- Effect of CeO2 addition on crystallization and thermo-physical properties of Li2O-ZnO-SiO2 glass-ceramics

Ruixue Li, Qian Zhang, Xingliang Peng and Weizhen Liu*

Faculty of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou 341000,China

The effect of CeO2

addition on crystallization and thermo-physical properties of lithium zinc

silicate (LZS) glasses containing Li2O-ZnO-SiO2-Al2O3-Na2O-P2O5

was investigated. The changes of CeO2 contents (2-8 wt.%) had an

obvious influence on the transition temperatures (Tg) and

crystallization temperatures (Tc) of LZS glass-ceramics, and

they increased with CeO2 content increasing. According to XRD

analysis, CeO2 promoted the formation of cristobalite and β-spodumene crystals, and β-spodumene

increased obviously. As the CeO2 content increasing, the

microstructure and microhardness (being 6.88 Gpa at 880 oC) of

glass-ceramics had great changes. The average thermal expansion coefficient (20

- 450 oC) showed first increasing then decreasing, having a wide

range. The maximum of thermal expansion coefficient was obtained when the

glass-ceramics contained 4 wt.% CeO2, being 175×10-7 K-1 (at 700 oC) and

178×10-7 K-1 (at 880 oC)

respectively. Excellent thermo-physical properties indicate the glass has

greater potential application, such as being used as sealing glass.

Keywords: Lithum zinc silicate, Crystallization, Thermal expansion coefficient, Microhardness

Currently there has been a considerable amount of interest

on crystallization behavior and thermo-physical property of Li2O-ZnO-SiO2

glass-ceramics [1-7] due to their beneficial performances, e.g., a wide range

of thermal expansion coefficient (α = 50 - 200 × 10-7 K-1)

by controlling heat treatments and adding different elements, high electrical

resistivity and good chemical durability. McMillan and Partridge in 1963 [8]

first reported lithium zinc silicate glass-ceramics containing high proportions

of zinc oxide. Later, they found glass-ceramics could also be employed to

produce superior glass-ceramic-to-metal seals [9]. Donald et al. [10] studied

a number of Li2O-ZnO-SiO2 materials containing

relatively high concentrations of ZnO, including the influence of nucleating

species and concentration, and an assessment of the thermal expansion

characteristics and mechanical properties. And they summarized

recent developments of glass-ceramic-to-metal seals and coatings

to gain a better understanding of diffusion and reaction behavior of individual

metallic [11]. The glass-ceramics are suitable for matching sealing to lots of

metals and alloys with different thermal expansion coefficients such as copper

alloys, nickel-based alloys, Fe-Ni-C alloys and stainless steel etc. It is

generally agreed that the properties of glass-ceramics are dependent

on the crystal contents, phases and their microstructure. Chemical compositions

of basic glasses play very important roles in the formation of crystals. The crystallization

characteristic of glass-ceramics is usually influenced

markedly by adding some specific elements, such as rare earth elements.

Recently, Y2O3, Nd2O3, Fe2O3,

B2O3, CuO, alkali oxides and alkali earth oxides also

have been used as flux in some glass-ceramics to study the changes of their

crystallization and thermo-physical properties [12-19].

Cerium oxide, as a rare earth oxide flux, has been reported

in many glass-ceramics studies. In some studies, it is used

as raw material in glasses [20-24]. Mostly CeO2 is used as additive

to regulate the properties of glass-ceramics [25-27]. Sohn et al. [28]

found that CeO2 as a flux markedly decreased viscosity in MgO-Al2O3-SiO2

glasses, and had a little influence on thermal expansion, mechanical properties

and chemical durability of glasses. Anmin Hu et al. [29] investigated

phase transformations of Li2O-Al2O3-SiO2

glasses with CeO2 addition, and showed that the transformations of

glass to β-quartz and of β-quartz to β-spodumene were

accelerated by addition of CeO2. Temuujin et al. [30] studied

the influence of CeO2 addition in crystallization behavior and

mechanical properties of glass ceramics in the Na2O-CaO-Al2O3-SiO2

system, and found that CeO2 added to glass ceramics enhanced

hardness because of an increased crystal size. Yongsheng et al. [31]

also found CeO2 could improve the integrity of the glass network

structure and enhance fracture toughness in CaO-Al2O3-SiO2

system. In the previous research, we know CeO2 in different glass

systems has various influences on thermo-physical and mechanical

properties. Therefore, in order to enhance the properties of lithium

zinc silicate (LZS) glass, it is essential to investigate the effect of CeO2

on LZS glass.

The purpose of this research

was to investigate the effect of different content of CeO2 addition on

crystallization and thermo-physical properties

of Li2O-ZnO-SiO2 glasses. After leaning its effect on the

properties, we could adjust them by adding different content of CeO2 to

make the glass-ceramic better seal to various metals.

Composition

and preparation of the glass

The chemical compositions (wt.%) of the glasses were given in Table 1.

We used the ingredients SiO2, ZnO, Li2O and Na2O.

P2O5 was used as nucleating agent. The starting materials

were SiO2 (≥99.0%), ZnO (≥99.0%), Li2CO3 (≥97.0%),

Na2CO3 (≥99.8%), NH4H2PO4

(≥99.0%) and CeO2 (≥99.0%). The weighted errors of all raw materials were controlled in

the range of ±0.01 g.

Glasses were prepared by fusing regent-grade chemicals

in a platinum crucible. The glass samples were melted and

maintained at 1,400 oC in an electric furnace for 3 h. The

molten glasses were then poured into a preheated

(480 oC) graphite mould and immediately transferred to an

annealing furnace set at 480 oC, being held for 2 h for

annealing before cooling down to room temperature. The

transparent and bubble-free glasses were obtained. Based on the DSC curves, we

made the nucleation temperature and crystallization temperature to obtain

glass-ceramics.

Analytical

methods

Differential scanning calorimeter (DSC, Netzsch 404PC,

Germany) was used to determine the glass transition temperature (Tg)

and crystallization temperature (Tc) of the glass samples.

The DSC measurements were performed using ~15 mg of powdered samples (45-53 μm),

which were placed in an alumina crucible. The temperature range of the samples

was between 20 and 1,000 oC at heating rate of 10 K/min.

The measurement error was ±2 oC.

X-ray diffraction (XRD, D/max, 2500 model, Rigaku,

Japan) was used to investigate the crystalline phases of the

samples. The diffractmeter was with Cu Kα radiation in the 2θ

range from 10o to 80o at 0.02 steps, which operated

at 40 kV and 50 mA at a scanning rate of 4 o/min.

The crystalline phases were identified by matching the peak

positions of the intense peaks with PCPDF standard cards.

The microstructure of glass-ceramics samples were examined

by the scanning electron microscope (SEM, FEI Quanta-200, America). The samples

were polished to under 1μm and eroded by HF (4 wt.%) for 60 s, then transferred

them to an ultrasonic cleaning equipment for 1 h to eliminate impurities that

did not dissolve in the acid before being sputtered with a gold coating.

Crystal morphology could be observed clearly.

Vickers hardness (Hv) tests were tested

on polished glass-ceramics samples, using a Matsuzawa

microhardness tester (HVS-1000) with a pyramid shaped diamond indenter,

applying loads 1.96 N for 30 s. At least 10 different positions measurements

were taken for each sample to take the average values. Indentation

diagonals were measured to calculate hardness values in GPa.

The thermal expansion coefficient (TEC) measurements

were carried out in a thermo-mechanical analyzer (Netzsch DIL 402EP, Germany)

in the temperature range 20-450 oC at heating rate of 2 K/min,

using a silica probe in an inert atmosphere using argon (50 ml/min). The

samples were machined into 3 mm × 3 mm × 20 mm

cuboid test bars. The average thermal expansion coefficient

values were calculated in the temperature range of 20-450 oC.

|

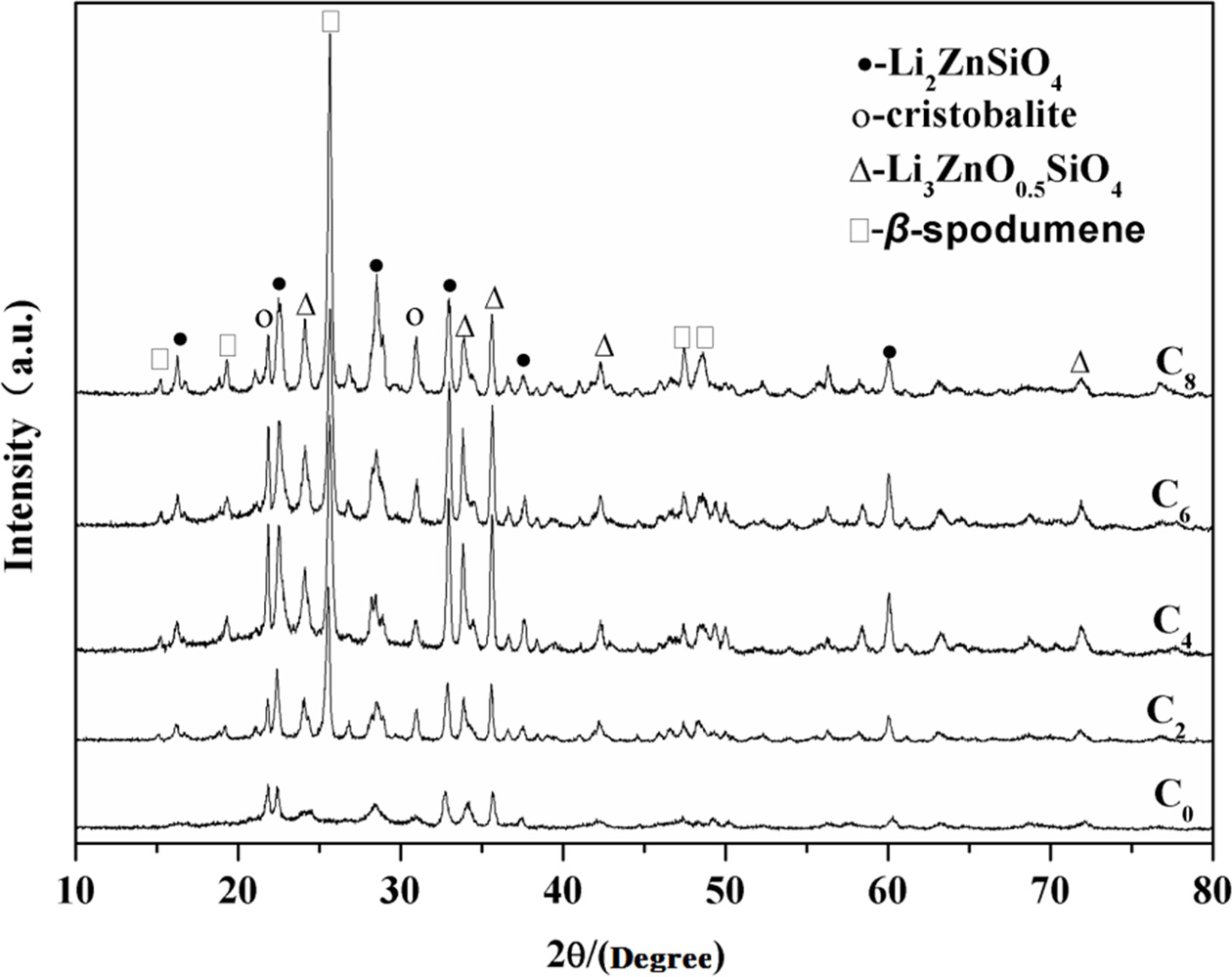

Table 1 Chemical compositions of the base glasses (± 0.02 wt.%)a. |

aThe error was caused by converting the content of oxide into that of raw material, weighting of raw materials, volatilizing of oxides and corroding on crucible surface |

Crystalline

phases and microstructure

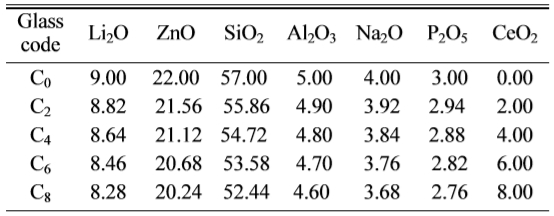

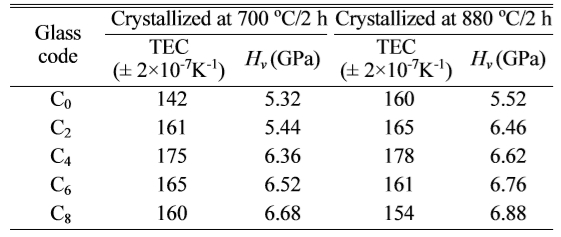

Fig. 1 shows the DSC curves obtained from as-cast LZS

glasses. There were obviously endothermic valleys on the

differential thermal curves. The start points of the endothermic valleys (Tg,

marked temperatures in Fig. 1) were from 485 to 510 oC with CeO2

content increasing. It indicated the glass transition temperature (Tg)

increased. Exothermic peaks were also obvious on the curves,

and the peaks had changed. The temperatures of first

peaks increased but the peak intensity (height and area) weakened at the same

time. Crystallization peaks correspond to the formation of

different crystalline phases. The curve shape of C0

is similar with that of C2, it showed that low content (under 2

wt.%) of CeO2 would not have obvious influence on

crystalline phases. As the CeO2 content increasing, when it

was above 4 wt.%, it had a bigger impact on the formation of

crystals. The curves of C4 and C6 showed new

peaks at 804 oC and 809 oC, and C6 and C8

both appeared another peaks at 867 oC and 874 oC. Table 2

given a summary of the results of

differential scanning calorimetry: glass transition temperatures (Tg)

and the peak temperatures of crystallization (Tp). The main

crystals of LZS are lithium zinc silicate

and cistobalite, and the formation temperatures of them are about 650 oC

and 750 oC [34]. However, β-spodumene crystal formation

temperature is about 850 oC.

According to the DSC curves, CeO2 might promote the formation of new

phase β-spodumene. On account

of the analysis of DSC curves above, the nucleation temperature of the samples

was set at 520 oC for 2 h, and the crystallization temperatures were

set at 700, 830 and 880 oC for 2 h, respectively, to obtain

glass-ceramics. We could know the crystal growth process from X-ray diffraction

patterns.

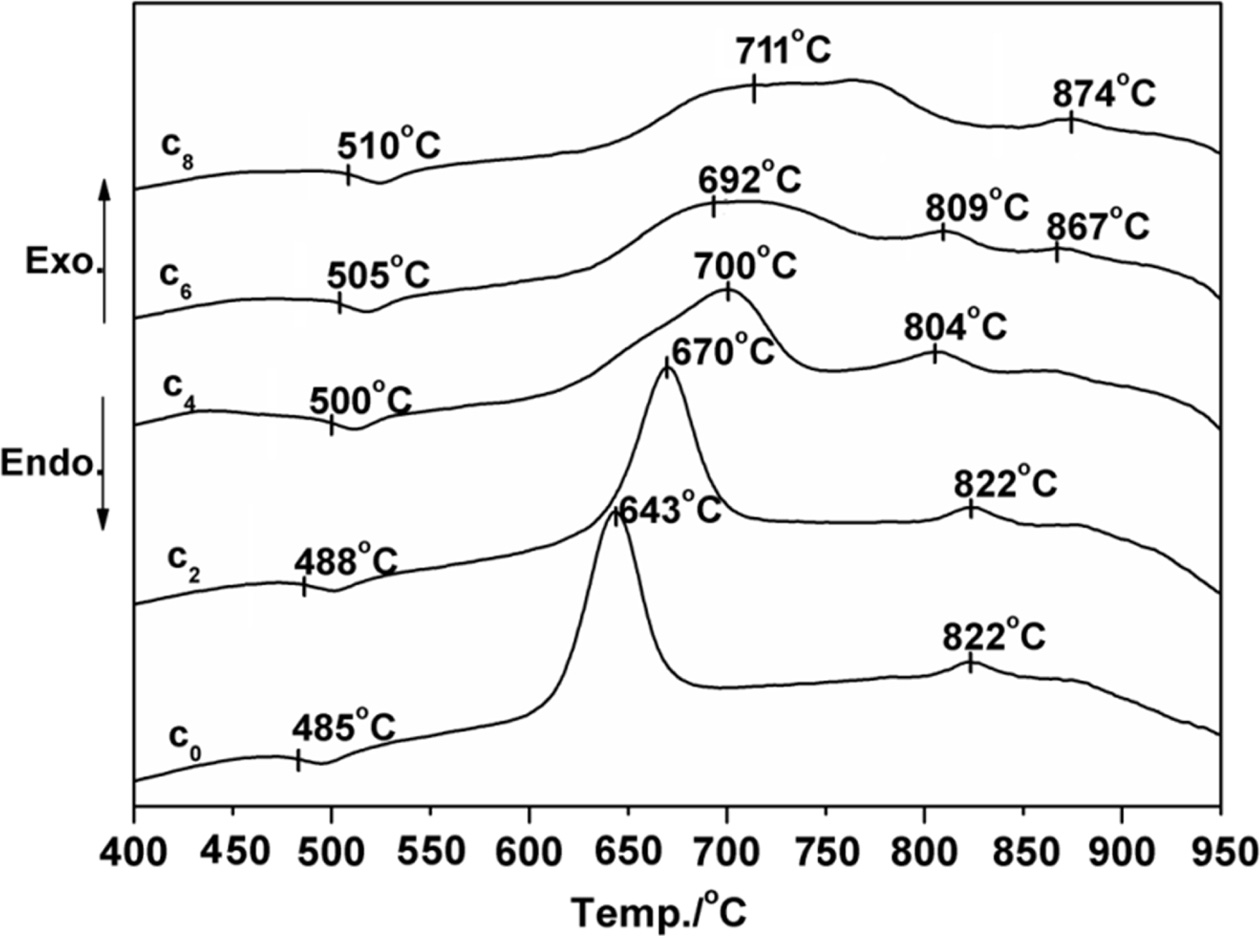

Fig. 2 and 3 show the X-ray diffraction

patterns of LZS glass-ceramics at different crystallization

temperatures (700 oC and 880 oC). Fig. 2

shows the XRD patterns of the samples containing different

amounts of CeO2 crystallized at 700 oC.

Crystallization consequence of the CeO2-free sample is quite simple,

as C0 showing. The major phases were Li2ZnSiO4

(PDF# 24-0677) and Li3Zn0.5SiO4 (PDF#

24-0667), which was the same to LZS system. The curves of C0, C2

and C4 in Fig. 2 are similar. It means that low content of

CeO2 (under 4 wt.%) in LZS system would not have obvious effect on

the main crystals in the glass-ceramics at low crystallization temperature (700 oC).

However, the amounts of main crystals

increased with CeO2 content increasing. When CeO2 content

was over 6 wt.%, β-spodumene (PDF# 35-0797) appeared, which could be

observed from C6 and C8 curves in Fig. 2. According to

the XRD analysis result in Fig. 2, the Li2ZnSiO4 and Li3Zn0.5SiO4

crystals were promoted by CeO2, and the amount of cristobalite

(PDF# 39-1425) also increased. High content of CeO2 (above 6 wt.%)

could accelerate crystals growth, especially for β-spodumene.

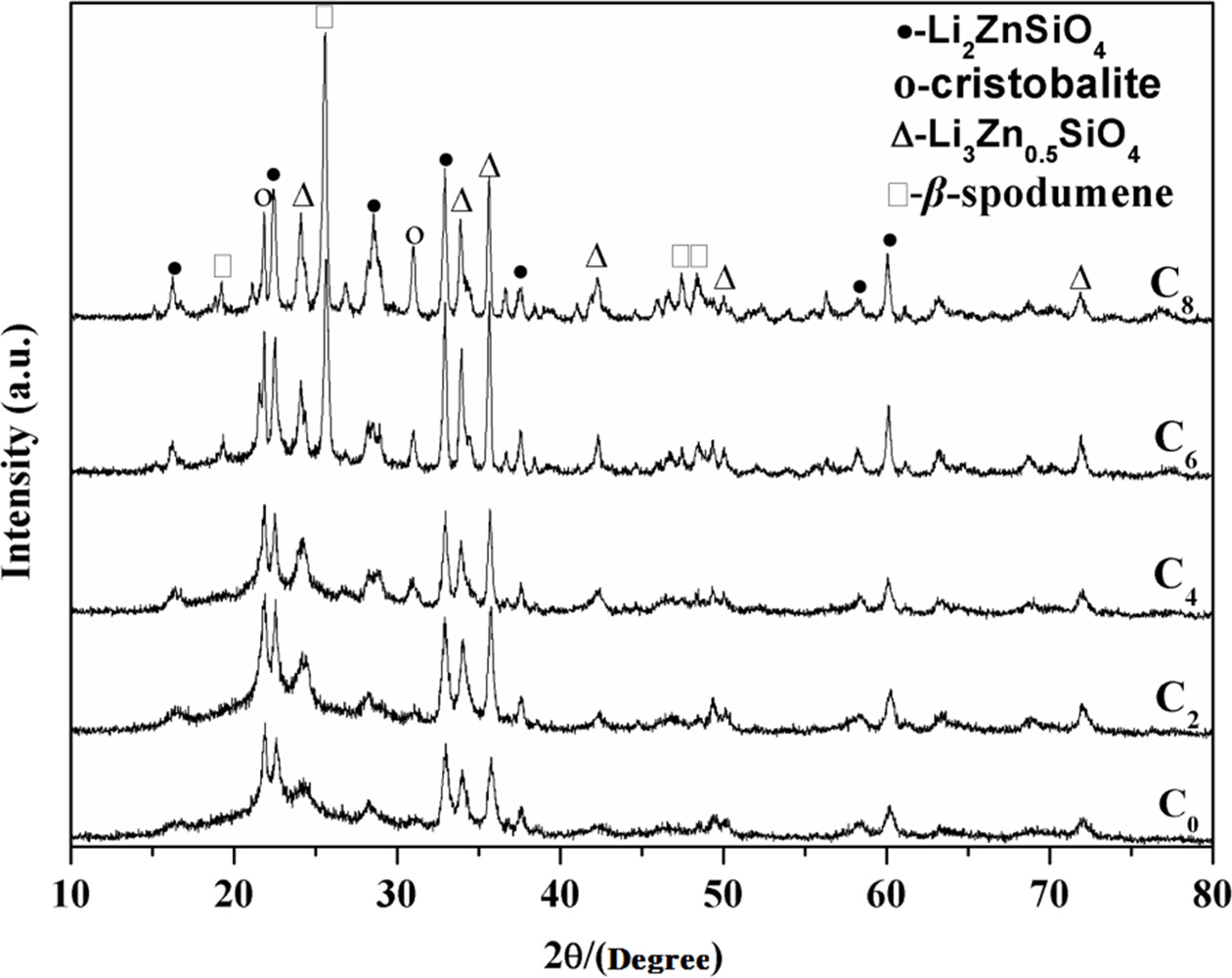

Fig. 3 shows the XRD patterns for the samples crystallized

at 880 oC. Li2ZnSiO4 and Li3Zn0.5SiO4

also were identified as major crystallization phases along with cristobalite

phase increasing when the amount of CeO2 was under 2

wt.%, according to C0 and C2 curves in Fig. 3. C0

curve in Fig. 3 had no obvious difference with C0 in Fig. 2, but at

880 oC, C2 appeared β-spodumene,

and cristobalite increased. It indicated that temperature also

had a distinct effect on the formation of β-spodumene

and cristobalite. At high crystallization temperature (880 oC), CeO2

could better promote crystals growth. The CeO2-free samples had no β-spodumene

phase, regardless of temperature. The amounts of Li2ZnSiO4,

Li3Zn0.5SiO4 and cristobalite also increased

as CeO2 increasing at 880 oC. The samples

containing high amount of CeO2 (6 wt.%) at low

crystallization temperature (700 oC) had the same crystalline phases

with the samples containing low amount of CeO2 (2 wt.%) at high

crystallization temperature (880 oC). When the content of CeO2

reached to 8 wt.%, the amount of β-spodumene was highest at 880 oC.

By contrasting Fig. 2 and Fig. 3, it indicated CeO2 could accelerate

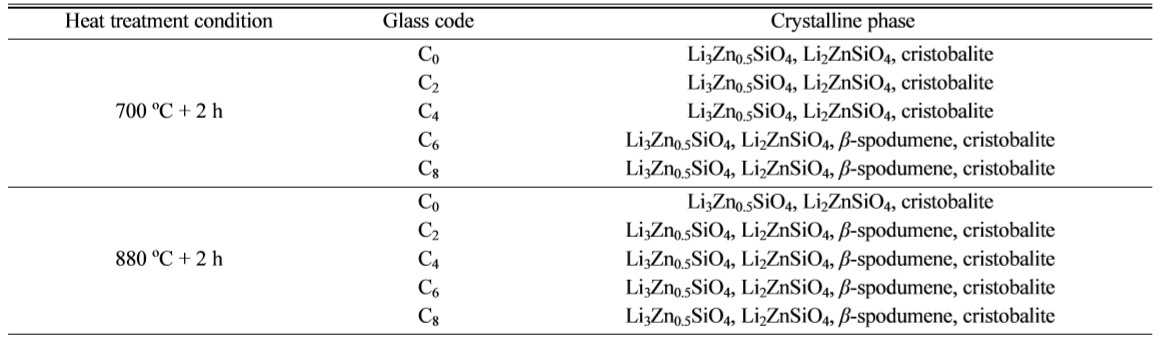

crystals growth in LZS system, and it is more obvious at higher temperature. Table 3 shows more details of crystalline phase changes

of the samples containing different content of CeO2.

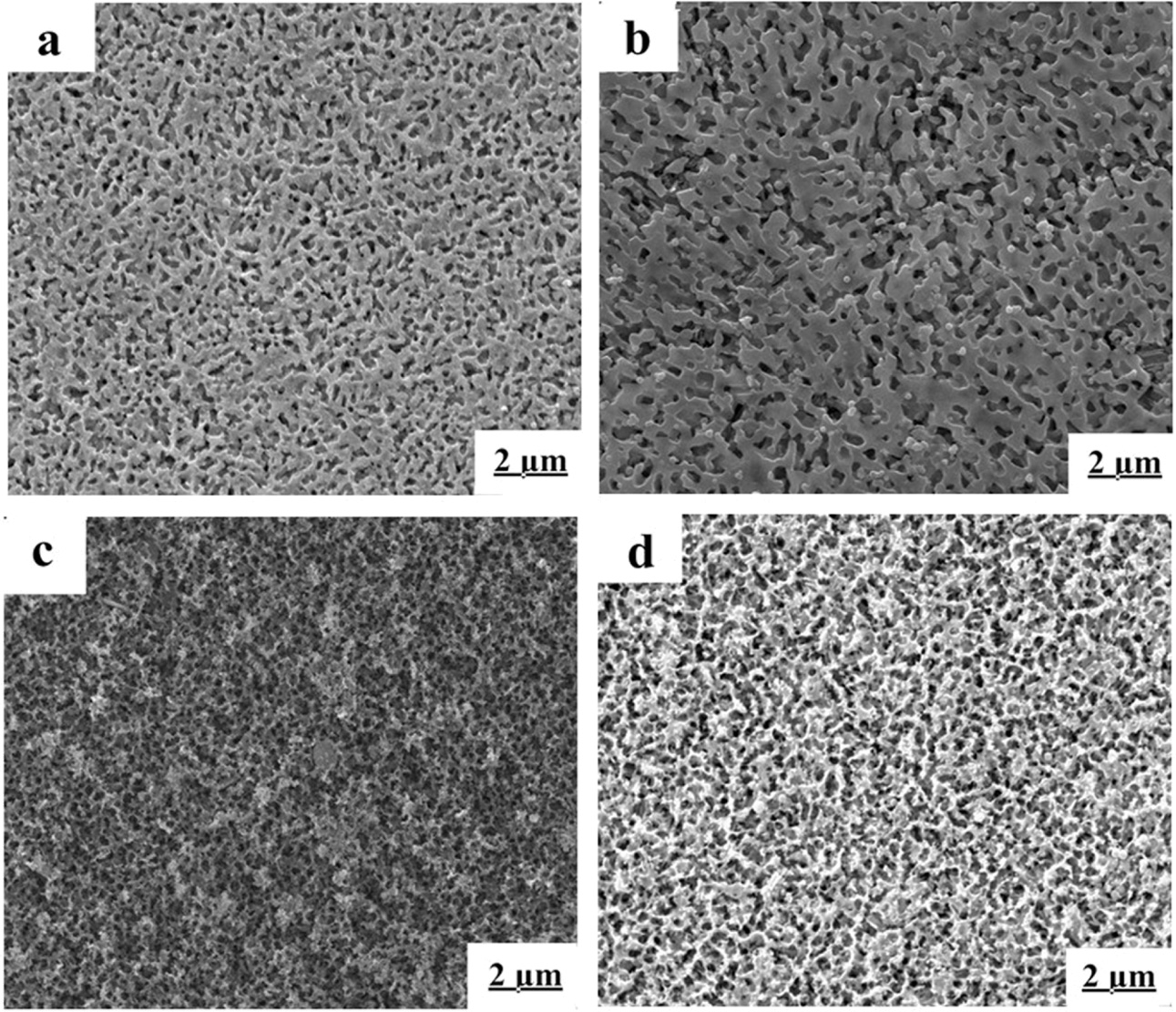

The microstructures of the samples are showed in Fig. 4

and 5. The chosen scanning electron microscope pictures were representative,

which were C0, C2, C6, C8

heat-treated at 700 oC and 880 oC for 2 h, respectively.

The morphology in Fig. 4(a) and (b) was similar. The interconnected network

microstructure formed by tiny dendritic crystals, and the crystals in picture

(b) was much bolder. According to the XRD analysis, the main crystals in Fig.

4(a) and (b) were Li2ZnSiO4 and Li3Zn0.5SiO4

at 700 oC. The microstructures of glass-ceramics had changed

significantly when CeO2 content were 6 and 8 wt.%, showing in Fig.

4(c) and (d). A lot of β-spodumene crystals formed. The

morphologies become smaller network-shaped microstructure, and crystals density

increased. The development and disorderly distribution

of massive thin small dendritic crystals resulted in the formation of

honeycomb-shaped network structure. As the amount of CeO2

increasing, the dendritic crystals became coarser, as shown in Fig. 4(d).

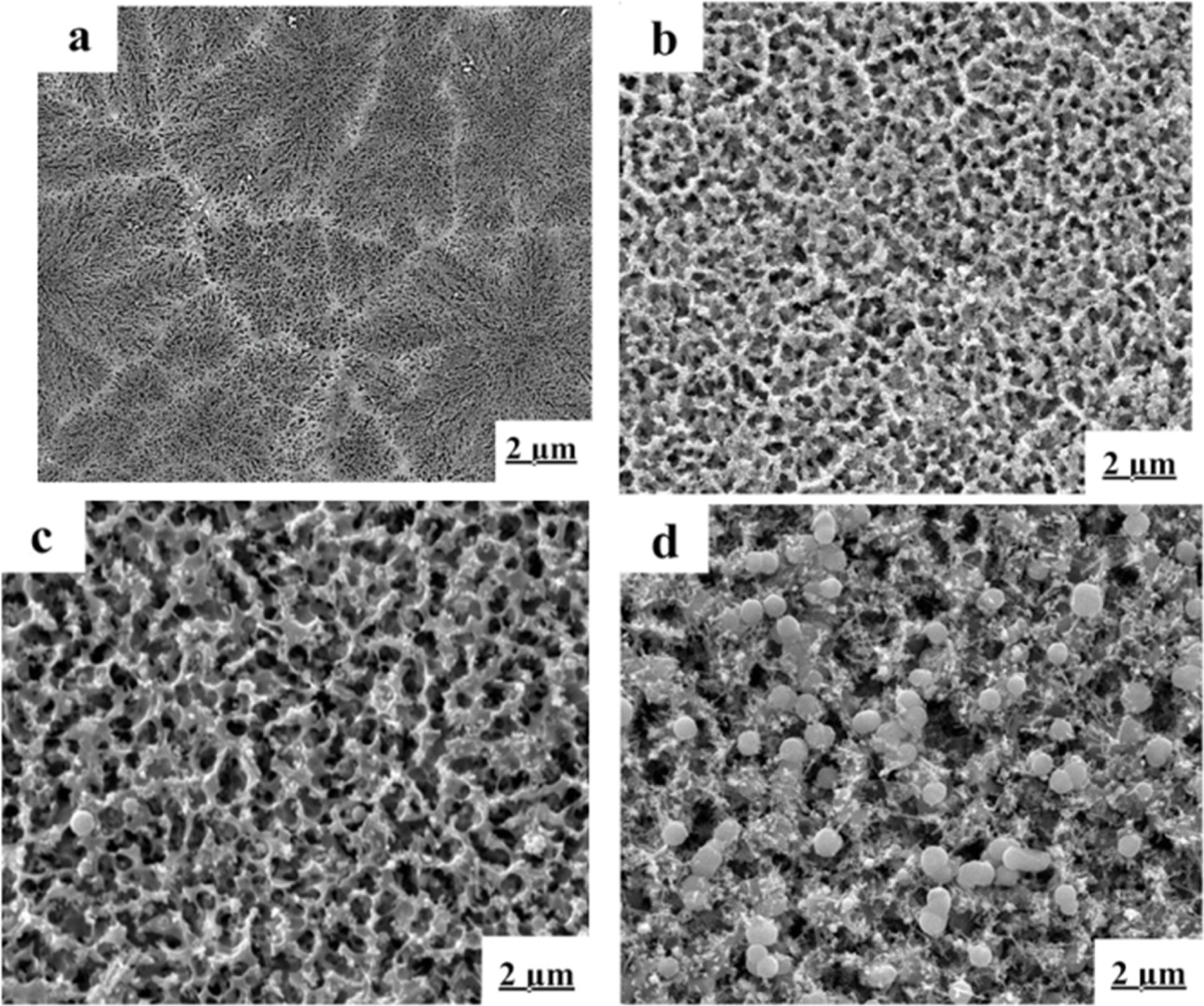

When the heat-treated temperature was 880 oC,

the effect of CeO2 on the crystals was more obvious. The

microstructures of CeO2-free sample appeared different parts

(Fig. 5(a)). The spherical crystals could be observed, which was

cristobalite crystal. Contrasting with Fig. 4(d), Fig. 5(b) had similar

crystalline structure with it. It showed that CeO2 would

have a much stronger impact on promoting crystals formation at a high

temperature (880 oC). The Fig. 5(c) has a looser

net-work structure than that of picture (b). The reason was that with the increasing

of CeO2, the effect of partial substitution of Si4+ by Al3+

ions became stronger [32] and caused crystallization and

development of β-spodumene. The grain of cristobalite grew bigger,

distributing in tiny dendritic β-spodumene crystals, which could be seen

in Fig. 5(d).

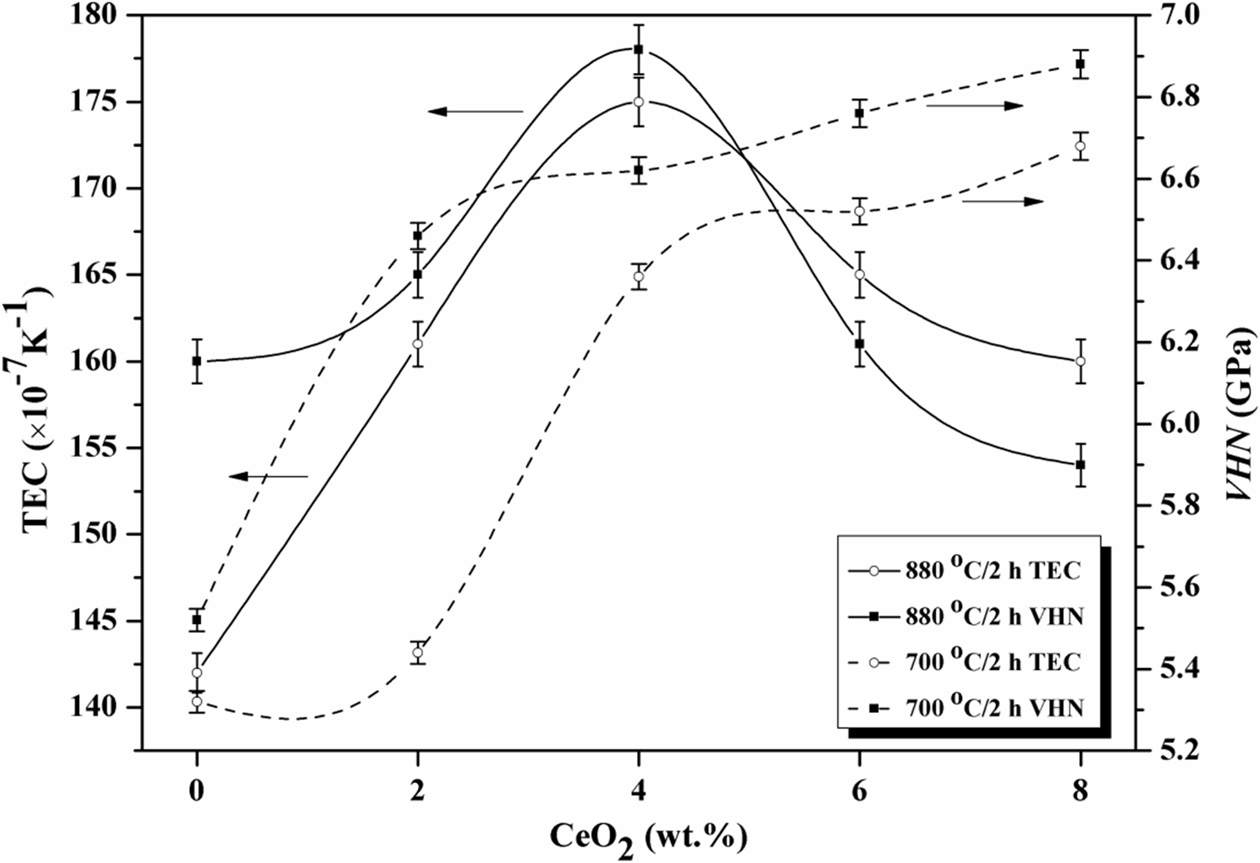

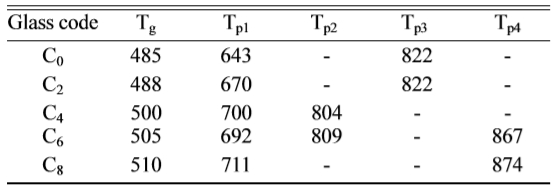

Hardness

(Hv) and Thermal expansion coefficient (α)

Vickers hardness of the glass-ceramics was an important

property. The samples crystallized at 730 oC and 880 oC

were tested, and the results were showed in Table 4. The microhardness of LZS glass-ceramics increased with CeO2

increasing, as showing in Fig. 6. It was already pointed out that β-spodumene

and cristobalite crystals increased in the glass-ceramics, which both have

higher bond strength than Li3Zn0.5SiO4 and Li2ZnSiO4

crystals. That was the reason of increase in hardness [33]. The hardness curves

crystalized at 700 oC in Fig. 6 had biggest changes when the amount

of CeO2 was from 2 to 4 wt.%. However, at 880 oC, the

changes happened when the amount of CeO2 was from 0 to 2 wt.%. They

were both reached to the maximums, 6.68

GPa and 6.88 GPa respectively, when CeO2 content was 8

wt.%. It suggested high temperature could enhance the effect of CeO2

in LZS glass-ceramics, which is similar with the XRD results. The increase of microhardness was in favour of

advancing the sealing application of LZS glass-ceramics.

The LZS glasses are mainly used to seal to metals, and the

thermo-physical property of the glasses is vital. The average thermal expansion

coefficient at 20-450 oC was investigated. The results were showed

in Table 4. Fig. 6 showed the change of thermal expansion coefficients at

different crystallization temperatures versus CeO2

content. The thermal expansion coefficients was first

increasing then decreasing, as showing in Fig. 6, and reached to the maximums

when the amount of CeO2 was 4 wt.%. According to the XRD results in

Fig. 2, when the amount of CeO2 is free, the main crystals are Li2ZnSiO4

and Li3Zn0.5SiO4, which have low thermal

expansion coefficients (α ≈ 110×10-7 K-1).

However, the amount of cristobalite (α ≈ 270×10-7 K-1)

increased with CeO2 increasing. The thermal expansion coefficient

of LZS glass-ceramics increased, and reached to the

maximum. With the amount of CeO2 increasing (above 4 wt.%), it

promoted the formation of β-spodu-mene, which has a lower thermal expansion coefficient (α ≈ 19×10-7 K-1).

The thermal expansion coefficient of LZS glass-ceramics decreased with β-spodumene

increasing. When the crystallization temperature reached

to 880 oC, the effect of CeO2 promoting β-spodumene

and cristobalite formation was more obvious, and β-spodumene crystals

increased more apparently with CeO2 content increasing. The

glass-ceramics had lower thermal expansion coefficient when

the amount of CeO2 was above 6 wt.% at 880 oC.

A small amount of CeO2 (under 4 wt.%) could increase the average

thermal expansion coefficients of LZS glass-ceramics, but it would markedly

decrease when high CeO2 content promoted the formation of β-spodumene.

It could be concluded that LZS glass-ceramics could have a wide range of

thermal expansion coefficients with the changes of temperature and CeO2

content. The change of thermal expansion coefficient would make it better seal

to more metals.

|

Fig. 1 DSC curves of the glass with different amounts of CeO2. |

|

Fig. 2 X-ray diffraction patterns of the present glasses heattreated at 700 oC for 2 h. |

|

Fig. 3 X-ray diffraction patterns of the present glasses heattreated at 880 oC for 2 h. |

|

Fig. 4 Microstructure of the LZS glass-ceramics heat-treated at 700 oC for 2 h with different mounts of CeO2: (a) 0 wt.%, (b) 2 wt.%, (c) 6 wt.%, (d) 8 wt.%. |

|

Fig. 5 Microstructure of the LZS glass-ceramics heat-treated at 880 oC for 2 h with different mounts of CeO2: (a) 0 wt.%, (b) 2 wt.%, (c) 6 wt.%, (d) 8 wt.%. |

|

Fig. 6 Variation of microhardness and thermal expansion coefficients (TEC) with CeO2 contents. |

|

Table 3 Effect of CeO2 and heat treatment on the formation of crystalline phase. |

|

Table 4 The average thermal expansion coefficients at 20-400 oC and Vicker’s hardness (± 0.02) of different amount of CeO2doped samples crystallized at 700 oC and 880 oC for 2 h. |

The amount of CeO2 could affect the

crystallization and thermo-physical properties of lithium zinc silicate

glass-ceramics. The glass transition temperature (Tg)

increased, but CeO2 promoted the formation of β-spodumene and

cristobalite crystals, which made the structure more rigid and caused the

change of thermo-physical property, and the effects were more obvious at high

crystallization temperature. The microhardness increased with CeO2

content increasing; however, the average thermal expansion coefficients

(20-450 oC) of LZS glass-ceramics showed first increasing then decreasing,

and it obtained a wider range and reached to maximums when the amount of CeO2

was 4 wt.%. The analysis indicated that CeO2 played

an important role in adjusted the crystallization and physical properties.

And a higher microhardness and a wider average thermal expansion coefficient

indicated the LZS glass-ceramics could better seal to metals.

The work was financially supported by Science and

Technology Research Foundation of Jiangxi Education Department (No.

GJJ170537/GJJ170498) and Startup Foundation for Docotors of Jiangxi University

of Science and Technology (No. jxxjbs17019).

- 1. S.C. Clausbruch, M. Schweiger, W. Höland, and V. Rheinberger, J. Non-Cryst. Solids 263 (2000) 388-394.

-

- 2. B.I. Shaima and M. Goswami, J. Mater. Lett. 58 (2004) 2423-2438.

-

- 3. I.W. Donald, J. Non-cryst. solids (2004) 345-346.

-

- 4. M. Goswami, S.K. Deshpande, and R. Kumar, J. Phys. Chem. Solid. 71 (2010) 739-744.

-

- 5. W.Z. Liu, Z.W. Lou, X.L. Hu, and A.X. Lu, Thermochim. Acta. 584 (2014) 45-50.

-

- 6. Y.Z. Chen, W.H. Li, Y. Zhang, Z.Q. Shen, D.L. Yang, and X. Z. Song, Ceram. Int. 42 (2016) 11650-11653.

-

- 7. S.M. Salman, S.N. Salama, and H.A. Abo-Mosallam, Bol. Soc. Esp. Ceram. V. 56 (2017) 205-214.

-

- 8. P.W. McMillan and B.P. Hodgson, Glass Tech. 7 (1966) 121.

- 9. P.W. McMillan, G. Partridge, and B.P. Hodgson, Glass Tech. 7 (1966) 128.

- 10. I.W. Donald and B.L. Metcalfe, J. Mater. Sci. 24 (1989) 3892-3903.

-

- 11. I.W. Donald, P.M. Mallinson, and B.L. Metcalfe, J. Mater. Sci. 46 (2011) 1975-2000.

-

- 12. A. Karamanov, P. Pisciella, and M. Pelino, J. Eur. Ceram. Soc. 20 (2000) 2233-2237.

-

- 13. J.J. Shyu and M.T. Chiang, J. Am. Ceram. Soc. 83 (2000) 635-639.

- 14. A.W.A El-Shennawi, E.M.A. Hamzawy, and G.A. Khater, Ceram. Int. 27 (2001) 725-730.

-

- 15. W. Zheng, J. Cheng, and L. Tang, Thermochim. Acta 456 (2007) 69-74.

-

- 16. H.B. Zhang, G. Gui, C.H. Su, Y.M. Wang, and J. Shao, Chinese J. Inorg. Chem. 26 (2010) 144-148.

- 17. Y. Demirci and E. Günay, J. Ceram. Process. Res. 12 (2011) 352-356.

- 18. Z. Shen, Z. Liang, and Z. Yong, Ceram. Int. 43 (2017) 7099-7105.

-

- 19. D. Lee and S. Kang, J. Ceram. Process. Res. 19 (2018) 504-508.

- 20. G.P. Singh and D.P. Singh, Physica B 406 (2011) 640-644.

-

- 21. E. Mansour, J. Non-Cryst. Solids 357 (2011) 1364-1369.

-

- 22. P.S. Gurinder and D.P. Singh, Physica B 407 (2012) 4168-4172.

-

- 23. H.J. Wang, B.T. Li, and H.X. Lin, Int. J. Appl. Glass Sci. 7 (2016) 310-318.

-

- 24. H.J. Wang, B.T. Li, and H.X. Lin, J. Mater Sci-Mater. El. 27 (2016) 2860-2865.

-

- 25. T. Liu and G. Chen, Ceram. Int. 39 (2013) 5553-5559.

-

- 26. F. Soleimani and M. Rezvani, Mater. Res. Bull. 47 (2012) 1362-1367.

-

- 27. S.A.M. Abdel-Hameed and F.H. Margha, J. Alloys Compd. 554 (2013) 371-377.

-

- 28. S.B. Sohn, S.Y. Choi, and Y.K. Lee, J. Mater. Sci. 35 (2000) 4815-4821.

-

- 29. A.M. Hu, K.M. Liang, and F. Zhou, Ceram. Int. 31 (2005) 11-14.

-

- 30. J. Temuujin, U. Bayarzul, E. Surenjav, K. D. Sung, and C. Y. Sik, J. Ceram. Process. Res. 18 (2017) 112-115.

- 31. Y. S. Du, J. Ma, X. F. Zhang, H. X. Zhang, H. Chen, S. Ouyang, and B.W. Li, J. Ceram. Process. Res. 20 (2019) 401-410.

- 32. M. Goswami and P. Sengupta, Ceram. Int. 33 (2007) 863-867.

-

- 33. A.X. Lu and Z.B. Ke, J. Non-cryst. Solids 353 (2007) 2692-2697.

-

- 34. J. Zarzycki, in “Material Science and Technology” (Weinheim press, 1991) p667-713.

This Article

This Article

-

2020; 21(1): 86-91

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.86

- Received on Sep 29, 2019

- Revised on Nov 18, 2019

- Accepted on Dec 9, 2019

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Weizhen Liu

-

Faculty of Resources and Environmental Engineering, Jiangxi University of Science and Technology, Ganzhou 341000,China

Tel : +8607978312071 Fax: +8607978312051 - E-mail: 9120170002@jxust.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.