- Thermal shock resistance of TaC / SiC coatings on carbon/carbon composites by the CVD process

Hyun-Mi Kima,b, Sung-Churl Choib, Yeontae Kimc, Hyung Ik Leec and Kyoon Choia,*

aEngineering Ceramic Center, KICET, Icheon, 17303, Korea

bDivision of advanced Materials Science and Engineering, Hanyang Univ., Seoul, 04763, Korea

cThe 4th R&D Institute, Agency for Defense Development, Daejon, 34186, Korea

Carbon/carbon composites (C / C)

have been widely studied in the aerospace field given their excellent thermal

shock resistance and specific strength at high temperatures. However, they are

associated with the problem of rapid oxidization and deterioration under normal

atmospheric environments. In order to overcome these problems, chemical vapor

deposition (CVD) coatings of ultra-high temperature ceramics to C / C have

become an important technical step. In this study, TaC coatings on C / C were

carried out by a CFD simulation and a subsequent CVD process. A TaC monolayer

and a SiC / TaC / SiC / TaC multilayer were compared with respect to the degree

of thermal shock resistance, accomplished in this case with an arc heater. The

TaC monolayer was mostly delaminated on the horizontally oriented carbon

fibers, which resulted in sharpened carbon fibers and porous Ta2O5

layers. However, the multilayer structure showed a protective vitreous coating

due to the oxidation of the SiC layer, with the inner C / C successfully

protected by the porous Ta2O5 layer underneath. It can be

concluded that multilayer coatings of SiC / TaC / SiC / TaC can be more

effective for thermal shock and oxidation resistance capabilities of composites.

Keywords: Ultra high temperature ceramics, Chemical vapor deposition, Tantalum carbide, Thermal shock resistance

The C / C composite is a high-temperature structural

material with a low density level, a small coefficient of thermal expansion,

and high specific strength, making it an ideal material as a thermal barrier of

aircraft nose tips, leading edges and reentry vehicles. In most cases, however,

these applications require oxidation and ablation resistance and therefore

require an appropriate coating layer for the protection of the C / C [1]. UHTC

carbides such as TaC, HfC, and ZrC can be used in an oxidizing atmosphere

because they have not only high melting points of the carbides but also high

melting points after the oxidation of the carbides [2, 3]. After

oxidation, however, a porous layer is formed such that the inflow of

oxygen into the interior is inevitable. Accordingly, gastight

characteristics can be expected via the formation of a multilayer as opposed to

using this approach alone [4].

As a multilayer material that complements the oxidation

resistance of UHTC carbide, silicon-based phases such as SiC and MoSi2

can help maintain a suitable level of oxidation resistance [5, 6]. The

multilayer forms an SiO2-based amorphous layer that can

prevent permeation of a gas even when oxidized, thereby allowing the

internal C / C to be preserved at temperatures below 1400 degrees Celsius [2].

As a means of forming the UHTC carbide and silicon carbide multilayer, CVD [7],

SAPS (supersonic atmosphere plasma spraying) [8, 9], pack cementation

[10], and slurry coating [11], have been used. The simplest and most stable

method is to form a multi-coating layer by CVD.

In this study, the heat-resistant oxidation

characteristics of two coating layers of TaC and SiC / TaC / SiC /

TaC were compared based on TaC and SiC as protective coatings for the oxidation

and ablation of C / C. In addition, a computational fluid dynamics simulation

was used to improve the uniformity of the coating layer.

The raw materials and equipment used for the experiments

were detailed in a previously published paper [12, 13]. TaCl5 (99.5%, H.C.

Starck, Germany), used as a raw material, was put into a vaporizer using a

powder feeder capable of delivering the powder at a constant rate in the form

of a solid powder. As a carrier gas, hydrogen gas containing 5% CH4

was used, with the gas mixed with TaCl5 in the vaporizer at 230

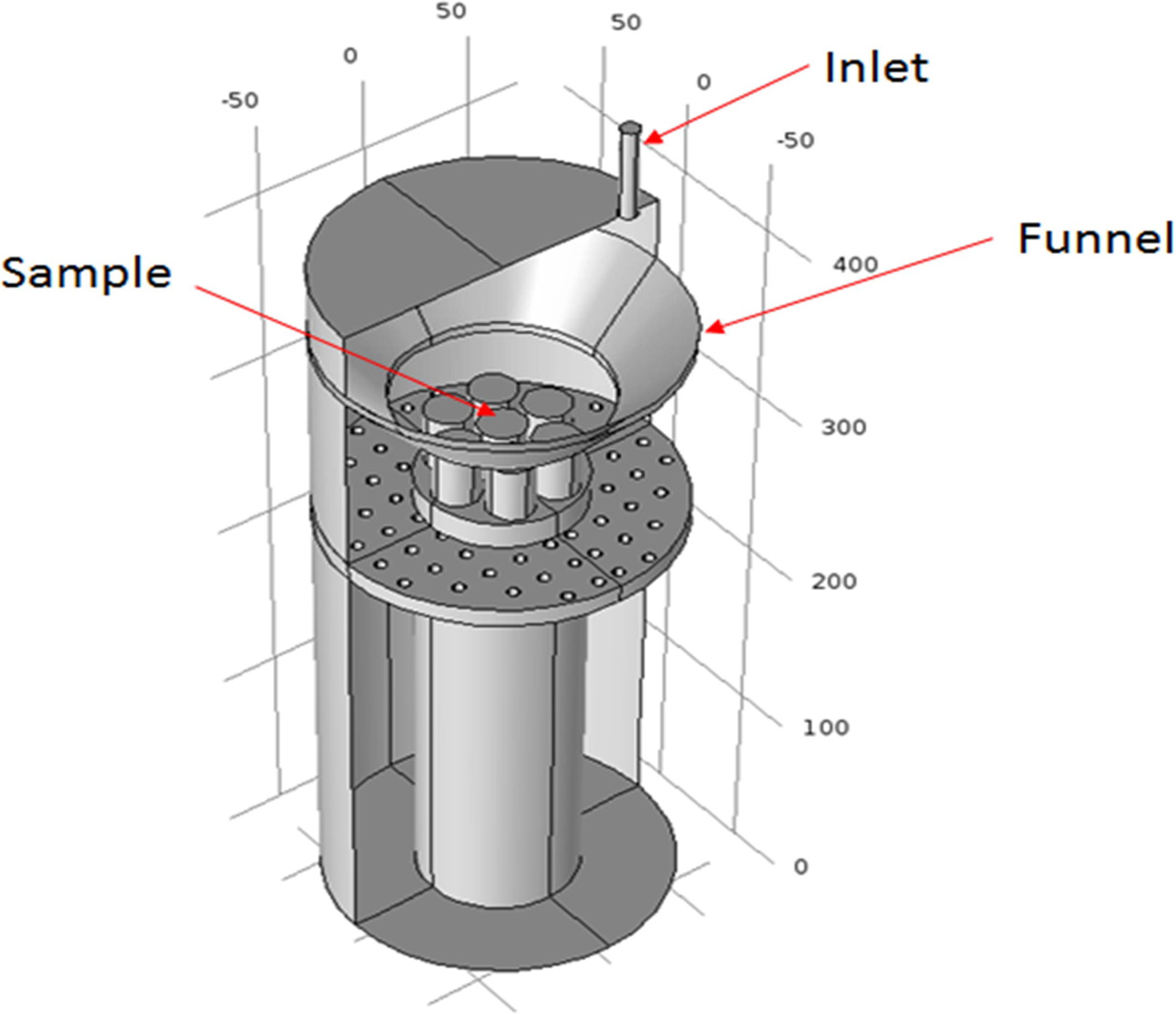

degrees Celsius and delivered along a heated gas line to the inlet, as shown in

Fig. 1.

The C / C sample was provided by DACC Co., Ltd. It was

cylindrical with a diameter of 15 mm and height of 50 mm. First, all samples

were coated with silicon carbide to a depth of 35 μm, after which 50 μm of TaC

or 50 μm of SiC / TaC / SiC / TaC were alternately raised and the

microstructures and heat resistance characteristics compared. The deposition

conditions for the silicon carbide and TaC are summarized in Table 1.

As shown in Table 1, hydrogen gas bubbling through a

bubbler containing an MTS liquid was transported to the reactor for the silicon

carbide, while the mixed hydrogen gas containing TaCl5 vapor

controlled by the powder feeder was provided for the tantalum carbide.

Therefore, the SiC / TaC multi-coating structure can be formed using deposition

processes alternately through two lines. The C / C composite sample

produced through this process was subjected to a thermal shock test

using a 200 kW arc heater. After the surface was subjected to a phase analysis

by XRD, the components remaining on the surface were confirmed by FE-SEM and

EDS.

|

Fig. 1 Schematics of the sample location in the deposition chamber for the TaC and SiC coating. |

|

Table 1 Details of experimental conditions for SiC and TaC deposition processes. |

Phase

prediction with FactSage 6.2

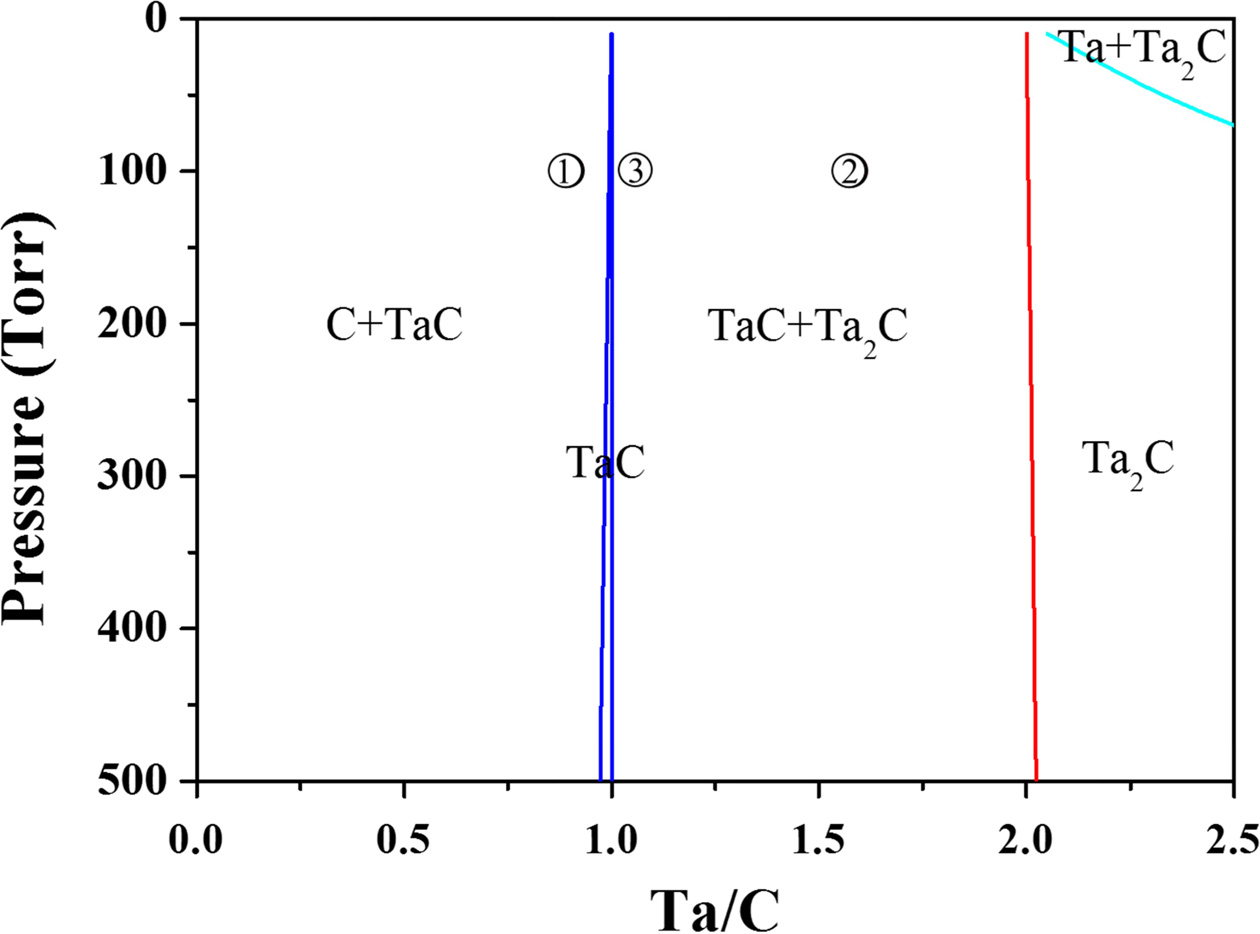

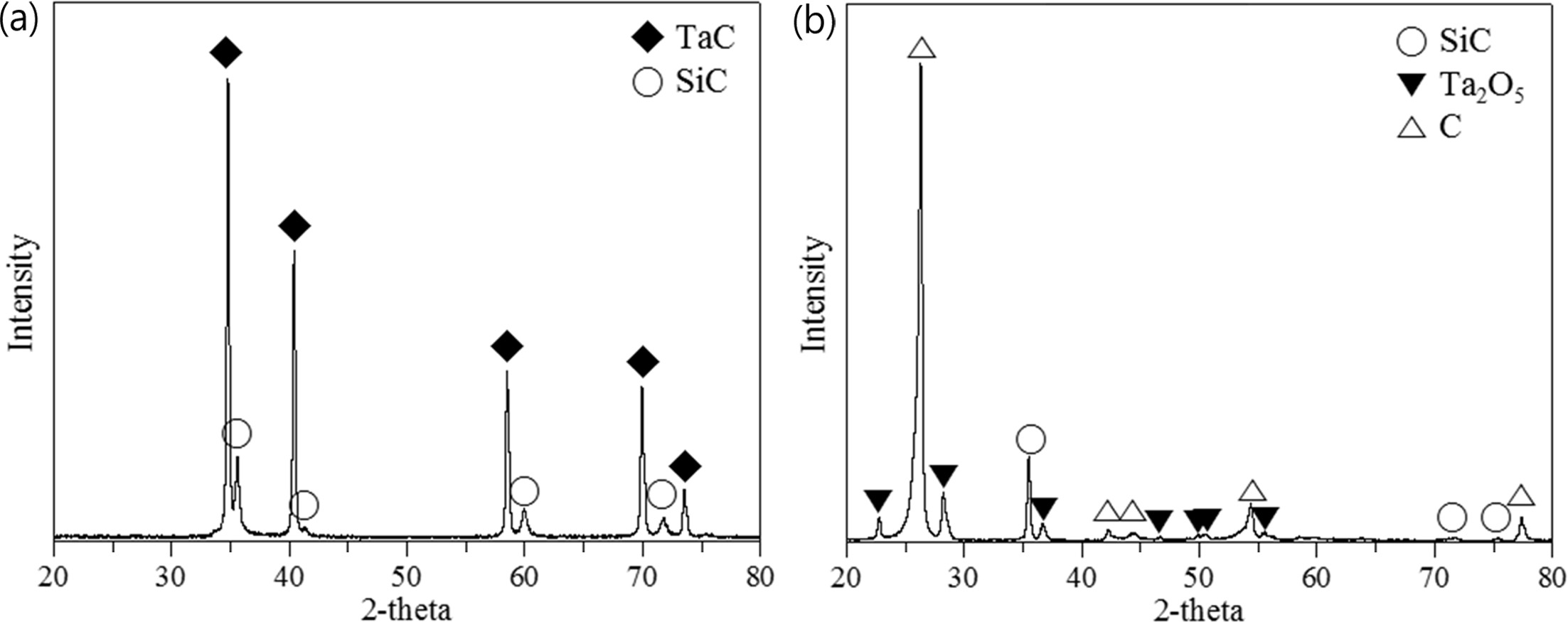

Fig. 2 shows the phase equilibrium when 5% CH4

containing hydrogen and TaCl5 are used as the raw materials. In this

system, a mixed phase of C and TaC or a mixed phase of TaC and Ta2C

is more easily obtained than a single TaC phase because the TaC single-phase

region is obtained only in a narrow region where the ratio of Ta and C is one.

Therefore, two microstructures were compared to determine the condition

under which the heat resistance characteristics are

expected to be better.

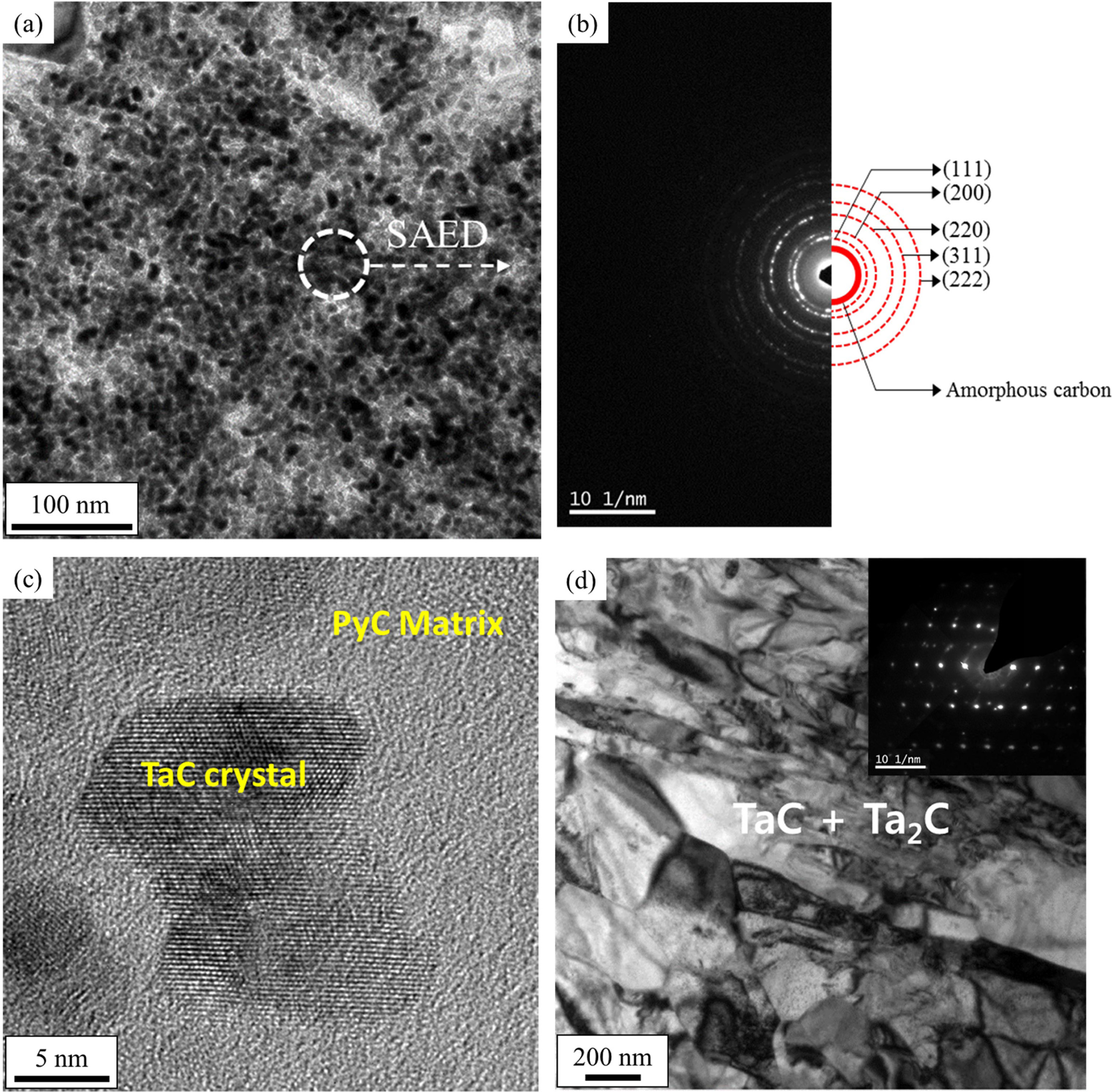

The microstructure obtained under the condition 1 shown in

Fig. 2 demonstrated a mixed phase of C and TaC, where small TaC crystals were

distributed in the pyrolytic carbon matrix, as shown in Fig. 3(a). This can

also be observed in the SAED pattern in Fig. 3(b) and in the HRTEM image in

Fig. 3(c), in which several nanometer-sized TaC crystals can be distinguished.

The microstructure is expected to be inadequate as an anti-ablation

coating due to the pyrolytic carbon constituting the matrix.

On the other hand, the microstructure obtained under condition 2 in Fig. 2

presents a mixed phase of TaC and Ta2C, in which case

micrometer-sized TaC and Ta2C crystals are homogeneously mixed. If

TaC and Ta2C crystals are mixed, each will likely prevent the growth

of the other to therefore maximize the heat resistance and anti-ablation

characteristics. Other studies [13-16] have reported that the heat-resistance

and anti-ablation properties of these types of coatings deteriorate when TaC

crystals grow in the form of a columnar structure. Therefore, the sample was

prepared under condition 3 in Fig. 2 because this condition utilized the

maximum amount of TaC for excellent ablation resistance while at the same time

suppressing the coarsening of the TaC crystals due to the small amount of Ta2C.

CFD

prediction for a uniform deposition

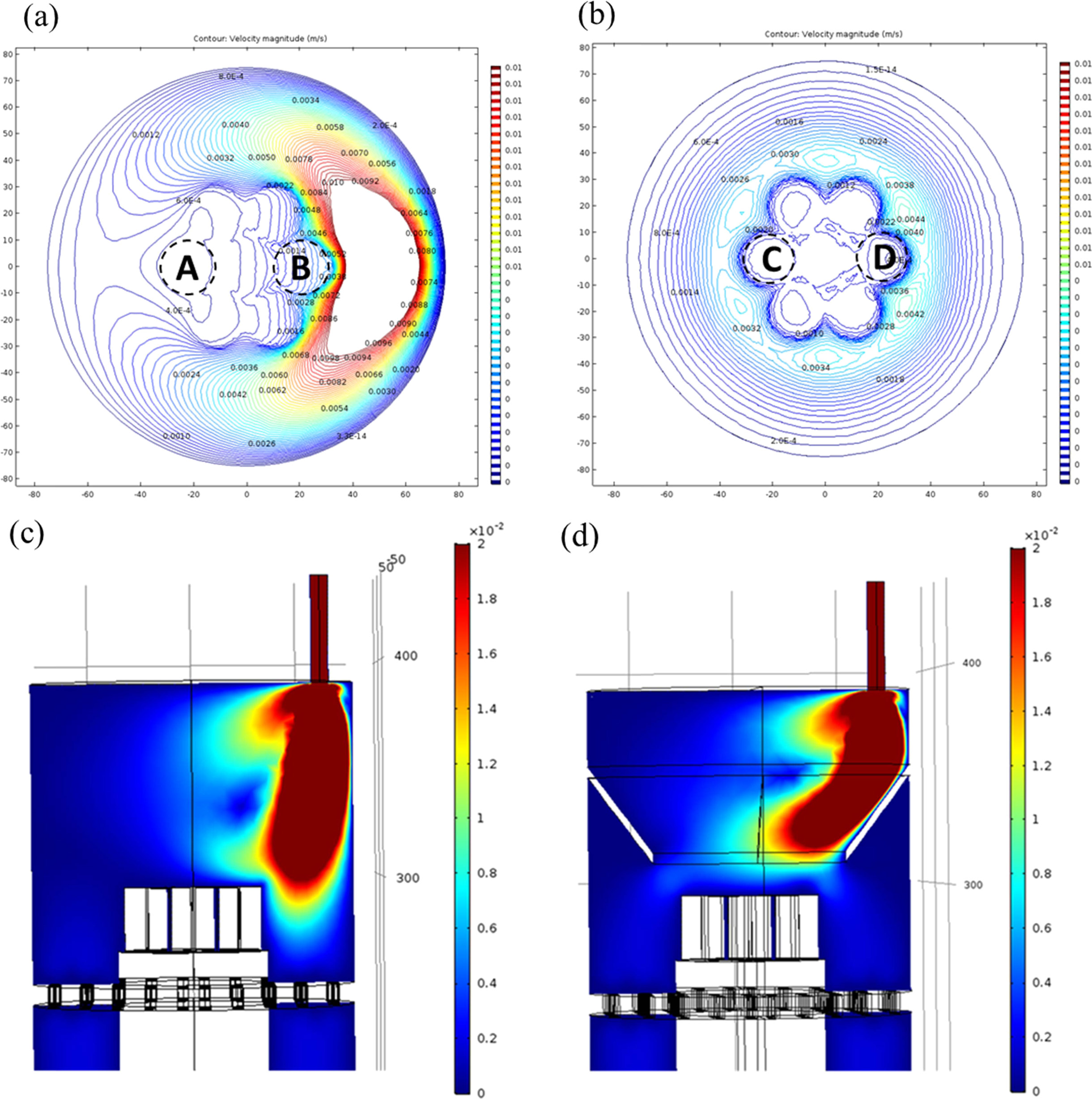

The sample holder was fabricated to deposit seven

cylindrical heat-resistant samples at the same time, and a funnel was installed

on top of it. The purpose of this installation was to reduce the

thickness deviation between the samples. The change of the flow

rate distribution before and after the installation of the funnel was confirmed

through a CFD analysis, the results of which are shown in Fig. 4. Checking the

velocity contours at positions “A” and “B” in Fig. 4(a), a steep slope of the

velocity is found at “B.” In contrast, the velocity distribution is much more

uniform in the “C” and “D” positions after the installation of the funnel, as

shown in Fig. 4(b). The reactant gas is well guided over the specimen by the

funnel to increase the deposition rate, as shown in Fig. 4(d).

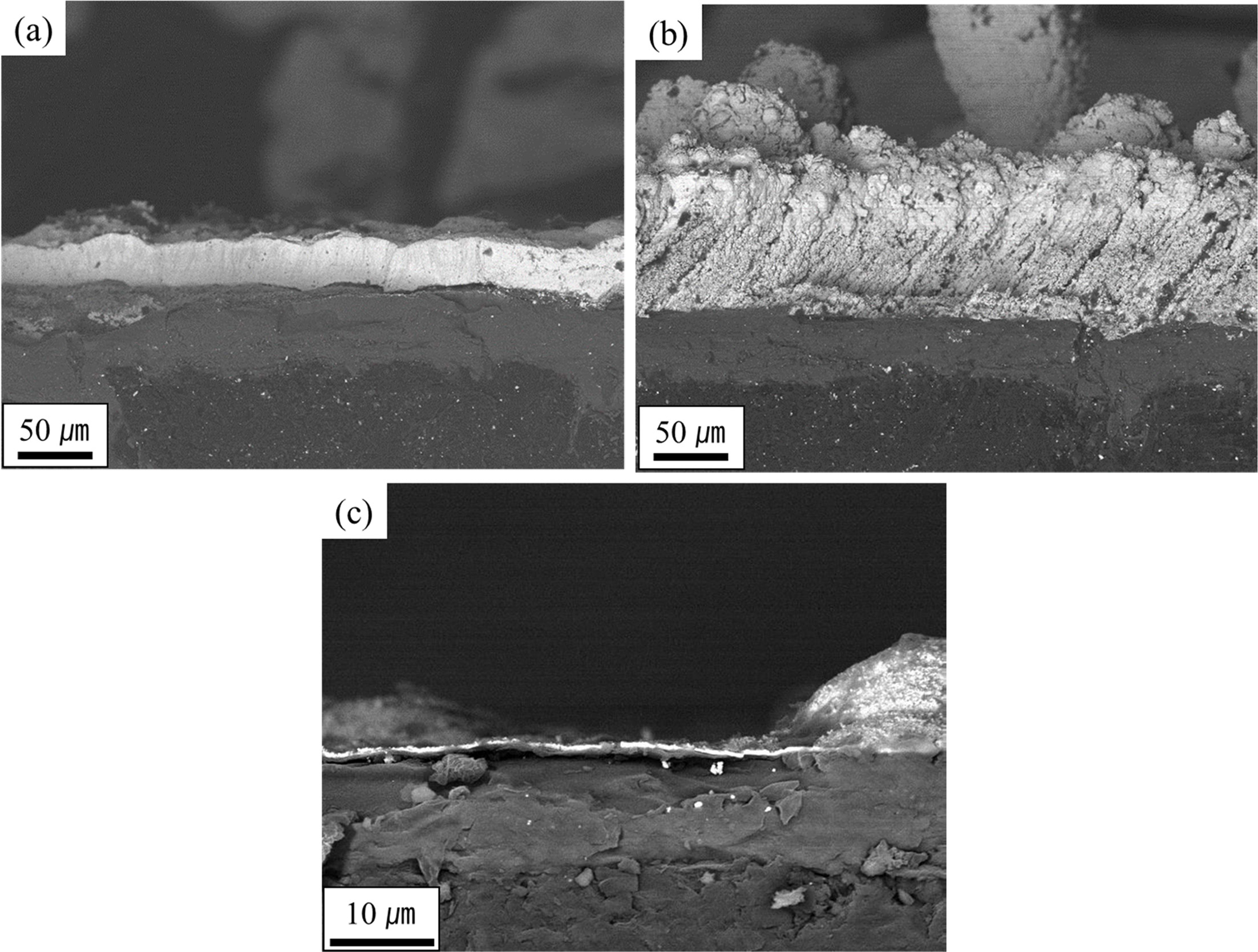

TaC was deposited at positions “A” and “B” to demonstrate

experimentally the large difference in the flow velocity distributions in Fig.

4(a). A film of TaC with a small amount of Ta2C was formed after

four hours of deposition under condition 3 in Fig. 2. Significant differences

in the thickness at the “B” site were found at the right and left ends of the

sample, as shown in Figs. 5(a) and 5(b), respectively. On the other hand, at

the “A” site, a very thin TaC layer was identified, as shown in Fig. 5(c).

Deposition

of the TaC/SiC multilayer

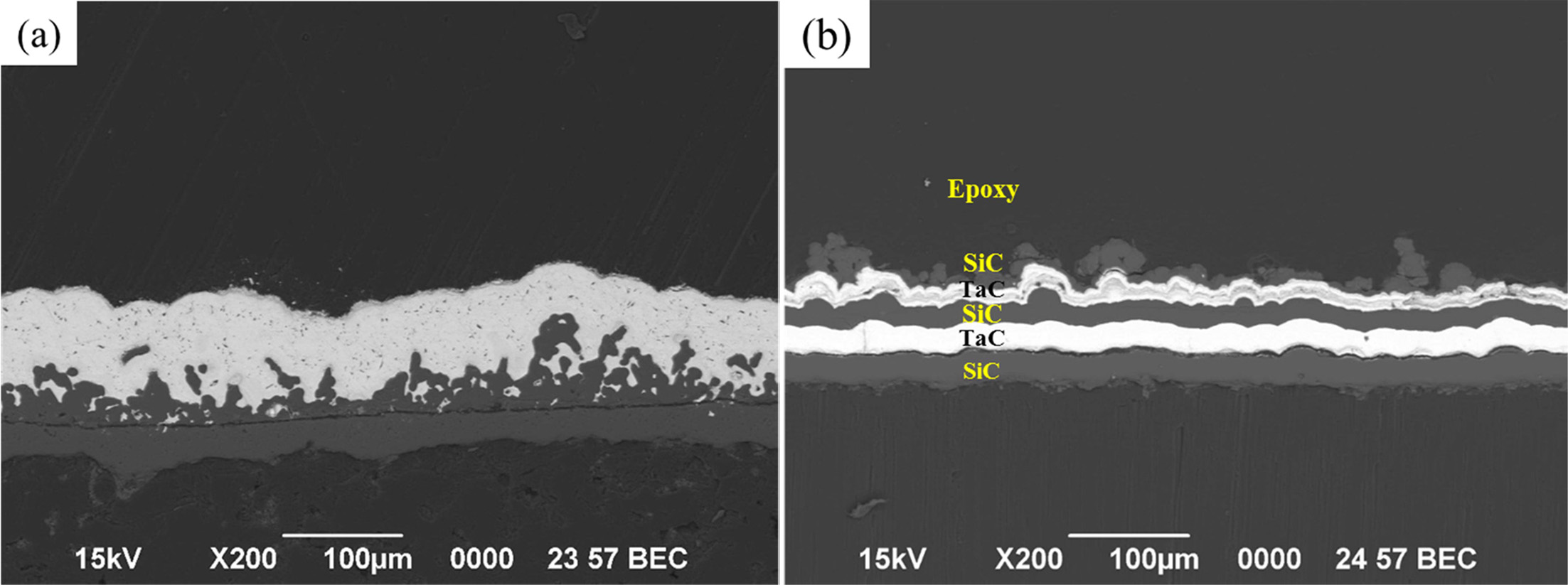

The cross-sectional microstructures of the TaC layer and

the SiC / TaC / SiC / TaC multilayer are shown in Figs. 6, and

these are used in the high heat flow experiments. It can be seen that a coating

layer of approximately 80 to 100 μm is added onto the 35 μm SiC intermediate

layer on the C / C. Silicon carbide layers occasionally have irregular or

porous surfaces that appear to have complex interfaces with TaC.

High

heat flux experiment on the TaC monolayer deposited C / C

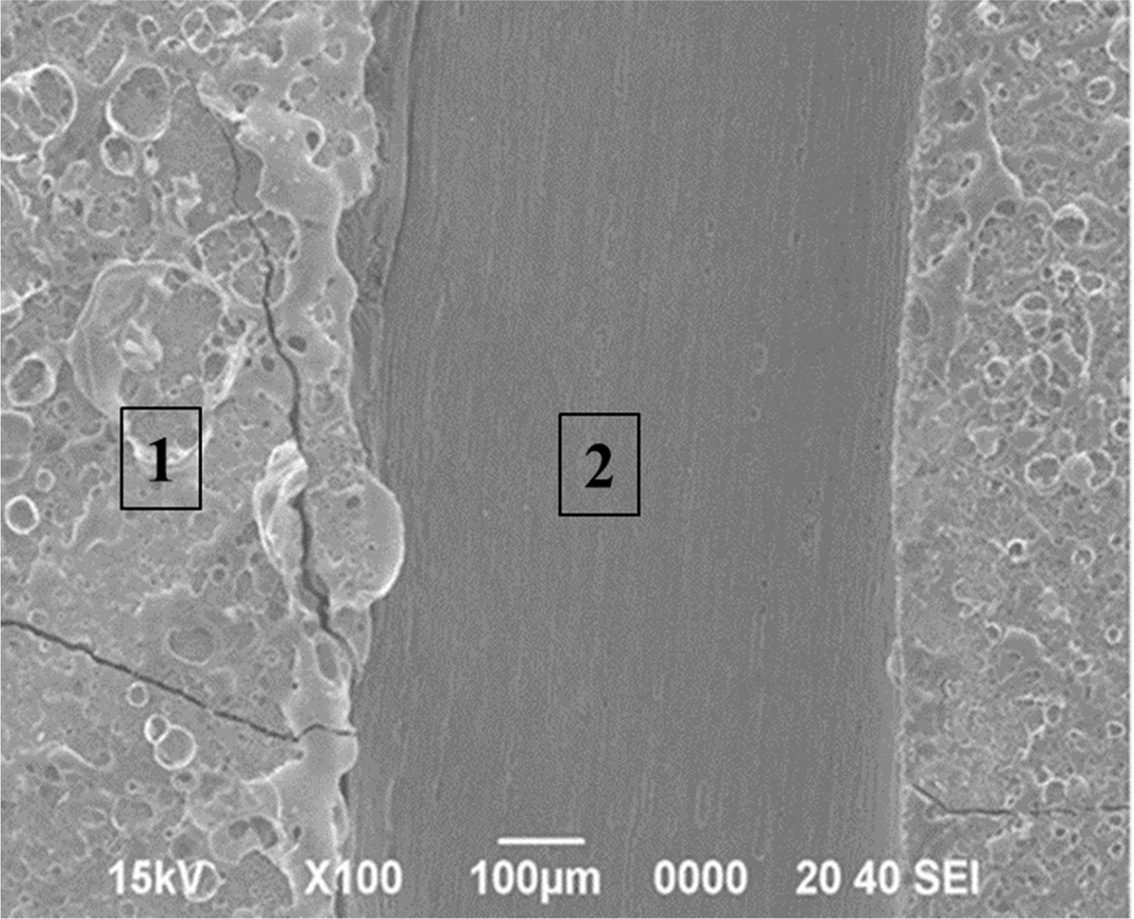

The sample of the TaC monolayer showed a severe appearance

change after the heat flux experiment. A large part of the coating layer had

peeled off, and the outer surface of the sample appeared to form a porous

coating layer composed of the Ta2O5 crystal phase. This

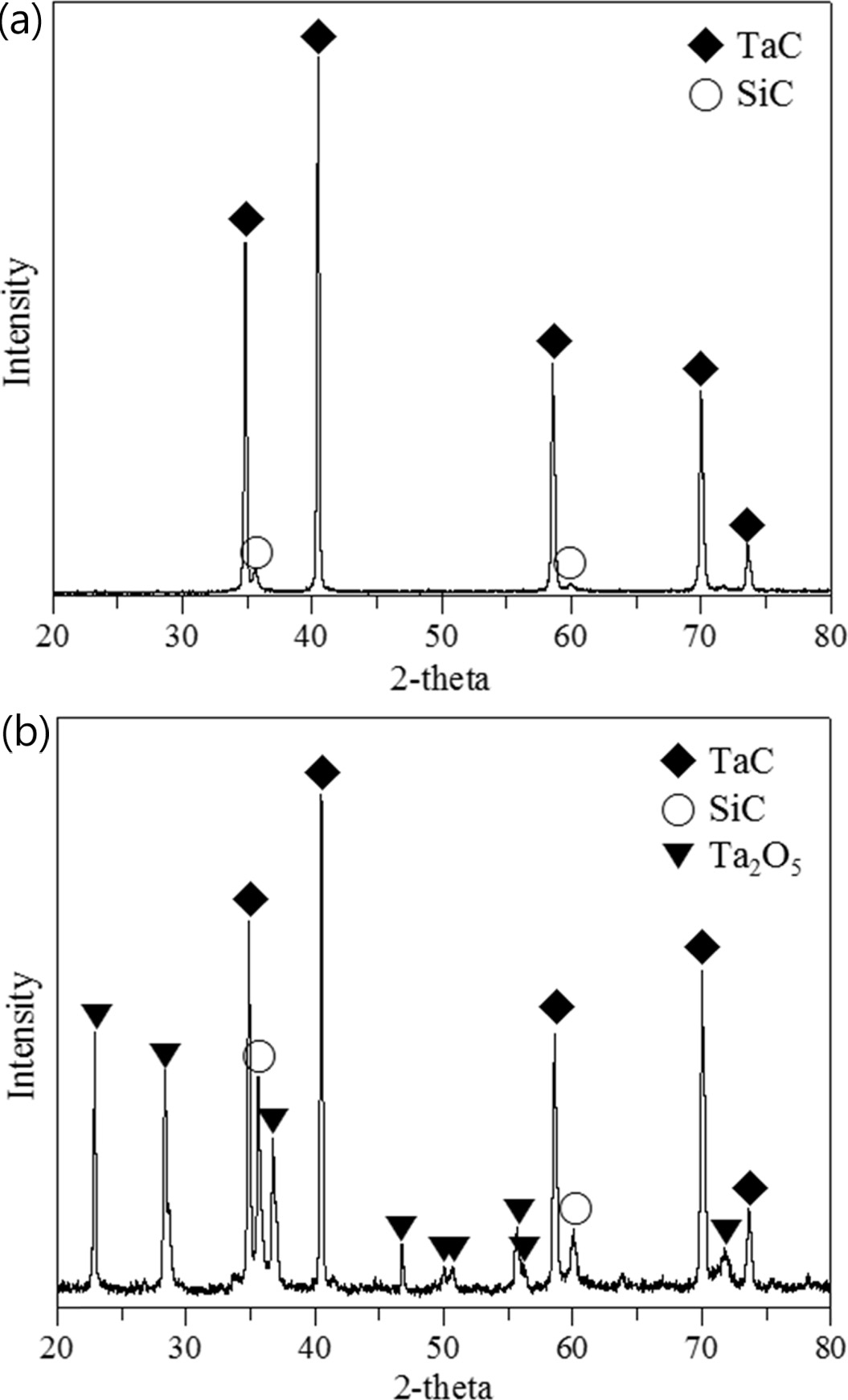

is clearly observable in Fig. 7 in the XRD results, which shows

strong carbon peaks indicating the significant portion of C

/ C exposure, with only the Ta2O5 crystal phase and

underlying SiC layer identifiable. A long strap peeled off due to the large

difference in the thermal expansion coefficient between the coating layer and

the C / C, as shown in Fig. 8. Most of the C / C exposed areas are those in

which the carbon fibers are horizontally oriented. It was also confirmed that

the tip of the carbon fiber is sharply oxidized, as shown in Fig. 9(b). The carbon

fibers are thought to have been exposed at the beginning of the high heat flux

experiment. According to the weaving direction of the carbon fiber, it could be

confirmed as to whether the Ta2O5 layer is attached. It

was noted that Ta2O5, which appears as a bright area,

scarcely remains in the area where it horizontally comes into contact with the

carbon fiber.

High

heat flux experiment on multilayer deposited C / C

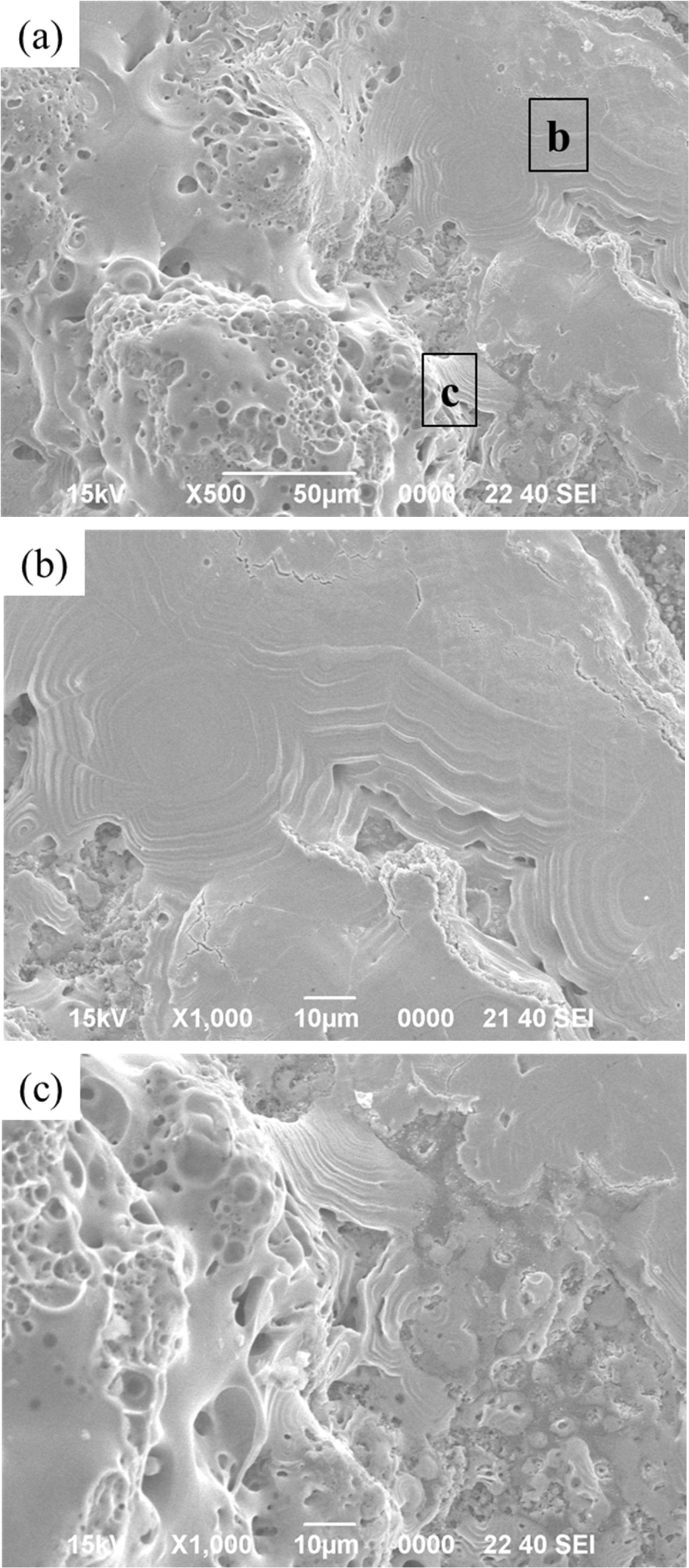

Fig. 10 shows the appearance after the high heat flux test

of the samples with the SiC / TaC / SiC / TaC multilayers to a thickness of 50 μm.

It was confirmed that a white oxide layer had formed along the outer edge of

the sample, with partial peeling also observed. The XRD results show that part

of the TaC layer was oxidized to Ta2O5 but that some TaC

remains robust under the SiC layer. The silicon carbide layer on the surface

was vitrified as it was oxidized, as shown in Fig. 11(b). With the flow of the

high heat flux, liquid silicate formed, appearing to flow

downward. Meanwhile, the TaC layer underneath is partially

oxidized to form a Ta2O5 layer. As shown in Fig. 11(c), it

has a porous appearance, similar to the microstructures observed

in other studies [17, 18]. It is estimated that the melting and covering

of the silicate glass on TaC protects against further oxidation of the TaC

layers, while the C / C can also be protected from oxidation.

|

Fig. 2 Thermodynamic phase diagram at 1200 oC with CH4 5% hydrogen and TaCl5 as the gas sources |

|

Fig. 3 TEM micrographs of (a) a specimen deposited under condition “1,” (b) corresponding SAED pattern, (c) high-resolution image, and (d) a sample deposited under condition “2” in Fig. 2. |

|

Fig. 4 Comparison of the surface velocity (a) without and (b) with the funnel designed to reduce the uniformity of the film thickness, and cross-sectional profile of the velocity distribution (c) without and (d) with the funnel. |

|

Fig. 5 Cross-sectional micrographs of (a) the left side and (b) right side of specimen “B” and (c) specimen “A” designated in Fig. 4(a). |

|

Fig. 6 Cross-sectional SEM micrographs of the (a) TaC layer and (b) SiC / TaC / SiC / TaC multilayer. |

|

Fig. 7 XRD results of the TaC layer (a) before and (b) after the high heat flux experiment. |

|

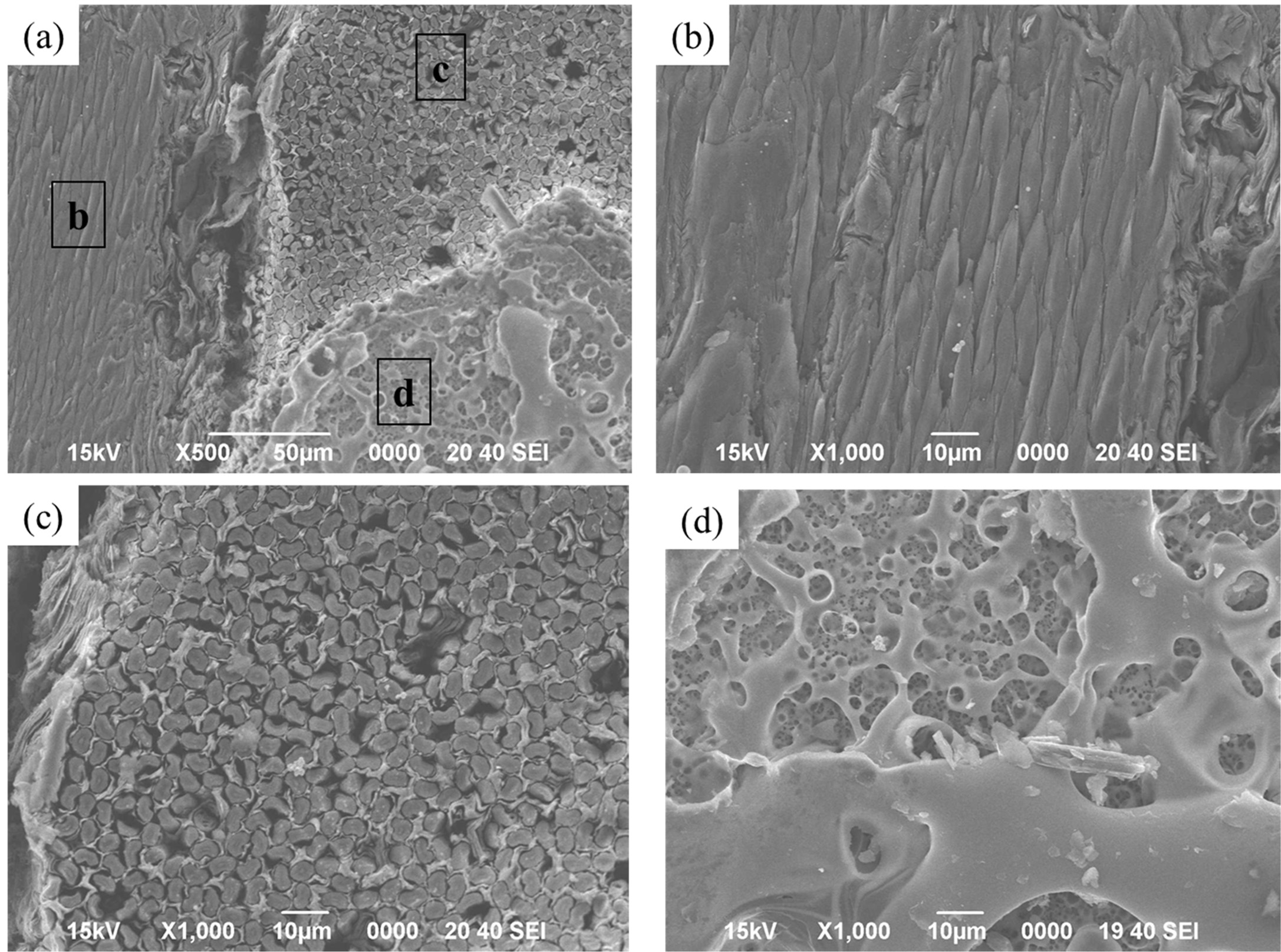

Fig. 8 SEM micrographs of the TaC layer showing local peel off regions after the high heat flux experiment. |

|

Fig. 9 SEM micrographs of the TaC layer after the high heat flux experiment: (a) surface and (b), (c), and (d) marked local magnifications of (a). |

|

Fig. 10 XRD results of the SiC / TaC / SiC / TaC multilayer (a) before and (b) after the high heat flux experiment. |

|

Fig. 11 SEM micrographs of the SiC / TaC / SiC / TaC multilayers after the high heat flux experiment: (a) surface and (b), (c) denoted local magnifications of (a). |

The combination of the oxidation resistance of SiC and the

abrasion resistance of TaC to form a new combination of UHTC coating layers has

been tried. TaC monolayers with a TaC phase containing trace amounts of the Ta2C

phase were CVD-coated on SiC-coated C / C and high thermal flux experiments

were carried out. After the high heat flux experiments, exfoliation of the TaC

layers occurred depending on the fiber arrangement of the C / C, with severe

morphological changes. One the other hand, the SiC / TaC / SiC / TaC

multilayers on SiC-coated C / C showed no delamination. For the

multilayer-coated samples, the internal TaC film mostly survived after the high

thermal flux experiments, most likely due to silicate formation caused by the

oxidation of the SiC top layer. Microstructures on which the liquid silicate

flowed down to a porous Ta2O5 layer were frequently

observed.

This work was supported by the Korean Government (Defense

Acquisition Program Administration, DAPA) through research institute (Agency

for Defense Development, ADD).

- 1. M.E. Westwood, J.D. Webster, R.J. Day, F.H. Hayes, and R. Taylor, J. Mater. Sci. 31[6] (1996) 1389-1397.

-

- 2. M.M. Opeka, I.G. Talmy, and J.A. Zaykoski, J. Mater. Sci. 39[19] (2004) 5887-5904.

-

- 3. E.L. Corral and R.E. Loehman, J. Am. Ceram. Soc. 91[5] (2008) 1495-1502.

-

- 4. F. Lamouroux, S. Bertrand, R. Pailler, and R. Naslain, Key Eng. Mater. 164 (1998) 365-368.

-

- 5. Q. Fu, X. Zou, Y. Chu, H. Li, J. Zou, and C. Gu, Vacuum 86[12] (2012) 1960-1963.

-

- 6. Y.-L. Zhang, H.-J. Li, X.-F. Qiang, K.-Z. Li, and S.-Y. Zhang, Corros. Sci. 53[11] (2011) 3840-3844.

-

- 7. G.-d. Li, X. Xiong, B.-y. Huang, and K.-l. Huang, Trans. Nonferrous Met. Soc. 18[2] (2008) 255-261.

-

- 8. Y. Zhang, H. Hu, P. Zhang, Z. Hu, H. Li, and L. Zhang, Surf. Coat. Tech. 300[25](2016)1-9.

-

- 9. Y. Zhang, Z. Hu, H. Li, and J. Ren, Ceram.Int. 40[9] (2014)14749-14755.

-

- 10. P. Wang, S. Zhou, P. Hu, G. Chen, X. Zhang, and W. Han, J. Alloy Compd. 682[15] (2016) 203-207.

-

- 11. S. Ramasamy, S.N. Tewari, and K.N. Lee, Mater. Sci. Eng. A 527[21-22] (2010) 5492–5498.

-

- 12. H.-M. Kim, K. B. Shim, J.-M. Lee, H.-I Lee, and K. Choi, J. Ceram. Proc. Res. 19[6] (2018) 519-524.

- 13. Y.-S. Jeong, K. Choi, and H.G. Yoon, J. Korean Ceram. Soc. 56[3] (2019) 291-297.

-

- 14. Y. Wang, X. Xiong, G. Li, Z. Chen, W. Sun, and X. Zhao, Corros. Sci. 65 (2012) 549-555.

-

- 15. Y. Wang, X. Xiong, G. Li, X. Zhao, Z. Chen, W. Sun, and Z. Wang, Solid State Sci. 20 (2013) 86-91.

-

- 16. Y. Wang, Z. Li, X. Xiong, X. Li, Z. Chen, and W. Sun, Appl. Surf. Sci. 390 (2016) 903-908.

-

- 17. C. Zhen, X. Xiong, G. Li, W. Sun, and Y. Long, Appl. Surf. Sci. 257 (2010) 656-661.

-

- 18. G. Li, X. Xiong, and K. Huang, Trans. Nonferrous Met. Soc. 18 (2008) s689-s695.

-

This Article

This Article

-

2020; 21(1): 92-98

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.92

- Received on Oct 4, 2019

- Revised on Dec 24, 2019

- Accepted on Dec 26, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Kyoon Choi

-

Engineering Ceramic Center, KICET, Icheon, 17303, Korea

Tel : +82-31-645-1456 Fax: +82-31-645-1493 - E-mail: knchoi@kicet.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.