, A, 695 (2017) 221-229.

-

- 2. L. Li, Compos B Eng, 66 (2014) 466-474.

-

- 3. N. Bansal and J. Lamon, Eds., in ”Ceramic Matrix Composites: Materials, Modeling, Technology, and Applications” (Wiley, 2013) p.217-234.

-

- 4. I.M. Low, Eds., in “Ceramic Matrix Composites: Microstructure, Properties and Applications” (Woodhead Publishing Limited, 2006) p.339-341.

-

- 5. H.H. Moeller, W.G. Long, A.J. Caputo, and R.A. Lowden, Ceram. Eng. Sci. Proc. 8 (1987) 977-984.

-

- 6. T. Fett, D. Munz, R.D. Geraghty, and K.W. White, Eng. Fract Mech 66 (2000) 375.

-

- 7. S. Kim, D.-Y. Yoo, and M.-J. Kim, Nemkumar Banthia, Cem. Concr. Compos. 104 (2019) 103335.

-

- 8. J.W.C. Pang and I.P. Bond, Compos. Sci. Technol. 65 (2005) 1791-1799.

-

- 9. C. Cluzel, E. Baranger, P. Ladevezèze, and A. Mouret, Composites, Part A 40[8] (2009) 976-984.

-

- 10. J. Lamon, in “Ceramic Matrix Composites: Materials, Modeling and Technology” (Wiley, 2014) p.40-64.

-

- 11. R.W. Rice, in Proceedings of the 5th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings, Vol. 2, January 1981, edited by J.S. William (The American Ceramic Society, 1981) p. 661-701.

-

- 12. H. Li and H.X. Lu, S. Wang. Ceram. Int. 35 (2009) 901-904.

-

- 13. R. Bharthasaradhi and L.C Nehru. Phase Transitions. 89[1] (2016) 77-83.

-

- 14. K. Ando, T. Ikeda, S. Sato, F. Yao, and Y. Kobayasi, Fatigue Fract. Eng. Mater. Struct. 21 (1998) 119-122.

-

- 15. K. Ando, B.S. Kim, M.C. Chu, S. Saito, and K. Takahashi, Fatigue Fract. Eng. Mater. Struct. 27 (2004) 533-541.

-

- 16. W. Nakao, K. Takahashi, and K. Ando, Mater. Lett. 61 (2007) 2711-2713.

-

- 17. T. Osada, W. Nakao, K. Takahashi, and K. Ando, J. Am. Ceram. Soc. 92 (2009) 864-869.

-

- 18. R.C.J. Howland, Trans. Roy. Soc. 229 (1930) 48-86.

-

- 19. W. König, Ch Wulf, P. Graß, and H. Willerscheid, Manuf. Technol. 34 (1985) 537-548.

-

- 20. R. Komanduri, Mach. Sci. Technol. 1 (1997) 113-152.

-

- 21. T. Osada, W. Nakao, and K. Ando, J. Am. Ceram. Soc. 92 (2009) 864-869.

-

- 22. S. Ozaki, T. Osada, and W. Nakao, Int. J. Solids Struct. 100-101 (2016) 307-318.

-

- 23. A.R. Bunsell and M.-H. Berger, in “Fine Ceramic Fibers” (Marcel Dekker, Inc., 1999).

This Article

This Article

-

2020; 21(2): 200-207

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.200

- Received on Oct 10, 2019

- Revised on Jan 8, 2020

- Accepted on Jan 17, 2020

Services

Services

- Abstract

introduction

test methods

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Wataru Nakao

-

Faculty of Engineering, Yokohama National University, 79-5, Tokiwadai, Hodogaya-ku, Yokohama 240-8501, Japan

Tel : +81-45-339-4016 Fax: +81-45-339-4016 - E-mail: Nakao-wataru-hy@ynu.ac.jp

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.