- Carbon nanotube-biomorphic composites and filter application: A Review

Jung Gyu Parka, Se Young Kimb, In Sub Hanb and Ik Jin Kima,*

aInstitute for Processing and Application of Inorganic Materials, (PAIM), Department of Materials Science and Engineering, Hanseo University, 46, Hanseo 1-ro, Haemi-myun, Seosan-si, Chungnam, 31962, Korea

bKorea Institute of Energy Research (KIER), 152, Gajeong-gu, Daejeon, 34129, Korea

As interest in environmental

pollution has increased, research in the field of filtration has been

concentrated. While various types of filters have been developed, research on

nanomaterial filtration has been limited. Since then, the development of new

materials such as carbon nanotubes (CNTs) has accelerated the study of new

filters. Especially, CNTs have been among the most attractive materials ever

synthesized for the development of nano-technologies. However, there are fundamental

technical problems to be solved the development of new CNT composites. One of

these problems is the development of a CNTs filter with excellent adsorption

behavior and a filter that is capable of filtering a specific substance. In

addition, it is necessary to develop a technology to increase the uniform

distribution of CNTs, and to reduce the high processing cost of CNT composite

production. In general, the chemical pathways for the production of CNTs

include hydrocarbon gases, such as methane (CH4) and acetylene (C2H2),

through metal nanoparticle catalysts. However, nano-metal particles have a

strong coagulation phenomenon at high temperature by catalytic chemical vapor

deposition (CCVD) method. In this review, attempts were made by applying three

different reaction techniques to form CNTs on biomorphic carbon materials (BCM)

coated with catalyst materials to control the shape and size of CNTs.

Hierarchical carbon substrates with pore size of 100 ~ 300 μm were

developed using carbonization reaction. Linde type A (LTA) zeolite,

silicalite-1, and mesoporous SiO2 template crystals were

simultaneously synthesized and coated on the BCM by an in-situ

hydrothermal process to synthesize high-yield CNTs composites.

Keywords: Carbon nanotubes, Template, Biomorphic carbon materials, Catalytic chemical vapor deposition, Nanofilters

Recently, there has been increased interest in approaches

used for the production of various hierarchical and complex

microstructures with biodiversity-carbon materials with natural

biological substances, such as wood [1], rattan [2], or rice husk [3] used as a

template. Of these, natural trees have received considerable attention, as

their cell structure is so large that their tissue structure is converted into

a template material [4, 5]. Biomorphic materials with unique and elaborate

structures can be obtained by the pyrolysis of tree varieties such as Chamaecyparis

obtusa (Cypress, a.k.a. Hinoki), Pinus resinosa,

and Picea [6], resulting in carbonaceous forms. This form

produces a steel and ceramic mold complex that can penetrate and react with

coated oxides and non-oxides to be used in a wide range of applications, such

as filtration and catalysts for potentially powerful technical applications.

Because of the wide range of applications, it is very important to produce

sufficient quantities of well-defined and organized carbon nanotube

(CNT) arrays at low cost [7, 8].

Recent reports of CNT composites research of medical,

energy storage, and filtration applications [9-12] due to their morphological,

physical, and chemical properties have been published [13, 14]. The high

efficiency of CNT in filtration can be explained by observing the structure in

which high surface area and large aspect ratio lead to the formation of strong

Van der Waals forces between individual CNTs. This is because the microbial

cytotoxicity of CNTs partially affects the filtration performance, which has a

larger pore size that can fix contaminants, including bacteria and viruses, in

flocculation and interstitial pore spaces [15, 16]. The use of such

nanomaterials embedded in membranes or other structural media has been

considered an effective method for more approaches than just water treatment.

The dense CNTs network, which forms a variety of pore sizes from micropores to

medium pores supported on ceramic substrates, can be used to

physical adsorbents for removing contaminants [17], which make them

advantageous for filters in gas adsorption, and water filtration and

purification systems [18-20] Other applications include

hydrocarbon separation [21], and polluted air filters [22].

All these characteristics provide fundamentally different opportunities

for the development of new CNT-containing composites

however, several technical challenges were remained. One

of them is a CNT oil filter with excellent adsorption

behavior, and a suitable filter to convert it to a filter that is suitable for

a specific application. In addition, the producing of CNTs

composites has a number of technical problems that need to

be addressed. These include the potential damage to CNTs in the substrate; it

has been found to be an important and difficult challenge

to obtain a uniform and un-agglomerated distribution of CNTs in

the matrix, also is the high cost of processes associated

with CNTs and their composites.

The chemical pathway for CNTs production is the

decomposition of hydrocarbon gases through metal nanoparticle catalysis using

metals such as cobalt (Co), iron (Fe), nickel (Ni), and copper

(Cu). However, as the CNTs size decreases to nanoscale,

the metal particles agglomerate strongly during the synthesis of CNTs at high temperatures.

Thus, with respect to template-coated porous ceramics and nanostructured

biomorphic carbon materials (BCM), it is desirable to maintain the shape

and size of the CNTs at chemical vapor deposition (CVD)

treatment temperatures of 650 ~ 750 oC, as they are

required to homogeneously penetrate carbon sources like methane

(CH4) and acetylene (C2H2) [23-25].

Generally, matrices or catalyst supports such as alumina

[26], mesoporous silica [27], and zeolite [28], have been used to prevent the

agglomeration of the catalyst nanoparticles. Among them, zeolites are

considered an excellent template for the support or encapsulation of catalyst

nanoparticles, because of their well-defined pore

structure, and high surface area [29], thereby leading to a catalyst-particle

stabilization, the production of a fine dispersion of nanoparticles, and the

increase of the number of nucleation sites, which is advantageous for

high-yield CNTs synthesis [30, 31].

This review summarizes the formation of CNTs in a template

coated BCM using the catalytic chemical vapor deposition (CCVD) method. The

synthesis was carried out with the application of a three-step

processing route for CNTs composites. First, a BCM was produced

by a carbonizing reaction. Secondly, the templates were synthesized within and

coated simultaneously on the carbon template using the in-situ method

and wet process. The BCM was then subjected to a wetting process that resulted

in the formation of a metal-ion loaded template; and finally, the

CNTs were synthesized using the CCVD method.

In the mid-1980s, Kroto et al. (1996 Nobel Prize in

Chemistry) discovered a new closed carbon form that consisted of

hexagonal and pentagonal faces (buckminster-fullerene-C60). Most

notable is the discovery of one-dimensional (1D) CNTs and two-dimensional (2D) single atomic layer carbon, graphene (Nobel Prize

2010) [32]. An important feature of

this carbon material has attracted a large number of researchers to explore its

unique properties for various engineering topics, and to develop new

applications. CNTs was first discovered by Dr. Sumio Iijima as a needle-shaped

tube composed of “coaxial tubes of graphite sheets” and has been cited more

than 10,000 times in almost all articles on CNTs to date [33].

Types

of carbon nanotubes

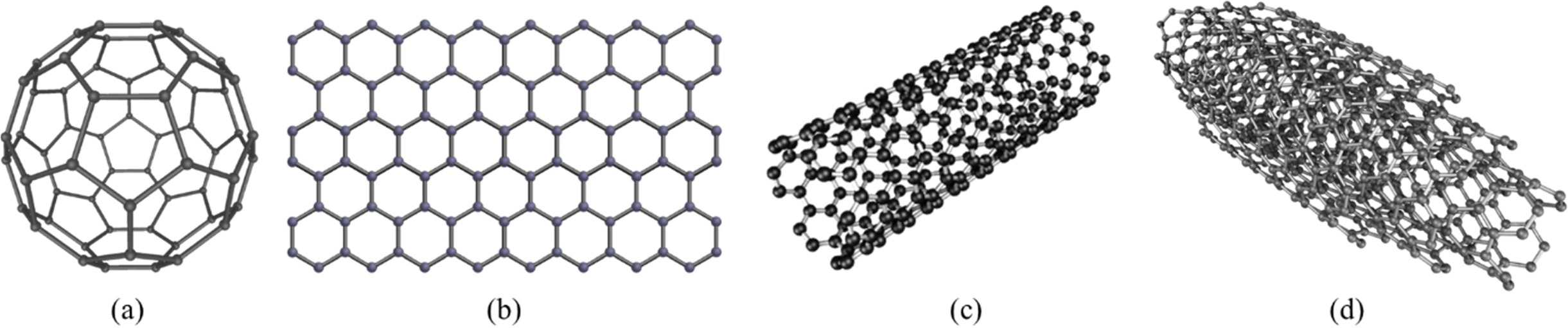

The ability to combine in different ways is a unique

feature of carbon that creates multiple homogeneous forms. If the four atoms of

the carbon atom are equally shared (sp3 hybridization), a diamond

will form Fig. 1. Graphite can be changed from diamond to diamond, and from

fullerene to CNTs and graphene. When three electrons are shared in one plane

and the fourth electron is localized (sp2 hybridization) between all

the atoms, graphite is formed [34, 35]. This type of bond shows a very strong

bond; but in graphite, the graphene layer is weak, with van der Waals bond.

Carbon, also called fullerene, is another overlapping graphene sheet of sp2-bonded

carbon atoms Fig. 1(b). These nanotubes are

concentric graphitic cylinders capped at either end by a half fullerene, owing

to the presence of five membered rings. Depending on the number of

carbon sheets, these nanotubes can be classified into two types: single-walled

CNTs (SWCNTs) and multi-walled CNTs (MWCNTs) with double-walled CNTs (MWCNTs),

as shown in Figs. 1(c) and (d).

SWCNTs have a small diameter of 0.4 ~ 4 nm and

exhibit a certain property that can be metallic or semi-conducting,

depending on their chirality [36]. On average, without

chirality control, one-third of metallic and two-thirds of semi-conducting

SWCNTs can be obtained. A SWCNTs is considered perfectly crystalline, that is

defect-free, if the grapheme sheet has no variations in the

hexagonal aromatic structure of the carbon atoms [37].

MWCNTs can be visualized as concentric SWCNTs, which have

several walls ranging from two to less than a hundred,

leading to the diameter of a MWCNT ranging from 1 nm,

and rarely reaching over 100 nm. In MWCNTs, the general innertube distance is

0.34 nm, which is the same distance as that between two parallel graphene

sheets in the graphite. Given the ratio of metallic to semi-conducting is 1/3

to 2/3 for SWCNTs, it can be expected that MWCNTs are metallic, in that at

least one of the walls will be metallic. Some teams have been

able to grow monochiral MWCNTs, indicating that all

walls have the same chirality [38, 39]. Ideally, crystalline SWCNTs and MWCNTs

have walls and caps without any defects, i.e. missing or added atoms, which are

extremely difficult to attain with our current synthesis techniques, and to

properly characterize. To date, some teams have grown individual or strands of

CNTs with a length of a few centimeters [40].

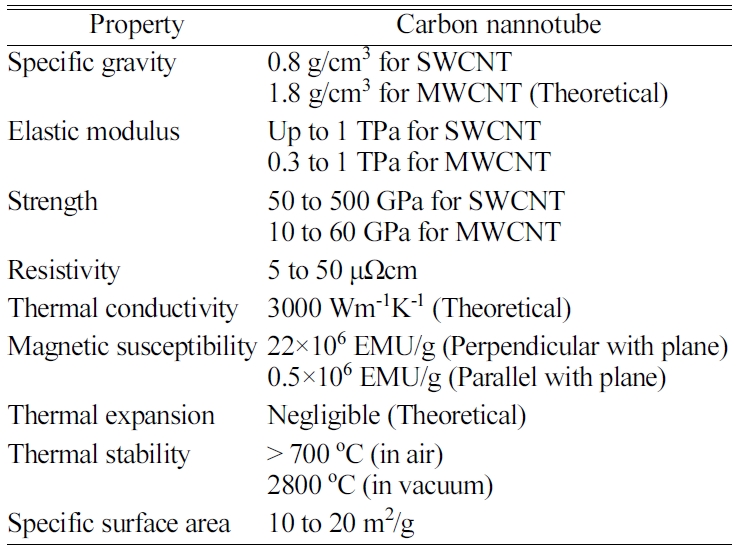

Properties

and application of CNTs

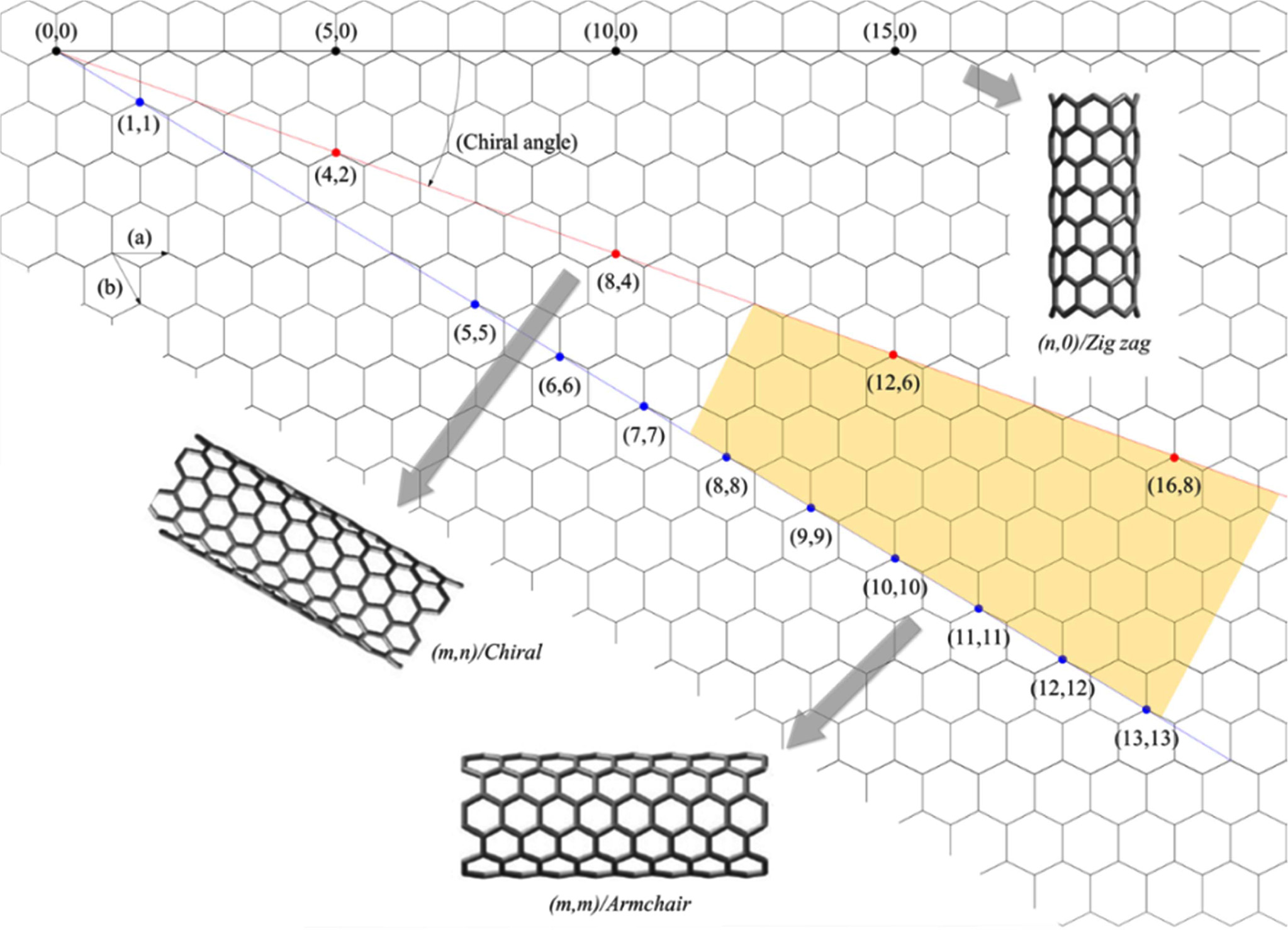

As mentioned previously, depending on the chirality,

SWCNTs can be metallic or semi-conducting. Due to this unique

structure, SWCNTs have been studied in focus. The

degree of twist of the graphite sheet is characterized

by a pair of vectors (n, m), which are called chiral

vectors, where the integers n and m represent the number of unit vectors along

two directions in the honeycomb crystal of graphene [41], as shown in Fig. 2.

Because of the varying degrees of twist of their rolled graphite sheets along

the length, CNTs can have a different chiral structure. In case of,

m = 0, the nanotubes are called “zigzag structure”; if

n = m, these nanotubes called “armchair structure”; other nanotubes

are called “chiral structure”. In addition, if (n – m) of the chiral vector is

a multiple of 3, SWCNTs exhibit a metallic behavior; if (n – m) is not a

multiple of 3, it exhibits a semi-conducting behavior. This is due to the

change in density of the Fermi energy state. Also depending on their diameter

and the helicity of the arrangement of graphite rings in the walls, they have been

demonstrated to possess unique electronic, photonic, magnetic,

thermal, and mechanical properties. Due to their unique physical and chemical

properties [42], Nanotubes are being used in a wide range of

applications, such as nano-electronic devices [43],

interconnects [44], sensors and actuators [45], energy storage media [46], and

field emitters [47] et al.

Theoretical

studies have suggested that the ideal CNTs are ballistic conductors for distances

in the order of a micron [48]. The 1D

confinement of electrons combined with the requirements for energy and momentum conservation leads to ballistic

conduction. The electrical properties of SWCNTs have been studied intensively

[49], often for the purpose of developing devices such as interconnects [50] or

CNTs-based transistors [51]. In contrast, the electrical properties of MWCNTs

have not been investigated at the same level of detail, due to their additional

complexities arising from the

structure, as every shell has different electronic characteristics and chirality, besides the

interactions between them [52].

However, for MWCNTs with both ends connected by metallic

contacts, electronic transport is dominated by outer-shell conduction at low

temperature and bias [53]. Theoretical models and experimental results point to

the critical role of shell-to-shell interactions to significantly lower the

resistance of MWCNTs with a large number of walls [54, 55]. Theoretical

calculations [56] and experimental results [57] indicate that CNTs are stiffer

than diamond, exhibiting the highest Young’s modulus and tensile strength.

Since CNTs are rolled-up graphene sheets, a first approximation for their

elastic modulus would be that of graphene, being approximately 1,000

GPa, five times that of steel. Many experiments have

confirmed the theoretical predictions. For example, Yu et al.

[58] measured the CNTs tensile load using Atomic Force Microscopy (AFM), and

found Young’s modulus values ranging 320 and 1,470 GPa (average 1,002

GPa), which is consistent with the value estimated by Krishnan

et al. [59] based on the observations of SWCNTs freestanding room temperature

vibrations in transmission electron microscopy (TEM). Using first-principles

calculations, Zhou et al. [60] estimated the Young’s modulus of 760 GPa and

tensile strength of 6.2 GPa for SWCNTs, while molecular dynamics studies by Yao

et al. [61] led to values of 3.6 GPa for Young’s modulus, and of 9.6 GPa for

tensile strength. Using TEM, Demczyk et al. [62] measured a Young’s modulus of

0.9±0.18 TPa and a tensile strength of 150 ±45 GPa, which are comparable to

those of graphene sheets.

Innertube

coupling in SWCNTs and inter-shell coupled

MWCNTs result in a low-temperature specific heat that resembles that of 3D

graphite [63]. Pop et al. reports the thermal properties of a suspended

metallic SWCNTs were extracted from high-bias (I-V) electrical characteristics

achieved by Joule self-heating over the 300 ~ 800 K temperature range

[64]. They measured a thermal conductivity of almost 3,500 Wm–1K–1

at room temperature (RT) for a 2.6 mm length of SWCNT with a diameter of 1.7 nm

and developed a model of thermal conductivity as a function of nanotube

diameter and temperature. Similarly, Kim et al. [65] measured a thermal

conductivity above 3,000 Wm–1K–1 at RT for MWCNTs using a

microfabricated suspended device. The property of field emission relates to the

extraction of electrons from a solid material by tunneling through the surface potential barrier. The emitted current

depends directly on the local

electric field at the emitting surface and its work function. The

Fowler-Nordheim model [66] shows an exponential dependence of the emitted

current on the local electric field and the work function. Given that the

emitter shape (geometric field enhancement) and the chemical state of the

surface have a strong impact on the emitted current, the small diameter and

elongated shape of CNTs lead to a high geometrical field enhancement, making

them ideal candidates for field

emission applications, such as displays

or triodes [67]. Another promising field of CNTs is nanostructure-based solar

cells [68]. The dispersion of CNTs in a solution of an electron donating

conjugated polymer is perhaps the

most common strategy to implement CNT

materials into organic photovoltaic devices to obtain higher efficiency. It has

been reported that enhancements of more than two orders of magnitude have been

observed in the photocurrent from

adding the SWCNTs to the poly (3-octylthiophene) matrix [69]. As is well

known, CNTs have 1D and wire-like

structure, making them better at forming electron- or hole-transporting

highways in the cell, and their large

surface area enhances the separation of the electron-hole pair, leading to conductivity several times

greater than that of conducting polymers. In these cells, they can act as both electron donors and acceptors,

depending on the redox properties of

the other component. The use of CNTs in dye-sensitized solar cells has achieved

double efficiency of this kind of photoelectrochemical solar cell [70].

Fabrication

method of carbon nanotubes

The most common method for synthesizing CNTs is as

follows:

1) Arc-discharge [71-74]

2) Laser ablation [75-77]

3) Chemical

vapor deposition from hydrocarbons (CVD) [78-82].

Techniques such as arc discharge and laser ablation enable

the synthesis of non-substrate CNTs with good crystallinity at high

temperatures. This simple method is the most widely used technique for

synthesizing CNTs without a substrate. The choice of the most suitable synthesis method depends on the properties and

possibilities required. Therefore, much research is underway to

increase yield and efficiency to

reduce current production costs. Mass production capability is key to using

CNTs in composites. Compared with CVD

processes, arc discharge and laser

cutting methods are costly, while CVD is the most suitable technique for

scale-up. In order to use CNTs in composites, large quantity production

capacity is the key [83]. Therefore, this research will mainly focus on the CVD

method.

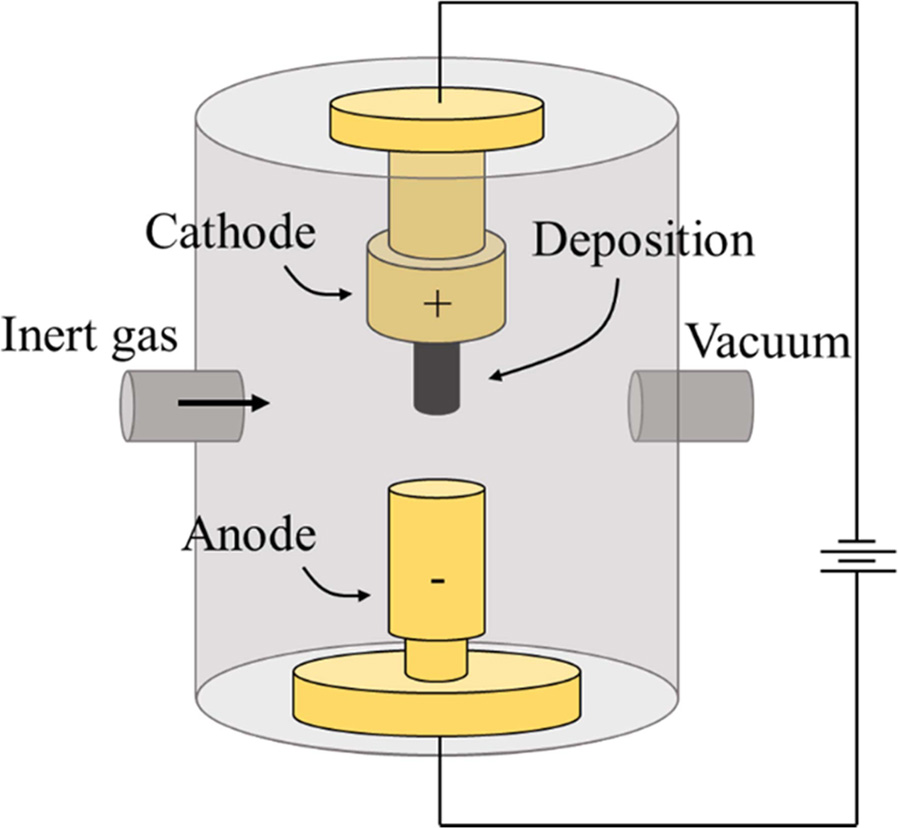

Electric-Arc discharge

Arc discharge, a method developed by Kratschmer et al. [73],

was the first available method for mass-producing

both SWCNTs and MWCNTs. This technique has been used

initially for fabricating carbon fibers and fullerenes, which may be the reason

for CNTs not being characterized, even though they were produced before 1991.

For example, Roger Bacon synthesized “thick” carbon whiskers in the

early 1960s, as mentioned by Yakobson and Smalley [74]. One

can imagine that if he had a HRTEM, he could have found CNTs in the soot. In

this technique, CNTs produced by striking an arc electrodes in an inert

atmosphere (e.g., He or Ar). If a catalyst is added to one of the electrodes,

they can be easily obtained. The mechanism is based on energy transfer between

the target material, graphite, which is kept at temperatures close to its

melting point, and an external radiation source, as shown in Fig. 3. The

technique has a major advantage, in that it is possible to produce CNTs with

good crystallinity by tuning the parameters, which leads to their superior

electrical and mechanical properties. This may be caused by the high

temperature where the process operates, even higher compared to CVD. The major

drawback is that CNTs products have to be separated from

other carbon products and catalyst residue.

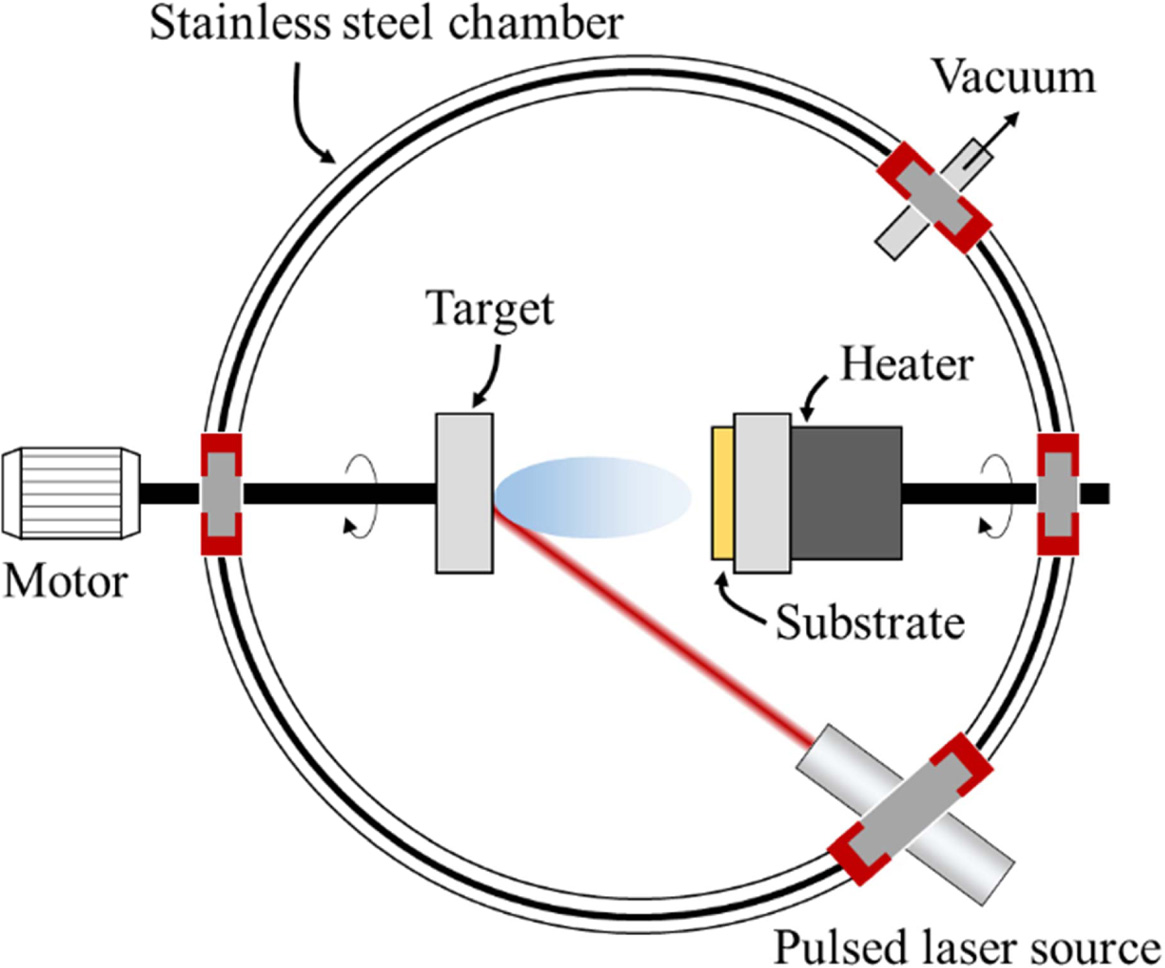

Laser ablation

This method was first introduced by Smalley’s group [75]

and was used for the production of fullerene clusters. The principle and

mechanism of this technique are similar to the arc-discharge technique, but the

difference is that the graphite pellets containing the metal-ion

catalyst (e.g., Ni or Co) are strike by a laser to generate

clusters. Pulsed or continuous laser irradiation to

species for vaporizes the carbon and catalysts. The vaporized species are led

to a water-cooled collector by a flow gas, where they condense, as shown in

Fig. 4. Using this method, MWCNTs can be collected in the soot with diameter of

1.5 to 3.5 nm, and with length of up to 300 nm [76, 77]. The function of the

reaction temperature (1,200 oC is optimum temperature for the best

quality of CNTs. By introducing small quantities of metal catalyst in the

pellet, SWCNTs can be achieved with good crystallinity. Unfortunately,

this technique has disadvantage for economic issues, because the process

involves high-purity graphite rods, the higher laser powers was required and

the amount of CNTs that can be manufactured per day is not as high as for the

arc discharge method.

Chemical vapor deposition (CVD)

Chemical Vapor Deposition (CVD) is a commonly used method

for the manufacture of thin films and is very different from the two methods

mentioned above in the synthesis of CNTs. CVD has the low set-up cost, easy

control of experimental parameters, simple synthesis conditions

and easy to scale-up to mass production make it one of the most widely used

methods of CNTs in recent years. CVD methods can be classified into various

methods such as plasma-enhanced CVD and thermal CVD

etc. In particular, Catalytic CVD (CCVD), which is a

CVD with catalytic pyrosis of hydrocarbon, is applied to the synthesis of CNTs,

which enables high yield of nanotubes [78, 79]. This technique provided

various advantages over other techniques, where CNTs are grown

over metal-ion catalysts containing nanoparticles of

transition metals (e.g., Ni, Fe, Co, Cu) or related oxides by the decomposition

of a various carbon source (e.g., CH4, C2H2,

etc.) [80-82]. Previously, while most CVD-grown CNTs were “spaghetti-like” and

defective, the potential of the method to satisfy technological requirements

was recognized. Since 1998, substantial and rapid progress has been made in the

development of CVD to establish it as a highly controlled

technology for producing CNTs. To date, it is possible to fabricate high-quality

SWCNTs and MWCNTs in bulk, or directly onto substrates as a raw

material [83-85]. In addition, it can be integrated as a step-in chip

fabrication, and by appropriate patterning, can be used to synthesize CNTs in

required locations on substrates, although a complete understanding of the

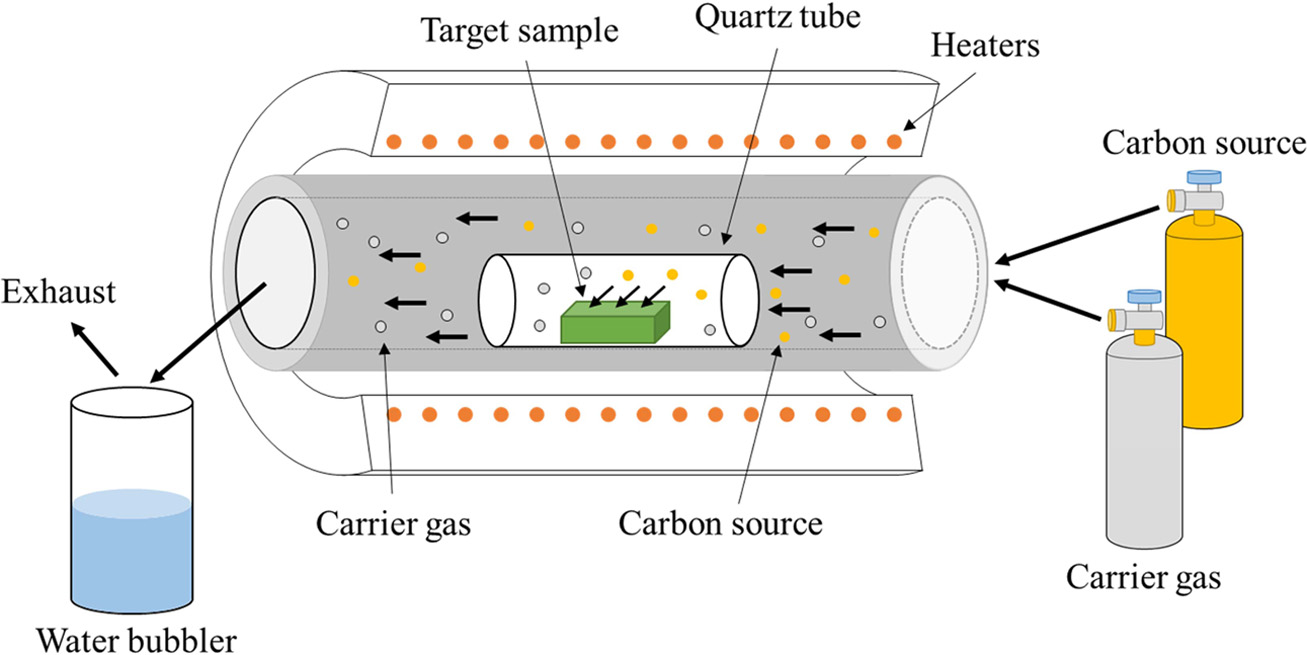

growth mechanism of CNTs is still unclear at this time. Fig. 5 shows the

synthesis techniques that we used.

|

Fig. 1 Illustration of ideal (a) fullerene, (b) graphene, and (c) SWCNT and MWCNT (all cited from Wikimedia Commons). |

|

Fig. 2 Chirality (θ) of SWCNTs derived by rolling the Hamada vector of the graphene sheet ((Reproduced from ref. 8, Copyright 2012 Springer). |

|

Fig. 3 Schematic diagram of electric-arc discharge apparatus (Reproduced from ref. 8, Copyright 2012 Springer). |

|

Fig. 4 Schematic diagram of laser ablation apparatus (Reproduced from ref. 8, Copyright 2012 Springer). |

|

Fig. 5 Schematic of CNTs production by CCVD (Reproduced from ref. 8, Copyright 2012 Springer). |

To apply nanostructures is one of the driving forces of

material development. The possibility of controlling the microstructure

complexity and interfacial and interconnectivity of microstructural units is a key technology for

producing new materials with improved multifunctional properties.

Recent research activities have addressed the question of how to transform

hierarchical cellular structures of trees to provide

specific functional properties [86-89]. Due

to the genetic evolution process, biological structures

exhibit excellent strength in low density, high stiffness and elasticity, and

are resistant to micro damage, as well as at the macroscopic scale. Wood is a

natural compound with cellulose, hemicellulose, and lignin as

major biopolymeric components and additional macromolecular

compounds. Carbonized wood is being used in a wide range of industries as the

demand for charcoal increases with the growth of the metal

industries.

Recently, carbonized wood has been used as activated

carbon in a variety of applications, such as fibers, composites, filters, and

catalyst supports [90]. As the importance of the fine chemical industry grows,

there is much interest and research in the micro reactor process

using activated carbon supported precious metal catalysts

[91]. The carbon support may be prepared in powder, pellet, or honeycomb form,

and is used as a catalyst filter support or absorbent. Catalysts such as Cu,

Pt, Ir, Ru, Pd, Rh, or Mn can be applied, and are used for the thermocatalytic

decomposition of methane for hydrogen production, without low

temperature selective catalytic reduction NO or CO2

[92]. However, carbonized wood is more difficult to commercialize, because it

has a lower specific surface area (SSA) than commercial activated carbon of

400 ~ 1,200 m2/g [93]. Mohan et al. [94] obtained

carbonized wood with SSA values of 2.04, 2.73, 25.4, and 1.88

m2/g by carbonizing oak, pine, oak

bark, and pine bark at 400 ~ 450 oC,

respectively. A recent breakthrough is Yao et al. [95], who

carbonized bamboo, sugar barge, and hickory wood at 600 oC,

and obtained SSA values of 234, 375.5, 388.3, and 401.0 m2/g,

respectively, under optimized heat treatment conditions [96].

In addition, in the case of interconnected biomimetic

structures, it is still a technical challenge to produce CNTs-inserted

complexes in all directions. Open pore matrix

composites, which are used as trusses depending on the

degree of porosity and the degree of filling with nanotubes,

can be applied as multifunctional engineering composites,

such as filters. CNTs has received special attention,

because it has excellent water treatment ability to filter

organic and inorganic pollutants [97, 98]. CNT-reinforced composite materials

can also potentially improve their mechanical properties.

Wood

structure and composition

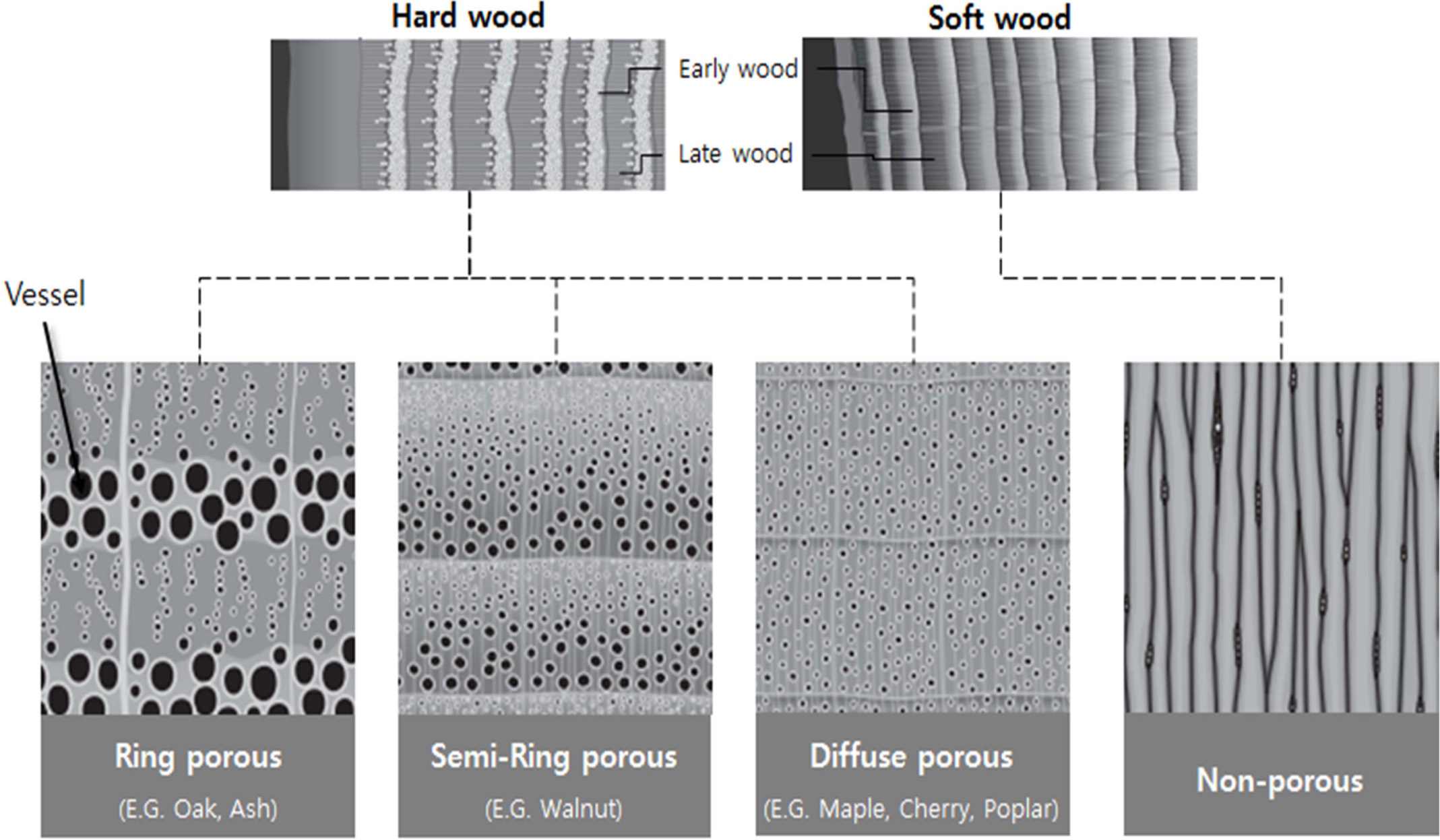

According to Ramirez-Rico et al. [99], the structure of

wood can be roughly divided into two groups for soft- and hardwood, according

to its microstructure and composition. The composition of the cell walls is

determined by the nature of the wood and the wood-derived product, as shown in

Fig. 6 [100]. This can be described as a lamellar or layered microstructure, in

which each layer is composed of cellulose, hemicellulose,

and lignin (lignocellulose). Cellulose is usually a long polymer chain (up to 1

μm long), agglomerated with microfilaments aligned with the longest dimension

of the cell. Hemicellulose is a short chain connecting cellulose

microfilaments, and lignin occupies the space left by the cellulose and

hemicellulose chains [99, 101, 102]. In addition to the presence of pores and

cells, the tree also shows two types of macrostructures: light rays,

and growth rings. Light rays are horizontally aligned cells that are used for

nutrient storage, and are released in three axes, while growth rings are

concentric circles that change pore size, due to seasonal changes in tree growth.

Since there is no fluid pathway, the softwood of gym plants, such as conifers,

is generally referred to as non-porous, while the hardwood of pizza plants is classified

as porous, semi-circular, or porous, depending on the shape

of the growth rings [103, 104].

Carbonization

and pyrolysis

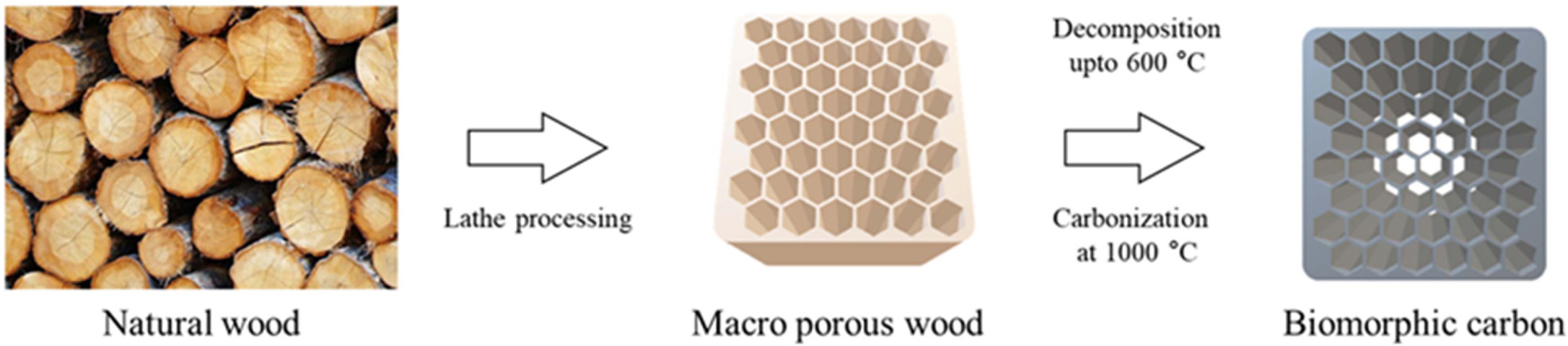

Pyrolysis of wood to produce a carbon support biomorphic

carbon materials (BCMs) by slowly heat up to a temperature above 800 °C with

the natural wood precursor in an inert atmosphere (typically Ar or N2).

In the pyrolysis process, the other polymer components of the wood decompose

hemicellulose at 200 ~ 260 °C and decompose cellulose at

240 ~ 350 °C and lignin at 280 ~ 500 °C,

stepwise [105]. In this work, to avoid collapse of the specimen

structure during the carbonization process, the specimens were slowly heated

in N2 gas flow 10 cm3/min in a horizontal electric

furnace at a heating rate of 0.5 °C/min to 600 °C for 6 ~ 8

h. Subsequently, the temperature was raised to 1,000 °C

at a rate of 3 °C/min to obtain a porous carbon template.

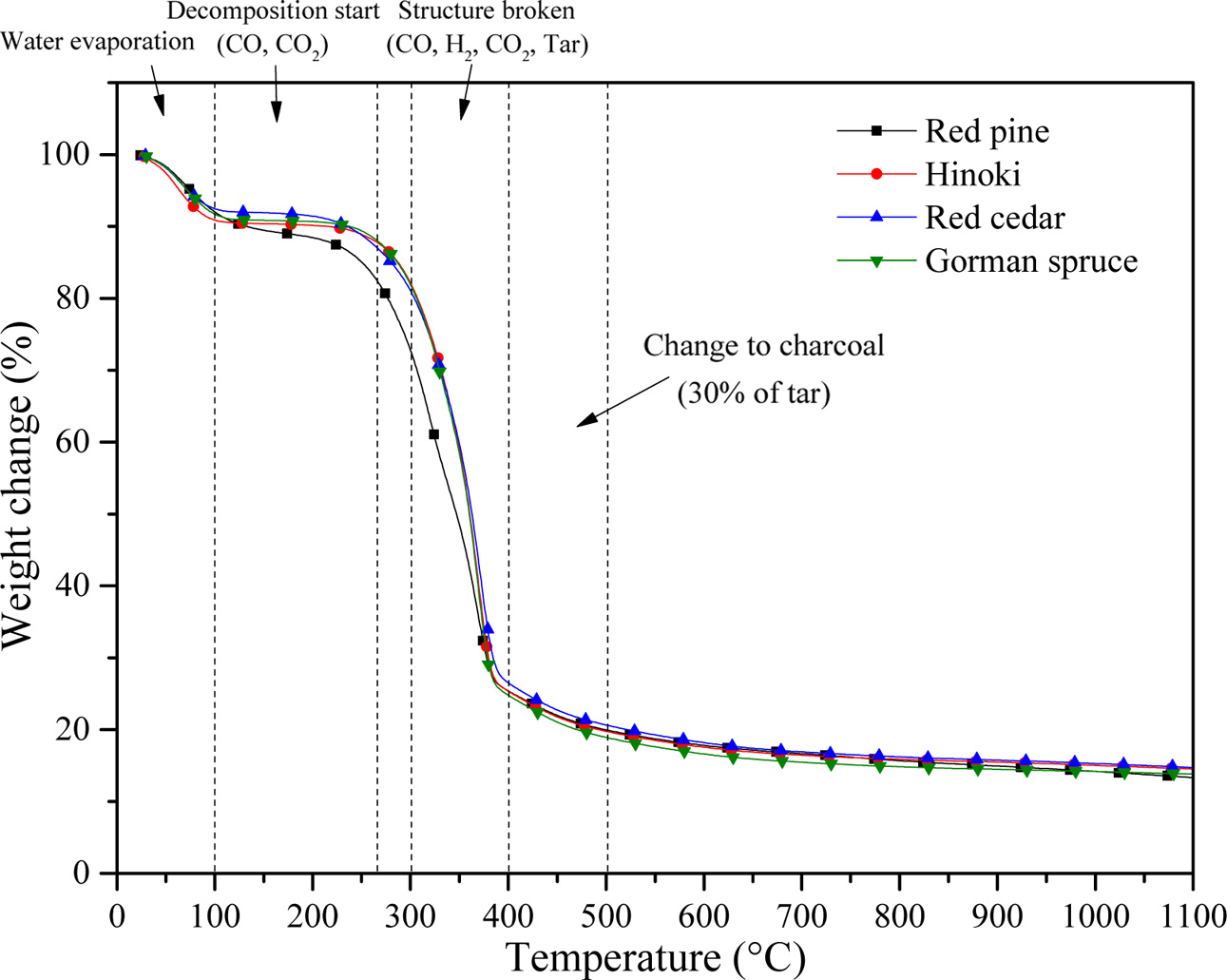

Fig. 8 shows that H2O, carbonyl groups, CO2

acids, and alcohols are released, due to degradation of the biopolymer

structure at temperatures up to 600 °C during pyrolysis. On the other

hand, the major biopolymer components of the cell wall material are rearranged,

and converted to carbon struts. Upon thermal decomposition at the initial stage

(T ≤ 250 °C), evaporation of water and decomposition of CO and CO2

begins with a weight loss of 15 ~ 20%, and then the wood structure

breaks CO, H2, CO2, and changes into charcoal having

about 30% tar between 300 and 500 °C with a weight loss of almost 80%.

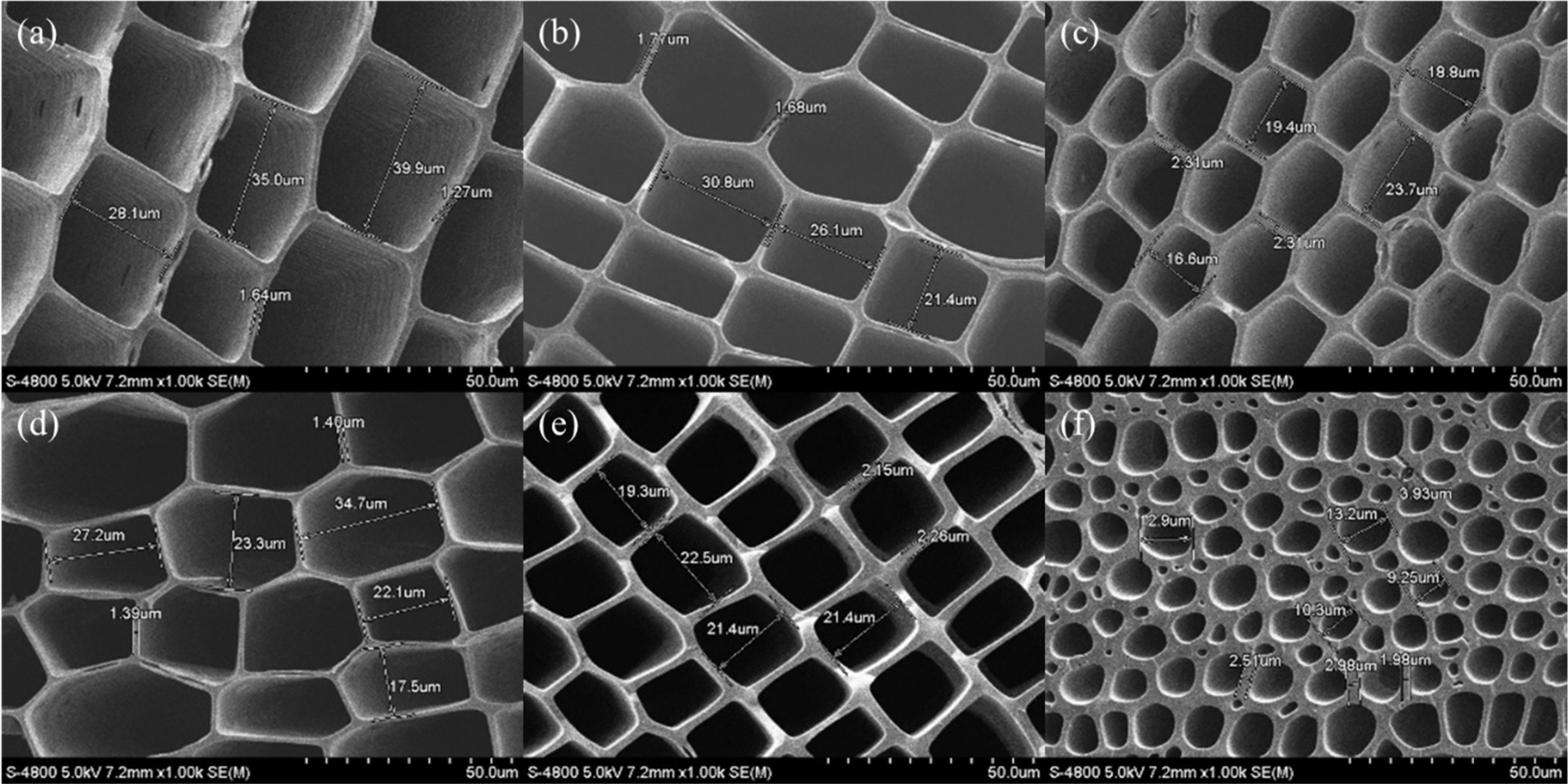

Fig. 9 shows the microstructure of the axial cross-section of the biomimetic

carbon material from pyrolysis of several different precursors used as the base

substrate for CNTs synthesis. In all cases, the unique anatomical

characteristics of the tissue can be maintained during pyrolysis,

producing porous materials that are composed mainly of honeycomb and

ring-porous carbon structures [106]. It is also clear that after pyrolysis, the

pore shape and distribution of the original wood are preserved.

Fig. 9(a) and (b) show a hexagonal cell structure, in

which the microstructure of hinoki and red cedar has a pore size (long side *)

in the range 18.8 to 23.7 μm, while each cell wall thickness is of about

2.30 ~ 1.40 μm. Fig. 9(c), (d), and (e) show the microstructure of

North American red pine, red pine, and Gorman spruce with a rectangular cell,

and square structure with pore size ranging 19.3 to 22.5 μm, and cell wall

thickness of about 1.45, 1.72, and 2.21 μm, respectively. Fig. 9(f) shows the

microstructure of Mahogany contains hollow channels of various diameters that

originate from tracheid cells that are parallel to the axis of the tree. The

hollow channels of the biocarbon template have a uniform arrangement, where the

black part is lumen, and the grey part is a carbon layer that is formed by carbonization

of the cell wall. The difference in diameters of hollow

channels is attributed to the non-uniform distribution of the texture of the

wood. The average range of diameters of cell is about 5 ~ 30 μm, and

the cell wall is about 2 ~ 3 μm thick. Most of the cellular pores

show a rectangular shape, and the distribution shows a regular net with carbon

wall joined to each other, as shown in Figs. 9(c) to (e). The topologically uniform

arrangement of cell of early wood is interrupted by growing

ring patterns, where late wood cell show a significantly higher strut thickness

[107].

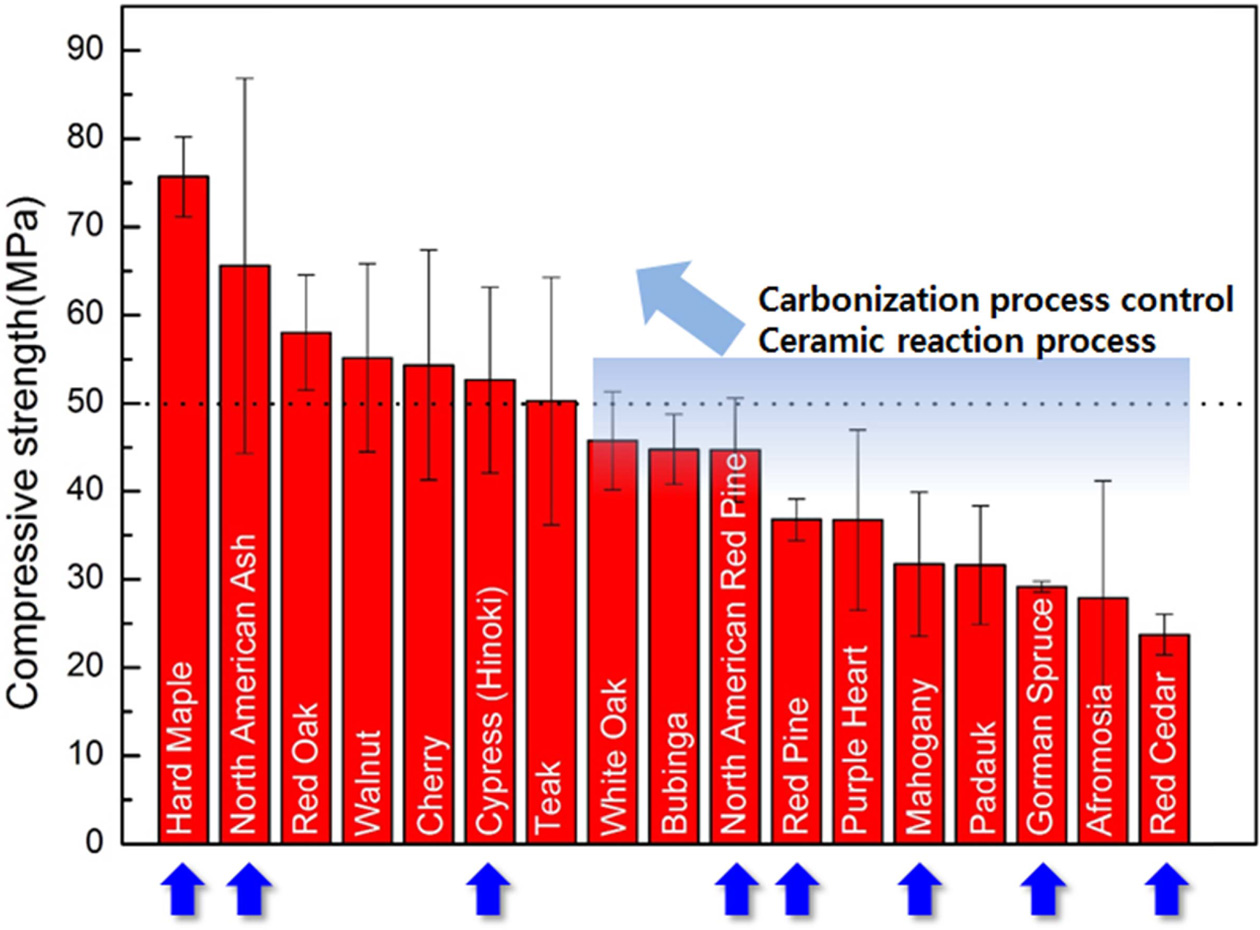

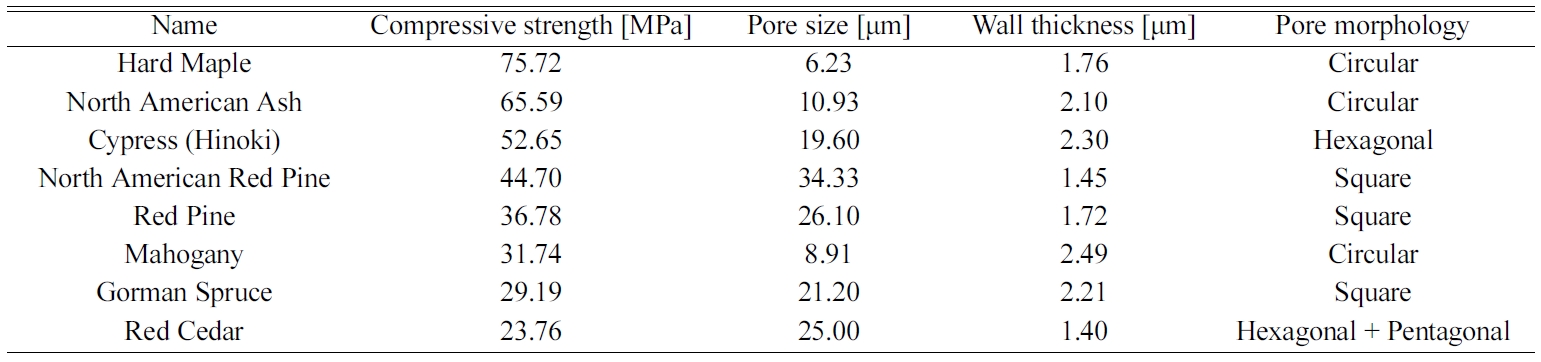

Physical

properties of biomorphic carbon materials

Table 2 shows the physical properties of BCM with its

unique structure obtained by pyrolysis of wood varieties,

such as Cypress, Red pine, Gorman spruce, and Hard maple, respectively [108].

Carbonaceous materials impregnate and react with coated

oxides and nano-oxides that can be used in a variety of applications, as well

as filtration and catalyst support. Greil’s research team [109, 110] was one of

the first to report the characteristics of melt-impregnated bio SiC/Si, the

properties of carbon preforms, and the mechanical properties of porous bioSiC

obtained by gas infiltration [111-113]. Gutierrez-Mora et al. [114] and Presas

et al. [115] studied the bending strength and fracture toughness of

various bioSiC/Si materials derived from hardwood, using

indentations to measure the hardness of eucalyptus, beech, and

pine-derived bioSiC/Si composites [116, 117]. Park et al. [118] studied flexion

and compressive strength as a function of the precursor density of bioSiC/Si

synthesized by various precursors. Hou et al. [119] measured the bending

strength as a function of penetration time to study the possible effects on the

final properties of the material. Kaul et al. [120] measured the mechanical

properties such as elastic modulus, compressive strength, and fracture

toughness of the porous bioSiC from other precursors. Table 1 shows that the

compressive strengths of Hinoki and Red cedar with pore size of 19.60, 25.0 μm,

and wall thickness of 2.3 and 1.73 μm are 52.65 and 23.76 MPa, respectively.

In addition, the Red pine having a pentagonal and

hexagonal honeycomb structure has a pore size of 36.78 μm, a

wall thickness of 1.72 μm, and a compressive strength

of 23.76 mpa. Fig 10 shows that the carbonized carbon

materials reveal increased compressive strength due to the ceramic reaction. Fig. 7 Fig. 10

|

Fig. 6 Axial sections of wood structure from ring porous hardwood and non-porous softwood (Modified from T. Nunlist, Popular Woodworking, Dec. 2012.). |

|

Fig. 7 Carbonization process of natural wood. |

|

Fig. 8 TGA curves of carbonized biomorphic carbon template from red pine, Cypress, Red cedar, and Gorman spruce. |

|

Fig. 9 Macrostructure of hinoki (a), red cedar (b), north american red pine (c), red pine (d), Gorman spruce (e) and Mahogany (f) (Reproduced and modified with permission from ref. 5, 107 and 156, Copyright 2018 Hanyang University and Inderscience publishers). |

|

Fig. 10 Compressive strength of biomaterials after the carbonization. |

In principle, finely dispersed, nanometer-sized metal

particle catalysts that preserve their morphology at the CVD processing temperatures

are required, because controlling the morphology of the

catalytic particles during CNTs growth strongly affects

nanotube characteristics, such as thickness, uniformity, and

yield. However, as the size of the metal particles decreases to the nanometer

scale, they tend to agglomerate. To prevent this, porous materials have been

proposed as supports. A porous support showing a non-continuous surface and

high SSA can not only contribute expressively to particle stabilization and

produce a fine dispersion of well-defined particles, but also radically

increase the number of catalytic particles, thus increasing the

number of nucleation sites, which are all advantageous to the

synthesis of CNTs [121]. Commonly used substrates in CVD include silicon [122],

quartz [123], silica [124], silicon carbide [125], alumina [126],

alumino-silicate (namely, zeolite) [127, 128], and magnesium oxide [129]. Among

all the catalytic supports, zeolites being molecular sieve materials with pore

diameters in the range 3 ~ 10 Å have had a significant impact due to

their structural homogeneity, and high reactive surface area, which makes them

excellent host candidates for different types of adsorbing

molecules [130]; and hence zeolites could be used as supports

for catalyst particles to synthesize and grow CNTs [131]. In this review, the zeolite

(LTA, Silicalite-1) and meso-porous SiO2 are used

as the templates for supporting catalyst nanoparticles to

synthesize CNTs biomorphic carbon composites via the CCVD method.

Template-coated

biomorphic carbon materials

Zeolites are typically defined as crystalline

aluminosilicate with the chemical composition Mx[(AlO2)x(SiO2)y]·nH2O.

Their structure is based on a three-dimensional regular connection of [AlO4]5- and [SiO4]4- tetrahedral units,

which are linked to each other via bridging oxygen atoms. As each aluminum atom in the framework generates negative charge, cations (M+) must

exit for charge balancing in the framework [132]. The framework structures

create unique three-directional features, high regular arrays of very open void

spaces that are often termed cages or

channels. Typically, the window diameter of its pores ranges 3 to 8 Å, while the inner diameter of interior

spaces ranges 5 to 13 Å. Up to now, 235 types of zeolite frameworks are

registered, having different 3-dimensional regular opened nanopore or

nanochannel structures. Based on

their structural features having high

surface area, zeolites are commonly

used as commercial adsorbents [133]

and catalysts [134, 135]. Recently, this unique structural feature provides a

vast templating system in applied synthesis fields, such as quantum dot [136-139], organic molecules [140, 141], etc. In

particular, zeolites have also been

extensively tested as template for carbon nanotubes, because their uniformly

arranged nanopores and nanochannels

can serve as nano templates for liberating series of three-dimensional ordered

micro- porous carbon materials [142, 143]. We term this material ‘zeolite-templated carbon’ (ZTC). Generally, ZTCs

of the three-dimensionally ordered

framework by replicating the zeolite template are obtained only when the

synthesis is carefully performed with

appropriate conditions, which is comprised of three steps: (a) uniform carbon

introduction only inside the zeolite nanochannels, (b) heat treatment, and (c)

template removal [144, 145]. The first formation of porous carbon using zeolite

templates was reported in 1997 with

description of some of the unique advantages of this technology. By

depositing graphene monolayers

uniformly on the internal surface area of zeolites, and by etching the zeolite

using a com- bination of acids, porous carbon replicas may be

produced with an ordered array of

microspores. The large variety of zeolites with more than 200 types available

allows an appropriate template to be selected for the desired pore size in a

ZTC [146]. This review addresses surface modification of the mesoporous

templates, such as Linde Type A (LTA) zeolite [147, 148], silicalite-1

[149-151], and mesoporous silica [152]. Among these matrices, zeolite is an

excellent template for supporting or encapsulating catalyst nanoparticles due

to the well-defined pore structure and high surface area and is responsible for

catalyst particle stabilization and the fine dispersion of nanoparticles [153]. Generally, silicalite-1 is pure SiO2 zeolite, and has high

surface area. It also has the potential to load catalytic materials on the

cavity of silicalite-1 of about 0.5 ~ 0.55 nm. But it is difficult to

load some materials on its surface firmly or in its pores, due to its smooth

surface and small cavity. In order to meet growing environmental challenges, it

is important to explore new technologies to treat or synthesize silicalite-1,

which can load a large amount of other materials, and retain its large surface

area [154, 155]. The mesoporous structure features a large specific surface

area and pore size of 2 to 50 nm in diameter. Mesoporous silica nanoparticles

(MSNs) can also be used as a host material to carry therapeutic agent or for

molecule encapsulation and can be used as a template for the synthesis of CNTs.

Good biocompatibility, high

loading capacity, and the possibility of attachment of a target ligand for

specific cell recognition, or a well-defined and adjustable porosity design,

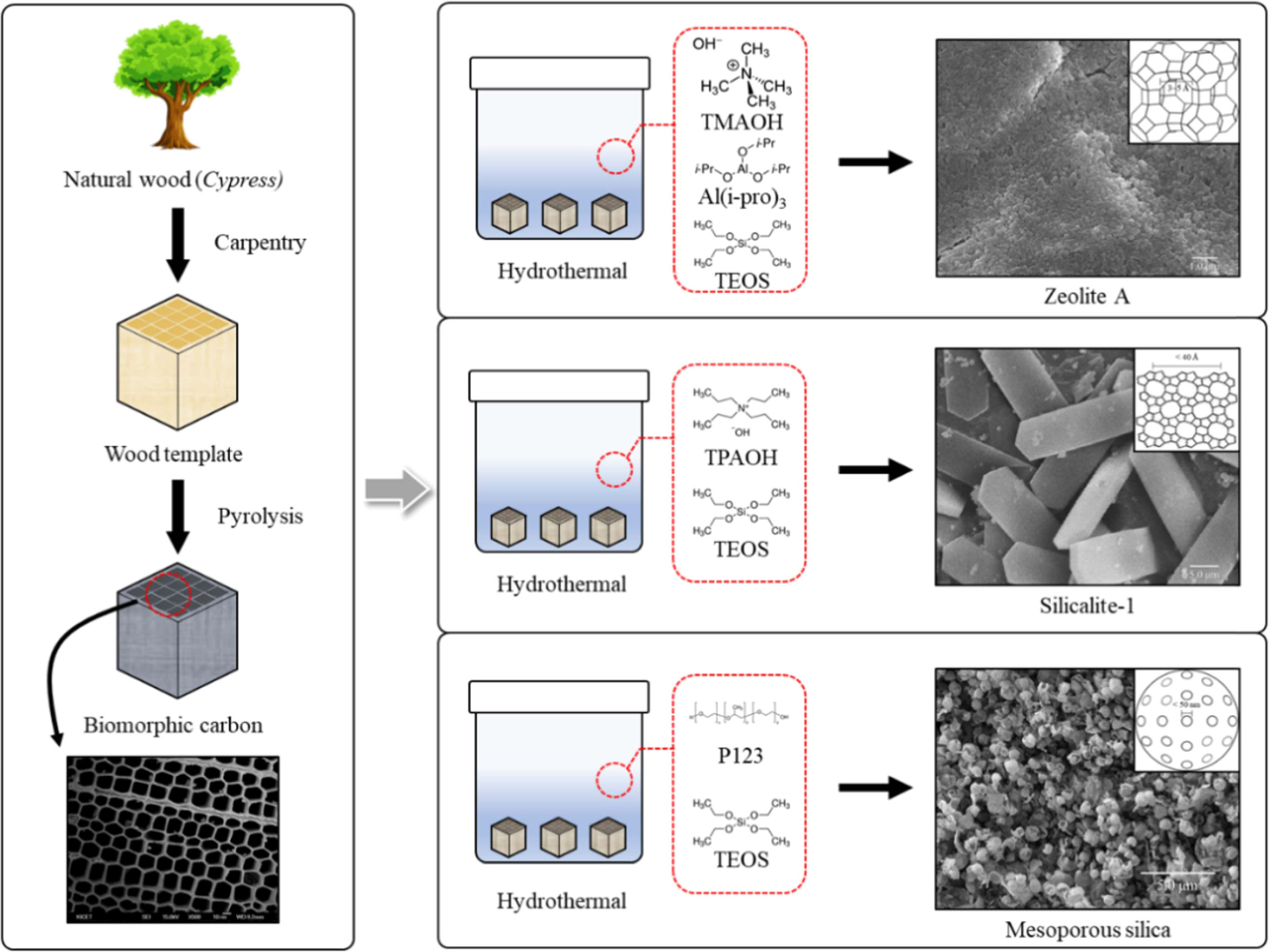

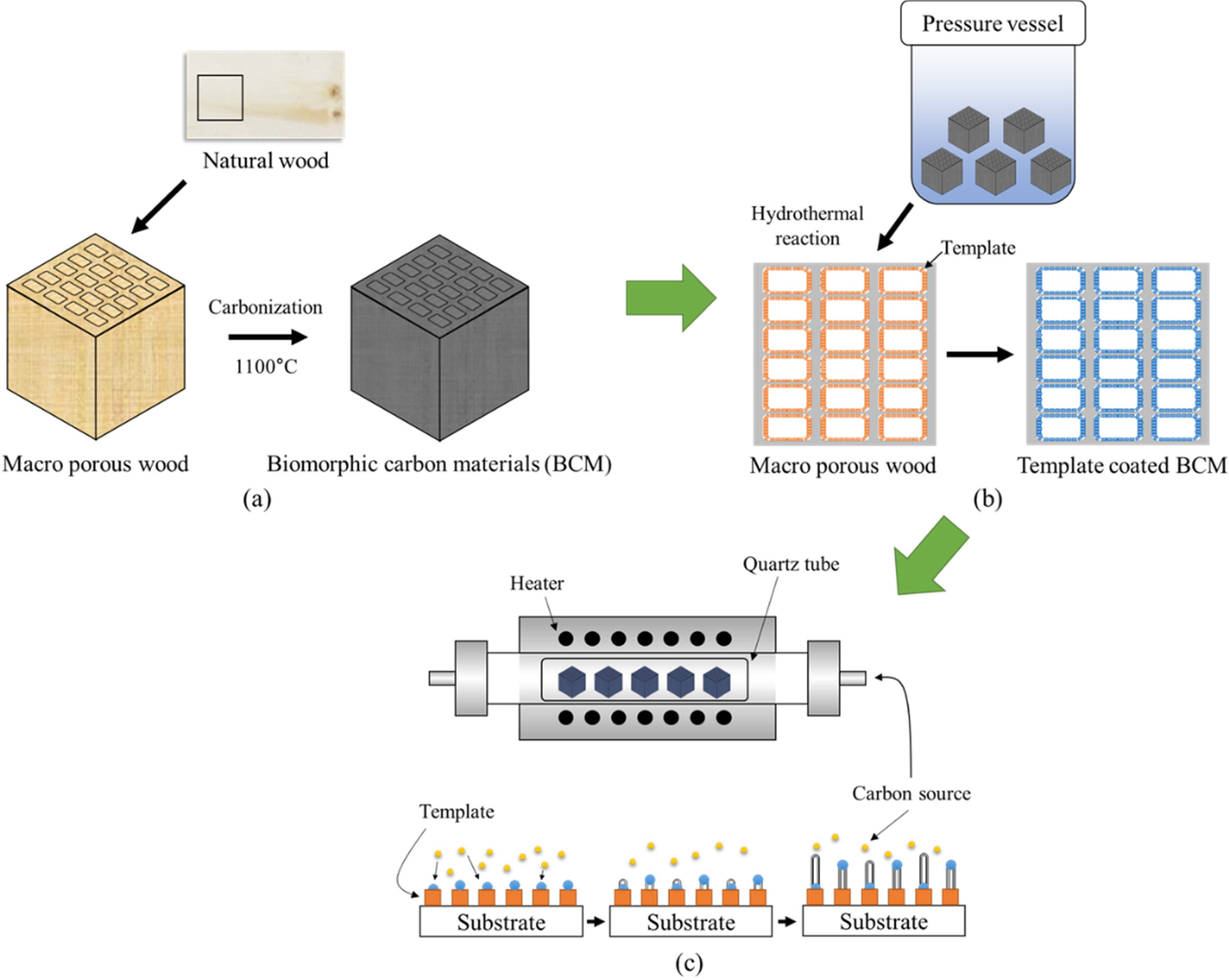

make MSN suitable for drug delivery. Fig. 11 shows a new process for

synthesizing and coating LTA zeolite,

silicalite-1, and mesoporous silica onto biomorphic carbon materials [156].

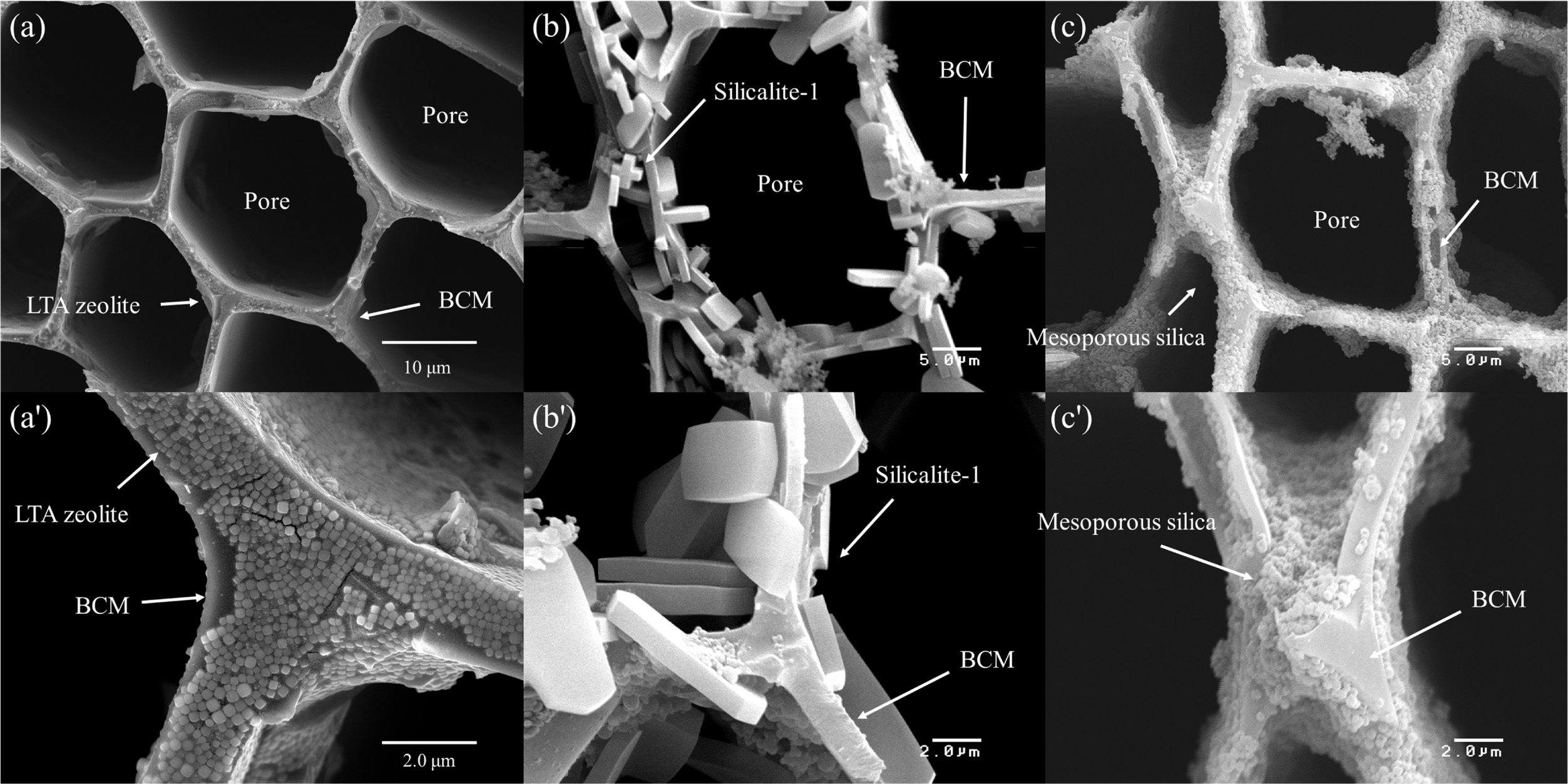

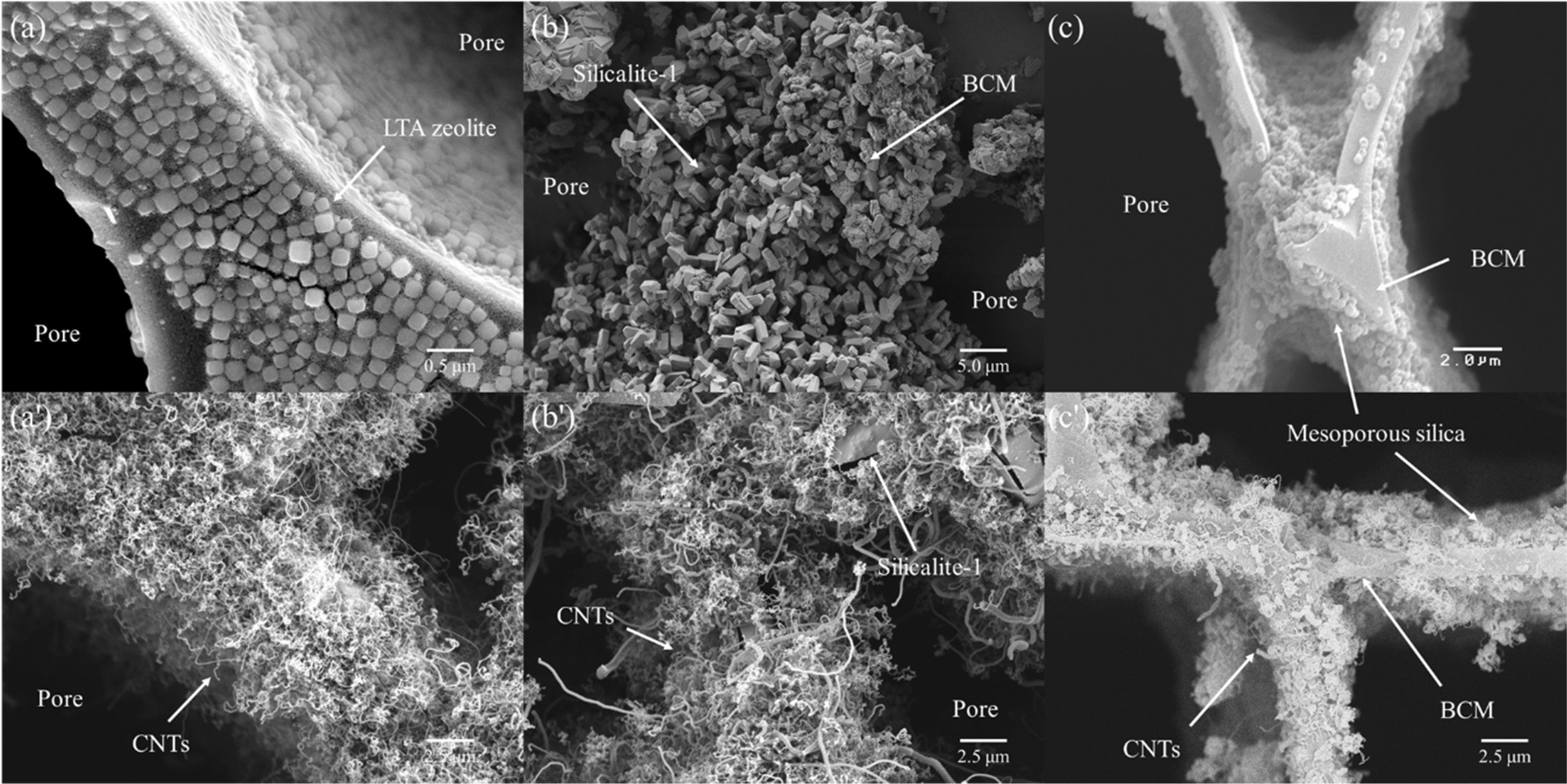

Fig. 12 shows microstructures of (a) and (a') LTA type

zeolite, (b) and (b') silicalite-1, and (c) and (c') mesoporous silica template

coated cypress BCM. The LTA zeolites are finely coated inside and outside of

the honeycomb structure, which can be observed in Fig. 12 (a'). The cubic shape

of LTA zeolite crystals has been achieved with the size of around 120 nm in a

configuration with a fine layer of well-controlled cube crystals. The cube

{001} is composed of six perfect square faces that make angles of approximately

90 o. The crystal structure of LTA zeolites

was homogeneously synthesized and coated on the surface of the

template by an in-situ hydrothermal process. Generally, the framework of

LTA zeolite crystals can be explained in terms of two types of polyhedra; one

is a simple cubic alignment of eight tetrahedra, and is termed D4R, while

the other is a truncated octahedron of 24 tetrahedra or cages,

as previously described for the sodalite-type minerals [157, 158]. As observed

with higher magnifi- cation, the

5.0 μm silicalite-1 particles were entirely interlocked and coated on the

surface of BCM. The images revealed the presence of a continuous and smooth

mesoporous silica film layer of less than 1.0 μm [156].

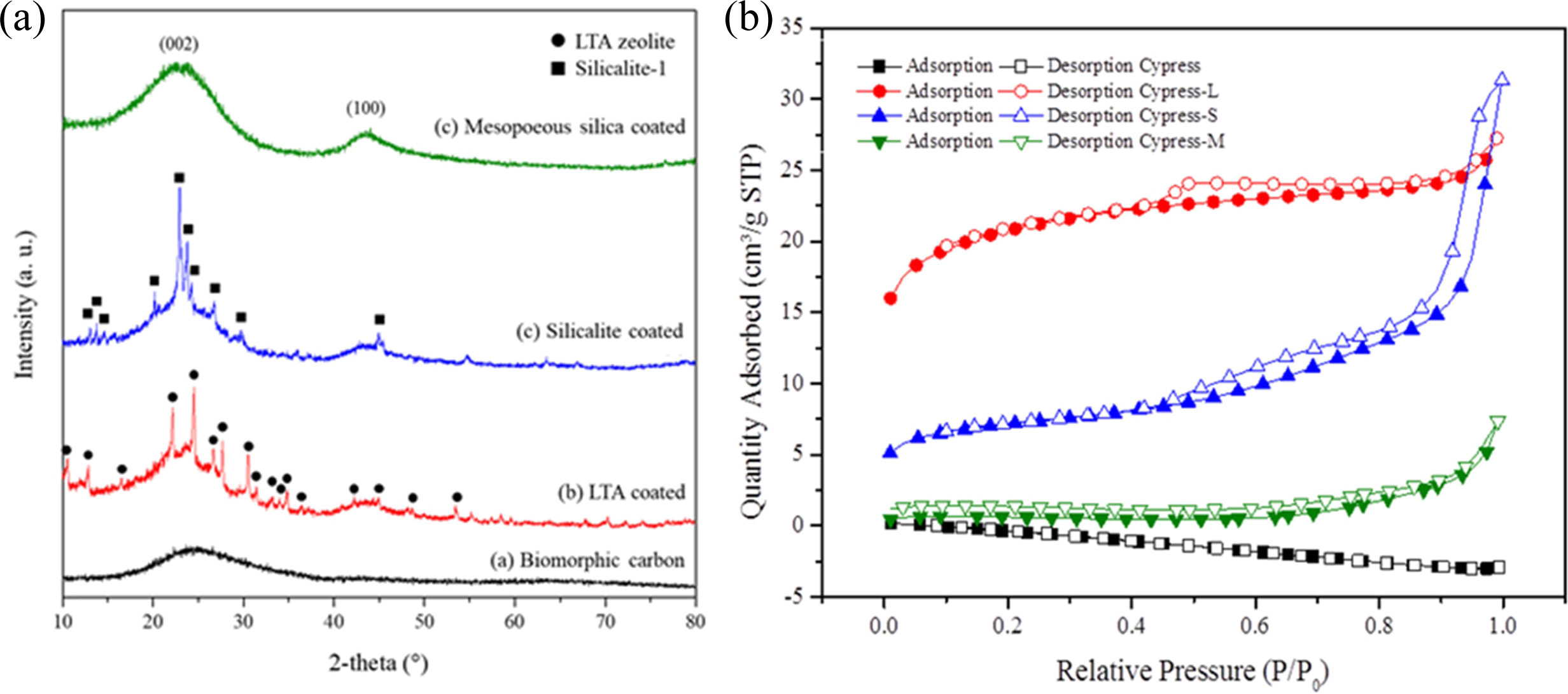

Fig. 13(a) shows XRD patterns of LTA, silicalite-1, and

mesoporous silica template synthesized on the surface of the BCM. These XRD

plots show different peaks, which indicate monolayer and multi-layer fine coating

of the template. These peaks were then compared to JCPDS

files. Compared to JCPDS file # 97-002-4901, the corresponding peaks reflected

the yield of LTA phase, 2θ = 10 ° (220), and 24 ° (600). A single

phase with an average lattice constant of 24.61 Å was found in the obtained

XRD. This is a simple cubic arrangement of eight tetrahedra with D4R [21, 156].

Similarly, when the obtained XRD plots were compared to

the JCPDS 42-0023 original JCPDS file for silicalite-1,

corresponding peaks were also found. This assures the synthesis of silicalite-1

in the BCM. Randomly oriented silicalite-1 crystals were coated as shown in

Fig. 12(b). BCM was also coated with mesoporous silica. However, it was hard to

recognize it with wide angle XRD, due to the mesoporous silica’s properties.

Instead, it needed to be analyzed with small angle XRD [22, 156]. The peak

intensity was the background of amorphous carbon.

Fig. 13(b) shows the N2-adsorption/desorption

isotherms of BCM coated with LTA, silicalite-1, and mesoporous

silica. According to the International Union of Pure and Applied Chemistry

(IUPAC) classification, isotherms of all the samples studied belonged to type

IV [23, 160], suggesting that these adsorbents are mesoporous materials.

Capillary condensation phenomenon may occur in their pore channels. Fig. 13(b)

shows that the N2-adsorption capacity of silicalite-1

seems to be greater than that of LTA zeolite or mesoporous

silica. This is probably because the pores of LTA zeolite and

mesoporous silica are partially covered by the active ingredient [161, 162],

thus reducing the surface area. Furthermore, the hysteresis loop shifts in the

relative pressure range of 0.4 ~ 1.0. The BET isotherms graphs (Fig.

13) show a typical type (IV) with type II-like hysteresis loops, indicating the

presence of mesopores in all samples (LTA zeolite, silicalite-1, mesoporous

silica). The position of the inflection point of P/P0 is related to

the diameter of the mesoporous range. The sharpness of the step shows uniform

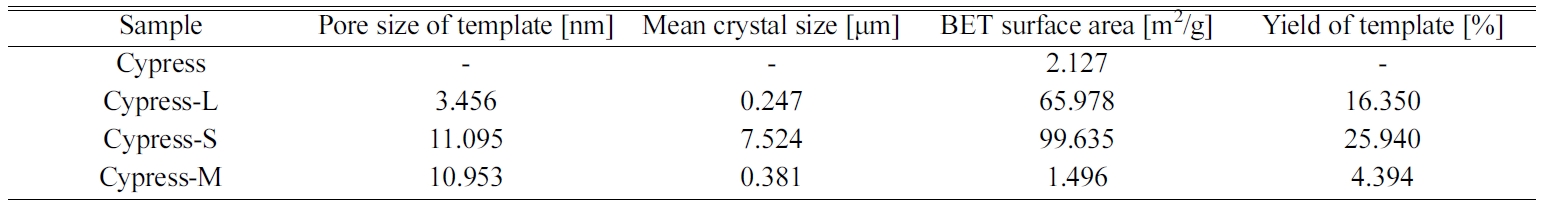

mesoporous size distribution. Table 3 summarizes the results of BET and the

yield. Templates were coated on BCM to increase the specific

surface area, especially of silicalite-1. The BET surface areas of the original

carbonized cypress, LTA zeolite, silicalite-1, and mesoporous silica were

2.126, 65.977, 99.634, and 1.496 m2/g, respectively [156].

Fabrication

of CNTs nanofilter composites

Fig. 14 shows that catalytic decomposition of acetylene

(C2H2) on the BCM was carried out in a quartz boat

centered in a horizontal tube furnace. The synthesis was carried out with

application of the three different processing routes for CNTs composites. First

of all, biomorphic carbon material was produced by the carbonizing

reaction. Secondly, LTA [148] and silicalite-1

[151] were synthesized within and coated concurrently on the

carbon template, which was then subjected to colloidal process, resulting in

the formation of Co ions loaded on template-coated BCM substrate; and finally,

the CCVD method was used for the synthesis of CNTs, as shown in

Fig. 14(c) [163, 164]. To maintain neutrality, the

temperature was elevated at a rate of 5 °C/min to the desired

reaction temperature in a nitrogen atmosphere (200 sccm). Carbon nanotubes were

grown by the introduction of carbon feeding gas C2H2@ 10

sccm. CNTs were separately synthesized at 650 and 700 °C for 40, 60, 120, and

180 min, respectively.

Fig. 15 shows FE-SEM images of multi-walled CNTs grown on

Co- catalyst loaded LTA-, silicalite-1, and mesoporous SiO2-BCMs for

60 min at 650 °C, respectively. Figs. 15(a), (b), and (c) clearly show the

CNTs synthesized on the BCM keeping template as a base for the FESEM images in

overview, respectively. All templates were uniformly and tightly coated on the

BCM surface. All CNTs were synthesized as multi-layered carbon nanotubes like

hair, so the yield of CNTs was very low in mesoporous SiO2 template,

as shown in Fig. 16.

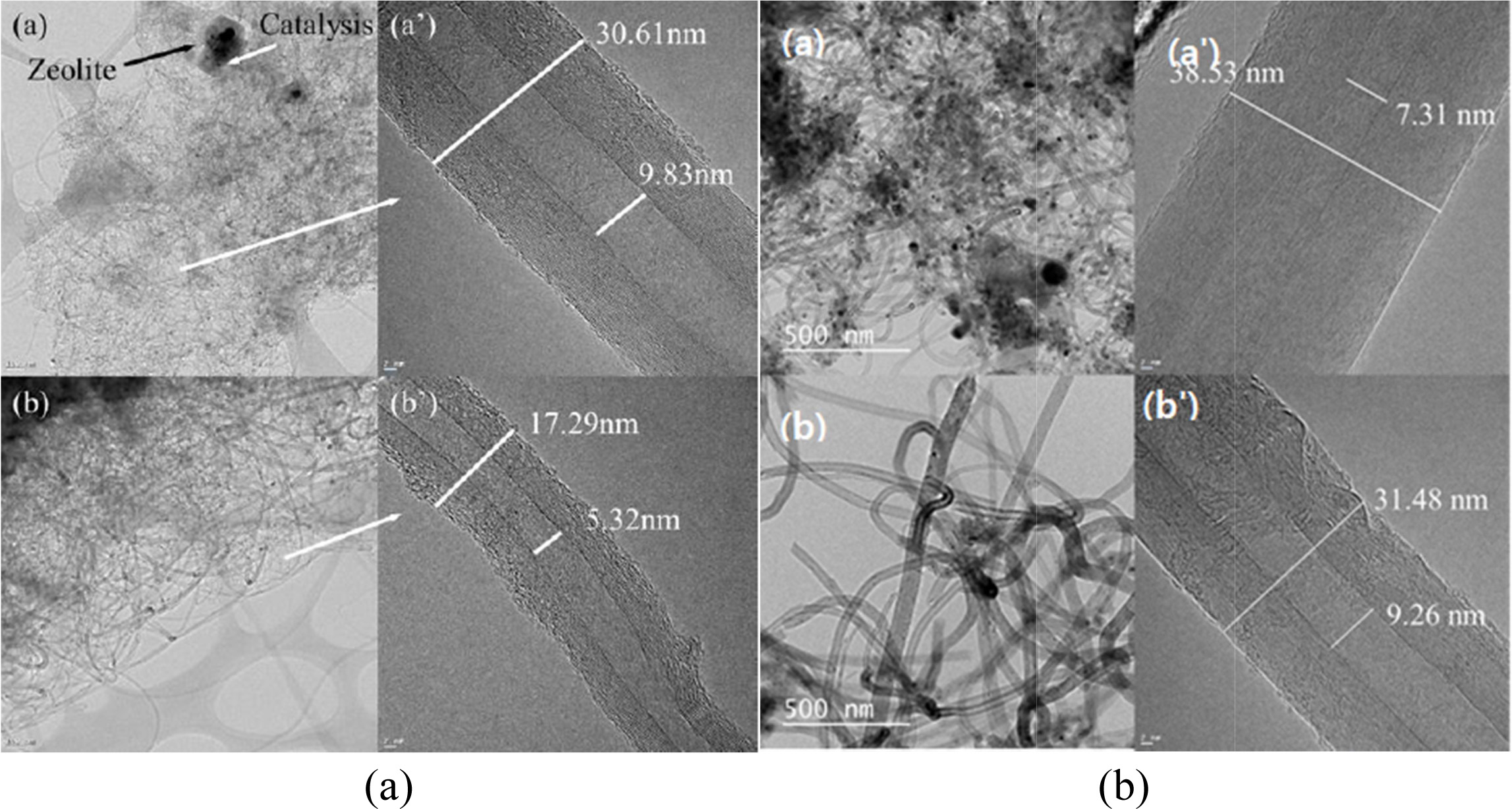

Fig. 16(a) shows the HRTEM images of multiwall CNTs

(MWCNTs) that were grown on (a) and (a,) Co-LTA-BCM and (b) and (b,)

Co-silicalite-1-BCM at 650 °C for 60 and 120 min, respectively. The CNTs in the

TEM image of Fig. 16(a) show small outer walls with a diameter of approximately

17.29 nm and an inner diameter of 5.32 nm. The outer walls

of the synthesized CNTs in Fig. 16(b) are comparatively thicker, and a

densely layered structure with outer and inner diameters

of approximately 30.61 and 9.83 nm, respectively, was formed. A base growth

mechanism can be clearly seen in the CNTs, which are known for better

attachment tendencies regarding the substrate. Also, note here the apparent

growth of the inner and outer diameters of the nanotubes.

Thus, it can be inferred that the decomposition of the

carbon atoms from C2H2, which formed a layered coaxial

cylindrical graphene sheet around the CNT core, is strongly related to the

reaction time and temperature. All of the CNT samples display a bamboo-like

structure and are typically MWCNTs. Moreover, it can be clearly inferred from

the following HRTEM images that the CNTs that were grown at 650 °C produced a

superior yield with smoother outer and inner walls, compared to the ones

synthesized at 700 °C [164, 165].

Figs. 16(b) and (b') show the HRTEM images of multi-walled

CNTs grown on Co-silicalite-1-BCM at 650 °C for (a) 60 min, and (b) 120

min, respectively. Fig. 16(b) shows thicker outer walls, with a diameter of

around 31.48 nm. with an inner diameter of 9.26 nm Also, note here the apparent

growth in terms of the inner and outer diameters. The synthesized CNTs at the

same temperature for 120 min shown in Fig. 16(b') have a comparatively thicker

outer wall, which forms a densely layered structure with an outer diameter of

around 38.53 nm and inner diameter of 7.31 nm. Moreover, it can clearly be

inferred from the HRTEM images below that the CNTs grown for 120 min have

better yield with smooth outer and inner walls, in comparison to the one

synthesized for 60 min [166].

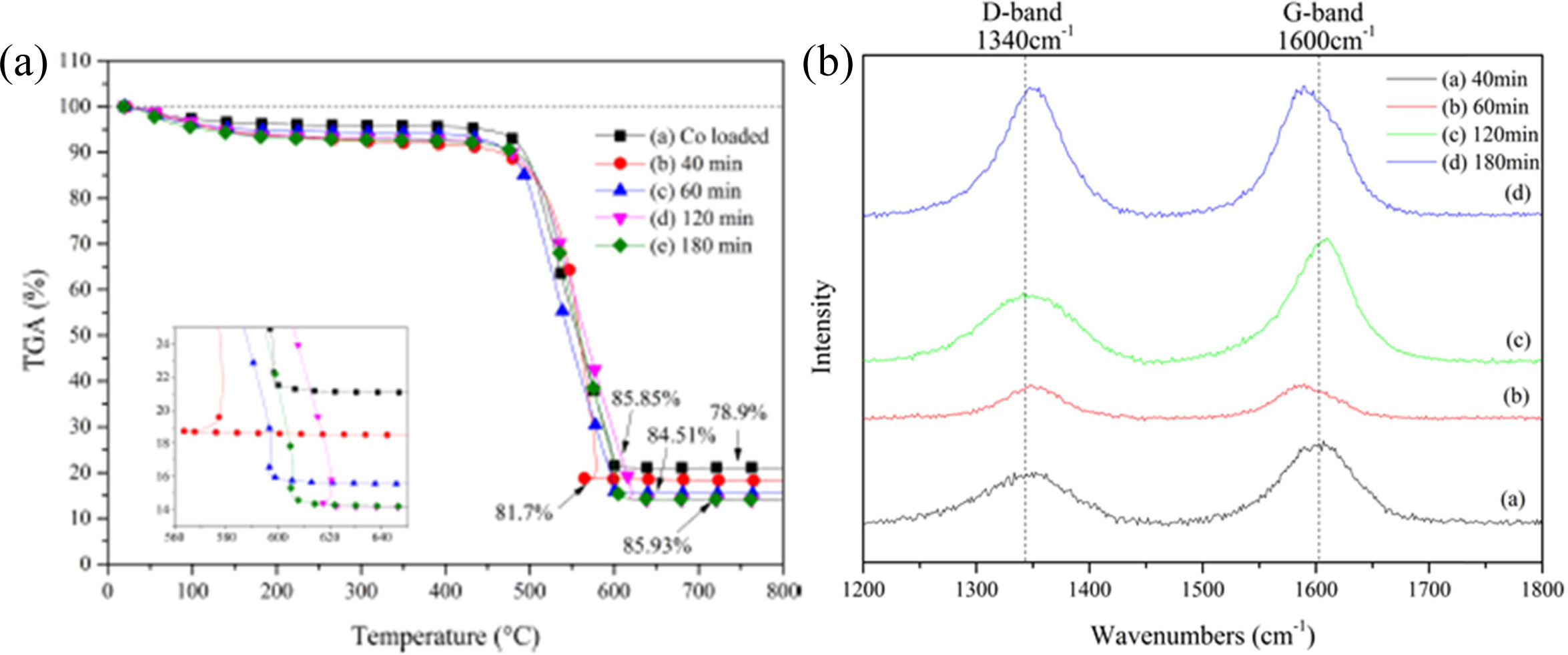

Fig. 17 shows the TGA curves of the CNTs grown on Co-LTA

BCM at 650 °C for (a) without CNTs, (b) 40 min, (c) 60 min, (d) 120 min, and

(e) 180 min, respectively. All samples represent an initial weight loss

tendency, which may occur through the loss of physically adsorbed water by the

zeolites until 195 °C. In the continuous increment of reaction time, all

samples undergo a weight loss pattern [165]. As compared with Fig. 17 (a), all

CNTs samples show a weight loss i.e. (b) 2.8 %, (c) 5.61 %, (d) 6.95 %, and (e)

7.03 %, respectively. These differences of weight loss can be explained by

carbon yield. The carbon yield from CNTs synthesized by metal containing CVD is

calculated as follows:

Carbon yield (%) = (mtot - mcat) / mcat × 100% (1)

where, mcat is the

initial catalyst amount (before reaction), and mtot

is the total sample weight after synthesis [166]. The TGA curves allow

estimation of the amount of carbon yield.

Fig. 17(b) shows the Raman spectra of the synthesized

CNTs. In these results, two strong peaks can be observed within the wavelengths

1,340 and 1,600 cm−1, designated as D- and G-bands, respectively.

These represent the presence of defects in the graphitic sheets, and

crystalline graphite carbon [166, 167]. The strength of the D-band relative to

the G-band is a measure of the amount of disorder in the CNTs and is used for

the qualitative analysis of nanotubes. The relative

intensities of the D- to G- bands (the ID/IG

ratio) revealed by the Raman spectroscopy is a measure of the degree of

graphitization. The ID/IG values are between 0.59 and

1.00, which is in accordance with those reported in the literature (ID/IG

= 0.7 ~ 1.3) for CVD grown MWCNTs [168, 169], revealing the

high-quality MWCNTs was grown.

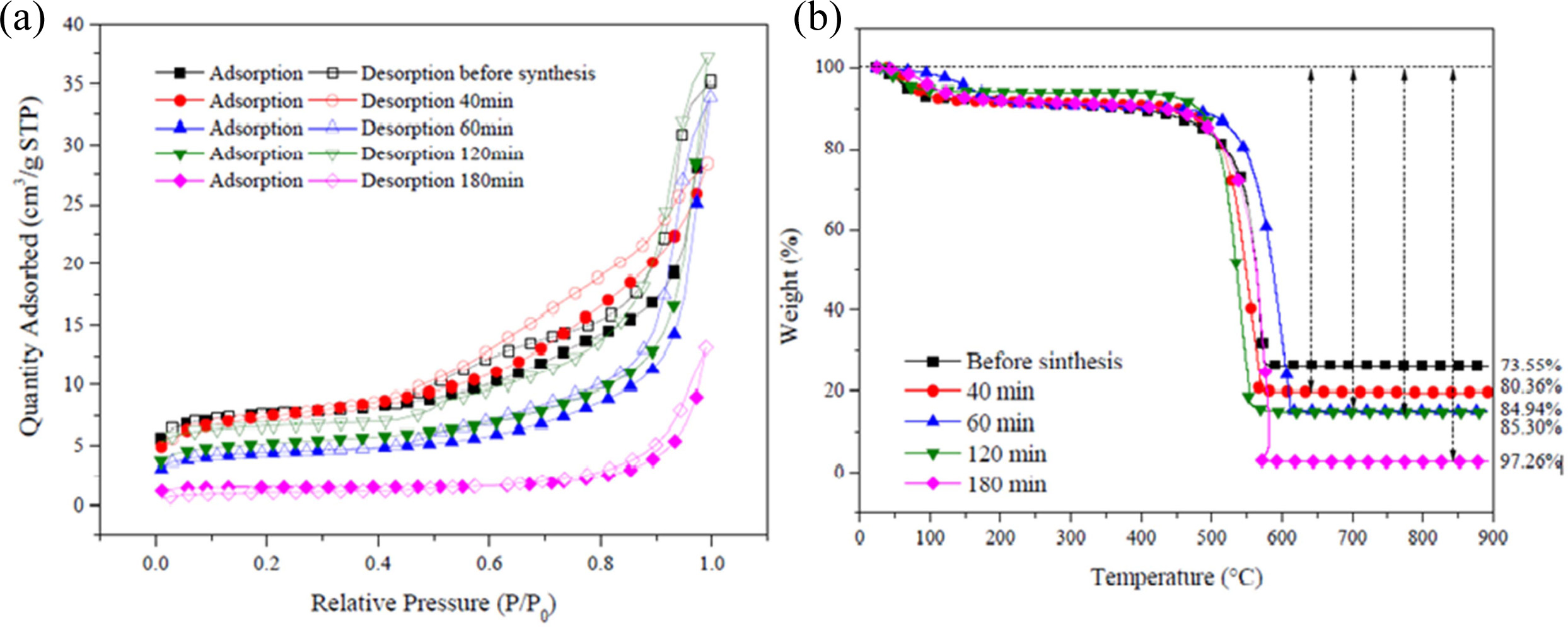

Fig. 18(a) shows the N2 adsorption/desorption

isotherms of Co-silicalite-1 BCM and CNTs grown at 650 °C for 40,

60, 120, and 180 min, respectively. The adsorption and desorption isotherms of

N2 for the Co loaded silicalite-1 on BCM and CNTs grown at

650 °C for (b) 40 min, (c) 60 min, (d) 120 min, and (e) 180 min are

clearly of type IV, according to the IUPAC classification

of adsorption isotherms. Type IV isotherms

characteristically show the simultaneous presence of micro- and mesopores. It

is evident that the adsorption capacities of CNTs were all increased with the

increase in reaction time [170-172]. All of the samples demonstrate

relatively high adsorption performance. Compared with Co-silicalited-1-BCM, the

adsorption capacity of CNTs silicalite-1 supported BCM is markedly

lower. For CNTs Co- silicalite-1-BCM, silicalite-1-BCM is the skeleton and is

coated on it, and then the silicalite-1 supported biomorphic carbon would be

the main adsorbent, as shown in Fig. 12(b).

Fig. 18(b) shows the TGA curves of the CNTs grown for 40,

60, 120, and 180 min at 650 °C, respectively. All CNTs samples represent an

initial weight loss tendency, which may occur through the loss of

physically adsorbed water by the silicalite-1 until 195 °C. In the subsequent heating

process, all samples undergo a two-step

weight loss pattern up to 97%. In the first step (458 ~ 633 °C

and 485 ~ 717 °C, respectively), the amorphous carbon has been combusted, while in the second step (≥ 633 and

717 °C, respectively), the MWCNTs have combusted until 800 °C.

After that, the samples maintain a weight loss pattern due

to biomorphic carbon combustion. The main reason for the

two-step pattern is that the decomposition of C2H2 on

metal catalysts leads to the formation of CNTs as amorphous carbon [173, 174].

All Raman spectra are dominated by two strong peaks at

1,340 and 1,620 cm-1.

The accepted terms for these two peaks are the D- and G-bands, respectively.

They are characteristic for disordered sp2-hybridised carbon

materials and have been observed in all reported Raman spectra of MWCNTs. The

D-band is formed by the defects in the graphite crystals, and by the finite

sizes of graphite crystallites in the material. Moreover, pyrolytic carbon

particles deposited on the nanotubes also contribute to the rise of D-band. The

G-band corresponds to the tangential stretching (E2g)

mode of highly oriented pyrolytic graphite (HOPG) and

indicates the presence of crystalline graphitic carbons in the MWCNTs. The

strength of the D-band relative to the G-band is a measure of the amount of

disorder in the CNTs and is used for qualitative characterizations of the

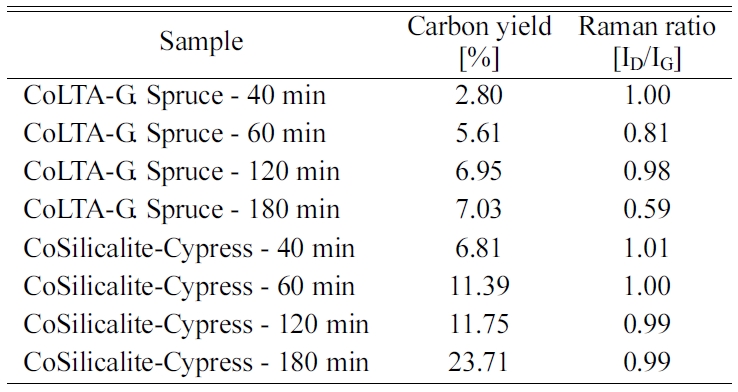

nanotubes [175, 176]. Table 3 shows the relative intensities of the D- to G-

bands (ID/IG ratio), as revealed by Raman spectroscopy, which

is a measure of the degree of graphitization. The carbon yield of 6.81 to

23.71% followed by BET ranging 4.31 to 22.24 m2/g was achieved with

the reaction time of 40 to 180 min, followed by the ID/IG

values from this work, which are between 0.99 and 1.01, which is

in accordance with that reported in the literature (ID/IG

= 0.97 ~ 1.00) for CVD-grown MWNTs [177, 178].

This finding can be attributed to the low permeability of

1.99 × 10–8 m2 compared to that of cypress

(Hinoki, 1.51 × 10–6 m2), which was tested

using Darcy’s law [179]. Table 4 summarizes the physical properties of the

Co-LTA and silicalite-1-BCM and CNTs grown at 650 °C for 40, 60, 120, and

180 min, such as carbon yield and Raman ratio.

|

Fig. 11 Process for synthesizing and coating LTA, silicalite-1 and mesoporous silica onto BCMs (Modified from ref. 156. Copyright 2018 Hanyang University). |

|

Fig. 12 FESEM images of cypress BCM coated with LTA (a), silicalite-1 (b), and mesoporous SiO2 (c) (Modified from ref. 156. Copyright 2018 Hanyang University). |

|

Fig. 13 XRD patterns (a) and N2-adsorption/desorption isotherms (b) of BCM coated with LTA, silicalite-1, and mesoporous silica [156] (Modified from ref. 156. Copyright 2018 Hanyang University). |

|

Fig. 14 Schematic diagram of growing Carbon nanotubes on BCM: Preparation of BCM (a), Template coating (b), and Carbon nanotube synthesis (c), respectively (Reproduced with permission from ref. 106. Copyright 2018 Inderscience Enterprises). |

|

Fig. 15 FESEM image of Co- catalyst loaded template coated BCM and synthesized CNTs (') on (a) LTA zeolite, (b) Silicalite-1, and (c) Mesoporous SiO2 template for 60 min at 650 oC. |

|

Fig. 16 HRTEM image of CNTs synthesis on Co-LTA(a) and Co-silicalite-1(b) coated BCM at 650 °C for (a) 60 min and (b) 120 min (Reproduced with permission from ref. 106. Copyright 2018 Inderscience Enterprises). |

|

Fig. 17 TGA curves (a) and Raman spectra (b) of CNTs synthesized on Co-LTA Gorman spruce BCM (Adapted from ref. 166. Copyright 2017 Hanyang University). |

|

Fig. 18 TGA curves(a) and BET surface area(b) of CNTs synthesis on silicalite-1 coated biomorphic carbon (Adapted from ref. 178. Copyright 2019 Hanyang University). |

|

Table 4 Quality of CNTs (Raman spectra) and Carbon Yield (TGA) with respect to the Reaction Time at 650 oC. |

Air and water pollution in industrial and metropolitan

areas is a threat to human health and natural resources, as millions of people

inhale polluted air, and particles in the air enter the body. Fine particles

can be trapped in the nostrils and can be in the hair at nano size below a

micron, but some fine particles can reach the lungs, and then remain in the lung cells,

causing serious diseases, such as lung

cancer or emphysema [180]. Clean air and water (no toxic chemicals and

pathogens) play a very important role in the human quality of life [181]. Water

and air are important sources of various food industries for maintaining good

health, including medicines [182]. In particular, it is difficult to remove

organisms such as bacteria and viruses from food, and much research is being carried out on the

contamination of inorganic substances

(e.g. heavy metal ions) from water, especially in the wastewater, metallurgy,

mining, and battery manufacturing industries [183]. Since these contaminants

can accumulate in living tissues, there is an increasing concern, and more

stringent regulations and standards for the discharge and removal of aquatic environments are being discussed. At present,

innovations and advances in

nanotechnology and nanomaterials can solve

many of the above-mentioned problems, in particular carbonaceous nanomaterial complexes. Individual

and bulk carbon-based nanomaterials have already paved the way for many

environmental applications. In particular, CNTs exhibit large absorption

properties, due to their high aspect ratio, and large specific surface area. They offer promise for applications in the

absorption, filtration, and

separation industries, in both gas and aqueous systems [180, 184].

- Air particulate filtration [185, 186]

- Biological contamination filtration [190, 191]

- Heavy metal ion adsorption [192, 193]

- Other applications [197, 198]

Air

particulate filtration

Heating, ventilation, and air conditioning (HVAC) filters

are ideal for dark, humid air cleaning. As conditions for bacteria

and malignant fungus, microorganisms become attached to the accumulated dust in

the filter, polluting the unpredictable air quality, as well as accumulating

the smell of dust in food. Nanofiber filter media are needed for

high-performance air purification, such as hospitals, medical facilities, and

laboratories [180]. In air filtration, especially in

laboratories, electronic component manufacturers, military

and government agencies, and food, pharmaceutical, and biotechnology companies,

contaminants are particles and mostly complex mixtures, which are generally

less than 1,000 μm in diameter [185]. Fiber filters are typically

fabricated from fibers with a diameter of about a few tens of micrometers,

which is a micrometer particle that enables high

efficiency removal of the sub-micrometer and has a relatively

low resistance to air flow. The filter is termed the most

penetrating particle size (MPPS), which is not as efficiently filtered as other

particles, and the fiber filter efficiency achieves the minimum value for this particle

size, which is generally between 0.1 and 0.5 μm [186, 187].

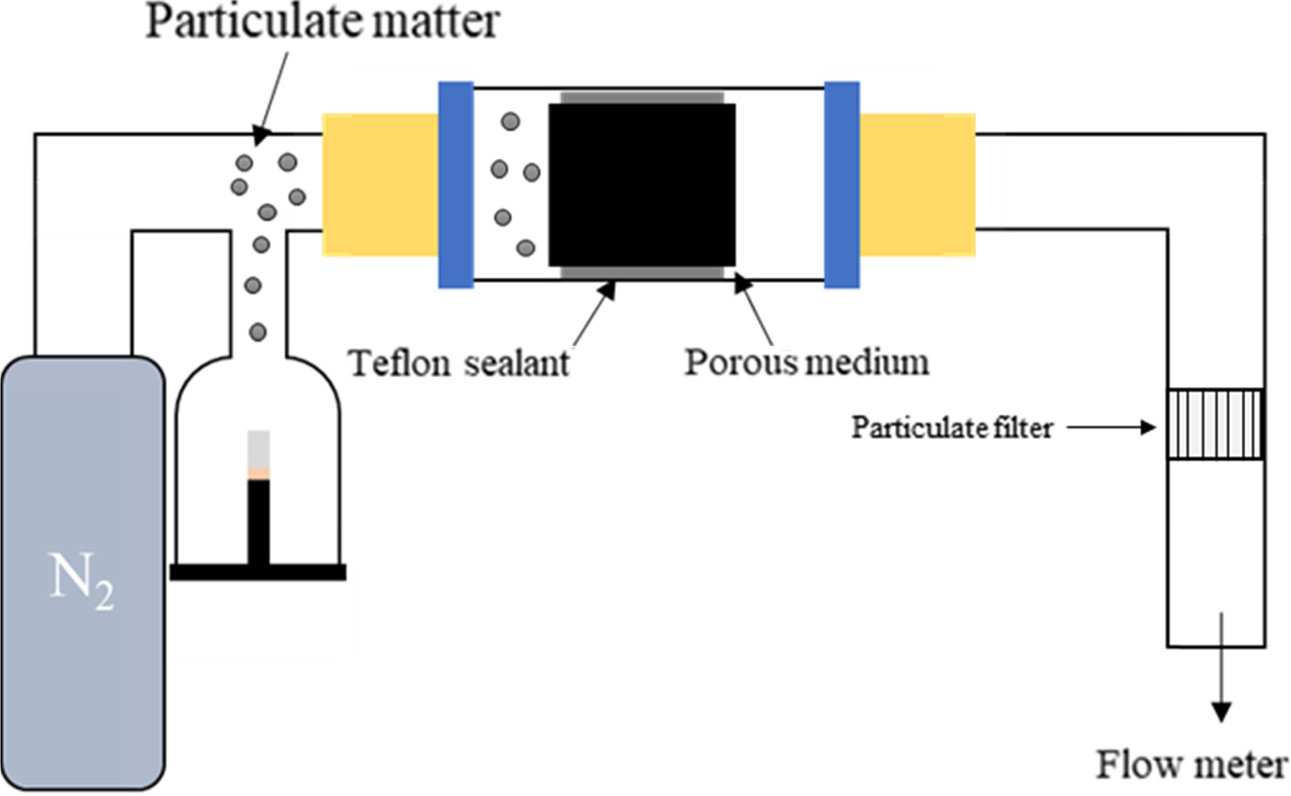

Park and Lee [188] grew CNTs 20 ~ 50 nm diameter using the CVD method

on micron-sized stainless steel fibers and evaluated the performance of air

particulate removal using sodium chloride (NaCl) as test particles, as shown in

Fig. 19. Web-like CNTs were fabricated to improve the efficiency from 75 to

98%. Park’s group reported similar results using fiberglass [189].

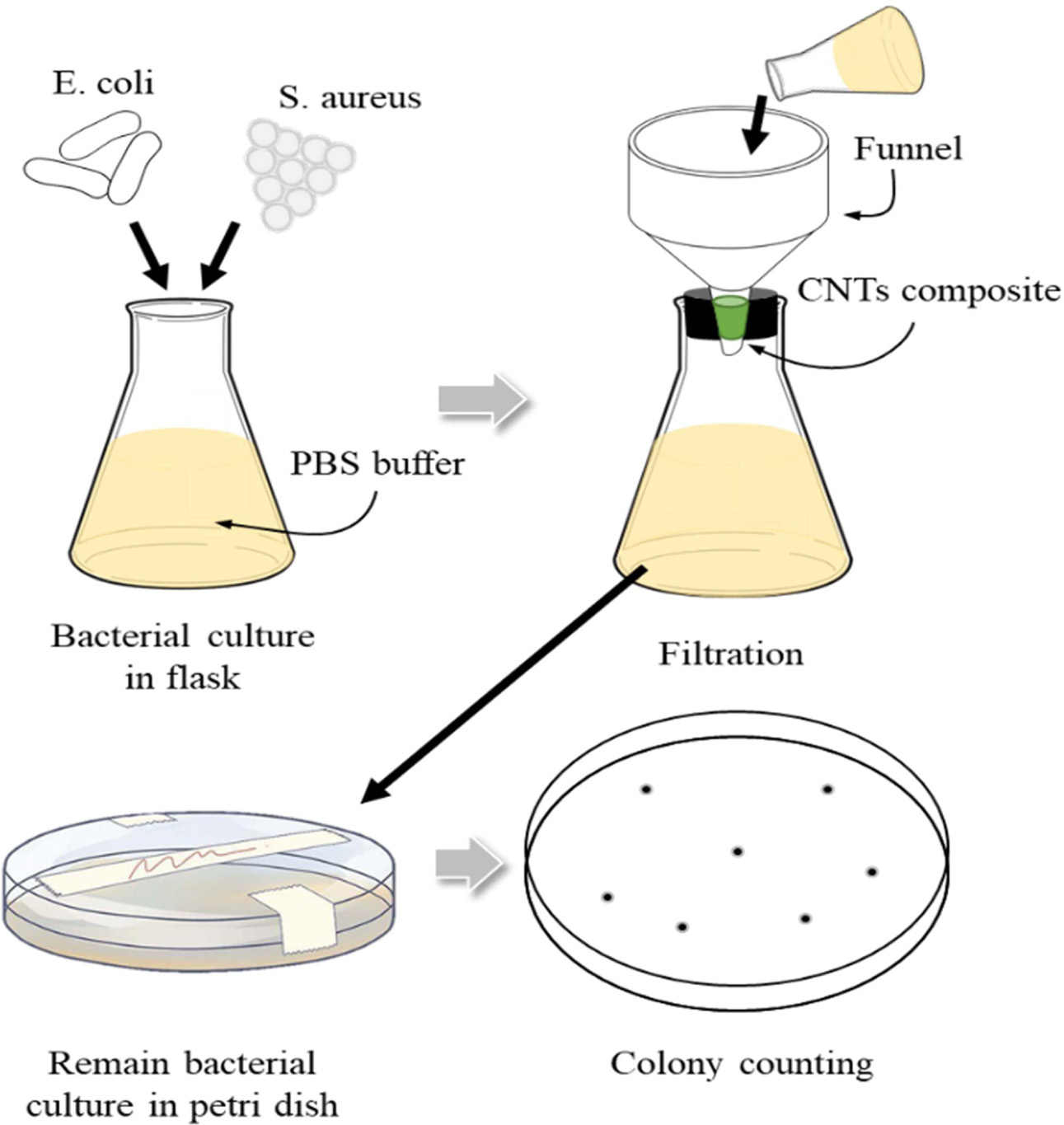

Biological

contamination filtration

Biological contaminants make up a significant portion of

drinking water, in terms of the number of pollutants

and the treatment probability. High-efficiency filtration

of contaminants is performed using ceramic or metal

membranes [180, 190]. The polymer membrane is fragile

and durable. In conventional membrane filters used for water filtration, the

adsorption of bacteria on the surface affects the physical

properties and is difficult to reuse. The use of CNTs in

membranes is also an effective way to create a practical hybrid filter with

excellent robustness for reuse. With high surface area and large aspect ratio,

high-density coagulated packed CNTs form a microporous and

mesoporous network with an appropriate pore size, which

adsorbs contaminants through physisorption [191, 192]. In

addition, the toxicity of microbial cells also plays a part

in the filtration performance of CNTs. The stability of CNTs at high temperatures

enables higher operating temperatures up to 400 °C. Compared with

conventional polymer membrane filters up to 52 °C,

these filters are very good, and for their reuse, simple filter

cleaning is sufficient for ultrasonication and autoclaving sterilization up to

121 °C for 30 minutes. Brady-Estevez et al. increased filter permeability by

immobilizing CNTs deposited on microporous ceramic filters with 5 µm pore size.

They demonstrated a filter to remove viral and bacterial pathogens

with very high efficiency [193]. Akasaka and Watari have

shown that moderately flexible SWCNTs and MWCNTs can be easily wound around the

curved surface of Streptococcus mutans, and used as a tool to remove nano-level

oral pathogens, as shown in Fig. 20 [194]. First, the CNTs was

dispersed in a solution containing bio-contaminants, the suspension was shaken

for a long time to achieve complete adsorption, and then the CNTs was removed

using a paper filter or a suitable membrane.

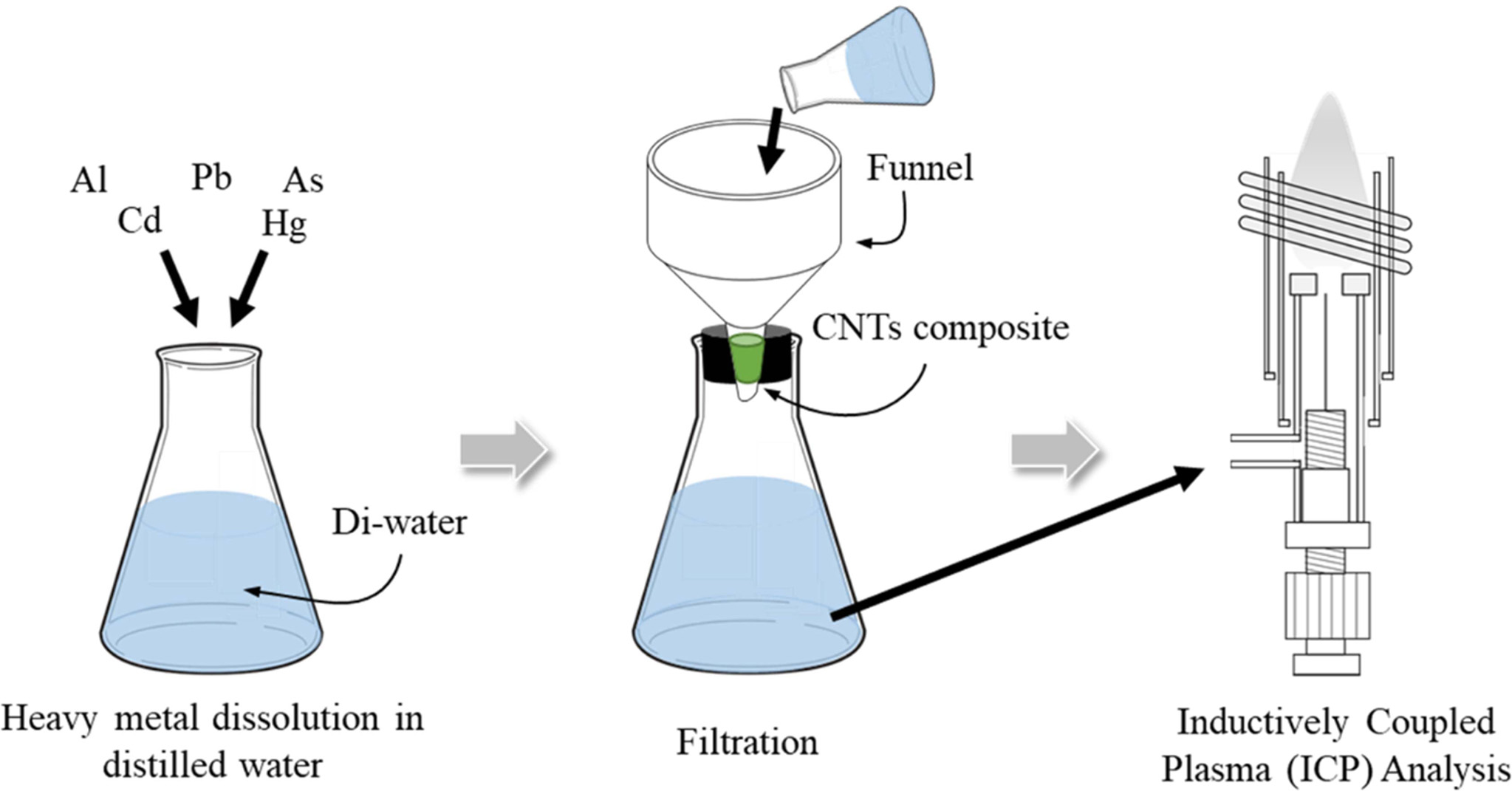

Heavy

metal ion adsorption

Water pollution caused by indiscriminate disposal of metal

ions has attracted worldwide attention [197]. In this regard, a number of

studies have attempted to use CNTs to remove such contaminants from wastewater.

Contaminants include Cu, Pb, Cd [195], Zn, Mn, Co [196], Ni [297], Cr [198], Hg

[199], and U [200] ions. Figure 21 shows that the adsorption mechanism of heavy

metals by CNTs is a chemisorption process. The chemical interaction between

metal ions and metal ions is dominated by the surface functionalities of CNTs formed

during oxidation rather than physical adsorption, which is

compared to electrostatic attraction and adsorption-precipitation

[201]. As a result, the chemical and thermal

treatments during the functionalization process have a leading influence on the

performance of CNTs for metal ion removal, and the adsorption

behavior is mainly determined by the nature and concentration of

the adsorbent surface functional group. Other terms and aspects of heavy metal

ion adsorption through CNTs synthesized and functionalized with different

adsorption capacities and different carbon sources and catalysts include

effective parameters. For example, increasing adsorption

temperatures result in a significant increase in adsorption

capacity [202, 203]. This is an endothermic reaction. As the mass of CNTs

increases, the adsorption rate of the metal increases. This is limited to a

certain value with an increase in the number of adsorption sites.

Other

applications

There are many other reports that have shown the

successful use of CNTs in filtering applications [180]. Sponges have been

successfully synthesized with CNTs by Gui et al., and could

clearly reflect the large adsorption properties of

these carbon clusters [204]. They produced

self-assembled and interconnected carbon nanotube backbone sponge-like bulk

materials close to airgels with > 99 % porosity and light density. Lee and

Baik also produced nanotube membrane filters that can affect the phase

separation of diesel and aqueous layers, surfactant stabilized emulsions, high

viscosity lubricants, and water emulsions [205]. They deposited a mesh-on-mesh

using an electron beam evaporator and made a filter on a

stainless-steel mesh using a sandwich type iron catalyst layer,

followed by a CVD process. Mainstream smoke (MS), published by Chen et al., has

a very high adsorption capacity of oxidized CNTs (O-CNTs) to nicotine and tar,

and adds about (20 ~ 30) mg to the filter tip of tobacco, to prevent

the influx of harmful substances [206].

|

Fig. 19 Schematic diagram of air filter evaluation of CNTs nanofilter. |

|

Fig. 20 Schematic of biological contamination filtration of CNTs nanofilter. |

|

Fig. 21 Schematic of the heavy-metal adsorption of CNTs nanofilter. |

The unique properties of CNTs, including high surface area

and strong Van der Waals forces at high aspect ratios, make them exceptional in

their ability to filter organic and inorganic contaminants on a

molecular basis. In particular, they exhibit a variety of

processing capacities to trap and fix contaminants in the pores of individual

CNTs during flocculation, and also to trap large-scale

pore-sized mesoporous networks with biological contaminants, such as bacteria

and viruses. A wide range of pore formation through the combination of CNTs and

porous ceramics can be advantageously used as a filter for gas through

physisorption. In particular, since the cytotoxicity of CNTs in microbial

treatment partially affects the filtration performance, an approach that can be

effectively applied in water as well as atmospheric filtration devices has been

studied. In this review, carbon nanotubes (CNTs) synthesized on metal-supported

template (LTA, silicalite-1, mesoporous SiO2 etc.) coated biomorphic

carbon materials (BCM) were achieved with both high quality, and high yield of carbons.

The amounts of MWCNTs were formed by the combination

of three different novel processing routes. Because of the uniform pore

structure, the template crystals can be located all over the BCM surface. Also,

owing to the high porosity template crystals, the acetylene

can supply carbon source to the catalytic metal nanoparticles

appropriately, to lead the growth of CNTs across the entire template. The

morphology of CNTs was influenced by reaction temperature. The

microstructure obtained at 700 °C exhibited

considerable wall thickness, and the widest inner hollow tube

structure; whereas that of CNTs obtained at 650 °C shows comparability thinner

outer wall and narrow inner hole. The maximum yield of

carbon was 23.71% at 650 oC for 180 min, but on comparison with

the Raman ratio, the synthesized CNTs were found to have better quality at (60

to 120) min, with a moderate yield of carbon. The ID/IG

ratio of Co-silicalite-1-BCM from Raman analysis was found between 0.97 and

1.00, which is in accordance with those reported in the Co-LTA-BCM for

CVD-grown MWNTs. Furthermore, the synthesized CNTs filter can be applied as a

filter for removing various pollutants. Especially, the filters are expected to

be used in HVAC, water quality and air purification through performance evaluation

such as air particulate, biological contamination and heavy

metal filtration.

This research was supported by the Basic Science Research

Program through the National Research Foundation of Korea (NRF), funded by the

Ministry of Education (201800790001) and special thanks for analysis support

and biomorphic carbon materials from Korea Institute of Energy Research (KIER).

- 1. F.S. Rojas, C.B. Ojeda, and J.M.C. Pavón, Am. J. Anal. Chem. 2[1] (2011) 66-74.

-

- 2. A. Zampieri, H. Sieber, T. Selvam, G.T. Mabande, W. Schwieger, F. Scheffler, M. Scheffler, and P. Greil, Adv. Mater. 17[3] (2005) 344-349.

-

- 3. Y. Shen, J. Agric. Food. Chem. 65[5] (2017) 995-1004.

-

- 4. S.Y. Kim, H.U. Kim, Y.H. Seong, I.S. Han, S.K. Woo, and S.H. Kim, J. Porous Mater. 25[2] (2018) 603-609.

-

- 5. J.G. Park, S.Y. Kim, Z. Wei, J.H. Jeon, S.Y. Kim, and I.J. Kim, J. Ceram. Proc. Res. 18[2] (2017) 161-165.

- 6. J. Li, Q. Xu, J. Wang, J. Jiao, and Z. Zhang, Ind. Eng. Chem. Res. 47[20] (2008) 7680-7685.

-

- 7. K.B. Choi, J.Y. Kim, S.M. Lee, K.H. Lee, and D.H. Yoon, J. Korean Ceram. Soc. 54[3] (2017) 257-260.

-

- 8. W. Zhao, B. Basnet, and I.J. Kim, J. Adv. Ceram. 1[3] (2012) 179-193.

-

- 9. S. Iijima and T. Ichihashi, Nat. 363[6430] (1993) 603-605.

-

- 10. C. Yu, L. Shi, Z. Yao, D. Li, and A. Majumdar, Nano. Lett. 5[9] (2005) 1842-1846.

-

- 11. K. Lee, S.Y. Shin, and Y.S. Yoon, J. Korean Ceram. Soc. 53[3] (2016) 376-380.

-

- 12. Y.L. Kim, J. Korean Ceram. Soc. 54[1] (2017) 66-69.

-

- 13. J. K. Holt, H. G. Park, Y. Wang, M. Stadermann, A. B. Artyukhin, C. P. Grigoropoulos, A. Noy, and O. Bakajin, Science 312[5776] (2006) 1034-1037.

-

- 14. Y. Zhao, H. Nakano, H. Murakami, T. Sugai, H. Shinohara, and Y. Saito, Appl. Phys. A. 85[2] (2006) 103-107.

-

- 15. V.K.K. Upadhyayula, S. Deng, M.C. Mitchell, and G.B. Smith, Sci. Total. Environ. 408[1] (2009) 1-13.

-

- 16. A.S. Brady-Estévez, S. Kang, and M. Elimelech, Small 4[4] (2008) 481-484.

-

- 17. A. Stafiej and K. Pyrzynska, Sep. Purif. Technol. 58[1] (2007) 49-52.

-

- 18. Y.H. Li, J. Ding, Z. Luan, Z. Di, Y. Zhu, C. Xu, D. Wu, and B. Wei, Carbon 41[14] (2003) 2787-2792.

-

- 19. Y.H. Li, Y.M. Zhao, W.B. Hu, I. Ahmad, Y.Q. Zhu, X.J. Peng, and Z.K. Luan, J. Phys. Conf. Series. 61 (2007) 698-702.

-

- 20. A. Srivastava, O.N. Srivastava, S. Talapatra, R. Vajtai, and P.M. Ajayan, Nat. Mater. 3[9] (2004) 610-614.

-

- 21. N. Halonen, A. Rautio, A.R. Leino, T. Kyllonen, G. Toth, J. Lappalainen, K. Kordas, M. Huuhtanen, R.L. Keiski, A. Sapi, M. Szabo, A. Kukovecz, Z. Konya, I. Kiricsi, P.M. Ajayan, and R. Vajtai, ACS. Nano 4[4] (2010) 2003-2008.

-

- 22. P.M. Ajayan, Chem. Rev. 99[7] (1999) 1787-1800.

-

- 23. W.Z. Li, J.G. Wen, Y. Tu, and Z.F. Ren, Appl. Phys. 73[2] (2001) 259-264.

-

- 24. D.J. Kim, S.M. Jeong, S.G. Yoon, C.H. Woo, J.I. Kim, H.G. Lee, J.Y. Park, and W.J. Kim J. Korean Ceram. Soc. 53[6] (2016) 597-603.

-

- 25. C. Weilach, C. Spiel, K. Föttinger, and G. Rupprechter, Surf. Sci. 605[15] (2011) 1503-1509.

-

- 26. K. An, N. Musselwhite, G. Kennedy, V.V. Pushkarev, L.R. Baker, and G.A. Somorjai, J. Colloid Interface Sci. 392 (2013) 122-128.

-

- 27. Y.M. Kim and I.J. Kim, J. Korean Ceram. Soc. 43[1] (2006) 1-3.

-

- 28. S.J. Park and D.G. Lee, Curr. Appl. Phys. 6[S1] (2006) e182-e186.

-

- 29. W. Zhao, S.D. Nam, A. Pokhrel, J. Gong, and I.J. Kim, J. Korean Ceram. Soc. 50[1] (2013) 1-17.

-

- 30. I.J. Kim, W. Zhao, X. Fan, J.H. Chang, and L.J. Gauckler, J. Ceram. Proc. Res. 11[2] (2010) 158-163.

- 31. Y. Yang, Z. Hu, Y.N. Lü, and Y. Chen, Mater. Chem. Phys. 82[2] (2003) 440-443.

-

- 32. K.S. Novoselov, A.K. Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos, I.V. Grigorieva, and A.A. Firsov, Science 306[5696] (2004) 666-669.

-

- 33. S. lijima and T. Ichihashi, Nat. 364[6439] (1993) 737-737.

-

- 34. K.W. Kolasiniski, in “Surface Science: Foundations of Catalysis and Nanoscience” (Wiely, 2012) p. 18.

-

- 35. A.P. Graham, G.S. Duesberg, W. Hoenlein, F. Kreupl, M. Liebau, R. Martin, B. Rajasekharan, W. Pamler, R. Seidel, W. Steinhoegl, and E. Unger, Appl. Phys. A. 80[6] (2005) 1141-1151.

-

- 36. R. Saito, in “Physical Properties of Carbon Nanotubes” (World Scientific Publishing Company, 1998) p. 36.

-

- 37. G.D. Nessim, Nanoscale. 2[8] (2010) 1306-1323.

-

- 38. D. Dass, R. Prasher, and R. Vaid, Int. J. Comput. Eng. Res. 2[5] (2012) 1447-1457.

- 39. Z. Xu, X. Bai, Z. L. Wang, and E. Wang, J. Am. Chem. Soc. 128[4] (2006) 1052-1053.

-

- 40. H.W. Zhu, C.L. Xu, D.H. Wu, B.Q. Wei, R. Vajtai, and P.M. Ajayan, Science 296[5569] (2202) 884-886.

-

- 41. H. Kataura, Y. Kumazawa, Y. Maniwa, I. Umezu, S. Suzuki, Y. Ohtsuka, and Y. Achiba, Synth. Met. 103[1] (1999) 2555-2558.

-

- 42. B.I. Kharisov. O.V. Kharissova, and U. Ortiz-Mendez, in “Handbook of Less-Common Nanostructures” (CRC Press, 2012) p. 31.

-

- 43. P.G. Collins, A. Zettl, H. Bando, A. Thess, and R.E. Smalley, Science 278[5335] (1997) 100-102.

-

- 44. M. Nihei, A. Kawabata, D. Kondo, M. Horibe, S. Sato, and Y. Awano, Jpn. J. Appl. Phys. 44[4A] (2005) 1626-1628.

-

- 45. R.H. Baughman, C. Cui, A.A. Zakhidov, Z. Iqbal, J.N. Barisci, G.M. Spinks, G.G. Wallace, A. Mazzoldi, D.D. Rossi, A.G. Rinzler, O. Jaschinski, S. Roth, and M. Kertesz, Science 284[5418] (1999) 1340-1344.

-

- 46. C. Liu, Y.Y. Fan, M. Liu, H.T. Cong, H.M. Cheng, and M.S. Dresselhaus, Science 286[5442] (1999) 1127-1129.

-

- 47. C. Liu, Y. Tong, H.M. Cheng, D. Golberg, and Y. Bando, Appl. Phys. Lett. 86[22] (2005) 223114.

-

- 48. J. Kong, E. Yenilmez, T.W. Tombler, W. Kim, H. Dai, R.B. Laughlin, L. Liu, C.S. Jayanthi, and S.Y. Wu, Phys. Rev. Lett. 87[10] (2001) 106801.

-

- 49. C. Zhou, J. Kong, and H. Dai, Appl. Phys. Lett. 76[12] (2000) 1597-1599.

-

- 50. D. Yokoyama, T. Iwasaki, K. Ishimaru, S. Sato, T. Hyakushima, M. Nihei, Y. Awano, and H. Kawarada, Jpn. J. Appl. Phys. 47[4] (2008) 1985-1990.

-

- 51. A. Javey, J. Guo, Q. Wang, M. Lundstrom, and H. Dai, Nat. 424 (2003) 654-657.

-

- 52. P.G. Collins, M.S. Arnold, and P. Avouris, Science 292[5517] (2001) 706-709.

-

- 53. S. Frank, P. Poncharal, Z.L. Wang, and W.A. Heer, Science 280[5370] (1998) 1744-1746.

-

- 54. A. Naeemi and J.D. Meindl, IEEE Electron. Device. Lett. 27[5] (2006) 338-340.

-

- 55. H.J. Li, W.G. Lu, J.J. Li, X.D. Bai, and C.Z. Gu, Phys. Rev. Lett. 95[8] (2005) 086601.

-

- 56. J.P. Lu, Phys. Rev. Lett. 79[7] (1997) 1297-1300.

-

- 57. J.P. Salvetat, J.M. Bonard, N.H. Thomson, A.J. Kulik, L. Forró, W. Benoit, and L. Zuppiroli, Appl. Phys. A. 69[3] (1999) 255-260.

-

- 58. M.F. Yu, B.S. Files, S. Arepalli, and R.S. Ruoff, Phys. Rev. Lett. 84[24] (2000) 5552-5555.

-

- 59. N. Yao, and V. Lordi, J. Appl. Phys. 84[4] (1998) 1939-1943.

-

- 60. G. Zhou, W. Duan, and B. Gu, Chem. Phys. Lett. 333[5] (2001) 344-349.

-

- 61. Z. Yao, C.C. Zhu, M. Cheng, and J. Liu, Comput. Mater. Sci. 22[3] (2001) 180-184.

-

- 62. B.G. Demczyk, Y.M. Wang, J. Cumings, M. Hetman, W. Han, A. Zettl, and R.O. Ritchie, Mater. Sci. Eng. A. 334[1] (2002) 173-178.

-

- 63. J. Hone, M. Whitney, and A. Zettl, Synth. Met. 103[1] (1999) 2498-2499.

-

- 64. E. Pop, D. Mann, Q. Wang, K. Goodson, and H. Dai, Nano. Lett. 6[1] (2006) 96-100.

-

- 65. P. Kim, L. Shi, A. Majumdar, and P.L. McEuen, Phys. Rev. Lett. 87[21] (2001) 215502.

-

- 66. R.H. Fowler and L. Nordheim, Proc. R. Soc. London. Ser. A. 119[781] (1928) 173-181.

-

- 67. S. Fan, M.G. Chapline, N.R. Franklin, T.W. Tombler, A.M. Cassell, and H. Dai, Science 283[5401] (1999) 512-514.

-

- 68. H. Zhu, J. Wei, K. Wang, and D. Wu, Sol. Energy Mater. Sol. Cells 93[9] (2009) 1461-1470.

-

- 69. E. Kymakis, I. Alexandrou, and G.A.J. Amaratunga, J. Appl. Phys. 93[3] (2003) 1764-1768.

-

- 70. A. Kongkanand, R.M. Domínguez, and P.V. Kamat, Nano. Lett. 7[3] (2007) 676-680.

-

- 71. C. Journet, W.K. Maser, P. Bernier, A. Loiseau, M.L. de la Chapelle, S. Lefrant, P. Deniard, R. Lee, and J.E. Fischer, Nat. 388 (1997) 756-758.

-

- 72. Y. Saito, K. Nishikubo, K. Kawabata, and T. Matsumoto, J. Appl. Phys. 80[5] (1996) 3062-3067.

-

- 73. W. Krätschmer, L.D. Lamb, K. Fostiropoulos, and D.R. Huffman, Nat. 347[6291] (1990) 354-358.

-

- 74. B.I. Yakobson and R.E. Smalley, Am. Sci. 85[4] (1997) 324-337.

- 75. T. Guo, P. Nikolaev, A. Thess, D.T. Colbert, and R.E. Smalley, Chem. Phys. Lett. 243[1] (1995) 49-54.

-

- 76. A.G. Rinzler, J. Liu, H. Dai, P. Nikolaev, C.B. Huffman, F.J. Rodríguez-Macías, P.J. Boul, A.H. Lu, D. Heymann, D.T. Colbert, R.S. Lee, J.E. Fischer, A.M. Rao, P.C. Eklund, and R.E. Smalley, Appl. Phys. A. 67[1] (1998) 29-37.

-

- 77. Y. Zhang and S. Iijima, Appl. Phys. Lett. 75[20] (1999) 3087-3089.

-

- 78. W. Zhao, D.N. Seo, H.T. Kim, and I. J. Kim, J. Ceram. Soc. Jpn. 118[1383] (2010) 983-988.

-

- 79. K.P. De Jong, and J.W. Geus, Catal. Rev. 42[4] (2000) 481-510.

-

- 80. Z.F. Ren, Z.P. Huang, D.Z. Wang, J.G. Wen, J.W. Xu, J.H. Wang, L.E. Calvet, J. Chen, J.F. Klemic, and M.A. Reed, Apply. Phys. Lett. 75[8] (1999) 1086-1088.

-

- 81. Z.F. Ren, Z.P. Huang, J.W. Xu, J.H. Wang, P. Bush, M.P. Siegal, and P.N. Provencio, Science 282[5391] (1998) 1105-1107.

-

- 82. Z.P. Huang, J.W. Xu, Z.F. Ren, J.H. Wang, M.P. Siegal, and P.N. Provencio, Appl. Phys. Lett. 73[26] (1998) 3845-3847.

-

- 83. E.T. Thostenson, Z. Ren, and T.W. Chou, Compos. Sci. Technol. 61[13] (2001) 1899-1912.

-

- 84. J. Kong, A.M. Cassell, and H. Dai, Chem. Phys. Lett. 292[4] (1998) 567-574.

-

- 85. J.H. Hafner, M.J. Bronikowski, B.R. Azamian, P. Nikolaev, A.G. Rinzler, D.T. Colbert, K.A. Smith, and R.E. Smalley, Chem. Phys. Lett. 296[1] (1998) 195-202.

-

- 86. M. Sarikaya and I.A. Aksay, Mater. Res. Soc. Symp. Proc. 255 (1992) 293-307.

-

- 87. P. Calvert, MRS Bull. 17[10] (2013) 37-40.

- 88. M. Sarikaya, Microsc. Res. Tech. 27[5] (1994) 360-375.

-

- 89. J.E. Mark and P.D. Calvert, Mater. Sci. Eng. C. 1[3] (1994) 159-173.

-

- 90. C.E. Byrne and D.C. Nagle, Carbon 35[2] (1997) 259-266.

-

- 91. E. Auer, A. Freund, J. Pietsch, and T. Tacke, Appl. Catal. A. 173[2] (1998) 259-271.

-

- 92. J.M. Gatica, A.L. García-Cabeza, M.P. Yeste, R. Marín-Barrios, J.M. González-Leal, G. Blanco, G.A. Cifredo, F.M. Guerra, and H. Vidal, Chem. Eng. J. 209[15] (2016) 174-184.

-