- Synthesis of three-dimensional cactus-shaped SnO2 crystals via thermal evaporation of Sn

Min-Sung Kim*

Department of Information & Communications Engineering, Tongmyong University, Busan 48520, Korea

SnO2 crystals were

fabricated by thermal evaporation of Sn powder at 900°C in an oxygen atmosphere

without any catalyst. The growth time was varied in a range of 1 ~ 3

h in order to investigate the morphological change during growth of the

crystals. Scanning electron microscopy, X-ray diffractometry, energy dispersive

X-ray spectroscopy, and cathodoluminescence spectroscopy were used to

characterize the morphologies, crystal structures, and luminescence properties

of the SnO2 crystals. X-ray diffraction analysis showed that the SnO2

crystals had a rutile crystallographic structure. When the growth time was 1 h,

SnO2 microrods with a rough surface were observed. With an increase

of the growth time to 2 h, many nanowires on the SnO2 microrods such

that microrod-nanowire assembly had a cactus-like appearance. When the growth

time was further increased to 3 h, micro/nanowires were observed. A strong

visible emission peak centered at about 480 nm was observed in the room

temperature cathodoluminescence spectra of all the samples.

Keywords: Tin powder, Thermal evaporation, Tin oxide micro-rods, Cactus shape

Metal-oxide micro/nanocrystals recently have attracted

attention due to their novel properties and potential applications in

electronics and optoelectronics. Micro/nanocrystals of functional metal oxides

have been synthesized because they lend the possibility of

fabricating smart devices by exploiting their novel electrical,

optical, and magnetic properties. Among functional metal oxides, SnO2

with a wide band gap of 3.6 eV is one of the most important metal oxides with

many applications. It has been widely employed in various fields of solar

cells, light emitting diodes, transparent electrodes, transistors, photovoltaic

cells, lithium ion battery electrodes, and gas sensors.

In particular, SnO2 is an outstanding material

for gas sensors due to its advantages including high sensitivity, fast response

and recovery time, chemical and thermal stability, and high mechanical

strength. Thus, SnO2 is widely used as gas sensing material to

detect extremely hazardous gases. The sensing mechanism of SnO2 is

based on the change in the conductivity which is caused by the reaction between

the oxygen and the detected gas on the surface of the SnO2 material.

Hence, the surface area has a strong impact on the sensing performance.

The sensing performance is improved with an increase in the surface area of

sensing material. In general, micro/nanocrystals have large surface area, which results in the

enhancement of the sensing performance [1-5]. Accordingly, consideration effort

has been devoted to the synthesis of SnO2

micro/nanocrystals.

So far, diverse morphologies of SnO2 micro/nano-crystals

such as wires [6], belts [7], rods [8], and tubes [9] have been

synthesized. Especially, a three-dimensional (3D)

hierarchical morphology such as flower-like and dendritic shapes is thought to

be most effective for improving the sensing performance of gas sensors due to

the high surface area relative to volume [10]. In addition, 3D morphology is

favorable for the diffusion of gas molecules, which is important for improving

the sensitivity and response time of gas sensors. Thus, the facile synthesis of

SnO2 crystals with a 3D morphology is of considerable interest.

SnO2 micro/nanocrystals with a 3D morphology

have been mainly synthesized using wet chemical methods including hydrothermal

and sol-gel methods [11-15]. The wet chemical processes are carried out at

relatively low temperatures. The drawback of the low-temperature processes

is the poor crystallinity of micro/nanocrystals. Therefore,

dry process methods have received increasing attention in

synthesizing 3D SnO2 micro/nanocrystals. The dry

methods include thermal evaporation, chemical vapor

deposition, and pulsed laser deposition. Among them, thermal evaporation is a

relatively simple and low cost technique. There are few

reports on the synthesis of 3D SnO2 micro/nanocrystals using thermal

evaporation [16, 17]. In the reports, the 3D SnO2

micro/nanocrystals were grown via vapor-liquid-solid (VLS) mechanism.

Metal catalysts are essential in the VLS mechanism. But the catalysts can

create contamination in the micro/nanocrystals. Thus, it is

worthwhile to develop a catalyst-free thermal evaporation process

for synthesizing 3D SnO2 micro/nanocrystals.

In this paper, the facile synthesis of 3D cacti-like SnO2

crystals via thermal evaporation of Sn powder without using catalyst is

reported.

Sn powder with a purity of 99.99% was used as the source

material. The alumina crucibles with the Sn powder were placed in the middle of

a horizontal quartz tube furnace. The quartz tube was evacuated to a pressure

of 1 × 10-1

Torr by using a mechanical pump. Then oxygen was introduced into the quartz

tube until the pressure reached 100 Torr. The pressure was maintained at 100

Torr throughout the experiment. The temperature was set to 900 °C and the

growth time was varied in a range of 1 ~ 3 h to investigate the

effect of growth duration on the morphology of the products. The

furnace was subsequently cooled to room temperature. The products

in the crucibles were collected for characterization.

X-ray diffraction (XRD) patterns were obtained to

investigate the crystalline structure of the as-synthesized products. Field

emission scanning electron microscopy (FESEM) was used to

investigate the crystalline structure of the as-synthesized

products. An energy dispersive X-ray (EDX) spectroscope was employed to study

the components of the products. The cathodoluminescence (CL) measurement was

carried out at room temperature.

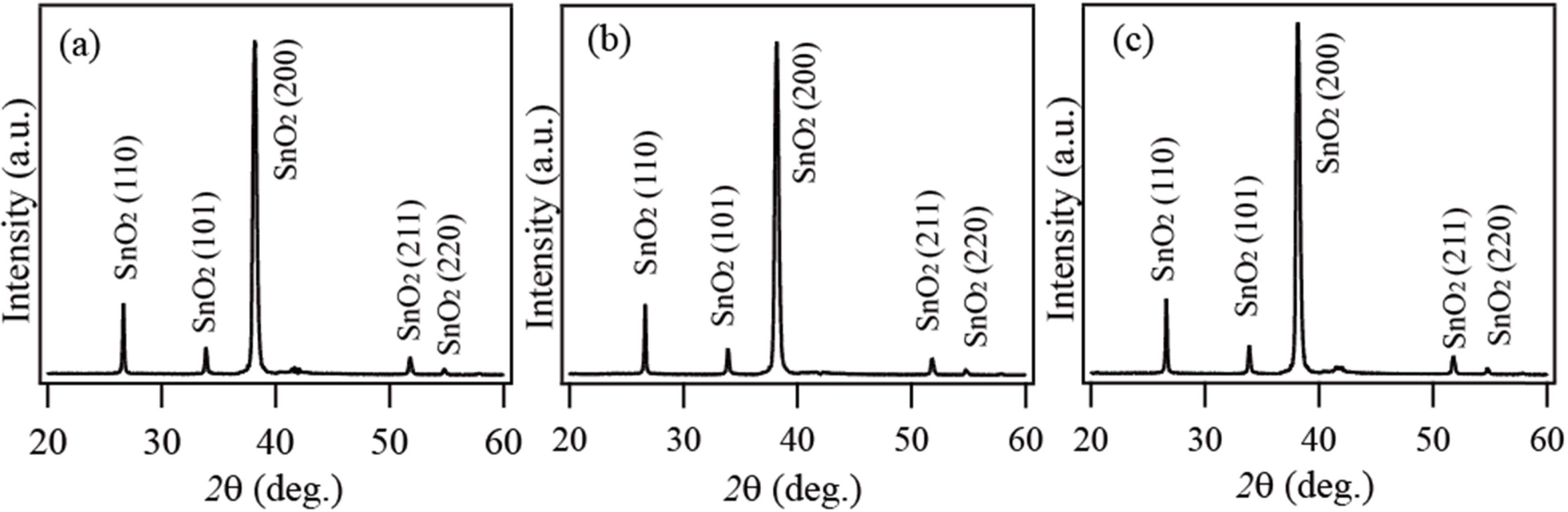

Fig. 1 shows the XRD spectra of the products synthesized

by thermal evaporation of Sn powder at 900 °C

in an O2 ambient for 1 h, 2 h, and 3 h, respectively.

XRD spectra reveal similar XRD peak patterns for all the products. The

diffraction peaks are identical to the tetragonal rutile structure of SnO2

with lattice constants of a = b = 0.473 nm and

c = 0.318 nm, indicating that all the products are SnO2 with

a rutile structure. No peaks were detected for other crystalline phase of

impurities.

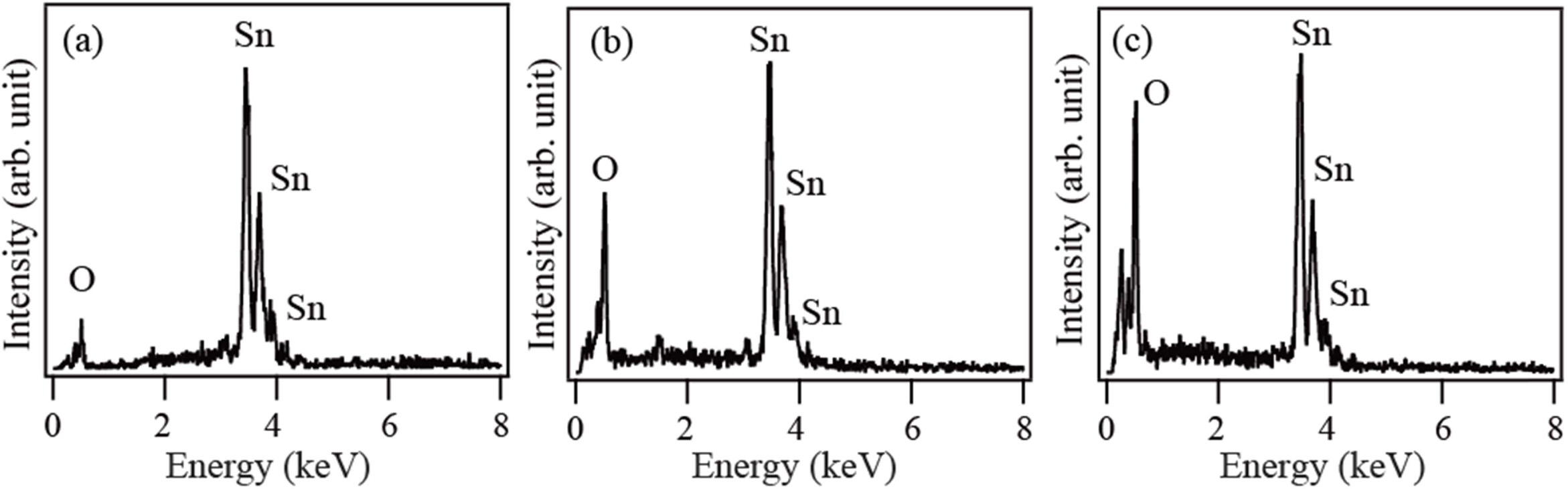

Fig. 2 shows the EDX spectra of the products synthesized

by thermal evaporation of Sn powder at 900 °C in an O2 ambient

for 1 h, 2 h, and 3 h, respectively. Only Sn and O are detected in the spectra,

which confirms that the products are high purity SnO2.

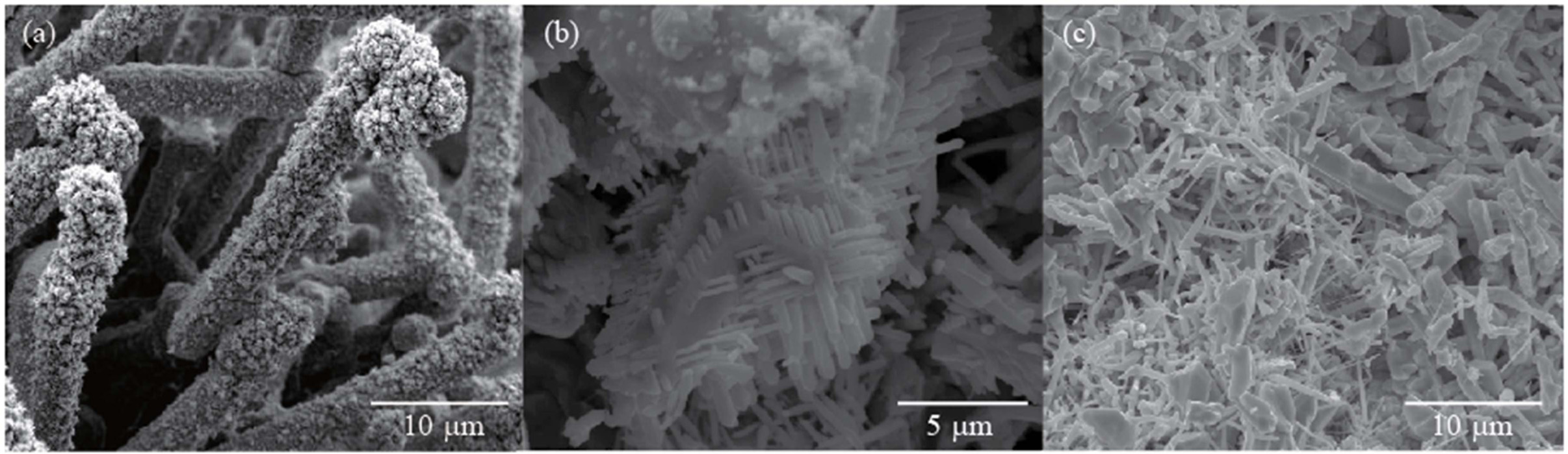

Fig. 3 shows SEM images of the SnO2 crystals

synthesized by thermal evaporation of Sn powder at 900 °C

in an O2 ambient for 1 h, 2 h, and 3 h, respectively.

When the growth time was 1 h, SnO2 microrods with a rough

surface were observed. The SnO2 microrods have

an average diameter of 4 μm and lengths of several tens of

micrometers. SnO2 micro/nanowires with a rough

surface have been observed in products synthesized through thermal evaporation

of Sn under a vacuum condition [18]. Upon increasing the growth time to 2 h,

the SEM image exhibits SnO2 microrods on which nanowires with high

density are grown. The SnO2 microrod consists of a main micro-sized

stem and numerous nanowires on the stem, which resembles a cactus-like

structure. The nanowires are grown on the rough surface

of the main stem. The main stems are 0.25 ~ 1 μm

in diameter and 7 ~ 15 μm in length, respectively.

The diameter and the length of the nanowires are 50 ~ 250 nm and

0.5 ~ 1.5 μm, respectively. Secondary branched nanowires as well as

primary branched nanowires are observed in the SEM images. The branched

nanowires have uniform diameter along the growth direction, which indicates

that the growth conditions remained constant during the growth. The secondary

branched nanowires were grown in a perfectly perpendicular direction to the

side of the main stem.

The growth mechanism of the cactus-like SnO2 microrods

with branched nanowires is posited as follows. Initially,

Sn powder is vaporized into Sn vapor. The Sn vapor reacts with the oxygen in

the atmosphere to form SnO2 nuclei. The nuclei grow along the

preferential direction, leading to the formation of main stems. The size of the

main stems increases with the growth time. Secondary nucleation and growth

occur on the main stems, which are sufficiently large to promote

secondary nucleation on their surfaces. The secondary nucleation

leads to the growth of primary branched nanowires on the main stems. The same

growth process is repeated on the primary branched nanowires, resulting in the

formation of secondary branched nanowires. The rough surface of the main stems would

favor secondary nucleation. On the other

hand, in the present experiment, the

growth of main stems and branched nanowires is considered to proceed via a vapor-solid (VS) mechanism because no catalysts were used and no catalyst

droplets were found at the tips of the nanowires. There are two growth mechanisms in the growth of the

one-dimensional nanowires and

nanorods. One is vapor-solid (VS) mechanism and the other is vapor-liquid-solid

(VLS) mechanism. In the VLS mechanism, metal catalyst is required to direct the

crystal growth on to specific orientation. The metal catalyst forms liquid

droplets and adsorbs vapor components

at the growth temperature. When the

liquid droplets become supersaturated with the absorbed components, the

components start to precipitate and continued precipitation results in the

growth of nanowires. Therefore, catalyst particles are typically observed at

the tips of nanowires grown via VLS mechanism [19, 20]. In this work, no

catalyst particles were observed at the tips of the branched nanowires,

indicating that the nanowires were grown via VS mechanism.

After growth time of 3 h, SnO2 microrods with

branched nanowires were not observed and micro/nanowires were found. It is

known that SnO2 is an oxide that becomes unstable above 500 °C

[21]. Thus, in the present work, the SnO2 microrods would decompose

into Sn and oxygen because of prolonged growth time and then Sn vapor would

react with oxygen to form SnO2 nanowires.

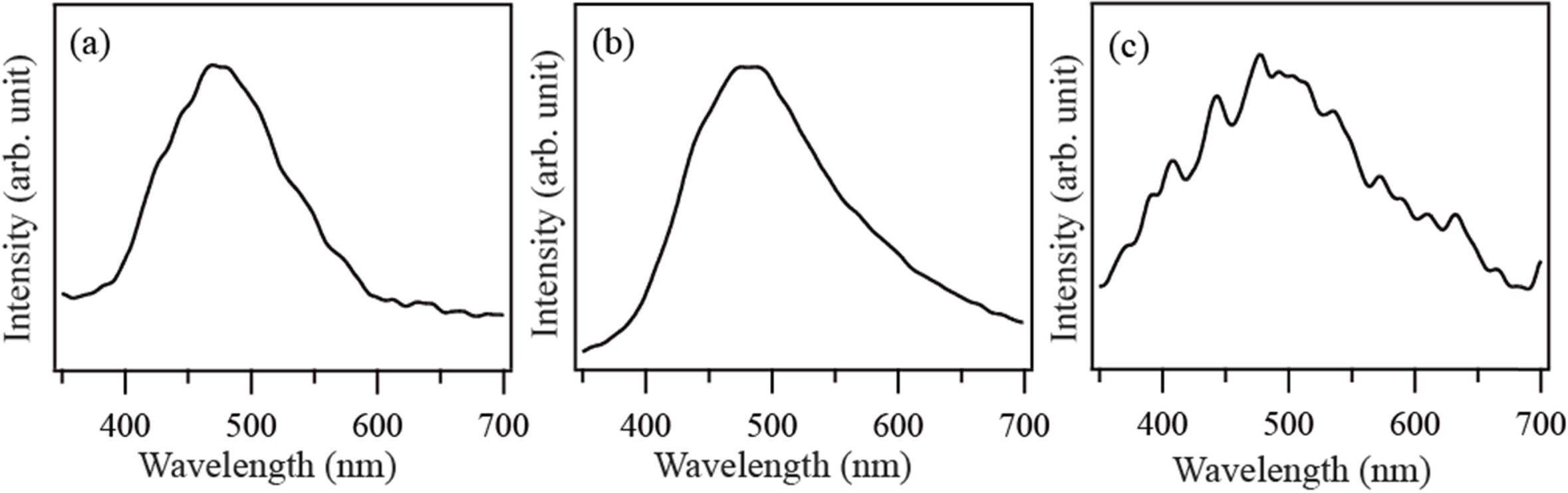

Figs. 4(a), (b), and (c) show the CL spectra of the SnO2

crystals synthesized by thermal evaporation of Sn powder at

900 °C in an O2 ambient for 1 h, 2 h, and 3 h,

respectively. A broad visible emission with a maximum at 480 nm is dominantly

observed in the CL spectra. The broad visible emission has been observed from

SnO2 crystals at room temperature [22, 23]. The visible

luminescence is known to be associated with oxygen vacancies. Luo et al

reported that the emission peak at 480 nm also originated from surface oxygen

vacancies [24]. Because SnO2 is an n-type semiconductor, the

presence of oxygen vacancies is related to the n-type semiconducting property.

Accordingly, it is suggested that the visible emission observed in the present

experiment can be attributed to oxygen-related defects.

|

Fig. 1 XRD spectra of the products synthesized at 900°C for (a) 1 h, (b) 2 h and (c) 3 h, respectively. |

|

Fig. 2 EDX spectra of the products synthesized at 900°C for (a) 1 h, (b) 2 h and (c) 3 h, respectively. |

|

Fig. 3 SEM images of the products synthesized at 900°C for (a) 1 h, (b) 2 h and (c) 3 h, respectively. |

|

Fig. 4 Room temperature CL spectra of the products synthesized at 900°C for (a) 1 h, (b) 2 h and (c) 3 h, respectively. |

SnO2 micro/nanocrystals with a tetragonal

rutile structure could be formed via thermal evaporation of Sn powder

in oxygen ambient at 100 Torr. The morphology of SnO2

micro/nanocrystals was significantly affected by an

increase in growth time. As growth time increased, the

morphology of the SnO2 micro/nanocrystals changed

from microrods to cactus-like microrods on which numerous nanowires were grown.

The cactus-like microrods consisted of main stems and many branched nanowires.

Secondary branched nanowires as well as primary branched nanowires were

observed on the microrods. It is considered that the 3D cactus-like

hierarchical SnO2 crystals were grown via VS growth. In the room

temperature CL spectra, a strong visible emission at 480 nm was observed, and

this might be attributable to oxygen vacancies. The unique 3D

cactus-like SnO2 crystals have high accessible

surface area and considerable inter-nanowire space, which can provide more

active sites. Thus the cactus-like crystals can be used as a potential material

for highly efficient gas sensors, catalysts, dye-sensitized solar cells, and

Li-ion batteries.

This Research was supported by the Tongmyong University

Research Grants 2019.

- 1. S. Supothina, M. Suwan, and A. Wisitsoraat, J. Ceram. Process. Res. 14 (2013) 226-229.

- 2. H. Yu, T. Yang, Z. Wang, Z. Li, B. Xiao, Q. Zhao, and M. Zhang, J. Alloy. Compd. 724 (2017) 121-129.

-

- 3. R. Zhao, Z. Wang, Y. Yang, X. Xing, T. Zou, Z. Wang, and Y. Wang, J. Phys. Chem. Solids 120 (2018) 173-182.

-

- 4. X. Lian, Y. Li, J. Zhu, Y. Zou, X. Liu, D. An, and Q. Wang, Curr. Appl. Phys. 19 (2019) 849-855.

-

- 5. T. Li, W. Zeng, H. Long, and Z. Wang, Sens. Actuat. B-Chem. 231 (2016) 120-128.

-

- 6. J.M. Jeong, Y.J. Kwon, H.Y. Cho, H.G. Na, and H.W. Kim, J. Ceram. Process. Res. 15 (2014) 428-432.

- 7. S.H. Sun, G.W. Meng, Y.W. Wang, T. Gao, M.G. Zhang, Y.T. Tian, X.S. Peng, and L.D. Zhang, Appl. Phys. A. 76 (2003) 287-289.

-

- 8. H.W. Kim, J.W. Lee, S.H. Shim, and C. Lee, J. Korean Phys. Soc. 51 (2007) 198-203.

-

- 9. W. Jin, Z. Tian, L. Lin, D. Jiatao, Z. Gang, Z. Pei, J. Yong, J. Zhifeng, and S. Xiaosong, Mater. Lett. 180 (2016) 38-41.

-

- 10. H. Wang, and A.L. Rogach, Chem. Mater. 26 (2014) 123-133.

-

- 11. J.R. Hunag, K. Yu, C.P. Gu, M.H. Zhai, Y.J. Wu, M. Yang, and J.H. Liu, Sens. Actuat. B-Chem. 147[2] (2010) 467-474.

-

- 12. H. Wang, Q.Q. Liang, W.J. Wang, Y.R. An, J.H. Li, and L. Guio, Cryst. Growth Des. 11 (2011) 2942-2947.

-

- 13. R. Yang, Y.G. Gu, Y.Q. Li, J. Zheng, and X.G. Li, Acta Mater. 58 (2010) 866-874.

-

- 14. Y.L. Wang, M. Guo, M. Zhang, and X.D. Wang, Scripta Mater. 61 (2009) 234-236.

-

- 15. Q, Wang, L.S. Zhang, J.F. Wu, W.D. Wang, W.G. Song, and W. Wang, J. Phys. Chem. C 114 (2010) 22671-22676.

-

- 16. Z. Guo, X. Chen, W.H. Xu, J. Li, G.M. Yang, M.Q. Li, J.H. Liu, and X.J. Huang, Mater. Today 14 (2011) 42-49.

-

- 17. S.H. Mohamed, J. Alloy. Compd. 510 (2012) 119-124.

-

- 18. N.M. Shaalan, T. Yamazaki, and T. Kikuta, Sens. Actuat. B-Chem. 153[1] (2011) 11-16.

-

- 19. W.I. Park, J. Ceram. Process. Res.9 (2008) 666-671.

- 20. R.S. Wagner, and W.C. Ellis, Appl. Phys. Lett. 4 (1964) 89-90.

-

- 21. D. Zhang, X. Li, F. Wan, C.J. Thong, M.A. Rindfleisch, M.J. Tomsic, M.D. Sumption, and E.W. Collings, Mater. Sci. Eng. 279 (2017) 012025.

-

- 22. S.H. Luo, Q. Wan, W.L. Liu, M. Zhang, Z.T. Song, C.L. Lin, and P.K. Chu, Prog. Solid State Chem. 33 (2005) 287-292.

-

- 23. S. Luo, J. Fan, W. Liu, M. Zhang, Z. Song, C. Lin, X. Wu, and Paul K. Chu, Nanotechnology 17 (2006) 1695-1699.

-

- 24. S. Luo, P.K. Chu, W. Liu, M. Zhang, and C. Lin, Appl. Phys. Lett. 88 (2006) 183112.

-

This Article

This Article

-

2020; 21(1): 119-122

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.119

- Received on Nov 14, 2019

- Revised on Dec 15, 2019

- Accepted on Dec 24, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Min-Sung Kim

-

Department of Information & Communications Engineering, Tongmyong University, Busan 48520, Korea

Tel : +82-51-629-1148 Fax: +82-51-629-1148 - E-mail: minsung@tu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.