- Optimization of process parameters in friction stir welding of aluminium matrix SiC-Al2O3 composites by genetic algorithm

P. Gopi Krishnana,*, B. Suresh Babub and K. Sivac

aAssistant Professor, Department of Mechanical Engineering, Dr.N.G.P. Institute of Technology, Coimbatore, Tamil Nadu, India

bAssistant Professor, Department of Mechanical Engineering, Sri Krishna College of Technology, Coimbatore, Tamil Nadu, India

cProfessor, Department of Mechanical Engineering, Hindusthan College of Engineering and Technology, Coimbatore, Tamil Nadu, India

Friction stir welding (FSW)

grabs more attention since the past decade among the researchers worldwide due

to its excellent characteristics such as no emission of fumes, no filler

material, comparatively economical and so on. Friction stir welding is

effectively used in bringing better joint without any appreciable defects in

light materials such as Aluminium, Magnesium etc., Experiments in FSW of

materials with high density such as steel, copper alloys etc., have also been

tried out. The selection of proper welding parameters determines a good

weldment. In this work, Aluminium matrix hybrid composite was manufactured

through stir casting with the matrix AA7010 and reinforcements SiC and Al2O3.

The hybrid composite workpieces were subjected to friction stir welding process

by varying the process parameters such as tool rotation speed, welding speed

and axial force using Taguchi L27 orthogonal array. Tensile strength of FS

welded composite was examined and regression analysis was done. Genetic

Algorithm technique was used to optimize the weld tensile strength within the

design space of 53 = 125 alternatives of parametric

combinations. The study focuses on the improvement of the tensile strength of

the welded specimens.

Keywords: Hybrid composite, Friction stir welding, Optimization, Genetic algorithm, Tensile strength

Composite materials gain more interest among the researchers

across the globe due to their attractive properties that suit the requirements.

The properties can be easily tailor-made according to the requirements in a

specific application. The mechanical properties of any matrix can be

modified by the addition of reinforcements with it

thereby enhancing the effectiveness of the material for the application. The

major advantage of composite materials over alloys is the incorporation of

anisotropic nature that leads to different physical and mechanical properties

of materials along different axes. Aluminium has many distinct properties such

as light weight, good formability, ductile, malleable and castable

and so on. Aluminium is used in many applications ranging from the household

vessels to space vehicles. Aluminium in composite form is used widely in the

skins of aircrafts’ wing upper and lower structures. Aluminium alloys are used

for both the structures which are primarily joined by the rivets that add up

the total weight of the aircraft resulting in the higher fuel consumption. In

order to reduce the weight of the wing structure, the welding process that does

not affect the homogeneity of the structure is required [1]. The wings of

aircraft carry the bending loads and moments, the direction of which subject to

change during flight and idle conditions. The tensile strength

is the key component for the wing structure to effectively transfer the

load to the fuselage.

Ghosh et al. [2] fabricated LM6 Aluminium alloy reinforced

with 7.5% SiC to observe the tribological characteristics that affect the

surface integrity of the machined surface using Taguchi L27

design. The test results show that the wear parameters such as time,

load and sliding speed have significant effects on the tribological

behaviour. Li-na et al. [3], investigated the influence of stirring time and

stirring temperature for the production of AA6061-ABOw—SiCp hybrid composite. The

results show that there exists a homogenised reinforcement

distribution and hence, better tensile strength was obtained at the decreased

stir temperature and increased stir time (640 oC and

30 min respectively). A study on the wear behaviour of Coconut shell

ash particulate (CSA) reinforced Aluminium Matrix composite

reveals that the incorporation of the reinforcements opposes the forces causing

wear on the composites [4]. When the load is increased, the CSA particles

increase the wear resistance of the composite. Many researchers have

tried out different techniques for the manufacturing of Aluminium

matrix composites. Methods such as Powder metallurgy, Rheocast technique and in

situ casting are used for the production of Al6061-AlN composites [5, 6].

Squeeze cast Al-Si-Mg matrix beryl composites show increase in the tensile

strength and wear resistance compared to the gravity cast method. The optimum

combination of weld speed reduction and rotary speed rise in the FS welding of

AA7039 alloy was estimated and the mechanical properties are analysed with the

different combinations in the work carried out by Sharma [7].

Lakshminarayananan et al. [8] employed Taguchi L9 orthogonal array during the

welding of RDE-40 Aluminium alloy. The results indicate that the rotational

speed, welding speed and axial force are the significant parameters in deciding

the tensile strength of the joint. Al5186 and mild steel are joined through FSW

by assigning the range of values for tool traverse speed, Plunge depth, tilt

angle and tool pin geometry [9]. The results show that the intermetallic

compounds tend to form during the low weld speed and get reduced during high

weld speed. The work by Kasman et al., conclude that the process parameters

have the greater influence over the strength of the weld [10]. Serio et al.,

used the infrared cameras to assess the correlation between the thermal

behaviour of joints and the process parameters for monitoring of the

quality of joints [11]. Vijayan and Rao [12] employed two

computational approaches, genetic algorithm and simulated

annealing algorithm in the dissimilar FSwelding of

AA6061-AA2024. The results conclude that the use of the computational

approaches influences the tensile properties significantly although

considerable number of iterations and substantial amount of time were

required to achieve the optimum parameter combinations. Hsieh and

Chen [13] combined TRIZ methodology in friction stir welding and concluded that

TRIZ in FSW will be used to establish correlation between parameters and will

serve as references to subsequent designers which in turn shorten R&D duration.

Ho et al. [14] proposed IHTGA (Intelligent hybrid Taguchi-genetic algorithm)

that performed Taguchi method between the crossover operation of GA, where the

genes for crossover are selected intelligently using Taguchi to get the

enhanced performance results in the optimization of bearing offsets

and shaft alignment in a marine vessel propulsion system.

Parka et al. [15] fabricated WC-10% Co using SPS process which was utilized to

improve the weld conditions of SS400 steel. Lina et al. [16] used Taguchi L18

array to optimize the machining parameters of EDM on zirconium dioxide and

aluminum oxide. The results clearly indicAted the impact of peak current and

pulse duration on material removal rate and surface roughness. Kamal et al.

[17] arrived the better combination of friction stir welding process parameters

in fabrication of aluminium alloy joints (cryorolled AA2219) using artificial

neural network.

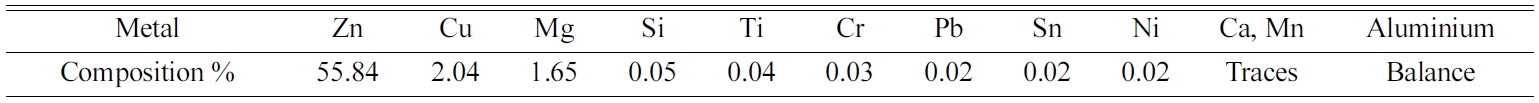

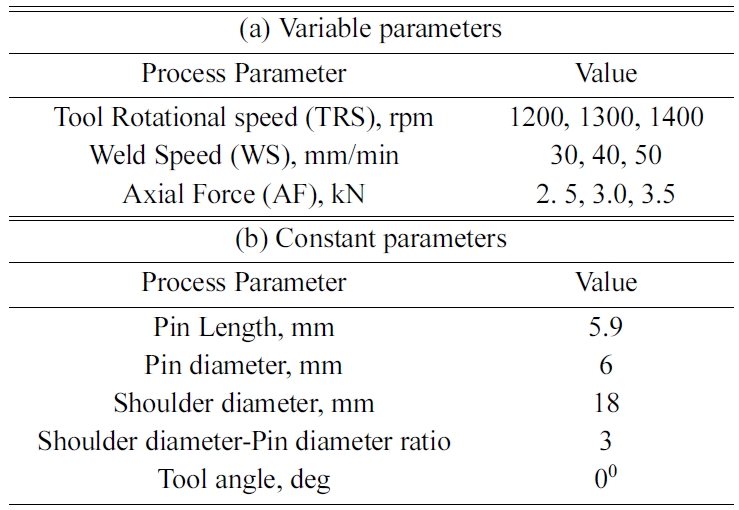

Preparation

of composite

AA7010-SiC-Al2O3 Hybrid Composite is

manufactured prior to the friction stir welding

process. The composition and mechanical properties of AA7010

alloy are listed in Table 1 and 2. AA7010 is one of the heat treatable

aluminium alloy with better properties in 7XXX alloys such as high

strength-to-weight ratio, comparatively high strength, high fatigue strength,

good resistance to corrosion and so on. The alloy is being replaced in the

components of rib and wing structures in aircrafts. Stir casting

technique was used to manufacture the composite. Aluminium

billets placed in a graphite crucible were heated to temperature of around

730 oC to be melted. Meanwhile, the reinforcements SiC and Al2O3

each 10% were preheated to 900 oC in a Muffle

furnace for a soaking time of one hour to remove the moisture content.

Mg powder of 1% by weight was added into the melt

to improve the wettability factor of reinforcements. The

reinforcement particles were added using a feeder through the vortex created by

stir action in the molten metal. The molten mix was poured into stainless steel

mould of dimension 100 mm × 50 mm × 7 mm, which was preheated to around

250 oC to promote gradual heat dissipation from the melt.

Genetic

algorithm

A genetic algorithm (GA) is an effective optimization tool

for solving constrained and unconstrained optimization problems

based on theory of natural genetics and natural selection process that

replicates the biological evolution. GA is particularly suitable for deriving

the better optimal combinations of process parameters in a potentially large

space through navigation. GA differs from the conventional strategies and

algorithms in obtaining the optimal solutions. Many conventional algorithms

provide the limited solutions whereas GA searches in a huge search space and

comes up with lot of local solutions arrives the best solution among them. Every

optimization problem converges based on a fitness function

that is dependent on a number of variables. In the present

work, GA is designed to maximize the fitness function of

the variables. To start the optimization, GA requires the encoding of real time

parameters into genetic parameters. Once the genetic parameters are assigned,

the required fitness functions will be evaluated from the

final optimal parameters. GA starts with the evolution of population which usually

starts from a population of randomly generated individuals. The population in

each iteration is called as generation. The fitness of every individual in

every generation is evaluated. The fitness

is the desired value of the objective

function in the optimization problem being solved. The fit individuals deserve

to be selected to next generation and a few selected individual's genome is

modified to form a new generation through genetic operations such as

reproduction (selection), cross over and mutation. In selection or reproduction phase, a section of the

existing population is selected to

breed and a new generation is formed through the fitness function evaluation.

The fit individual is more likely to

be selected to next generation.

Several methods provide the fitness value for every individual which is a

time-consuming process, whereas GA picks the individuals in a generation

randomly to come up with the best local solution for the particular generation.

The next phase, crossover operator is a genetic operator

that combines coding of two parents to produce a new coding called

as offspring. The strategy behind crossover is that the

new offspring is better than both of the parents by taking the best

characteristics from each of the parents. Crossover occurs during

evolution according to a user definable crossover probability between

0.5-0.99. Cross over is designed in such a way to occur in the predefined site

of the codings. For instance, cross over may be a Single point,

N-point, Uniform, Arithmetic, Partially mapped, Order or Cycle

cross over types. The third phase, mutation is one of the genetic operator

which is used to change only one bit in a coding so as to provide the diversity

in the generation. Mutation rate is generally selected a little lower to ensure

that the variation of chromosomes bring much better offspring. The product of

number of bits, number of experiments taken in the iteration and mutation rate

is taken as the number of change of bits in that generation. Mutation can

be classified as random, swap, scramble or inversion type.

Once the mutation is performed, the fitness function for

the individuals is evaluated for the offspring. The better offspring in the

current generation deserve to be selected mostly in the next

generation. Thus the iteration process continues in a cycle and

gets terminated until all the individual parameter settings are completed. The

coding with the optimal setting is selected according to the fit value. As the

GA is programmed in such a way to select the maximum fitness value, the optimal

parameter setting will be obtained. Thus the GA gets terminated after the

desired fitness is obtained in the cycles.

Friction

stir welding

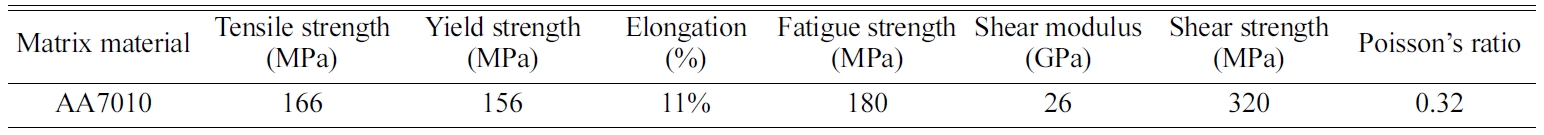

Trial welds were tried out to find the range of FSW

process parameters that fetch good welding results. The parameters

and their range were selected as: Tool rotation speed

(TRS) 1,200-1,400 revolutions/minute, Weld speed (WS) 30-50

mm/minute and Axial Force (AF) 2.5-3.5 kN. Butt joint configuration was

selected to fabricate the FSW joints. A non-consumable square tool, made of

high carbon high chromium steel, was used to fabricate FSW joints in vertical

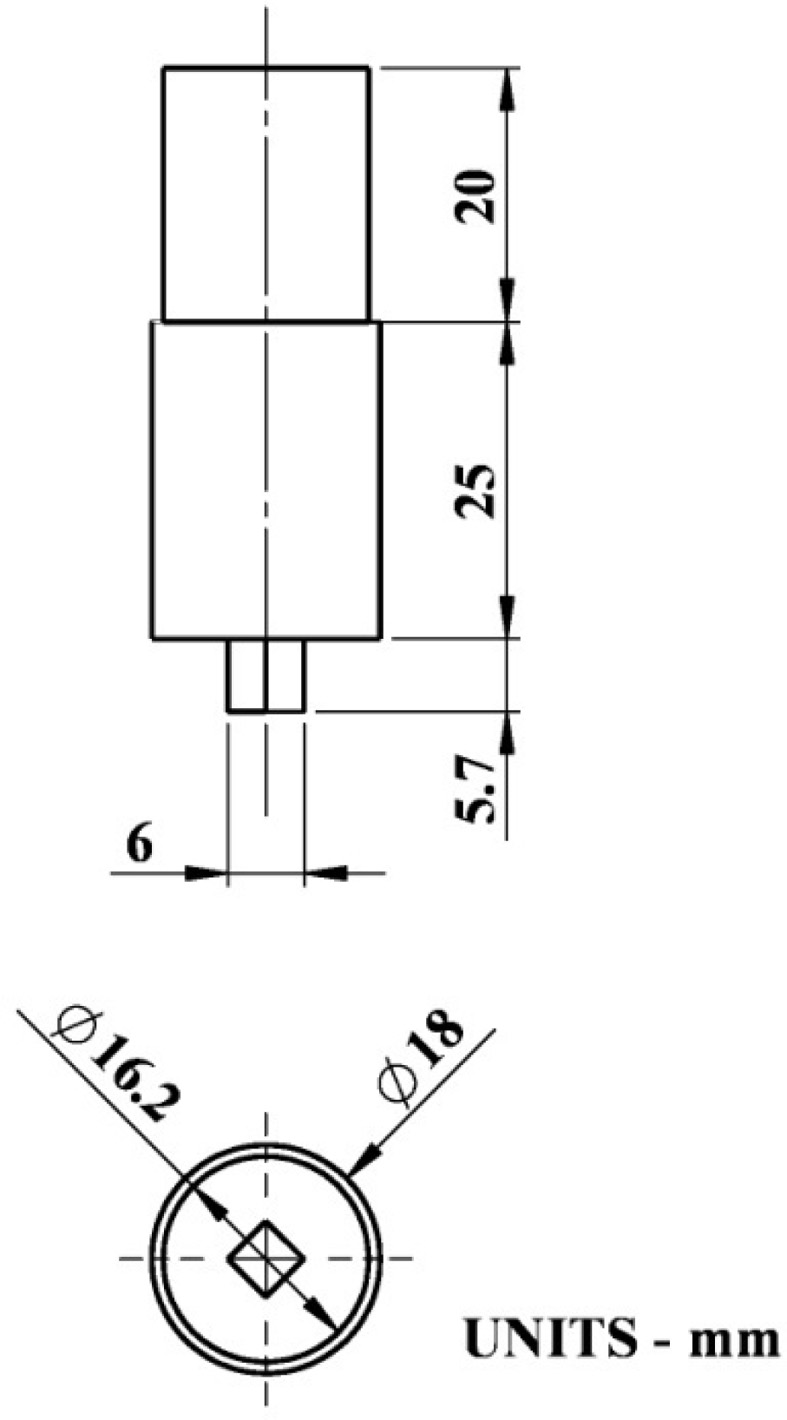

milling machine. The dimensions of the FSW tool are given in Fig. 1. Taguchi

design is used to find the proper control factor settings against relatively

uncontrollable noise factors. Signal-to-Noise ratio is the effective measure

used to evaluate the robustness of the design that indicates the minimum variation

against noise. The higher Signal-to-noise ratio indicates the effectiveness of

control factor settings that minimize the noise factor effects. For the design

of 3 parameters with each 3 levels, L27 orthogonal array is

selected to carry out the experiments. The process parameters of FSW are shown

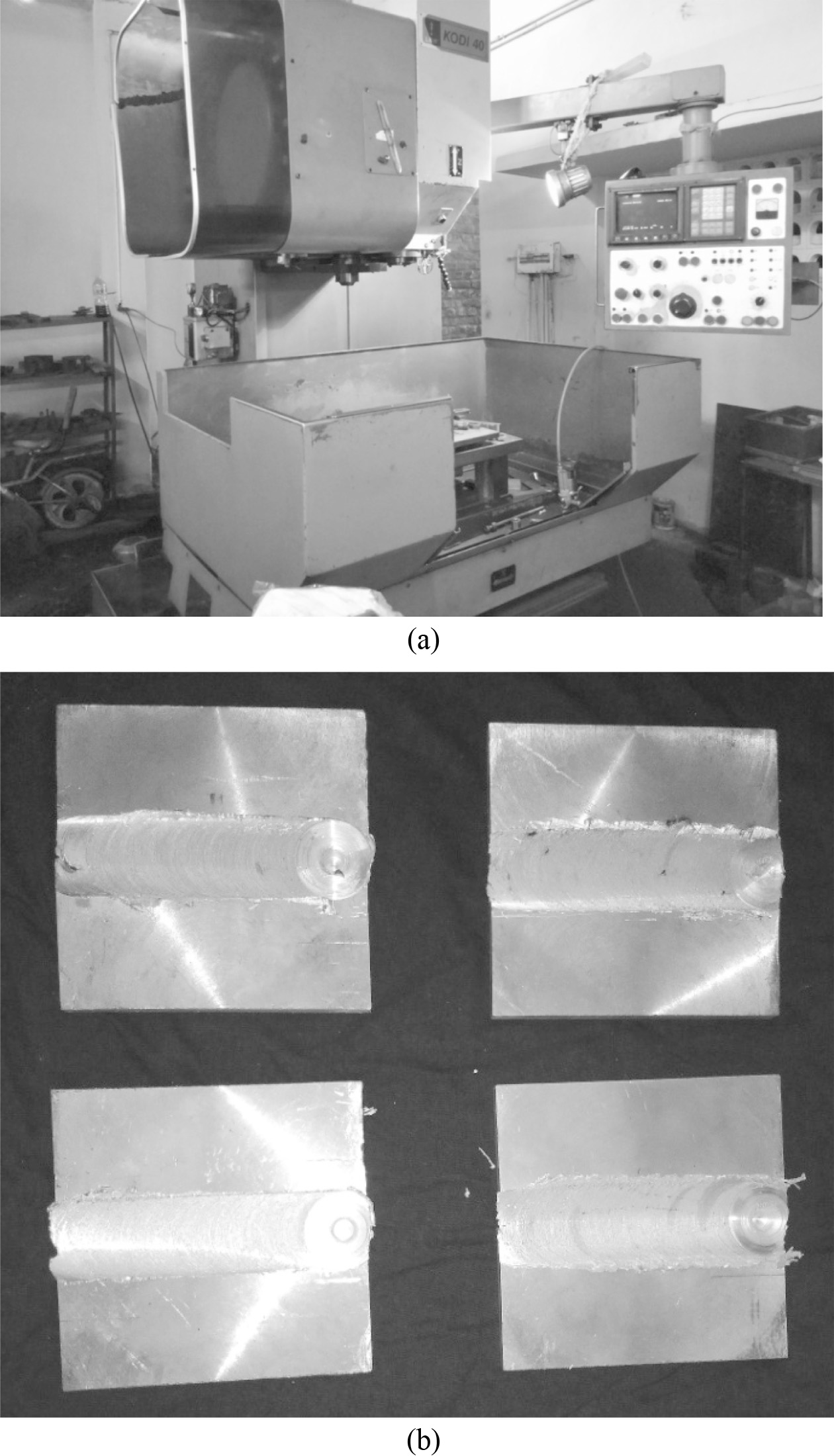

in Table 3. The FSW machine and the weld specimen are shown in Fig. 2. Table 2

|

Fig. 1 FSW tool dimensions. |

|

Fig. 2 (a) FSW machine and (b) welded specimens. |

Taguchi

design and ANOVA results

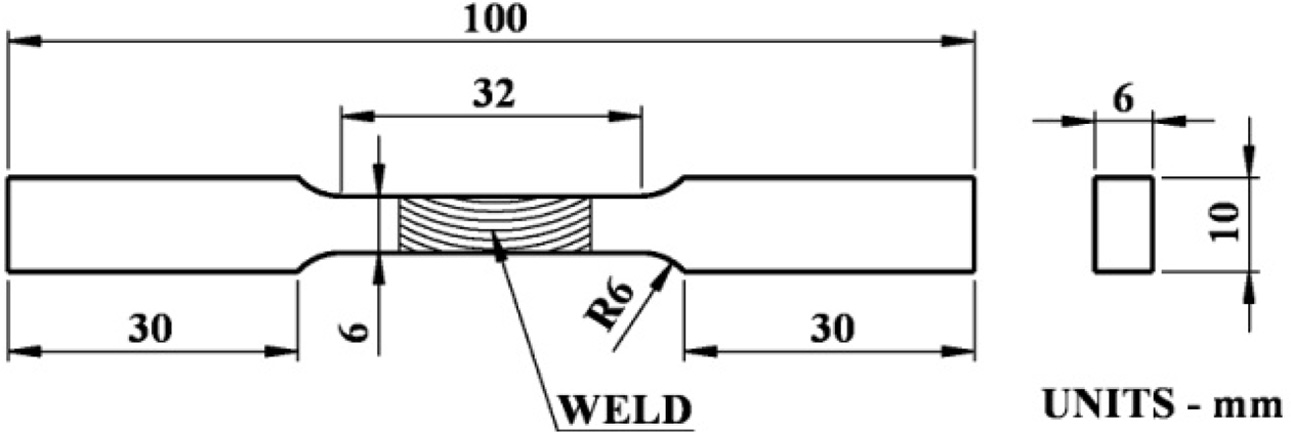

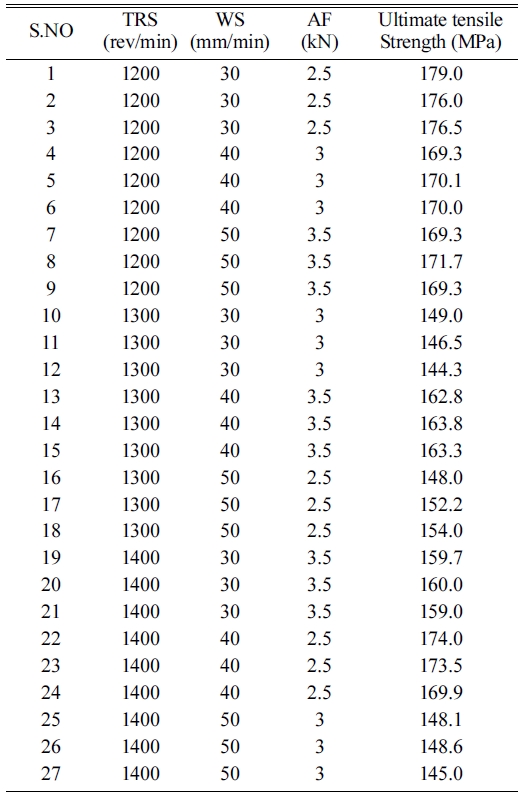

Tensile strength is the mechanical property considered

in this investigation that describes the better FSW joint quality. As per the

L27 orthogonal array design, the experiments were conducted in the

machine and welding between the components was performed. The plates,

after welding, were cut into the required size (50 mm × 50 mm × 6 mm) by power

hacksaw and then machined as per the ASTM E8 standard. The observed tensile

strengths for the 27 weld specimens are tabulated in Table 4. The schematic

diagram of tensile specimen is shown in Fig. 3.

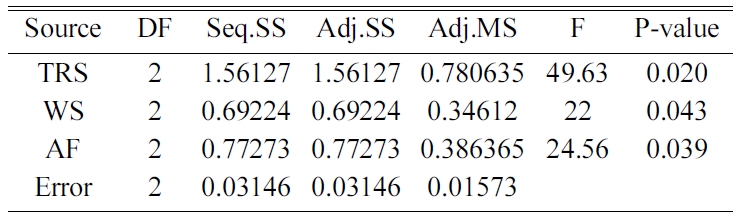

The adequacy of the experiments conducted is checked using

ANOVA table using MINITAB V17 software shown in Table 5. ANOVA table shows the

significance of each parameter involved in the process. The

Probability value (or P-Value) for all parameters given shows values less than

5% or 0.05 thereby indicating that all three parameters of FSW are significantly

influencing the tensile strength of the weld joint. Tool rotation speed is the

most significant parameter affecting the response followed by axial force and

welding speed. The R-Square and Adjusted R-Square values are greater than 95%

stating that strong relationship exists between the response and the predictor.

The regression formula for the ultimate tensile strength is obtained and shown

below:

UTS = 261.7 – (2.69 * AXIAL FORCE)

– (0.063 * TOOL

ROTATION SPEED)

– (0.244 * WELD

SPEED) (1)

Genetic

algorithm methodology

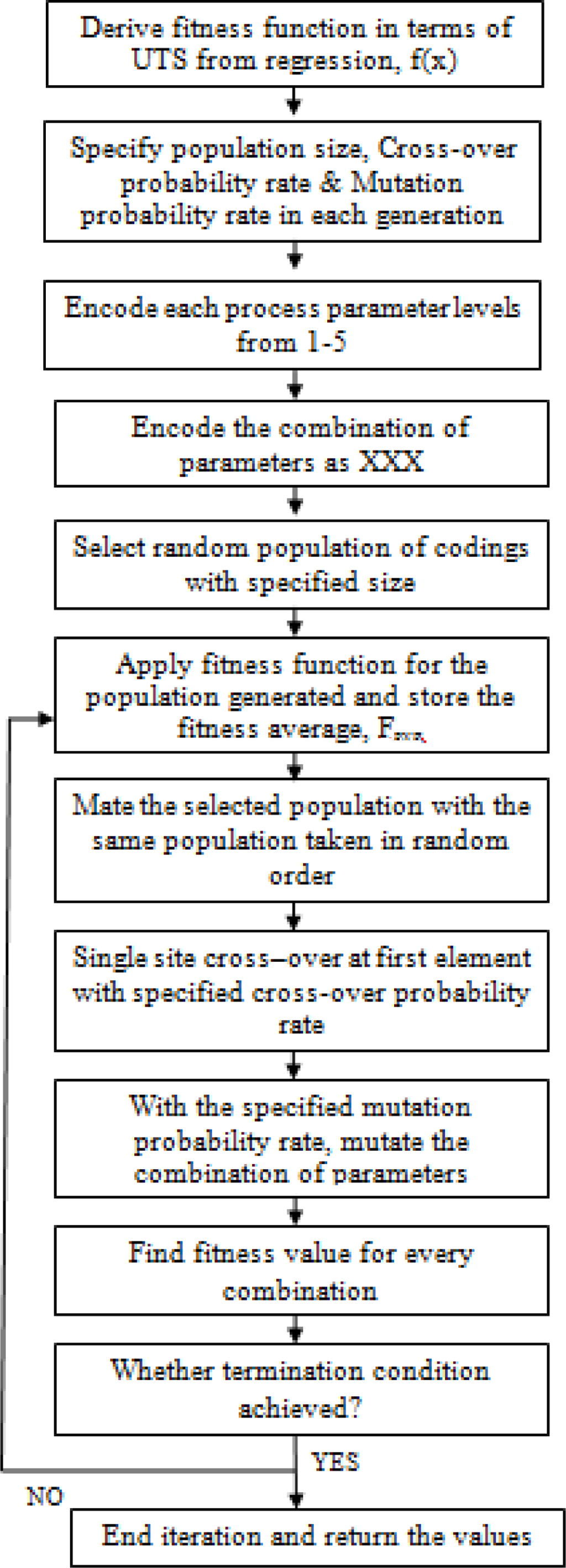

The methodology used in the study are summarised as

flowchart in Fig. 4. The regression formula derived from the Taguchi design

comprises the simple terms of process parameters. As the adequacy is safe, the

fitness function for the GA analysis can be taken as the maximisation of

Ultimate tensile strength in the design space. The design space selected in GA

is similar to the levels used in Taguchi design but to find the best solution

that maximizes the UTS requires a lot of time, man power, utilization of

resources etc., in the conventional way. The best solution can be predicted

through GA using the regression formula as GA explores the desired output

within the space through iterations. Programming for the Genetic Algorithm is

prepared in C package. Here, the fitness function is written as shown below:

F(x) = 261.7 – (2.69 * AXIAL FORCE)

– (0.063 * TOOL ROTATION SPEED)

– (0.244 * WELD SPEED) (2)

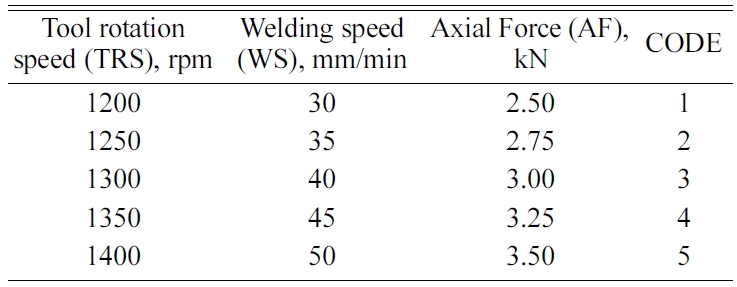

The levels of process parameters are increased from 3 to 5

considering the flexibility in the machine settings. The levels are decoded

accordingly as shown in Table 6. The design space for the optimization is thus

increased from 33 = 27 to 53 = 125.

The

population size, Cross-over probability rate and Mutation probability rate are

specified as 10, 0.70 and 0.033 respectively. Cross-over rate is selected to

0.70 to ensure that the better combination of parameters with good fitness

value is retained to the next generation. In order to get the desired

variability in the population, mutation rate is selected to 0.033 to change one

bit in the population of 10 using the formula given below.

No. of bits for formulation

= Population size * no. of bits * mutation probability rate

(3)

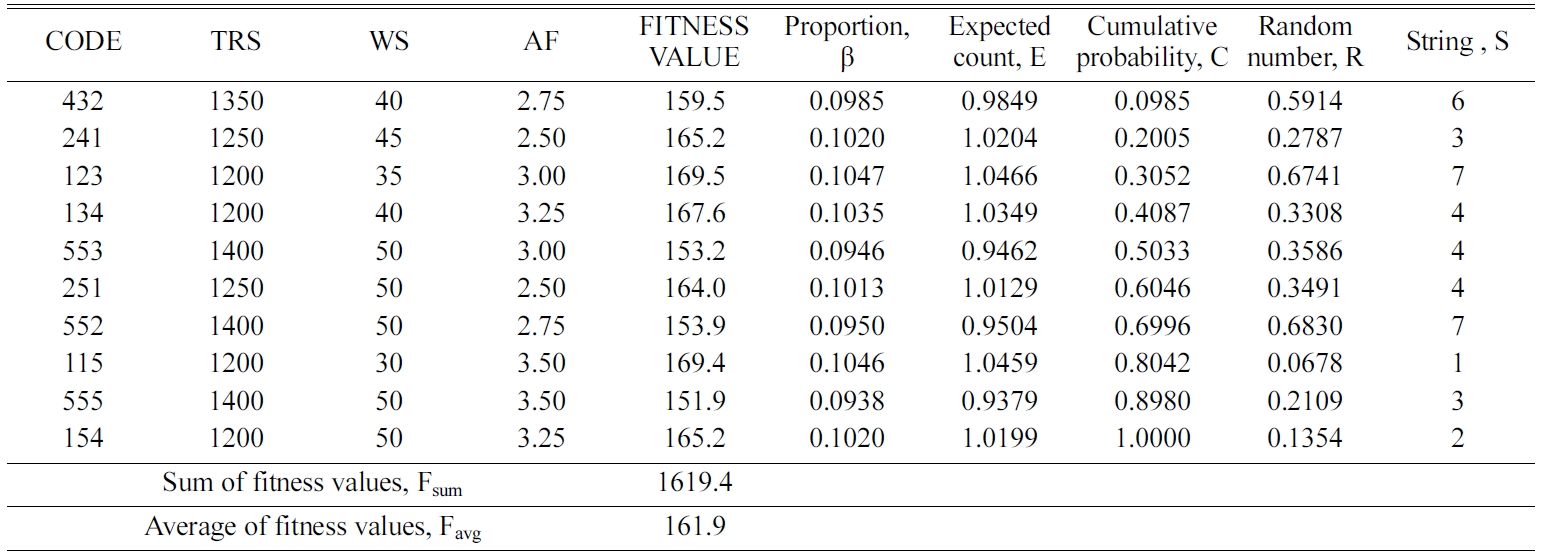

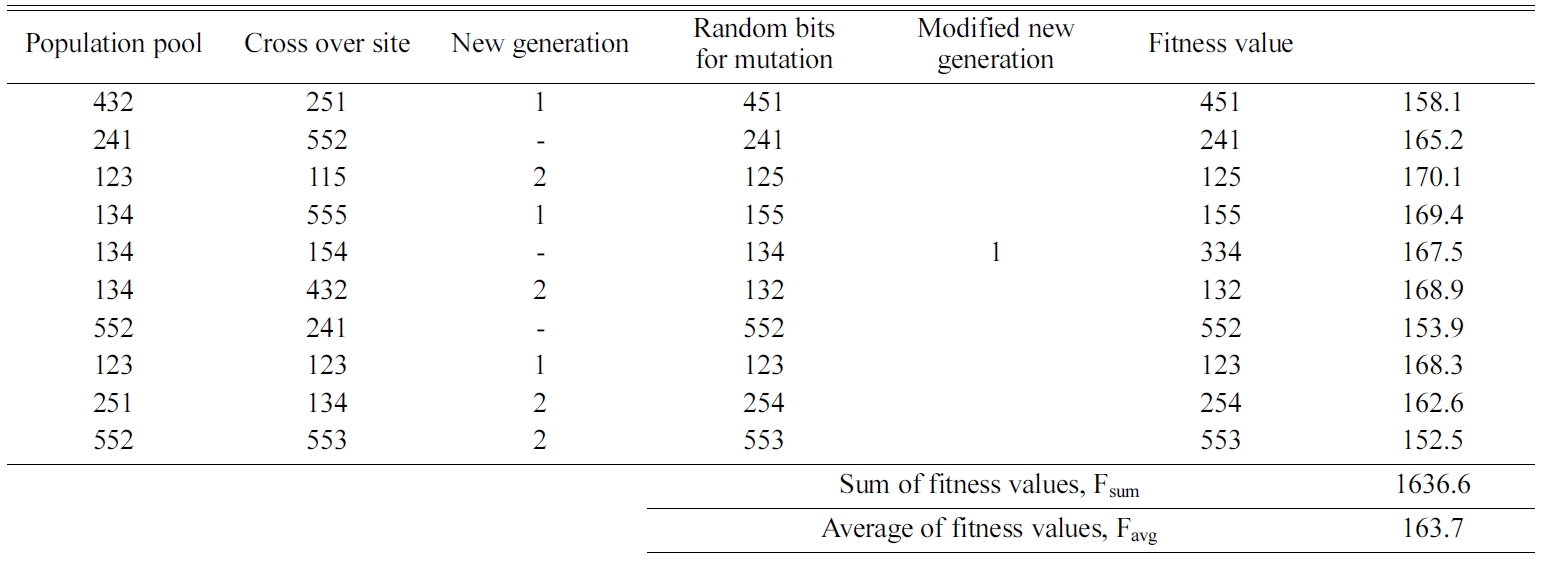

The combination of first generation parameters are

selected randomly as shown in Table 7. Then, the fitness functions for the

first generation are computed as shown in the last column. Sum and average of

the fitness values are also tabulated and saved as Fsum and Favg

respectively. The values for proportion (β) and Expected count (E) are

tabulated from the following formulae:

β = Fi / Fsum ; E = Population

size * β (4)

Roulette wheel method of selecting the best parents for

mating is used here for the cross-over phase. The values for the codes 1, 5, 7

and 9 are observed less than the Favg.. These values have the less

probability to get selected in the population pool while using Roulette wheel

since the circumference of the wheel is linear with the expected count.

Similarly, the values 2, 3, 4, 6, 8 and 10 with expected count greater than Favg

are likely to be selected in the population pool. The

cumulative probability (C) is calculated from the expected count, E.

Thus, the C value for the last row is 1. Programming is done in such a way that

10 random numbers are generated and the corresponding parents are selected

based on the intervals of cumulative probability in terms of string, S. It is

observed that the parents in rows 5, 8, 9 and 10 are not selected; 1, 2, and 6

are selected once; 3 and 7 are selected twice; 4 is selected thrice

as tabulated. Correspondingly the new population pool is

generated and are mated with the previous generation as shown in Table 8. It is

also noted that any code providing high Fi value may also be

neglected and vice versa thereby improving the Favg value for every

generation progressively.

It is noted that the number of bits for mutation are

calculated as 1 and changed in the first bit of 5th row. The bit

selected for mutation is programmed such that the old codes are not selected in

order to explore the undiscovered design space. It is observed that Favg

value for the first iteration process has improved from 161.9 to 162.4. The

same procedure is repeated until all the possible combinations are verified. It

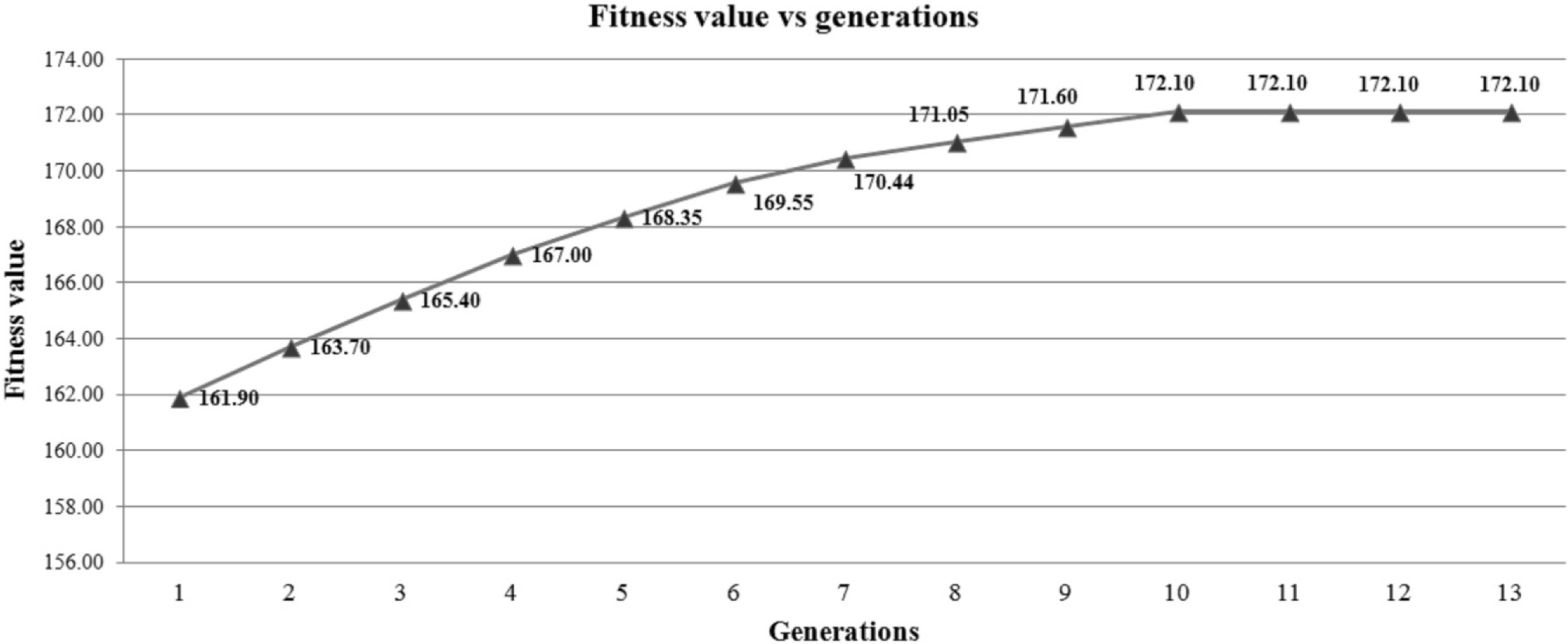

is observed that fitness value, Favg value increases and reaches the

maximum value of 172.10 MPa shown in Fig. 5.

Confirmation

test

The final Favg value after the program run

obtained is to be verified with the experimental results in order

to validate the GA methodology. The corresponding parameters

for the maximum ultimate tensile strength are obtained as code 111 indicating

TRS – 1,200 rpm; WS – 30 mm/min; AF – 2.5 kN. The code 111 is set with the

vertical milling machine and five trial welds are carried out in order to

eliminate any unwanted noise in the run. The average value of the trial welds

results for the confirmation test obtained is 176.8 MPa with 1.22% error at 95%

confidence level.

|

Fig. 3 Tensile specimen. |

|

Fig. 4 Genetic algorithm methodology. |

|

Fig. 5 Plot between fitness value vs generations. |

Genetic Algorithm is effectively used to optimize the

Friction stir welding parameters. The stir cast hybrid composite AA7010-SiC-Al2O3

was friction stir welded by varying the Tool rotation speed, Weld speed

& Axial force and keeping the other key FSW parameters constant.

Taguchi L27 orthogonal array design was used to conduct the experiments. GA way

of optimization was used to investigate the maximum ultimate

tensile strength of the hybrid composite. Friction stir welding of aluminium

matrix composites is used efficiently for joining of aluminium alloys. The

tensile strength of the weldment of composites depends upon the Friction stir

welding parameters. Every parameter has its effect over the tensile strength.

The maximum tensile strength is optimized from the design space by genetic

algorithm through C programming. The optimum parameters for Friction stir

welding of AA7010-SiC-Al2O3 hybrid composite

are: Tool rotational speed (TRS) – 1200 rpm; Axial Force

(AF) – 2.5 kN and Weld Speed (WS) – 30 mm/min. The

tensile testing in trial welds also confirms that the

optimized results by GA are agreeable with the experimental results.

- 1. E. A Starke and J.T. Staleyt, Prog. Aerospace Sci. 32[2-3] (1996) 131-172.

-

- 2. S.Ghosh, P. Sahoo, and G. Sutradhar, J. Compos. (2013) 1-9.

-

- 3. G. Li-na, G.Lin, Z. Hong-wei, and H. Lu-jun, Tran Nonferrous Met. Soc. China 21[2] (2011) 274-279.

- 4. A. Apasi, P.B. Madakson, D.S. Yawas, and V.S. Aigbodion, Tribol. Ind. 34[1] (2012) 36-43.

-

- 5. M.H. Robert and J.B. Fogagnolo, in Proceeding of the 11th International Scientific Conference (AMME'2002), 15-18 December 2002, Achievements in Materials and Manufacturing Engineering, pp. 463-466.

-

- 6. S. Lezhnev, D. Kuis, A. Volochko, A. Shegidevich, N. Svidunovich, and A. Naizabekov J Material Sci Eng 4[3] (2015) 3-5.

- 7. C. Sharma, D.K. Dwivedi, and P. Kumar, Mater. Des. 36 (2012) 379-390.

-

- 8. A.K.K Lakshminarayananan and V. Balasubramanian, Trans. Nonferrous Met. Soc. China 18[3] (2008) 548-554.

-

- 9. M. Dehghani, A. Amadeh, and S.A.A. Akbari Mousavi, Mater. Des. 49 (2013) 433-441.

-

- 10. S. Kasman and Z. Yenier, Int. J. Adv. Manuf. Technol. 70[1-4] (2013) 145-156.

-

- 11. L.M. Serio, D. Palumbo, L.A. Filippis, U. Galietti, and A.D. Ludovico, Materials (Basel). 122 (2016) 1-19.

-

- 12. D. Vijayan and V. Seshagiri Rao, Revista Tecnica De La Facultad De Ingenieria Universidad Del Zulia 39[1] (2016) 55-70.

- 13. H.T. Hsieh and J.L. Chen, Int. J. Adv. Manuf. Technol. 46[9-12] (2010) 1085-1102.

-

- 14. W. Ho, J. Tsai, J. Chou, and J. Yue, IEEE Access 4 (2016) 2304-2313.

-

- 15. B. Parka, H. Youna, J. Ryua, H. Sona, H. Bangc, I. Shonb, and I. Oha, J. Ceram. Process Res. 13[6] (2012) 705-712.

-

- 16. Y. Lina, J. Hungb, H. Chowc, and A-Cheng Wangd, J. Ceram. Process. Res. 16[2] (2015) 249-257.

-

- 17. K. Kamal Babu, K. Panneerselvam, P. Sathiya, A. Noorul Haq, S. Sundarrajan, P. Mastanaiah, and C. V. Srinivasa Murthy, Int. J. Adv. Manuf. Technol. 94[9-12] (2018) 3117-3129.

-

This Article

This Article

-

2020; 21(2): 157-163

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.157

- Received on Aug 5, 2019

- Revised on Nov 11, 2019

- Accepted on Nov 22, 2019

Services

Services

- Abstract

introduction

methods and materials

experimental procedure

results and discussion

conclusion

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- P. Gopi Krishnan

-

aAssistant Professor, Department of Mechanical Engineering, Dr.N.G.P. Institute of Technology, Coimbatore, Tamil Nadu, India

Tel : +91-8940585563 - E-mail: rs.wldg@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.