- Multi objective optimization of wear characteristics on Al 7075/Al2O3/B4C composites - Desirability approach

Pridhar. Ta,*, Ravikumar. Kb, Sureshbabu. Ba, Srinivasan. Ra and Sathishkumar. Ba

aDepartment of Mechanical Engineering, Sri Krishna College of Technology, Coimbatore, India

bDepartment of Mechanical Engineering, Dr.NGP Institute of Technology, Coimbatore, India

Aluminium hybrid metal matrix

composites comprises of Al alloy embedded with multiple hard particulates to

improve the wear characteristics. In this study Al 7075/Al2O3/B4C

hybrid composite was fabricated with 5 wt.% B4C particles addition

and 2, 4, 6, 8 and 10 wt.% of Al2O3 by liquid metallurgy

route. The dry sliding wear behaviour of hybrid composites was investigated

under various sliding parameters using a pin on disc tribometer. Numerical

models were developed to predict the frictional and wear characteristics of the

composites. Analysis of variance method and confirmation experiments were

employed to validate the adequacy of the developed model. The composites with

high particle content exhibits better wear resistance at various sliding

conditions. Detailed metallurgical investigations were carried out on the on

worn surface. The wear rate was severe at higher loads due to the crater formation

and in addition to abrasive wear. The wear rate and coefficient of friction

were optimized using desirability based multi criteria optimization technique.

Keywords: Alumina, Boron carbide, SEM, XRD, EDS, Dry sliding wear, RSM, Optimization

Composite materials have become a need in the modern

decade to obtain numerous properties which were not achieved by monolithic

materials. It caters the increasing demand for enhanced mechanical and

tribological properties in aerospace, marine, defence and automotive

applications [1-3, 40]. The commonly used techniques in fabrication of hybrid

metal matrix composites (HMMC) are stir casting and powder metallurgy

technique. Stir casting route has remained as the most explored technique for

fabrication of hybrid composites due to its flexibility, simplicity and

commercial viability [4, 5, 38, 39]. Baradeswaran et al. [6] observed that the

addition of aluminium oxide to base alloy improved the tensile strength,

hardness, flexural strength and compression strength. Also the inclusion of

graphite improved the wear characteristics of the hybrid composites.

Investigations of Veeresh Kumar et al. [7] on addition of silicon carbide and aluminium

oxide to aluminium alloy indicate improvement in density,

tensile, micro hardness and wear of the base alloy. Ravikumar et al. [8]

observed that the wear in Aluminium/flyash composites,

decreased with increased fly ash particle size primarily due

to the interfacial strength between the base metal and its reinforcement. Dora

Siva Prasad et al. [9] in the studies of tribological behavior on

A356/SiC/Rice Hush Ash (RHA) composites observed

that increase in wear resistance was owing to the strengthening mechanism of

the matrix due to the thermal mismatch between the reinforcements and the base

alloy. Ravinder Kumar et al. [10] made an investigation on Al 7075/SiC/graphite

and concluded that load was the most noteworthy factor that affects the wear

rate. On observation of the wear SEM image of

Al/SiC/mica composites Rajmohan et al. [11] reported that

numerous long grooves and craters were found on worn

surfaces at higher load and the mechanism changed from

abrasive wear to delamination at higher load. Uthayakumar et al. [12] observed

high melt wear at high sliding speed and higher load because of the higher

order existence of local stress. Krishnan et al. [13] revealed that abrasive

wear prevails in particle reinforced composites, whereas adhesive wear was dominant

in base alloy. Radhika et al. [14] found a MML layer in the

surface which formed due to the increase in velocity on the counter

face of the specimen. An attempt has been made by Ravikumar et al. [15]

to predict the wear rate and coefficient of friction of Al356/fly

ash composites using Artificial Neural Network (ANN). Ravinder

Kumar et al. [10] made a comparison between Response

Surface Methodology (RSM) and ANN for the prediction of Surface

roughness measurement on Al 7075 hybrid composites and concluded that prediction

of RSM is good as compared to ANN. S. Selvi et al. [16] developed a

mathematical model for calculation of wear rate using response surface

methodology. Suresh et al. [17] applied RSM Box Behnken design method effectively

to reduce the number of trials and to develop a mathematical model

with high confidence level and employed ANOVA to verify the adequacy of the mathematical model. Vembu et al. [18]

developed a second order polynomial equation for the prediction of tensile

strength using RSM. Ravikumar et al. [19]

employed a multi response optimization technique based on desirability approach

to reveal the optimal process parameters of WEDM on Aluminium hybrid

composites. Ravikumar et al. [20] applied desirability based multi response

optimization to optimize the wear rate and coefficient of friction in abrasive

wear test.

From the above literature survey it is evident that many

researchers have put tremendous efforts to manufacture light weight and

efficient material for the automobile, marine and aerospace industries. However

limited works were carried out on Al 7075 hybrid composites.

Al 7075 aluminium alloy is being used to manufacture rock

climbing equipment, automotive components, hang glider

airframes, M16 rifles and aerospace applications due to their high strength to

weight ratio and good mechanical properties. The present investigation is to

manufacture Al 7075 hybrid composite by reinforcing the Al2O3

and B4C particulates and to study the dry sliding wear

of the hybrid composites. Scanning electron micrographs

(SEM) were used to study the influence of parameters on wear mechanisms. A

mathematical model was developed to predict the wear rate and coefficient

friction using RSM. The model adequacy was tested using ANOVA. Desirability

based Multi response optimization technique was instituted to

predict the optimized parameters. The

significance of this study is to develop a low weight superior

strength material in an affordable cost. This novel material may replace current

used alloys with superior quality. The Desirability optimization

technique which is used in this research is user friendly and has more accuracy

compared to other optimization techniques.

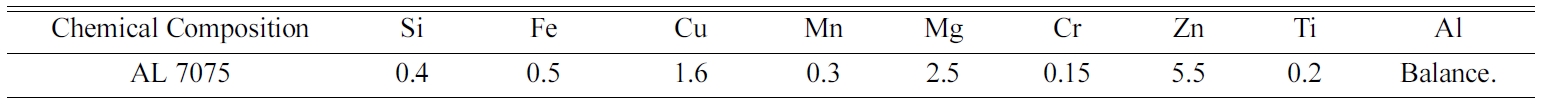

Materials

The composite comprises of Al 7075 as base material,

alumina and boron carbide as reinforcement. The chemical composition of the

matrix metal (Al 7075) used for the current study is shown Table 1. Al2O3

and B4C particulates are used to manufacture the composite with an

average particle size of 40 microns.

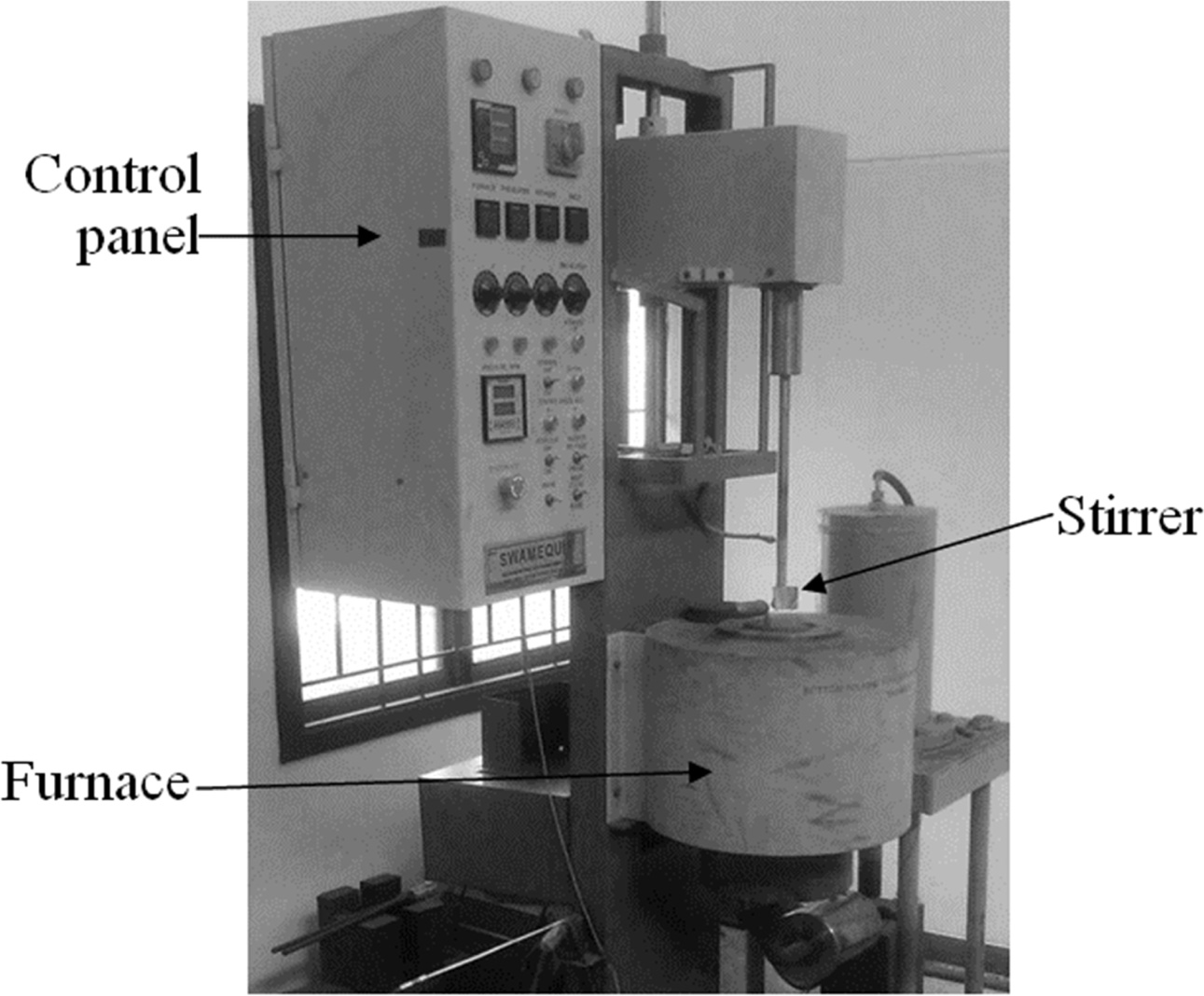

The casting was prepared using stir casting machine shown

in Fig. 1, Al 7075 reinforced with 2, 4, 6, 8 and 10 wt.%

alumina with constant 5 wt.% of boron carbide were

prepared by a stir casting technique. A weighed amount of Al 7075 alloy was

superheated to 750 °C in a conical shaped graphite crucible by

using an electrical resistance furnace. The melt was degassed using solid dry

hexachloroethane (C2 Cl6). The particulates

were preheated at 700 °C for 20 min. to remove the moisture content and the

reinforcements were added to the vortex at a constant feed rate. The composite

slurry was stirred continuously at a speed of 530 rpm for 15 minutes. 2 wt% of

magnesium was also included to enhance the wettability of the composites.

For proper mixing of the reinforcements with the matrix

alloy, stirring was continued for about 10 min even after the completion of

particulate additions. For comparative study, unreinforced aluminium alloy was

also prepared under similar cast conditions.

Micro

Structural Examinations

The microstructure of Al 7075/Al2O3/B4C

composites was examined using a scanning electron microscope

(JSM-6360). The cast samples for microstructure in- vestigation

were polished metallographically. The Polished specimen

was then etched with 10% of sodium hydroxide solution and

examined for uniformity in distribution of particulates

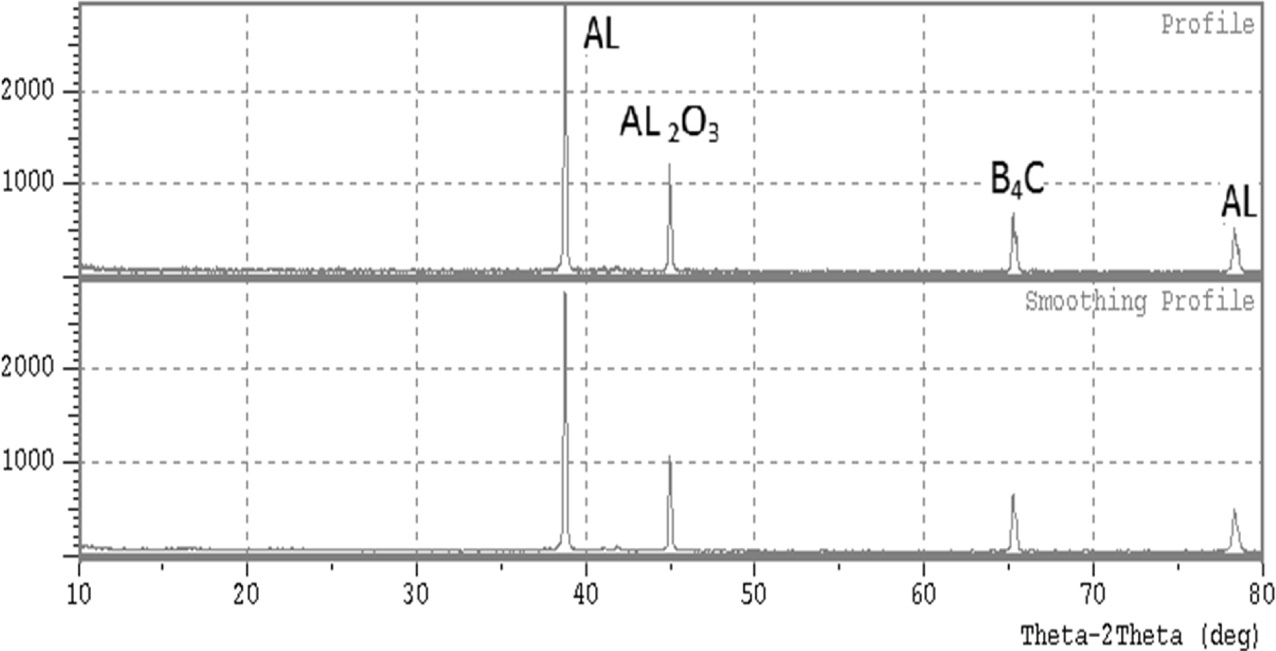

in cast specimens. X-ray Diffraction technique was employed

to ensure the presence of base alloy and its dispersed reinforcements.

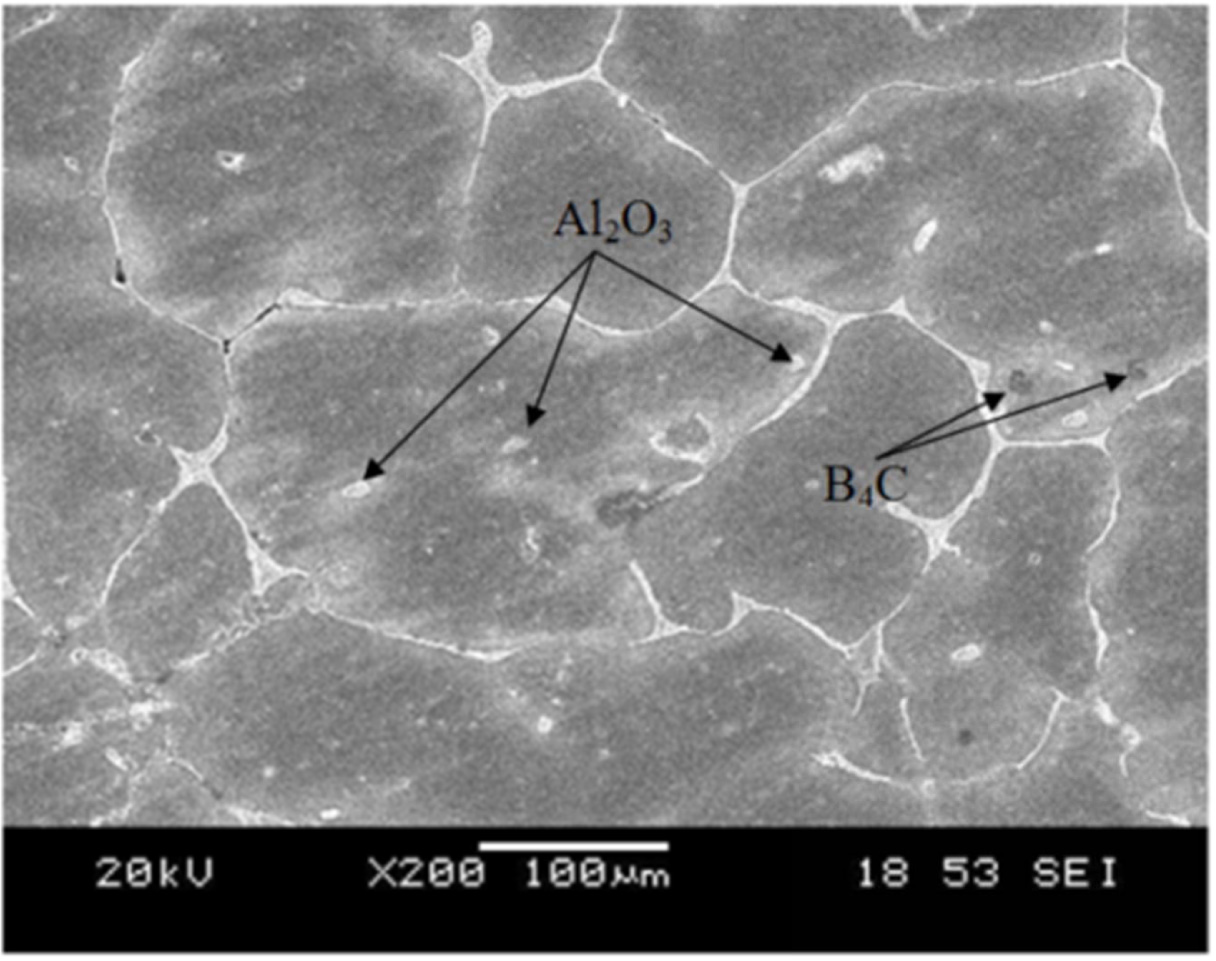

Fig. 2 represents the SEM micrographs of Al 7075/ Al2O3/B4C

composites. It is evidently exposed that the dispersion of the particulates are

embedded into the Al 7075 aluminium matrix. Further the image reveals the

homogeneity of reinforcement in the specimen which indicates the

effectiveness of dispersion of the particulates during

stirring. XRD of the cast specimen Fig. 3 confirms the presence of Al2O3

and B4C particulates in the composites.

Wear

Test

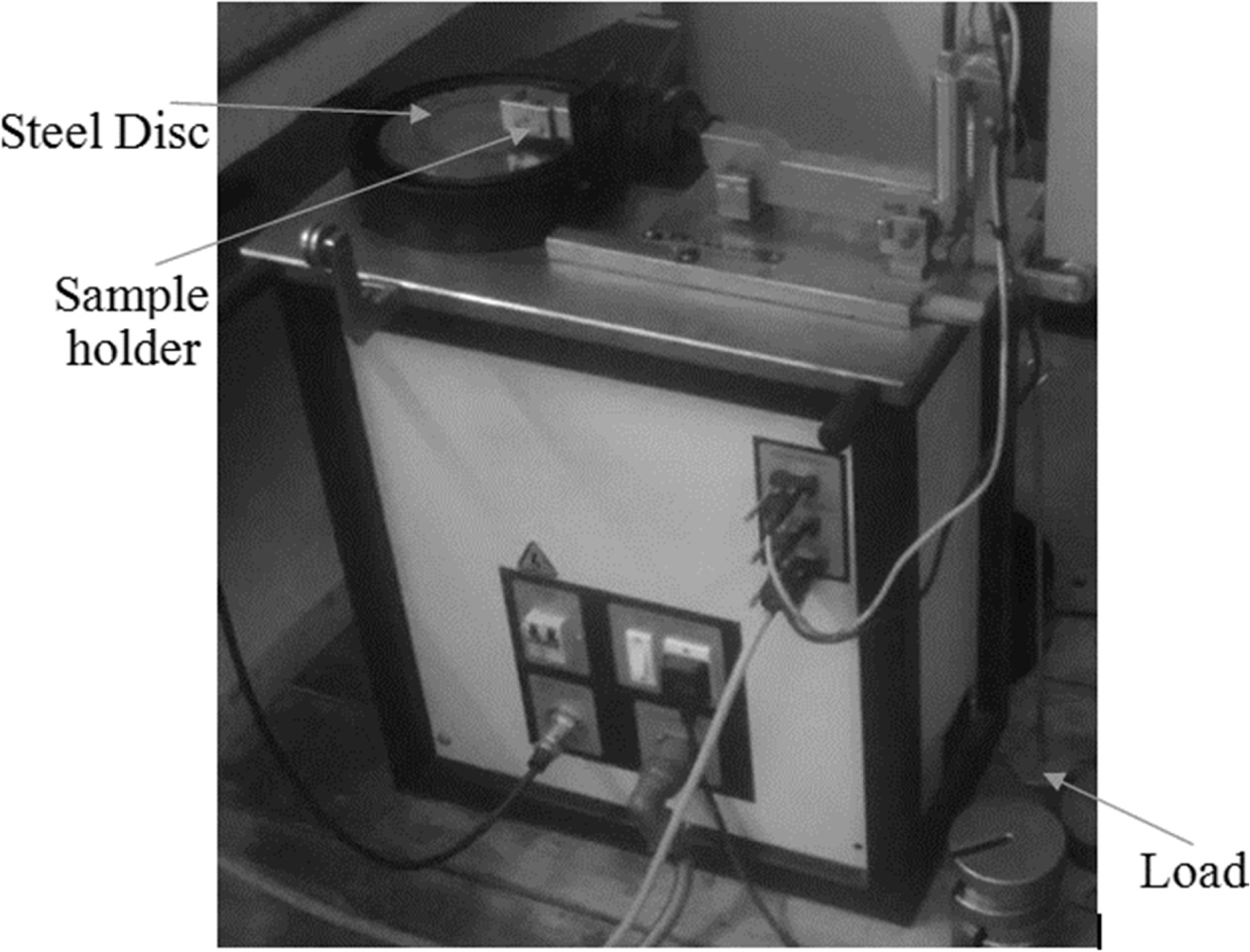

Dry sliding wear behaviour of hybrid composite specimens

was investigated using Ducom TR 20 pin on disc apparatus as per ASTM G99

standards. The wear testing machine is shown in Fig. 4.

The specimens were machined for 10mm in diameter and

40mm in length and polished with emery paper of grade 600,

800, and 1,000 respectively. The cast pins were then pressed against an EN32

steel disc of surface roughness 1.2 µm and a hardness of 65HRC at room

temperature. The frictional forces were documented during the

entire wear experiments and average value was recorded.

The initial weight of the sample was measured using an electronic weighing

machine (SHIMADZU BL-220H) with the accuracy of 0.01mg. The pin

was weighed before and after testing to find out the amount of weight loss. The

wear rate was calculated using the eq. (1) based on the mass loss

where W is the wear rate (mm3/m),

M is mass loss (g), ρ is the density (g/mm3) and D

is the sliding distance (m).

The co-efficient of friction was determined by dividing

normal force against frictional force. The Dry sliding wear test were conducted

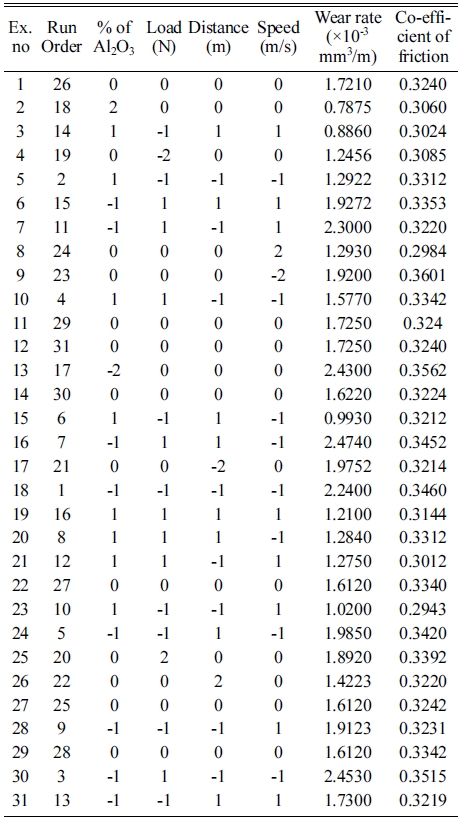

as per the design matrix established is shown in Table 2.

|

Fig. 1 Stir casting setup. |

|

Fig. 2 SEM image of 4% Al2O3reinforced hybrid composites. |

|

Fig. 3 XRD Analysis of the hybrid composites. |

|

Fig. 4 Ducom TR 20 wear testing machine. |

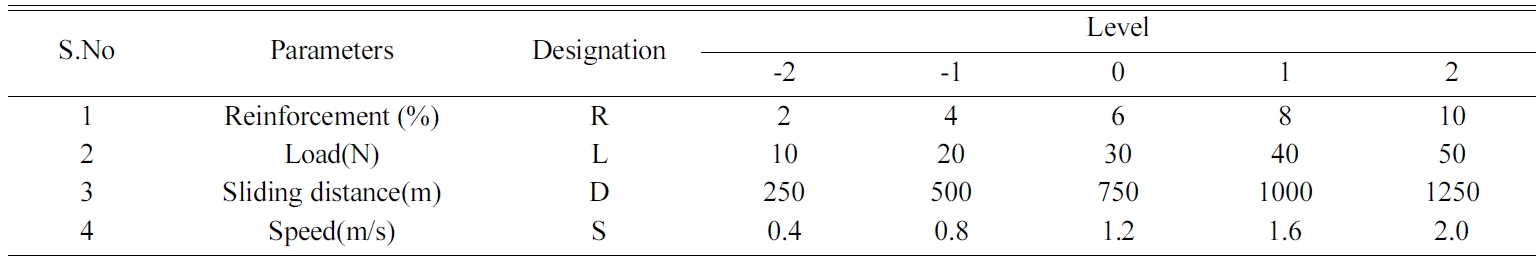

Response

surface methodology

Response Surface methodology is a collection of mathematical and

statistical techniques used for empirical

model building. It identifies the relations between wear parameters and

response functions with minimal number of experiments [21]. Design Expert 10.0

was employed for designing the experiments and to study the influence of

parameters on wear rate and coefficient of friction of the hybrid composites.

The four factors that affect the wear rate and Coefficient of friction are % reinforcement (R), load (L),

sliding distance (D) and speed (S). A

central composite design (CCD) model was chosen to determine the dry sliding

wear behaviour of the cast composites. The levels of each factor were chosen as

2, -1, 0, 1 and 2 in the coded form. The sliding wear parameters and their levels

are given in Table 2. The trials were carried out as per the design matrix and

their responses are presented in Table 3.

Development

of mathematical model

A second order polynomial regression model is constructed

to predict the relationship between the parameters and their responses which

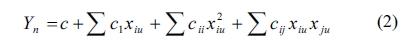

shown in eq. (2).

where Y is response c, ci,

cii and cij are coefficient respectively.

The response function representing the wear parameters,

namely, percentage as a function of reinforcement (R), load (L),

sliding speed (S) and sliding distance (D) can be

expressed as Y = f(R, L, S, D), where Y is the

response. A numerical model was developed using Design Expert Software

R10 and the regression coefficients are

calculated. The non-significance coefficients were curtailed and the

mathematical models developed for predicting the wear rate and coefficients of

friction in coded form are given in eq. (3) and eq. (4).

Development

of mathematical model Normality of data

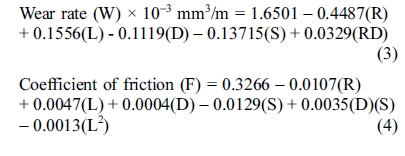

Normality of data is investigated by plotting a graph

between the residuals and the normal probability [22]. The probability plot for

wear rate and coefficient of friction is shown in Fig. 5. From the plot it is

evident that the residuals fall on a straight line and the errors are

distributed in normal showing accuracy of the model.

Independency of the data

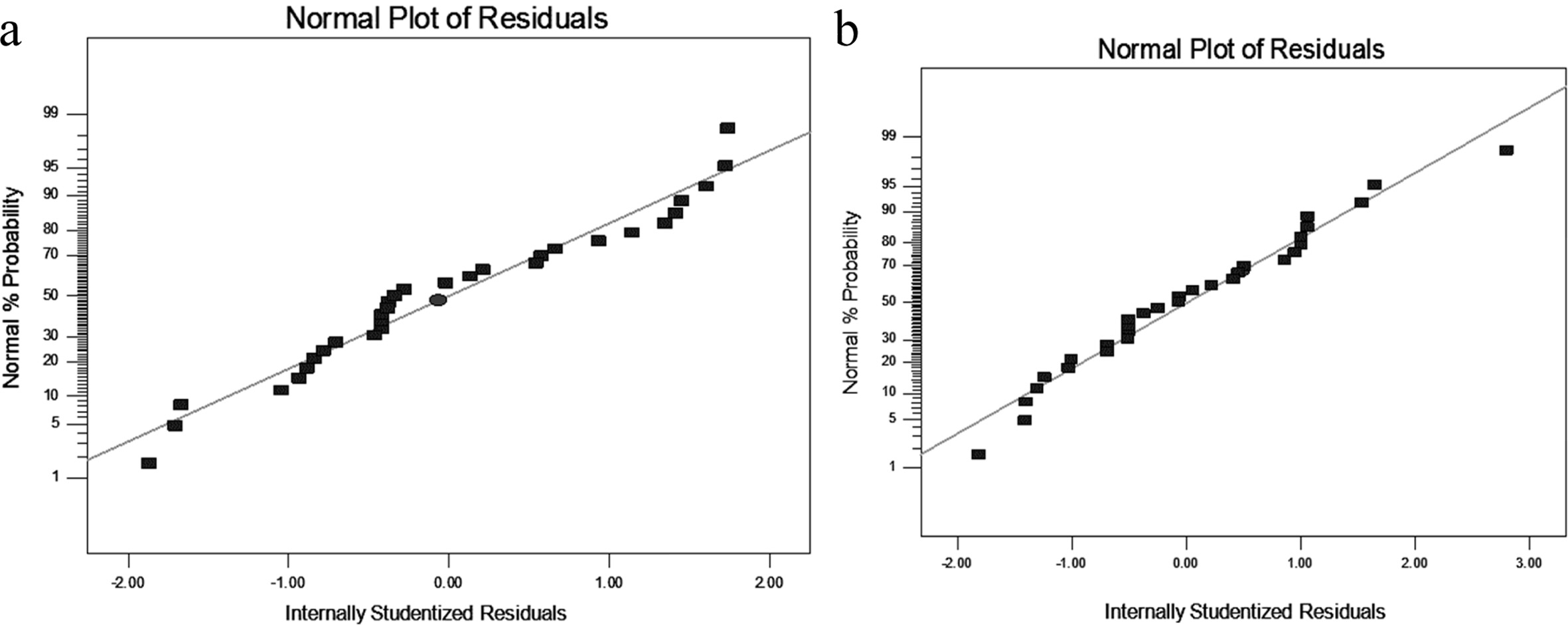

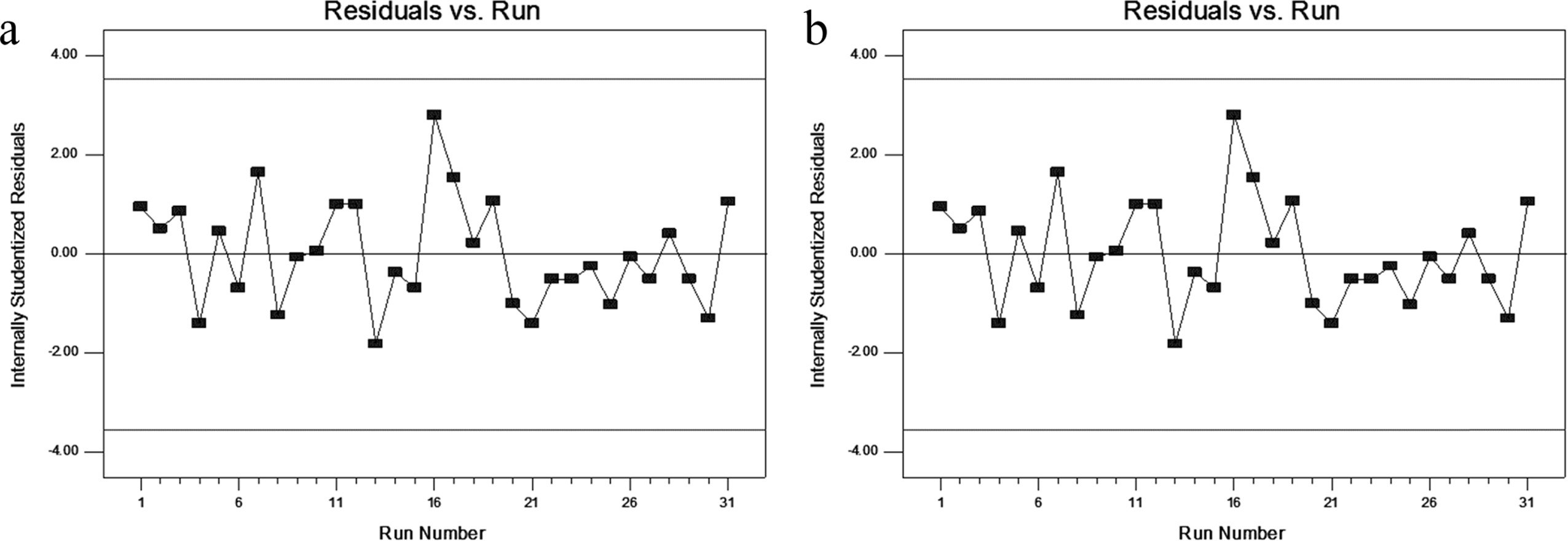

Independency of the data was tested by means of residual

plot. This was done by plotting the residuals against run order [23]. Fig. 6,

shows the residual plot for wear rate and coefficient of friction respectively.

This plot depict that the no predictable pattern was observed because almost

all the residuals lies between -2 to 2 levels.

Analysis of variance

Adequacy of the developed model was checked using ANOVA

technique. The correlation coefficient (R2) indicates the goodness

of fits for the model [13]. In this work, the value of regression coefficient

(R2 = 0.9774) and adjusted regression coefficient

(adjusted R2 = 0.9728) indicates that only 5% of the total

variations are not explained by the model. The value of “Prob < F”, which

depicts that the model is statistically significant [24].

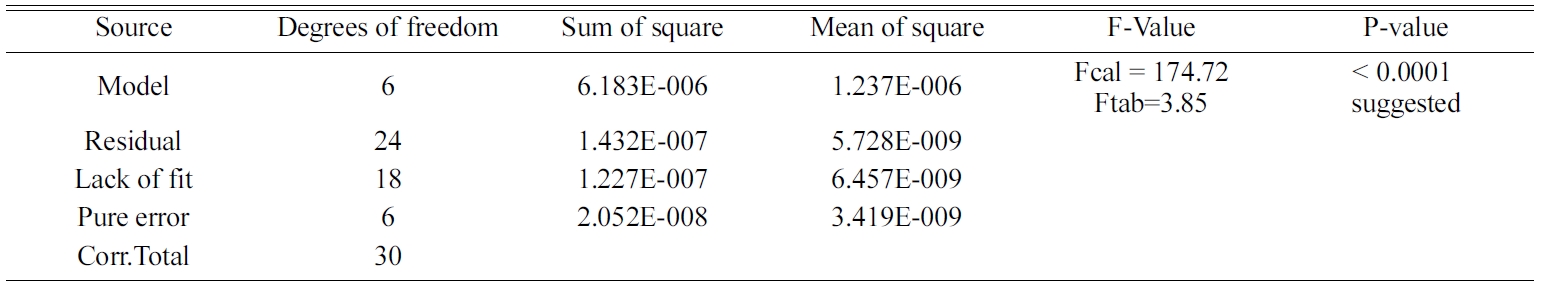

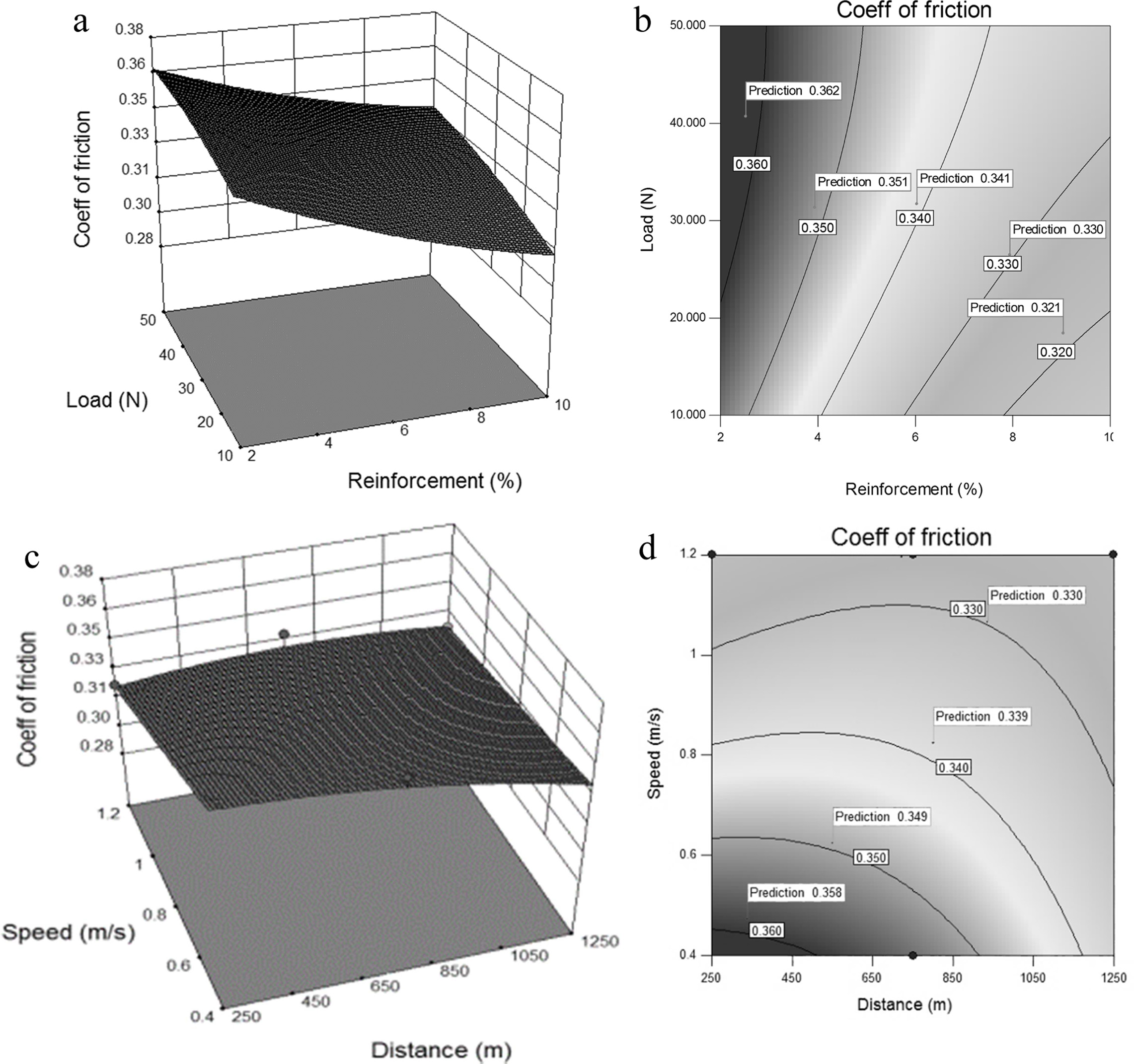

The ANOVA test results of wear rate were presented in

Table 4. The square of the regression coefficient (R2) value

0.9774 confirms that equation 3 is highly reliable. In addition

the computed F value = 174.72 is greater than the tabulated value F

(5, 25) = 3.85, suggesting that the test is more accurate. The P

value (< 0.0001) indicates that the empirical model is statistically

significantly [25].

The ANOVA test results of coefficient of friction were

depicted in Table 5, the Square of the regression coefficient R2

value 0.9239 confirms that equation (4&5) is highly reliable. In addition,

the computed F value 60.68 is more than the tabulated value F (5, 25)

= 3.85, confirming that the test is significant. The P value

(< 0.0001) admits that the empirical model is significant. Thus the

proposed mathematical model could be used for the prediction of coefficient of

friction of the hybrid composites

|

Fig. 5 Normal probability plot (a) wear rate (b) coefficient of friction. |

|

Fig. 6 Residual plot (a) wear rate (b) coefficient of friction. |

|

Table 4 ANOVA results of wear rate using the mathematical model. |

R2: 0.9774 adjusted R2: 0.9728 and predicted R2: 0.9631 |

|

Table 5 ANOVA results of coefficient of friction using the mathematical model. |

R2: 0.9239 adjusted R2: 0.9086 and predicted R2: 0.8839 |

Study

of Wear Behaviour of Al 7075/ Al2O3/B4C hybrid

composites

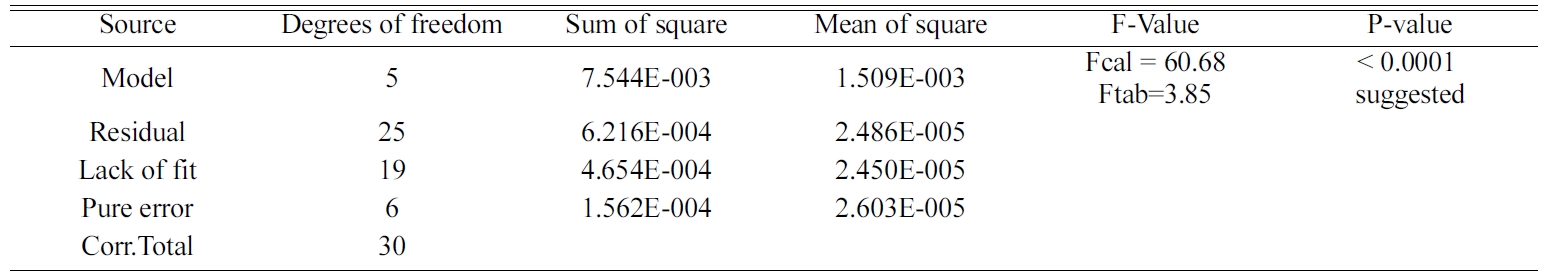

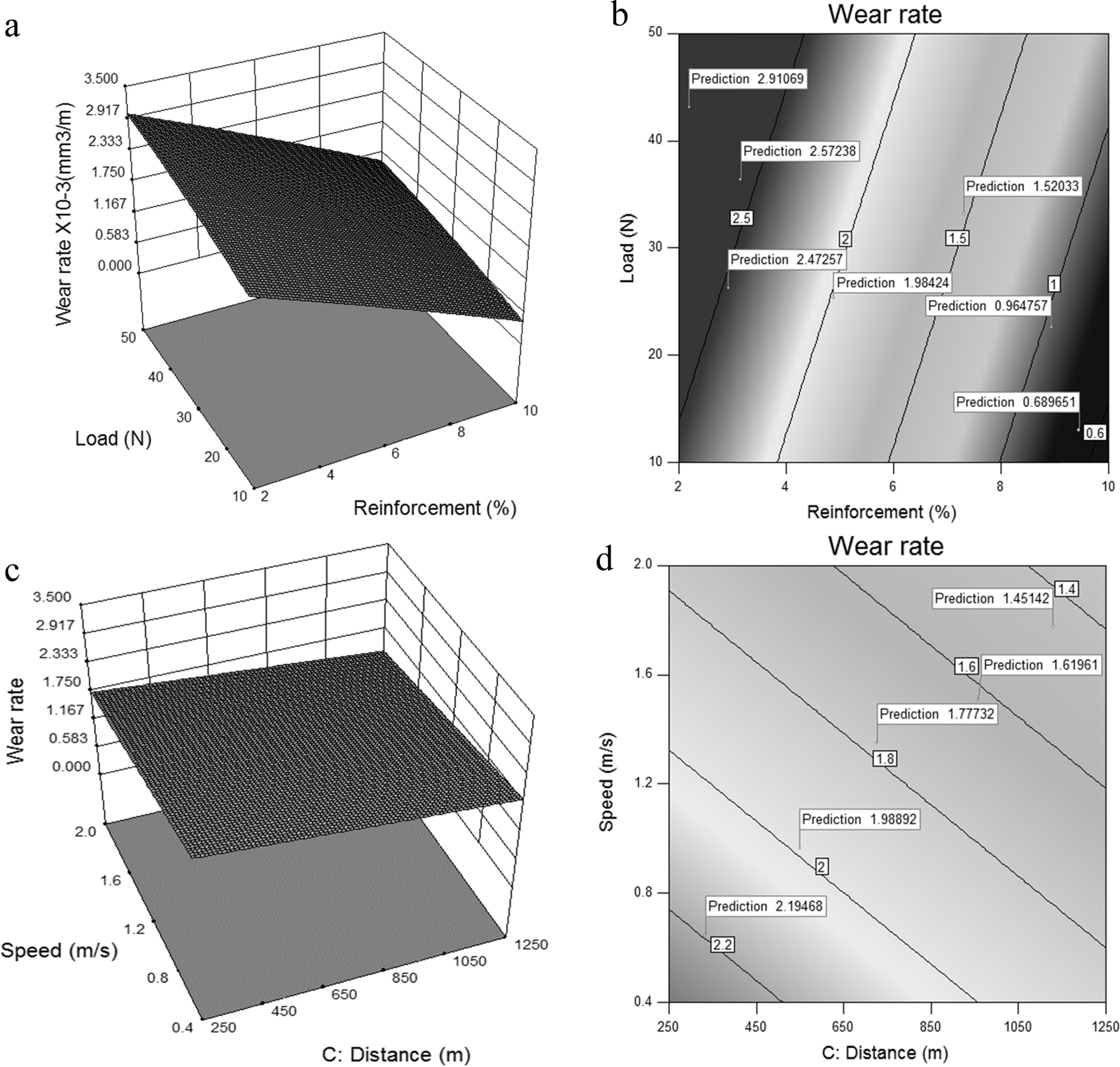

Fig. 7 & 8, represents the 3D interaction effect of

the input parameters on wear rate and coefficient of friction

on aluminium hybrid composites. From the equation (3 & 4), it can be

ascertained that the wear rate and coefficient of friction were fundamentally

influenced by reinforcement percentage and preceded by load, distance and

speed.

Effect of parameters on wear rate

The

influence of input parameters on wear rate is represented in Fig. 7. The effect

of reinforcements and load on wear rate was depicted in Fig. 7(b). The

inclusion of reinforced particulates in Al 7075 alloy decreased the wear rate compared with the base alloy. The wear rate

declined due to the reinforcements which act as a load bearing ingredients

thereby restricting the material removal in composites. Fig. 7(b), depicts a 2D

contour plot, with different colour, namely blue for minimum value, cyan for

medium value, green for high and red for very high value. The plot indicates

that wear rate increases with increase in load at minimum reinforced conditions.

A similar trend was observed by [26, 41] in their

work on adhesive wear behaviour of metal matrix composites. It is also

attributed that increase in reinforcement percentage increases the dislocation

density at the time of solidification process resulting in interruption of particle dislocation movement and improving the wear rate of the composites

[27].

The wear rate of the base alloy was higher than that of

the hybrid composites for all the load conditions. The surface plot depicts

that wear rate accelerated with increasing in load. An externally applied load

on to the cast samples with continuous contact on the counter face, deforms the

surface of the sample, which in turn leads to thermal softening of the specimen

and the wear regime changes from mild to severe wear. A similar

observation was recorded by [6] and [14] in wear study of Aluminium hybrid

composites. In summary, the % of reinforcements has negative effect on the wear

rate and it accelerates with the applied load

.

The influence of speed and distance on the wear rate is represented

in Fig. 7(c, d). The 3D surface plot and 2D counter plot indicates that the

wear rate declined with increasing speed and sliding distance. When the sliding

speed increases, a frictional heat was observed at the contact surfaces and a

molten layer was formed which in turn reduces the wear rate. It is also

recognized that the reinforcements bear a significant portion of load applied

on the composites during the test. At higher speeds the fragmented wear debris

particles are forced to combine with the specimen and form a mixed layer, which

in turn contribute to the better wear resistance. A similar type of behaviour

was observed by [28] & [29]. During increase of sliding distance the hard

ceramics available on the surface of the specimen were polish

ed out producing a lower wear rate. Abedini et al. [30]

reported that at higher sliding distance oxide layers were formed on the

surface which was the main reason for the declination of wear rate in the

hybrid composites.

Effect of parameters on

coefficient of friction

The influence of input parameters on coefficient of friction

is represented in Fig. 8. The effect of reinforcement and

load was presented in Fig. 8(a, b). The chart depicts that

coefficient of friction decreases with addition of reinforcement. It may be

credited due to the addition of alumina and boron carbide to the base alloy

where the surface asperities prevent the counter face from mating with the

rotating disk. This reduces the coefficient of friction. A related result was

revealed by [31] in Al 7075/ SiC /B4C composites.

The coefficient of friction was increasing with respect

to the given load conditions. Initially coefficient of friction increases

gradually and it accelerates with the higher load conditions. Singh [32]

reported that at initial loads, an oxide layer was formed with low shear

strength and ductility which reduces the metal to metal contact. But at higher

load conditions the oxide layers were not capable of preventing metal to metal

contact resulting in higher coefficient of friction.

The influence of sliding speed and distance on coefficient

of friction is represented in Fig. 8(c, d). The 3d plot depicts that increase

in sliding speed decreases the coefficient of friction. At higher sliding speed

the specimen gets thermally softened due to increase in interfacial

temperature, which in turn leads to a lower coefficient of friction. These

results were well matched with [33] experimentation in Al/SiC/B4C

Composites. Similarly Hemanth et al. [34] pointed out that higher sliding speed

resulted to the lower coefficient of friction. The plot also indicates that

increase in sliding distance decreases the coefficient of friction. It may be

credited to the presence of Al2O3 and B4C

which cater abrasion resistance, resulting in negative effect to the coefficient

of friction. These results were well correlated with [35]

investigated in A390/Grp composites, second order polynomial

regression model is constructed is investigated by plotting a graph between the

residuals and the normal probability. The probability plot for wear rate and

coefficient of friction is shown in Fig. 5. From the plot it is evident that

the residuals fall on a straight line and the errors are distributed in normal

showing accuracy of the model.

Validation

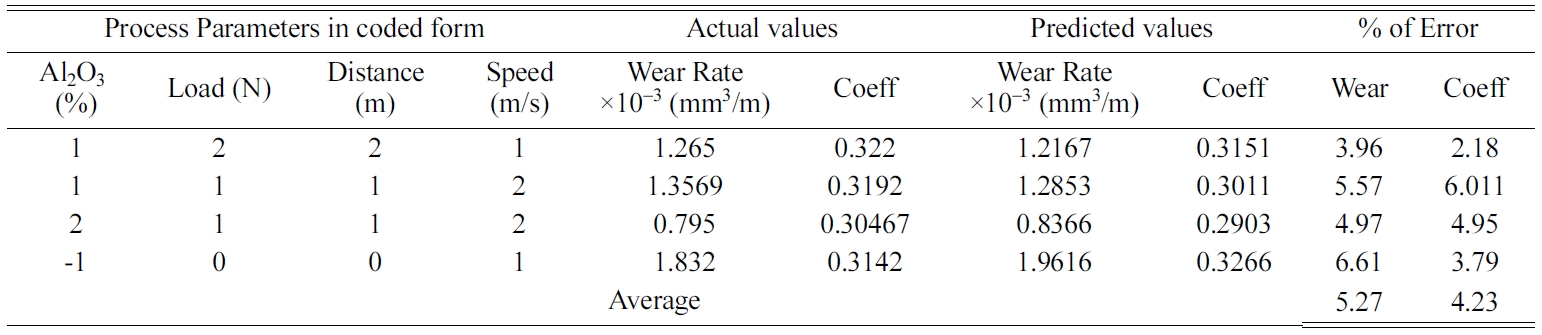

The mathematical models developed by regression analysis

were checked for their aqdequency using confirmation

experiments. The different input parameters, predicted

and actual responses were measured and reported in Table 6. From the results it

was evident that percentage of errors between the actual and the

predicted values were within the acceptable range. Hence the model

is highly efficient in predicting the wear rate and coefficient of friction

with 95% confidence level.

SEM

Analysis

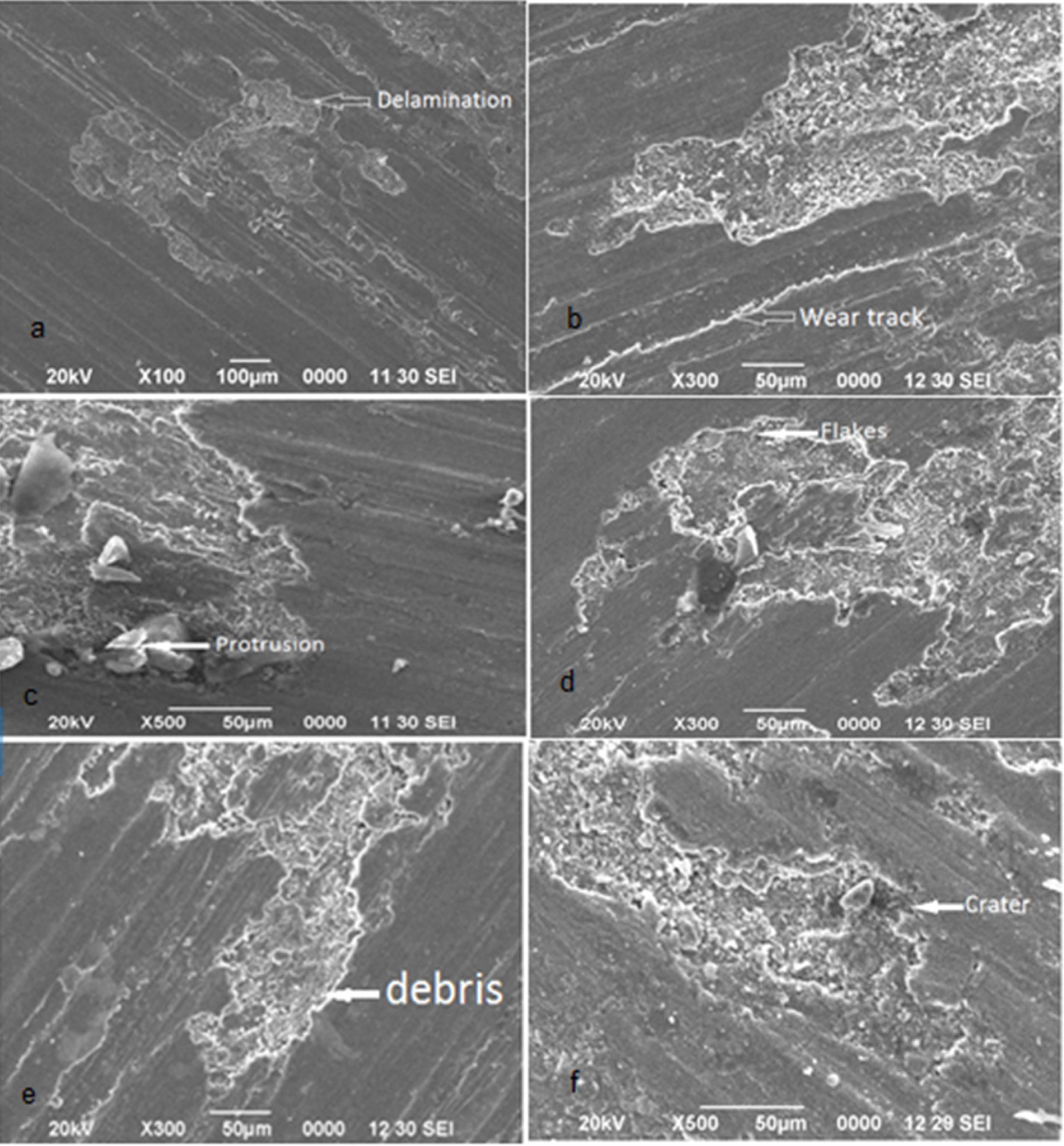

Scanning Electron Microscope (SEM) studies of the worn

specimens were carried out using JOE JSM 6360 make equipment. It can be

observed from Fig. 9(a) that the composite with 2% Al2O3

was characterized by delamination type of wear due to the adhesion between the

composite pin and the disc surface. This is due to the presence of fewer

amounts of Al2O3 particles in the composite leading to

the higher material removal from the

surface. Uthayakumar et al. [12] studied the micrograph of Al/SiC/B4C

composites and the results were well agreed with above observations. With an increase in Al2O3 it can be

observed that the delamination type

of wear behaviour was transformed to abrasive type of wear mechanism due the

increase in Al2O3 and B4C particle content

(Fig. 9(a-f)). The abrasive type of wear

mechanism is characterised by plastic deformation whereas the delamination is due to elastic deformation.

Decrease in wear rate is due to the increased bonding

strength between the Al2O3 and the aluminium matrix

defending the composite surface against delamination. The presence of shallow

wear grooves running parallel to the direction of loading was established along

the surface of the specimen (Fig. 9(b-c)). This is due to the ploughing of the

fractured Al2O3 particles along the surface in the form

of wear debris. With a further increase in Al2O3 to 6%

(Fig. 9(d-f)) and greater, the presence of both abrasive wear and delamination

in the form of patches were observed along the surface. This can be correlated

to the ANOVA results that increase in Al2O3 and B4C

decreases the wear rate.

Higher wear rate at higher loads was characterised due

to the formation of crater in addition to the abrasive wear (Fig.

9(f)). The protrusion of the Al2O3 particles is also

evidenced in the composite specimen at higher loads (Fig. 9(c)). This confirms

the results observed in Fig. 9(d) that an increase in load increases the wear

behaviour of the composite. Selvi et al. [16] reported that high abrasive wear

occurs at higher loads. The formation of debris in the form of flakes was prime

mechanism at higher speeds due to the thermal softening

of the material leading to a decrease in wear rate as shown in Fig. 7(c). This

may due to the fact that with an increase in sliding speed, the effective

indentation due to the Al2O3 particles will be reduced

due to the entrapment of the debris in the space between the Al2O3

present in the composite.

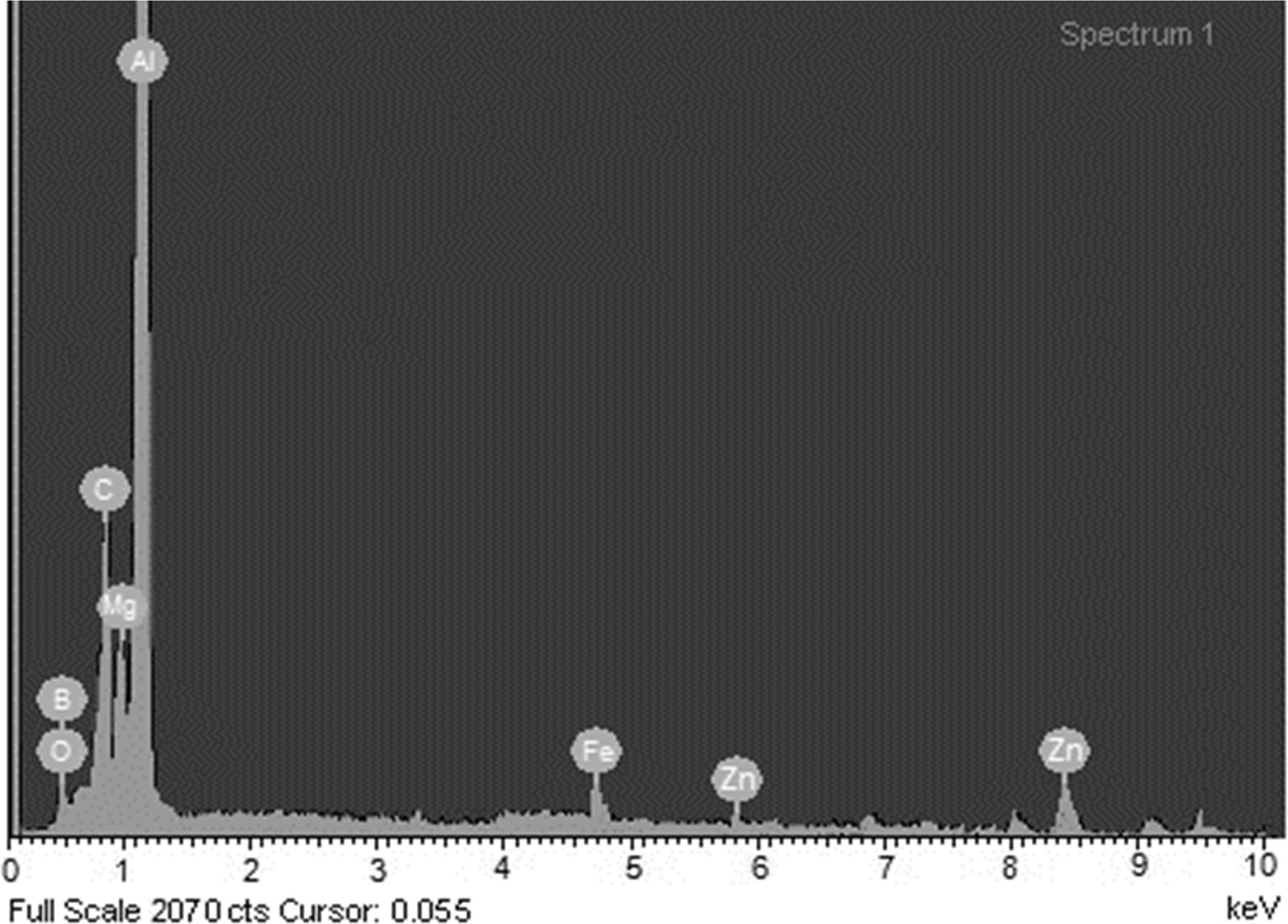

The worn surface of the hybrid composite under 20N load

was analysed using energy dispersive spectrometer (EDS).

Fig. 10 shows the EDS plot of 4% Al2O3

reinforced composite. The presence of Fe indicates the

transfer of iron from the counter disc to worn surface of the

specimen which results in forming of mechanically mixed layer

on the wear surface. Oxygen present in the composite confirms the oxidation reaction,

which in turn reduces the wear rate.

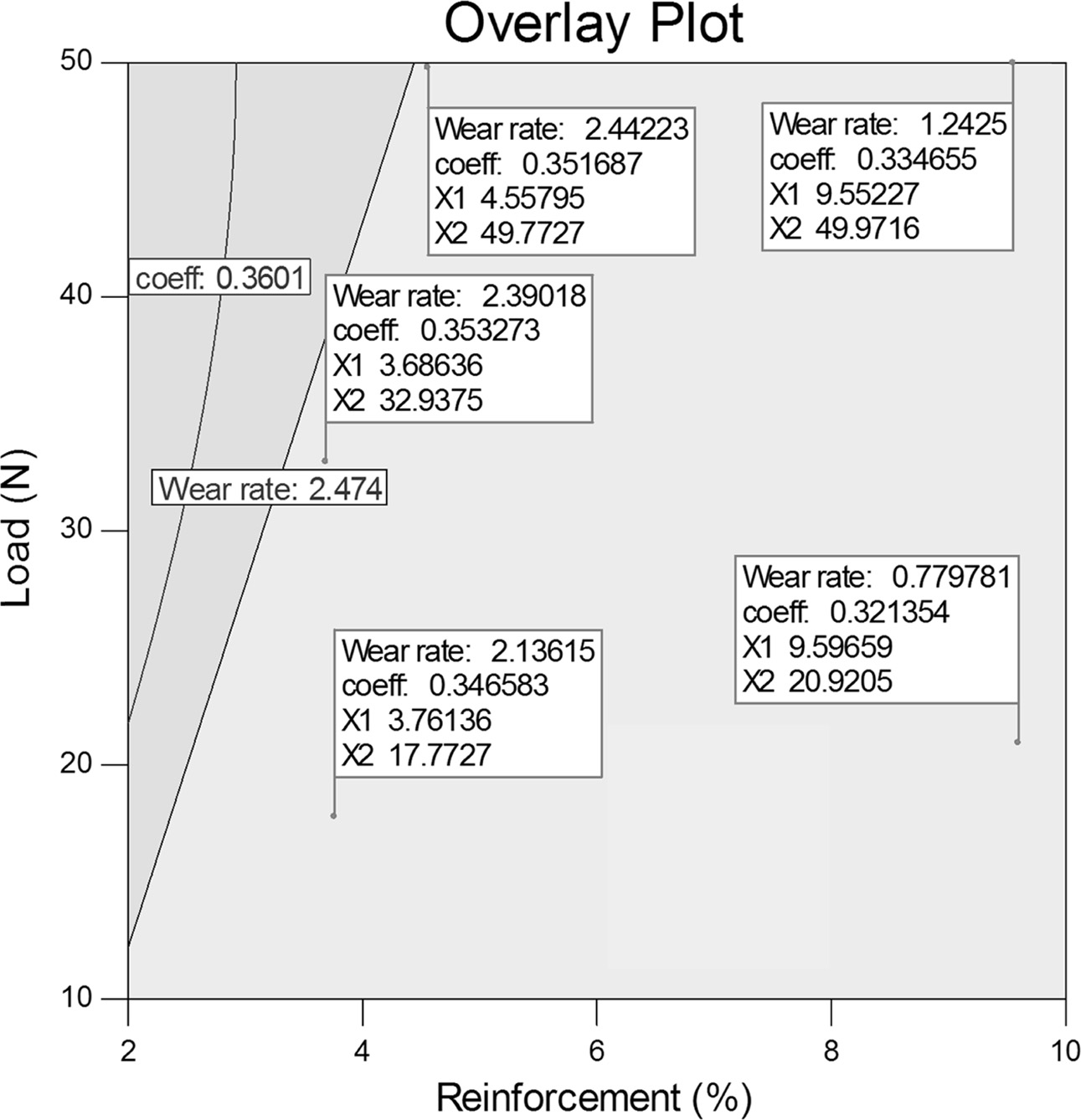

Fig. 11 shows the overlay

contour plot wear of Al/ Al2O3/B4C hybrid

composites in terms of % reinforcement in abscissa and load in ordinate. It is evident from

the plot that wear rate of hybrid composites continuously declines with

increase in reinforcement % for all load conditions. It is also observed that the wear rate

improved with increase in load for any

amount of reinforcements. The wear rate increases from 2.136 to 2.390 for an

increase in load (X2) from 17.7 to 32.9 for similar % reinforcement (X1). It is

credited to the third body abrasion of pull out and protruded particulates

which can be observed in Fig. 9(c). The coefficient of friction is reduced with increase in

load and % of reinforcement. It may be attributed that the reinforced ceramics

prevents the mating between the specimen and the disc, which in turn reduces

the coefficient of friction.

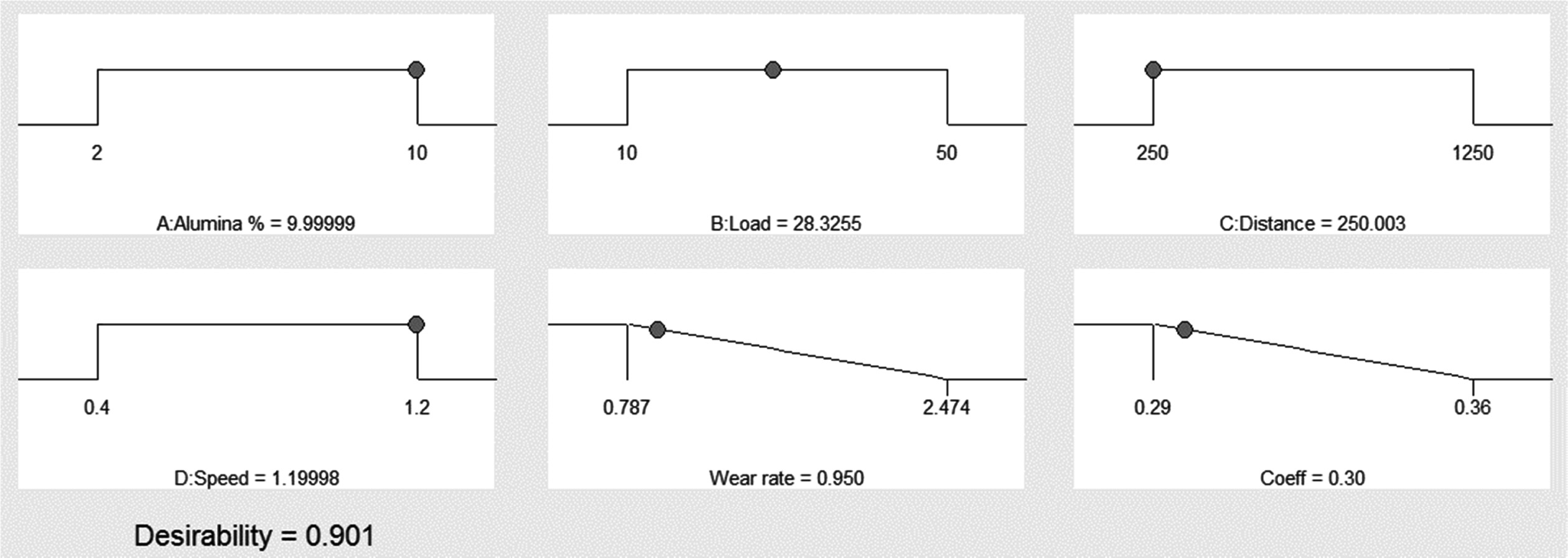

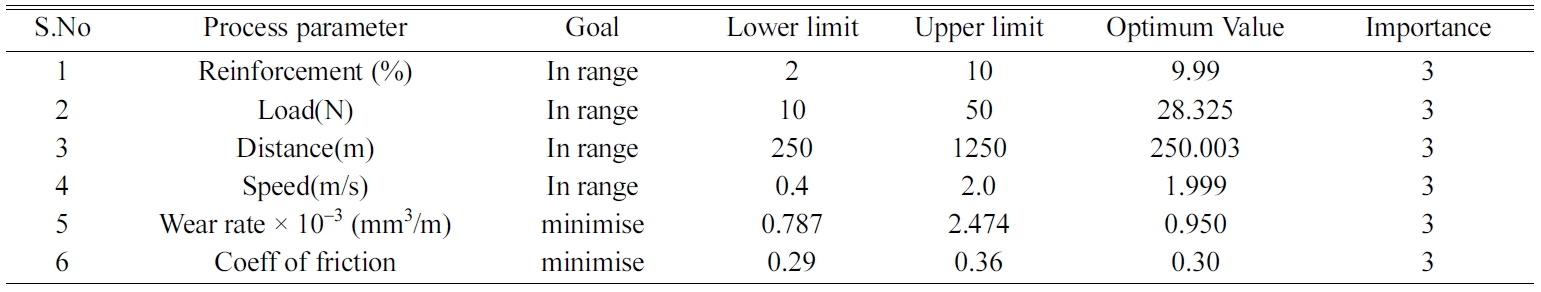

Desirability Based Multi Response Optimization

It is a challenging task to select the optimal process parameter

combinations for achieving improved wear rate and coefficient friction. Girish

et al. [36] employed Taguchi experimental design to

optimise the tribological parameters on wear rate. Derringer

et al. [37] explained a novel procedure on multiple response optimization named

Desirability approach. It is a smart technique used for optimizing the multiple

response problems. An objective function is created named desirability function

is transformed to an estimated response called desirability, which ranges from

0 to 1. The range respresents from least to the ideal case.

Gopalakannan et al. [19] applied combined central composite design and desirability

approach to improve the EDM characteristics of

aluminium matrix composites. The desirability evaluation was

done using Design Expert 10.0 software. In this study RSM was the

tool used to derive the optimized wear rate and coefficient of

friction values. Table 7 depicts the goals, range, optimal values

of the various input parameters and output responses ie. wear rate, coefficient

of friction. The analysis was made on 31 different input parameter pairs as

shown in Table 3. The input parameter pair with highest desirability value is

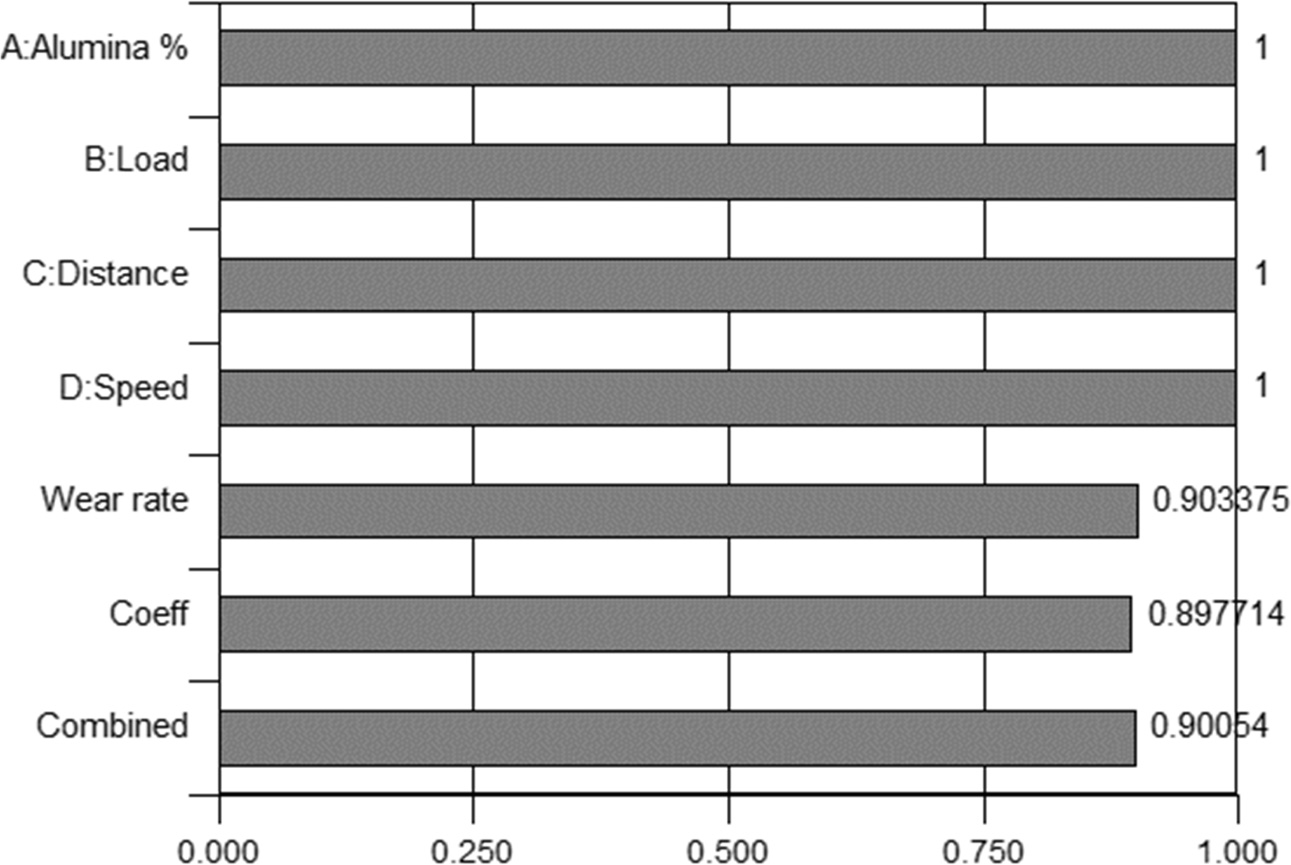

chosen as optimal condition for the output responses. The ramp function graph and

bar graph shown in Fig. 11, indicates the desirability of output responses. The

ramp function graph presents a clear picture on prediction

of response for particular parameters indicated by a dot. The bar graph (Fig.

13) represents the desirability values of each response and the combined

desirability of the model. The optimal region had a combined desirability

of 0.90054 which is an indication of closeness to the

response target. Fig. 12

|

Fig. 7 (a-d). Interaction plot for wear rate (a, b) 2D Contour plot (c, d). |

|

Fig. 8 (a-d). Interaction plot for coefficient of friction (a, b) 2D Contour plot (c, d). |

|

Fig. 9 (a-f). Worn Surfaces of Al Hybrid composite specimen under various conditions. |

|

Fig. 10 EDS analysis of worn surface at a load of 20N with 4% Al2O3. |

|

Fig. 11 Over lay counter plot for the effect on wear rate and coefficient of friction. |

|

Fig. 12 Ramp function graph of desirability. |

|

Fig. 13 Bar graph of desirability. |

|

Table 6 Mathematical comparison of actual and predicted results of wear rate and coefficient of friction model. |

Aluminum alloy reinforced with Al2O3

and B4C of different compositions were prepared by stir casting

method. The wear and frictional behaviour of the specimen were studied using

pin-on-disc equipment. The major outcome of the current investigations is

summarised.

• Al 7075/Al2O3/B4C matrix composite were manufactured successfully with a uniform dispersion of

particulates in the matrix which was authenticated by the SEM micro graph and

XRD.

• RSM Box Behnken design method was

employed to develop the model with 95% confidence level.

• A numerical model was developed to

predict the wear rate and coefficient of friction of aluminium hybrid

composites incorporating the effects of percentage of Alumina, sliding

distance, applied load, and sliding speed.

• The adequacy of the proposed model

was checked using ANOVA method. The result indicates that the developed model

has good agreement with the experimental results.

• The 3D interaction plot illustrate

that the wear rate decreases with increasing of

• Al2O3 content and incremented in increasing of load. The

wear rate has a negative impact in increase of sliding speed and sliding

distance.

• The coefficient of friction exhibited

an inversely proportional relationship with the percentage of reinforcement and

sliding speed.

• The input parameters were optimised

by adopting Desirability based multi response optimization to minimize the wear

rate and coefficient of friction.

• The optimum parameters of combination

is % of Alumina 9.99, Load 28.32 N, Sliding distance 250 m, Sliding speed 1.99

m/s, for a minimized wear rate of 0.950X 10-3

mm3/m and coefficient of friction 0.30 with a combined desirability

of 0.901.

- 1. M.K. Surappa, Sadhana 28[1-2] (2003) 319-334.

-

- 2. D.B. Miracle, Compos. Sci. Technol. 65[15-16] (2005) 2526-2540.

-

- 3. J. Eliasson and R. Standstorm, Key Engg Materials 104-107 (1995) 3-36.

-

- 4. M.O. Bodunrin, K.K. Alaneme, and L.H. Chown, J. of Mater. Res. Technol. 4[4] (2015) 434-445.

-

- 5. J. Hashim, L. Looney, and M.S.J. Hashm, J. Mater. Process. Technol. 92-93 (1999) 1-7.

-

- 6. A. Baradeswaran and A. Elaya Perumal, Compos.: Part B 56 (2014) 464-471

-

- 7. G.B. Veeresh Kumar, C.S.P Rao, N. Selvaraj, and M.S. Bhagyashekar, J. of Miner. & Mater. Char. & Engg 9[1] (2010) 43-55.

-

- 8. K. Ravi Kumar, K.M. Mohanasundaram, G. Arumaikkannu, and R. Subramanian, Tribol. - Mater., Surf. & Inter. 6[1] (2012) 15-19.

-

- 9. D.S. Prasad and C. Shoba, J. of Mater. Res. and Technol. 3[2] (2014) 172-178.

-

- 10. R. Kumar and S. Chauhan, Measurement 65 (2015) 166-180.

-

- 11. T. Rajmohan, K. Palanikumar, and S. Ranganathan, Trans. of Nonferr, Metals Soc. of China 23 (2013) 2509-2517.

-

- 12. M. Uthayakumar, S. Aravindan, and K. Rajkumar Mater. and Des. 47 (2013) 456-464.

-

- 13. K.R. Kumar, K.M. Mohanasundaram, G. Arumaikkannu, and R. Subramanian, Sci. and Engg of Compos. Mater. 19 (2012) 247-253.

-

- 14. N. Radhika and R. Raghu, Tribol Letters, 59[2] (2015) 1-9.

-

- 15. K. Ravi kumar, K.M. Mohanasundaram, G. Arumaikkannu, and R. Subramanian, Tribol. Trans 55 (2012) 723-729.

-

- 16. S. Selvi and E. Rajasekar, J. of Mech. Science and Technol. 29[2] (2015) 785-792.

-

- 17. S. Suresh, N. Shenbaga Vinayaga Moorthi, S.C. Vettivel, and N. Selvakumar, Mater. and Design 59 (2014) 383-396.

-

- 18. V. Vembu and G .Ganesan, Defence Technol. 11[4] (2015) 390-395.

-

- 19. K. Ravi Kuamr and Nishasoms, Arabian J. of Sci. Eng. 44 (2018) 893-909.

-

- 20. K. Ravi Kumar and V.S. Sreebalaji, Tribol. 9[3] (2015) 128-136.

-

- 21. S.C. Vettivel, N. Selvakumar, R. Narayanasamy, and N. Leema, Mater. and Design, 50 (2013) 977-996.

-

- 22. A.K. Lakshminarayanan and V. Balasubramanian, Trans. of Nonferr. Met. Soc. of China 19[1] (2009) 9-18.

-

- 23. X. Wang, X. Song, M. Jiang, P. Li, Y. Hu, K. Wang, and H. Liu, Optics & Laser Technol. 44[3] (2012) 656-663.

-

- 24. S. Rajakumar, C. Muralidharan, and V. Balasubramanian, Trans. Nonferrous Met. Soc. China 20[10] (2010) 1863-1872.

-

- 25. K. Velmanirajan, A. Syed Abu Thaheer, R. Narayanasamy and C. Ahamed Basha, Mater. and Des. 4 (2012) 239-254.

-

- 26. N. Radhika, R. Subramanian, S. Venkat Prasat, and B. Anandavel, Indl. Lubr. and Tribol. 64[6] (2012) 359-366.

-

- 27. A. Mazahery and M.O. Shabani, Trans. Nonferrous Met. Soc. China 23[7] (2013) 1905-1914.

-

- 28. V.C. Uvaraja and N. Natarajan, J. Tribol. 135[2] (2013) 021101.

-

- 29. K.M. Shorowordi, A.S.M.A Haseeb, and J.P Celis, Wear 256[11-12] (2004) 1176-1181.

-

- 30. M. Abedini, H.M. Ghasemi, and M. Nili Ahmadabadi, Tribol. Transactions 55[5] (2012) 677-684.

-

- 31. V.C. Uvaraja and N. Natarajan, J. of Miner. and Mater. Char. and Engg. 11 (2012) 757-768.

-

- 32. M. Singh, B.K. Prasad, D.P. Mondal, and A.K. Jha, Tribol. Inter. 34[8] (2001) 557-567.

-

- 33. U. Soy, A. Demir, and F. Findik, Indl. Lubr. and Tribol. 63[5] (2011) 387-393.

-

- 34. J. Hemanth, Wear 258[11-12] (2005) 1732-1744.

-

- 35. T.S. Mahmoud, J. of Mech. Engg Science 222[2] (2008) 257-265.

-

- 36. B.M. Girish, B.M. Satish, Sadanand Sarapure, and Basawaraj, Metallur. and Mater. Trans. A 47[6] (2016) 3193-3200.

-

- 37. G. Derringer and R. Suich, J. of Qual. Technol. 12[3] (1980) 214-219.

-

- 38. K. Kaviyarasan, T. Pridhar, B. Sureshbabu, C. Boopathi, and R. Srinivasan, IOP Conf. Ser.: Mater. Sci. Eng. 402 (2018) 01-07.

-

- 39. B. Sureshbabu, G. Chandramohan, C. Boopathi, T. Pridhar, and R. Srinivasan, Int. J. Ceram. Process. Res. 19[1] (2018) 69-74.

- 40. C. Saravanan, S. Dinesh, P. Sakthivel, V. Vijayan, and B. Suresh Kumar, Mater. Today:. Proc. 21[1] (2020) 744-747.

-

- 41. A.E. Pramono, Int. J. Ceram. Process. Res. 20[1] (2019) 01-07.

-

This Article

This Article

-

2020; 21(2): 131-142

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.131

- Received on Jul 12, 2019

- Revised on Jan 20, 2020

- Accepted on Jan 21, 2020

Services

Services

- Abstract

introduction

experimental procedure

response surface methodology and mathematical modelling

results and discussion

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Pridhar. T

-

Department of Mechanical Engineering, Sri Krishna College of Technology, Coimbatore, India

Tel : +919790003531 - E-mail: preeth_t@rediffmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.