- Fabrication of cross-ply Cf/C-SiC composites and the investigation of pyrolysis conditions on their properties

Kati Raju, Seyoung Kim*, Young-Hoon Seong, Soo-Hyun Kim and In-Sub Han

Energy Efficiency and Materials Research Division, Korea Institute of Energy Research, Daejeon 34129, Korea

The fabrication of continuous

carbon fiber-reinforced carbon-silicon carbide matrix (Cf/C-SiC)

cross-ply composites is highly attractive from a practical viewpoint due to

their homogeneous microstructures and isotropic mechanical properties. However,

the properties of Cf/C-SiC composites depend significantly on their

processing conditions and temperatures, especially the pyrolysis conditions and

temperatures. In this study, cross-ply Cf/C-SiC composites were

fabricated using different pyrolysis protocols with phenolic resin via a liquid

silicon infiltration. The effects of the pyrolysis conditions on the

microstructures of the composites and their mechanical properties as well as on

crack formations were evaluated at room temperature. Pyrolysis was performed at

600 °C for 1 h in a nitrogen atmosphere at different heating rates. The

flexural strength varied from a minimum of 47 ± 3 MPa to a maximum of

62 ± 6 MPa (~ 35% increase) depending on the pyrolysis

conditions.

Keywords: Pyrolysis; Microstructure; Cf/C-SiC composites; Flexural strength

Research into the fabrication of continuous carbon fiber-reinforced

carbon-silicon carbide matrix composites (Cf/C-SiC)

is active at present because of their remarkable properties,

such as low density, low coefficient of thermal expansion,

high fracture toughness, high specific stiffness, and

excellent oxidation resistance [1-4]. Due to these outstanding properties,

these composites are recognized as potential candidates for

applications in many advanced technological

industries, including the automotive, energy, aerospace,

and defense sectors [2-8]. The global market for these composites is increasing

rapidly and it was reported that in the aerospace sector alone, they will be

worth an estimated value of ~ 1.07 trillion US$ by 2028 because of the

manufacture of about 231,000 new aircraft engines [9].

Various fabrication techniques have been developed for

manufacturing Cf/C-SiC composites, including liquid

silicon infiltration (LSI), chemical vapor infiltration (CVI), and polymer

impregnation and pyrolysis (PIP) [1, 10-12]; each of these

techniques has certain advantages and disadvantages. In particular,

the CVI and PIP methods employ many hazardous and cost-ineffective reactive

gases and liquid precursors, respectively; these processes are very time

consuming (> 24 h). Moreover, the fabrication of complex and large-sized

composites is very difficult. From an industrial viewpoint, it has

been demonstrated that LSI is an effective and economically

viable technique for fabricating Cf/C-SiC composites [1, 2]. Its

advantages mainly include low costs, short fabrication periods (~ 3 h),

low residual porosities, and the simplicity of large, complex, and near-net

shaping. However, disadvantages such as the presence of residual silicon and

fiber damage due to the exothermic reaction of silicon with carbon limit the

usage of LSI. Nonetheless, these problems can be overcome by adjusting the

processing parameters and coating with a suitable interphase layer wherever

required.

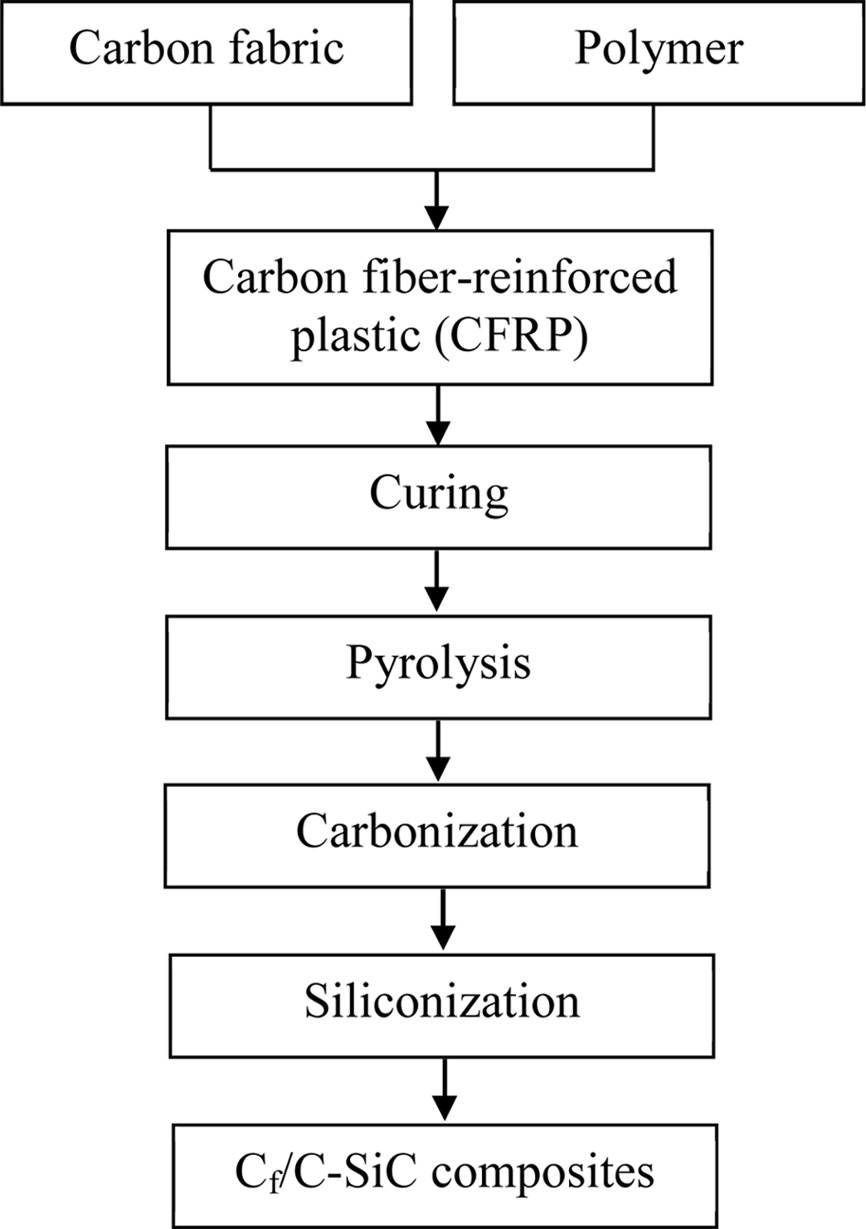

Curing, pyrolysis, carbonization, and siliconization are

the main sequential steps involved in the fabrication of Cf/C-SiC

composites via LSI. Fig. 1 presents flow-chart for a

typical LSI technique. Carbonization at higher temperatures

may be applied sometimes after pyrolysis depending on

the requirements. After preparing a carbon fiber-reinforced

plastic (CFRP) with the desirable preform and polymer,

curing is normally performed at lower temperatures (< 250 °C),

where cross-linking of the polymer occurs and it hardens. Different

thermosetting and thermoplastic polymers can be used, such as polyetheretherketone,

polyetherimide, phenolic, silicone, and epoxy resins [13-16]. In

the next step, pyrolysis is performed at moderate temperatures below

1,000 °C and the polymer is converted into amorphous/glassy carbon. Cracks

are generated within the CFRP during pyrolysis due to shrinkage of the matrix.

Subsequently, carbonization is conducted at temperatures greater than

1,600 °C in order to obtain the porous Cf/C preform. Finally,

siliconization is performed at temperatures higher than

1,420 °C (melting temperature of Si), where the liquid

silicon infiltrates under the driving capillary force and expands to fill the

pores. Moreover, the liquid silicon reacts with carbon in the porous preform to

yield a dense Cf/C-SiC composite.

Each step in the LSI process plays a crucial role in

determining the final characteristics of the Cf/C-SiC composites

because their properties depend significantly on the

processing conditions [16-18]. The pyrolysis of CFRP is

considered a vital step because segment cracks (transverse),

micro-cracks, and micro-delaminations start generating during this

stage [19, 20]. The properties of composites are governed primarily by

these crack patterns. However, these cracks can be controlled by adjusting

parameters such as the pyrolysis temperature, heating rate, and fiber

treatment, and by adding filler materials to the polymers [21-26]. Furthermore,

the properties of Cf/C-SiC composites depend greatly on the

fibers employed, fiber orientation, fiber architecture,

interphase coating layers, matrix phase, and many other factors

[1, 27]. From a practical viewpoint, using cross-ply Cf/C-SiC

composites with homogeneous microstructures and

isotropic mechanical properties is more attractive than employing woven and

unidirectional composites. Cross-ply composites have received little attention

in previous studies. Thus, in the present study, cross-ply Cf/C-SiC

composites were fabricated with different pyrolysis

protocols via the LSI method. The micro-

structures of the composites and their mechanical properties, such as

the flexural strength and fracture toughness, were evaluated at room

temperature.

|

Fig. 1 Flow-chart for the fabrication of Cf/C-SiC composites through LSI. |

In order to fabricate cross-ply Cf/C-SiC

composites, unidirectional carbon fibers (T-300, Toray, Japan) of

6 × 6 cm2 in size were initially impregnated using

phenolic resin (KRD-HM2, Kolon Chemical Co. Ltd, Korea). The volume fraction of

fiber content was about 0.49%. CFRP was prepared by stacking 16-ply fabrics in

alternative 0° and 90° directions under vacuum bagging, before slowly curing at

120 °C for 24 h. The cured CFRP was heat-treated to achieve pyrolysis in a

nitrogen atmosphere at 600 °C for 1 h with two

different temperature ramp-up rates of 25 and 50 °C/h. The

temperature was selected based on thermogravimetric analyses of phenolic resins

in our previous studies and other reported data [24, 25, 28]. The carbonization

of CFRP was performed at 1,600 °C. LSI was conducted with the porous Cf/C

preform at 1,600 °C in vacuum for 30 min. Four different composites were

fabricated using different pyrolysis conditions as shown in Table 1 along with

their labels.

The densities of the composites after LSI were exper- imentally determined using the

well-known Archimedes’ method [29]. The microstructures of

the composites after pyrolysis and LSI were observed by scanning electron

microscopy (SEM; Model: S-4800, Hitachi Co.). The flexural strengths of the

composites were measured using the three-point bending test according to the

ASTM C1161 standard with a universal testing machine (UTM: H5KT, Tinius Olsen,

USA). Flexural tests were conducted with a cross-head speed of 0.5 mm/s at room

temperature using polished specimens with dimensions of 40l × 4w × 3t

mm3. The bending strengths were calculated based on the maximum load

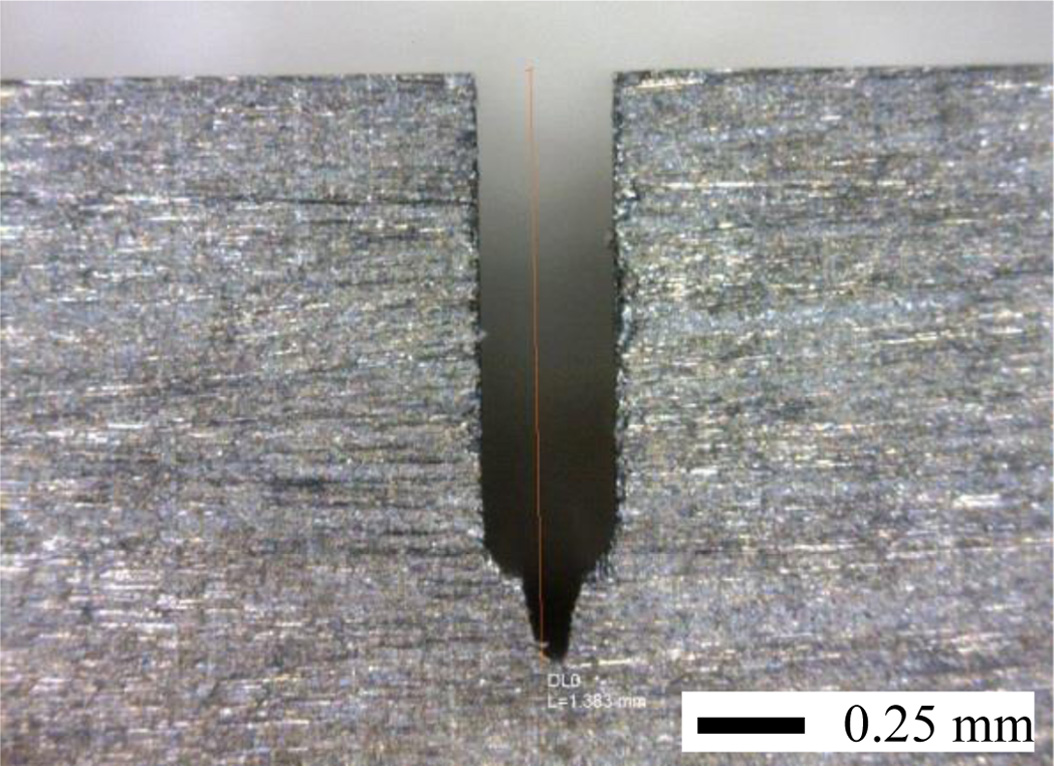

after fracture. The fracture toughness (KIc)

of each com- posite

was evaluated using the single edge V-notched beam method according to the ASTM

C1421 standard. Fig. 2 shows optical microscopic image of a typical composite

used for fracture toughness measurement. Averages based on five measurements

were determined for the flexural strength and fracture toughness.

|

Fig. 2 SEVNB optical microscopic image of composite C4 used for fracture toughness test. |

|

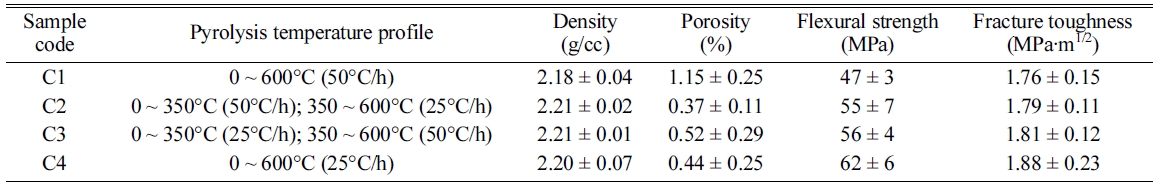

Table 1 Density, porosity, flexural strength and fracture toughness values for all of the composites. |

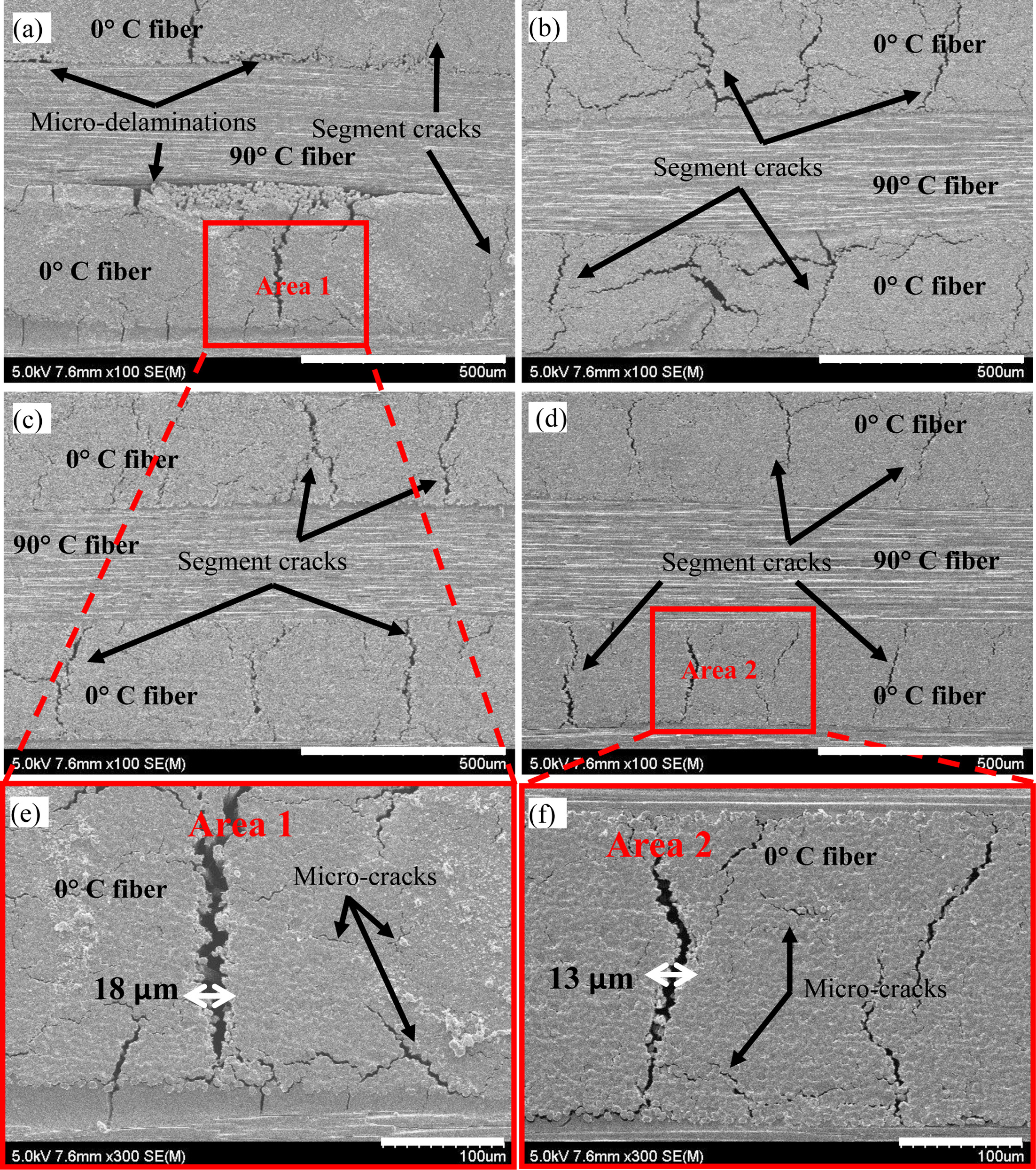

Previous studies have demonstrated the importance of the

pyrolysis conditions for the fabrication of composites via LSI [16, 30]. Chang et al.

[16] studied the effects of the pyrolysis heating rate on the mechanical

properties. They observed that the flexural strength decreased as the heating

rate increased. This was attributed to the higher number of voids and cracks

generated within the composite at higher heating rates. During pyrolysis, the

phenolic resin was converted to amorphous/glassy carbon. The weight

loss was substantial between temperatures of 400 ~ 700 °C

(approximately 27.1%), which corresponded to more than 90% of the total gases

that evolved [28]. Based on our previous thermogravimetric analyses of phenolic

resins [24, 25], pyrolysis was performed at 600 °C in this study with

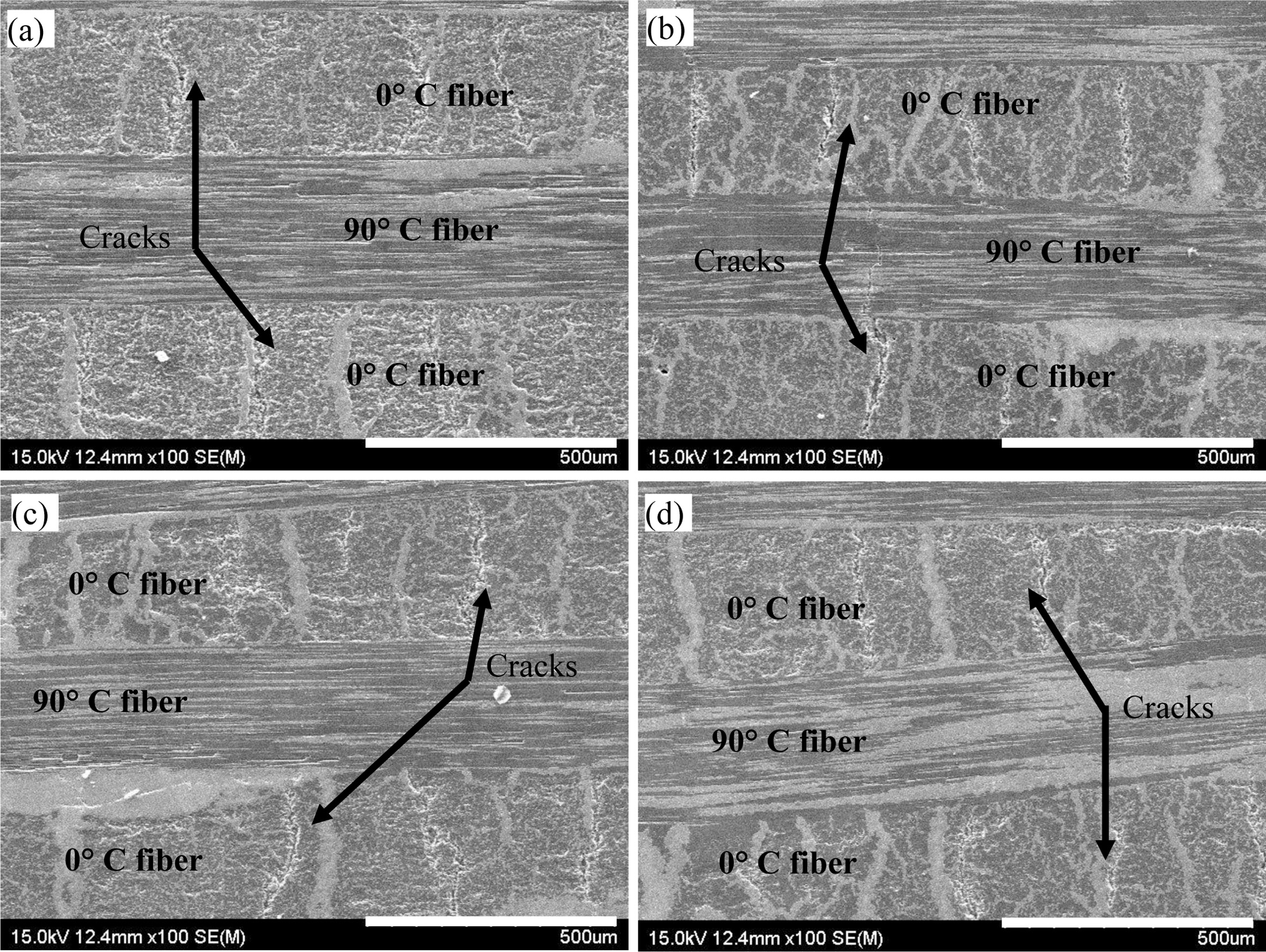

heating rates of 25 and 50 °C/h. Fig. 3 shows SEM images of all the

composites after pyrolysis at 600 °C using different protocols. Magnified

images of areas 1 and 2 in Figs. 3(a) and (d) are shown in Figs. 3(e) and (f),

respectively. All the composites exhibited similar segment cracks and

micro-cracks. However, sample C1 contained a few additional

micro-delaminations, as shown in Fig. 3(a), which may be attributed to the

higher heating rate of 50 °C/h. During the pyrolysis process, CFRP was

transformed into a porous Cf/C structure via the development of

cracks that allowed the liquid silicon to penetrate. Different cracks such as

segment cracks (transverse) developed within the 0° fiber bundles and

micro-delaminations in the opposite fiber bundles (0° and 90° directions).

Moreover, some micro-cracks and voids also developed within the segments [23].

Each of these different types of cracks was generated due to an offset of the

compressional stresses generated within the segments after the carbon matrix

shrinks. The widths of the segment cracks were directly

related to the pyrolysis temperature and heating rates. The

widths of the segments were expected to increase as the temperature and heating

rate increased. We found that when the heating rate decreased from 50 to

25 °C/h, the crack width also decreased from about 18 to 13 μm, as shown

in Fig. 3(e & f). Table 1 presents the density and porosity values for all

the four composites prepared using different pyrolysis conditions.

Evidently, the density and porosity values were similar and

they were not affected considerably by the pyrolysis conditions.

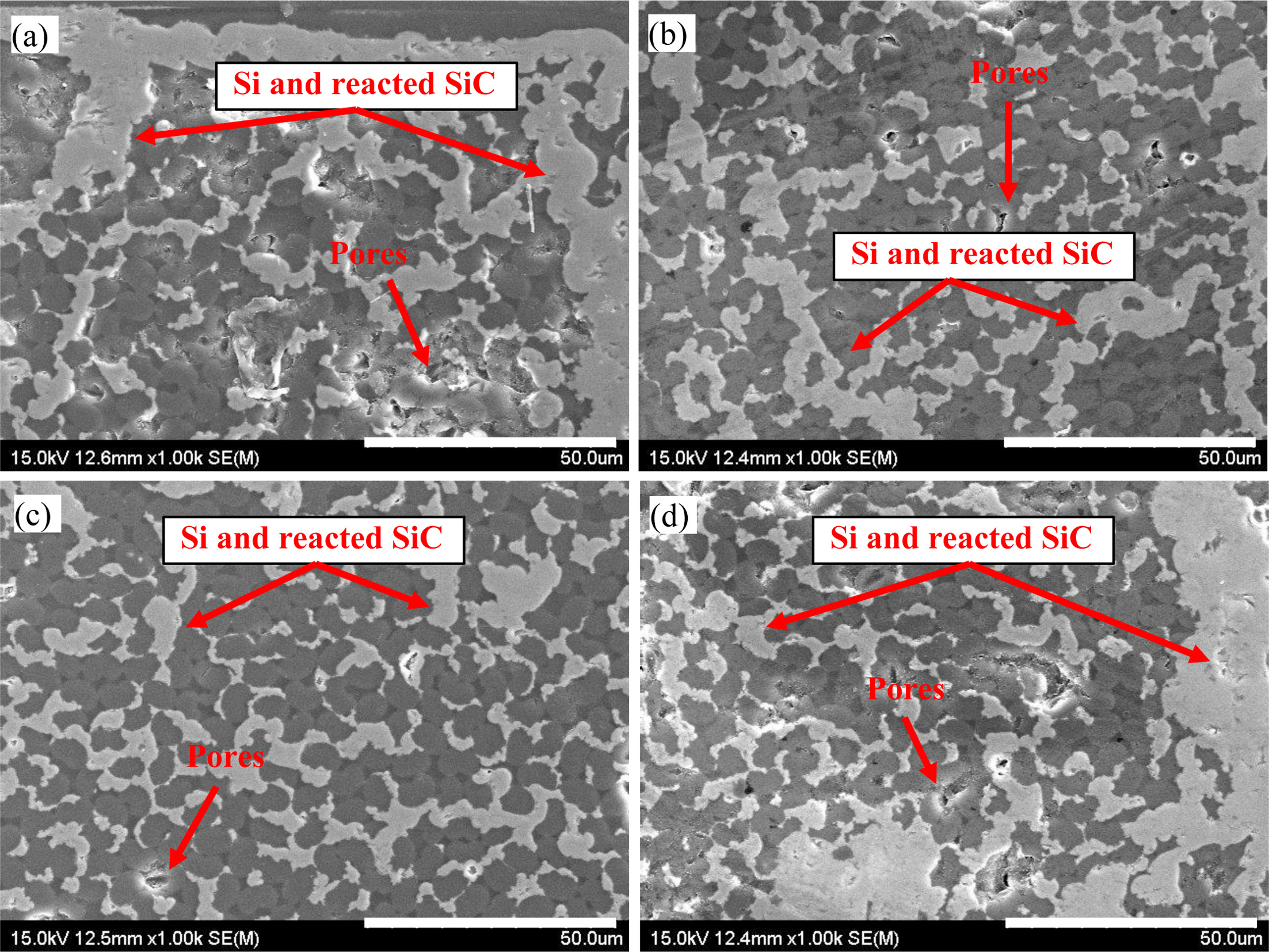

SEM images of all the composites after LSI are compared in

Fig. 4 at the same magnification (×100). The composites comprised carbon fibers

in both the 0° and 90° directions, where the matrix consisted of carbon,

residual silicon, and reacted SiC, and transverse cracks were

present (within 0° C fiber). The cracks are marked by black arrows in Fig. 4,

which clearly shows that all of the composites had similar microstructures.

Higher magnification (×1,000) SEM micrographs of the entire composites are also

compared in Fig. 5, which demonstrate that all of the samples exhibited similar

fiber damage after LSI. These microstructures are comparable with those

obtained in previous studies of Cf/C-SiC composites fabricated via

LSI [30-34]. The cracks (transverse) occurred during cooling from

higher temperatures after LSI because of the mismatched thermal

expansion coefficients for C, Si, and SiC resulting in thermal residual

stresses, as shown in Fig. 4. Figs. 4 and 5 indicate that all of the composites

were fully infiltrated with molten silicon. Evidently, the carbon fibers were

damaged and not fully protected as the silicon reached the carbon fibers

surrounded by the carbon matrix and reacted to form SiC, possibly

because temperatures higher than 2,000 °C are expected to

allow the reaction between carbon and silicon to occur instantaneously

[35]. In addition, the continuous formation of SiC was

controlled by the diffusion of silicon through the previously formed SiC layer.

The flexural strength and fracture toughness values for

all of the composites prepared under different pyrolysis conditions are

compared in Table 1. The flexural strength varied from a minimum of

47 ± 3 MPa to a maximum of 62 ± 6 MPa (~ 35%

increase), and the fracture toughness varied from 1.76 to 1.88 MPa·m1/2

(~ 7% increase), depending on the pyrolysis conditions. Among all of the

composites, composite C4 had the greatest mechanical properties, with a

flexural strength of 62 ± 6 MPa and fracture toughness of 1.88 MPa·m1/2.

These mechanical properties were greatly improved compared with those of the

other composites. Therefore, it can be concluded that Cf/C-SiC

composites with superior mechanical properties were obtained using a

typical heating rate of 25 °C/h. All of the composites exhibited brittle

behavior and no fiber pull-out was observed after the mechanical tests, thereby

indicating that all of the composites were characterized by strong interface

bonding between the fiber and the matrix.

Therefore, considering the similar densities, porosities,

and microstructures, and the availability of the same amount of carbon to react

with silicon, except in the presence of some micro-delaminations (C1

composite), the mechanical properties decreased as the heating rate increased

because more silicon reacted with carbon, and thus more fiber damage occurred,

although the formation of SiC could enhance the mechanical properties.

|

Fig. 3 (a-d) SEM images of all the composites after pyrolysis at 600 °C; magnified images of areas 1 and 2 in Figs. 3 (a) and (d) are shown are in Figs. 3 (e) and (f), respectively. |

|

Fig. 4 SEM images of all the composites after LSI. |

|

Fig. 5 Higher magnification (×1,000) SEM images of all the composites after LSI. |

In this study, cross-ply Cf/C-SiC composites

were successfully fabricated using the LSI technique. We examined the effects

of different pyrolysis conditions on crack formation as well as the

microstructures and mechanical properties of the Cf/C-SiC

composites. Pyrolysis of CFRP was performed at 600 °C for 1 h in a

nitrogen atmosphere at two different heating rates of 25 and 50 °C/h

before siliconization. The composites pyrolyzed at a heating rate

of 25 °C/h exhibited superior mechanical properties. These

results demonstrate that crack formation and the microstructures of composites can

be modified by selecting suitable pyrolysis conditions. This is

done in order to improve the mechanical properties of the microstructures.

The authors acknowledge financial support from the Korea

Institute of Energy Research (KIER) under grant number B9-2433.

- 1. B. Heidenreich, Ceramic Matrix Composites: Materials, Modeling and Technology (Eds: N. P. Bansal, J. Lamon), John Wiley & Sons, Inc., Hoboken, US 2015, pp. 147-235.

- 2. W. Krenkel, B. Heidenreich, and R. Renz, Adv. Eng. Mater. 4 (2002) 427-436.

-

- 3. F. Christin, Adv. Eng. Mater. 4 (2002) 903-912.

-

- 4. H. A. El-Hija, W. Krenkel, and S. Hugel, Int. J. Appl. Ceram. Technol. 2 (2005)105-113.

-

- 5. S. Schimdt, S. Beyer, H. Immich, H. Knabe, R. Meistring, and A. Gessler, Int. J. Appl. Ceram. Technol. 2 (2005) 85-96.

-

- 6. W. Krenkel and F. Berndt, Mat. Sci. Eng. A 412 (2005) 177-181.

-

- 7. J. Schmidt, M. Scheiffele, M. Crippa, F. Peterson, E. Urquiza, K. Sridharan, L. C. Olson, M. H. Anderson, T. R. Allen, and Y. Chen, Int. J. Appl. Ceram. Technol. 8 (2011) 1073-1086.

-

- 8. F. Infed, K. Handrick, H. Lange, A. Steinacher, S. Weiland, and C. Wegmann, Acta Astronaut. 70 (2012) 122-138.

-

- 9. N.P. Padture, Nat. Mater. 15 (2016) 804-809.

-

- 10. S. Dong, H. Wen, Q. Zhou, and Y. Ding, J. Ceram. Process. Res. 10 (2009) 278-285.

- 11. X. Peng, L. Zhuan, Z. Zi-bing, and X. Xiang, J. Ceram. Process. Res. 11 (2010) 335-340.

- 12. Q. Zhang, L. Cheng, L. Zhang, and N. Dong, J. Ceram. Process. Res. 14 (2013) 247-250.

- 13. T.-H. Ko, Polym. Composite. 14 (1993) 247-256.

- 14. J.-Y. Liu, K. Jian, Z.-H. Chen, Q.-S. Ma, and S. Wang, Key Eng. Mater. 368-372 (2008) 1022-1024.

-

- 15. F. Reichert, N. Langhof, and W. Krenkel, Mater. Sci. Forum 825-826 (2015) 232-239.

-

- 16. W.-C. Chang, C.-C. Ma, N.-H. Tai, and C.-B. Chen, J. Mater. Sci. 29 (1994) 5859-5867.

-

- 17. J. Chlopek and S. Blzewicz, Carbon 29 (1991) 127-131.

-

- 18. C.R. Choe, K. H. Lee, and B.I. Yoon, Carbon 30 (1992) 247-249.

-

- 19. J. Schulte-Fischedick, S. Seiz, N. Lutzenburger, A. Wanner, and H. Voggenreiter, Composites: Part A 38 (2007) 2171-2181.

-

- 20. J. Schulte-Fischedick, A. Zern, J. Mayer, M. Ruhle, and H. Voggenreiter, Composites: Part A 38 (2007) 2237-2244.

-

- 21. J. Jortner, Carbon 24 (1986) 603-613.

-

- 22. T.-H. Ko and P.-C. Chen, J. Mater. Sci. Lett. 10 (1991) 301-303.

-

- 23. F. Gao, J. W. Patrick, and A. Walker, Carbon 31 (1993) 103-108.

-

- 24. S. Kim, S.-K. Woo, I.-S. Han, D.-W. Seo, B.-K. Jang, and Y. Sakka, J. Ceram. Soc. Jpn, 118 (2010) 1075-4078.

-

- 25. J.H. Choi, S. Kim, S.-H. Kim, I.-S. Han, Y.-H. Seong, and H.J. Bang, J. Ceram. Process. Res. 20 (2019) 48-53.

- 26. Y. Cai, L. Cheng, H. Zhang, X. Yin, H. Yin, and G. Yan, J. Alloy. Compd. 770 (2019) 989-994.

-

- 27. W.-S. Kuo and T.-W. Chou, J. Am. Ceram. Soc. 78 (1995) 745-755.

-

- 28. T.-H. Ko, W.-S. Kuo, and Y.-H. Chang, J. Appl. Polym. Sci. 81 (2001) 1084-1089.

-

- 29. ASTM D792, Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement, ASTM International, West Conshohocken, PA, 2013, www.astm.org

-

- 30. Y. Li, P. Xiao, Z. Li, W. Zhou, T. Liensdorf, W. Freudenberg, N. Langhof, and W. Krenkel, Ceram. Int. 42 (2016) 6850-6857.

-

- 31. Y. Li, P. Xiao, H. Luo, R.S.M. Almeida, Z. Li, W.Zhou, A. Bruckner, F. Reichert, N. Langhof, and W. Krenkel, J. Eur. Ceram. Soc. 36 (2016) 3977-3985.

-

- 32. Y. Li, P. Xiao, Y. Shi, R.S.M. Almeida, W. Zhou, Z. Li, H. Luo, F. Reichert, N. Langhof, and W. kel, Composites: Part A 95 (2017) 315-324.

-

- 33. X. Wu, N. Langhof, W. Krenkel, R. Habath, and F. Lenz, Ceram. Int. 44 (2018) 16325-16332.

-

- 34. Z. Ma, Ceram. Int. 44 (2018) 13145-13151.

-

- 35. P. Sangsuwan, S.N. Tewari, J.E. Gatica, M. Singh, and R. Dickerson, Metall Mater Trans B 30 (1999) 933-944.

-

This Article

This Article

-

2020; 21(1): 113-118

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.113

- Received on Nov 8, 2019

- Revised on Dec 23, 2019

- Accepted on Jan 2, 2020

Services

Services

- Abstract

introduction

fabrication and characterization

results and discussion

summary

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kati Raju, Seyoung Kim

-

Energy Efficiency and Materials Research Division, Korea Institute of Energy Research, Daejeon 34129, Korea

Tel : +82-428603471 Fax: +82-428603133 - E-mail: saykim@kier.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.