- Comparative studies on bentonite clay and peanut shell carbon recovering heavy metals from printed circuit boards

Murugesan Manikkampatty Palanisamya,* and Kannan Kandasamyb

aDepartment of Chemical Engineering, Erode Sengunthar Engineering College, Erode, Tamil Nadu 638057, India

bDepartment of Chemical Engineering, Kongu Engineering College, Perundurai, Erode, Tamil Nadu 638060, India

The quantity of electronic

waste subjected to disposal annually is increasing alarmingly and is of major

environmental concern due to the existence of heavy metals and other toxic

substances. In this present study, by combining leaching and adsorption the

recovery of heavy metals from Printed circuit boards (PCBs) has been performed.

The two stage aqua-regia leaching extracts Copper (Cu), Tin (Sn), Lead

(Pb), and Zinc (Zn) from PCB. Bentonite Clay (Bent) and Peanut Shell Carbon

(PSC) in their pristine, thermally and chemically activated forms were employed

as adsorbents to remove the heavy metals from leached solution. Effect of

parameters (contact time, temperature, adsorbent dosage and size) on %

adsorption was studied. Chemically activated bent (C-A Bent) has proven to be

an effective among all adsorbents studies with % adsorption for Cu 97%, Sn 98%,

Zn 96%, and Pb 96%. Leaching and adsorption combination can become a promising

methodology for handing electronic waste.

Keywords: Leaching, Adsorption, Bentonite clay, Peanut shell carbon, Printed Circuit Board (PCBs)

Nowadays, electronic devices are rapidly growing due to

human population and industrialization. E-waste has been increased every year

around 18.5 lakh metric tons [1]. Electronic waste like television (TV),

personal computer (PC), Mobile phone, DVD Player, Printed circuit boards

(PCBs), and Printed wiring board scraps contain heavy metals. PCBs are one of

the major important Electronic wastes. The PCB scraps have 50% of iron and

steel elements, 21% plastics, 13% non-ferrous metals and others 16% [2]. In

addition to that metals contain 10-30% of copper and further

metals such as Zn 2%, Pb 4%, etc., based on the source and category

of the circuit board [3]. Skin damage, headache, cardiovascular diseases, hair losses, brain effects are the impact of

heavy metals on human [4-8]. Due to these problems, heavy

metals should be disposed of properly. At first, incineration method was used

to dispose of the circuit boards [9-11]. Since it affects the environment by CO

and CO2 emissions, solidification and landfill methods were implemented to

dispose of the circuit boards [12, 13]. Later, these

practices were identified to be polluting the nature of soil by reducing the

interface mass transfer rate of soil. Cu2O and CuO were found from the oxidation method of the toxic metals from

PCBs by use of NaOH-supercritical water [14]. The preheating

method (Pyrolysis) recommended recovering the metals from electronic waste

[15]. PCBs were dissolved in aqueous solution (HNO3, H2SO4, and HCL), the Electro-deposition techniques achieved more than 90% of Cu recovered [16]. Sodium cyanide solution was used as a leaching agent in leaching column technique and the

result obtained was recovery of Au 46%, Cu 62% and Ag 51% [17]. Leaching agents

Cyanide, Thiosulphate, Thiourea, and Halide were used to

separate the precious metals like Ni, Zn, Sn, Au, Cu, Pb and other elements

[18-20]. Several inorganic Chemicals were tested as leaching agents such as HCL

[21], H2SO4 [22, 23], Aqua Regia [24], HNO3 [25]. 85.4% of copper was leached from waste PCBs by the principle of leaching methodology. It was analyzed based on the

concentration and agitation time. The study emphasized that as the

concentration increases, the leaching of metal ions increased [25, 26].

There are different conventional

methodologies like Incineration, landfilling,

gasification, pyrolysis, hydro-

metallurgical and chemical leaching techniques have their own merits and

demerits in various aspects like cost, environmental effects and metal recovery. However, there are more difficulties to recover the heavy metals in

various processes like Electro-winning, Electro-deposition, Acids leaching and

others. Therefore, heavy metals like Cu, Sn, Zn, Pb, As, Zi and Cr are

recovered by adsorption techniques by Bent adsorbent [27, 28]. Natural

clay adsorbed Cu and Zn based on various parameters like temperature

(25 ℃), Agitation speed (200 rpm) and pHfrom aqueous solution [6, 29].

The result reveals that copper is recovered from phosphoric acid solution by

A-Bent. It summarizes that the effect of concentration decides the rate of

recovery by adsorbent [30]. The ability of the Bent was investigated by

adsorption of Cu and Ni. The characterization of bent is based on concentration

(5 ppm-30 ppm) and temperature (20-80 ℃) [28]. The activated carbon (AC) was prepared by using chemical

reagent (HCL). The adsorption capacity of A-Bent to recover the heavy metals

like Pb, Cadmium (Cd), and Cu was analyzed. The results showed maximum

adsorption capacities in natural and A-Bent and were found to be Pb 83 mg g-1 and 92 mg g-1 [31]. Natural clay (Sepiolite) can be used to adsorb the Cu and Zi

from aqueous solution [32]. The result gave the metal ions (Cu2+ and Zn+) adsorption efficiency with the respective parameter from aqueous

solution and it concluded that the Natural clay is effective one

for recovery of heavy metals and minerals [33-36]. Till now many studies were

done focusing on extraction of heavy metals from PCBs but have not focused on

handling the extracted solution and it is applicable to recover the metals from LCD monitors boards, LED, LCD Boards, mobile phone boards.

On the other hand several researchers used adsorption technique for recovery of

heavy metal from aqueous solutions. Here in this present study, it is focused

on the extraction and recovery of heavy metals from crushed

and sieved printed circuit boards using two stage leaching combined with

adsorption.

Materials

Raw Printed Circuit Boards (PCBs)

The waste (PCBs) raw materials were obtained from Global

E-Waste management services, a waste collection unit in

Tamil Nadu, India. For experimental purpose, 5 kg scraps of PCBs were utilized.

The sample initially cleaned manually to remove dust particles by Air Blower.

Later other elements such as capacitors, resister, integrated

circuits, diodes, transistor etc., were detached with the

help of mechanical tools (saw metal cutter, sheet metal cutter, metal lathe

cutting tool, cutting pliers and materials separation toolkit. The sample PCBs

and disassembled samples were taken out and shredded using scissors to a 15 mm

× 15 mm size [22, 37, 38]. Raw boards were crushed with the help of jaw crusher

having capacity 80 kg hr-1

with a clearance of 10 and 5 mm. PCBs of 5-10 mm sizes samples were obtained.

Then the samples were further subjected to Ball mill having a ball weight 500

gm at a speed of 60-120 rpm with a mill diameter 200 mm driven by 0.25 HP, 3

phase motor. Then the samples were further subjected to Ball mill having a ball

weight 500 gm at a speed of 60-120 rpm with a mill diameter 200 mm driven by

0.25 HP, 3 phase motor. Since, the samples obtained 5 mm sizes to 3 mm from

ball mill were it is not meeting the specified size requirements; these PCBs

are then subjected to heating operation at 700-900 ℃ using muffle

furnace to enhance the flexibility and crushing properties of PCBs [16]

followed by continues size reduction operations of Drop-weight crusher,

Pulverizer and ball mill for two hrs. The crushed sample thus

obtained were converted into powdered form using pulverizer having disc

diameter 175 mm driven by 3 phase motor at 1,400 rpm in 225-445 V supply. The

resultant powdered samples were screened under various mesh size and weight

fraction of bottom products (sieves from 52 B.S.S to pan) becomes higher but

not sufficient for expected recovery. The pulverized PCB powders were milled in

a ball mill which results high size reduction and highest weight fractions were

obtained at lowest sieves. The weight fractions obtained at

each sieves were separately collected and subjected for leaching operation.

Results obtained were in the range of 4 mm-0.05 mm particle sizes

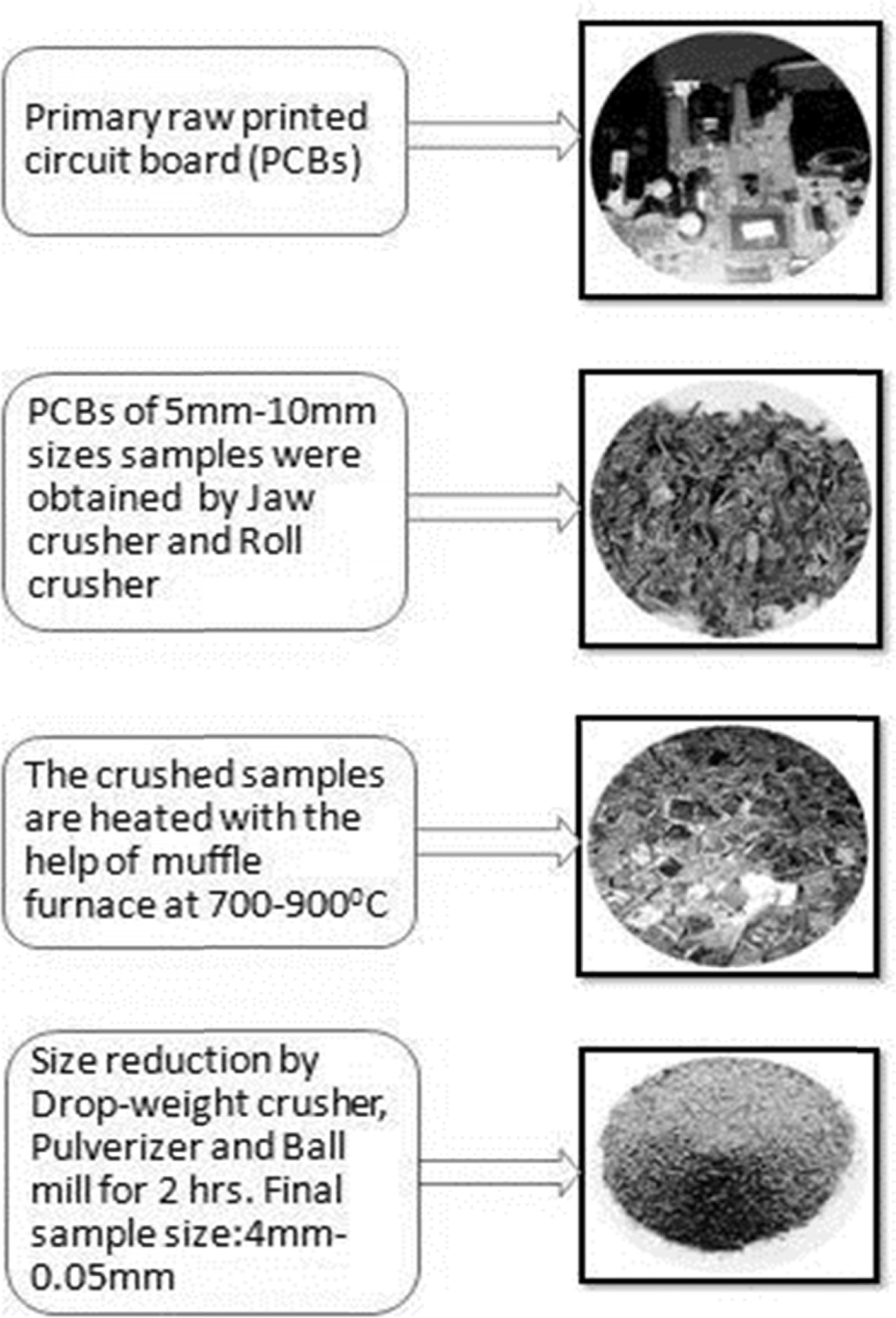

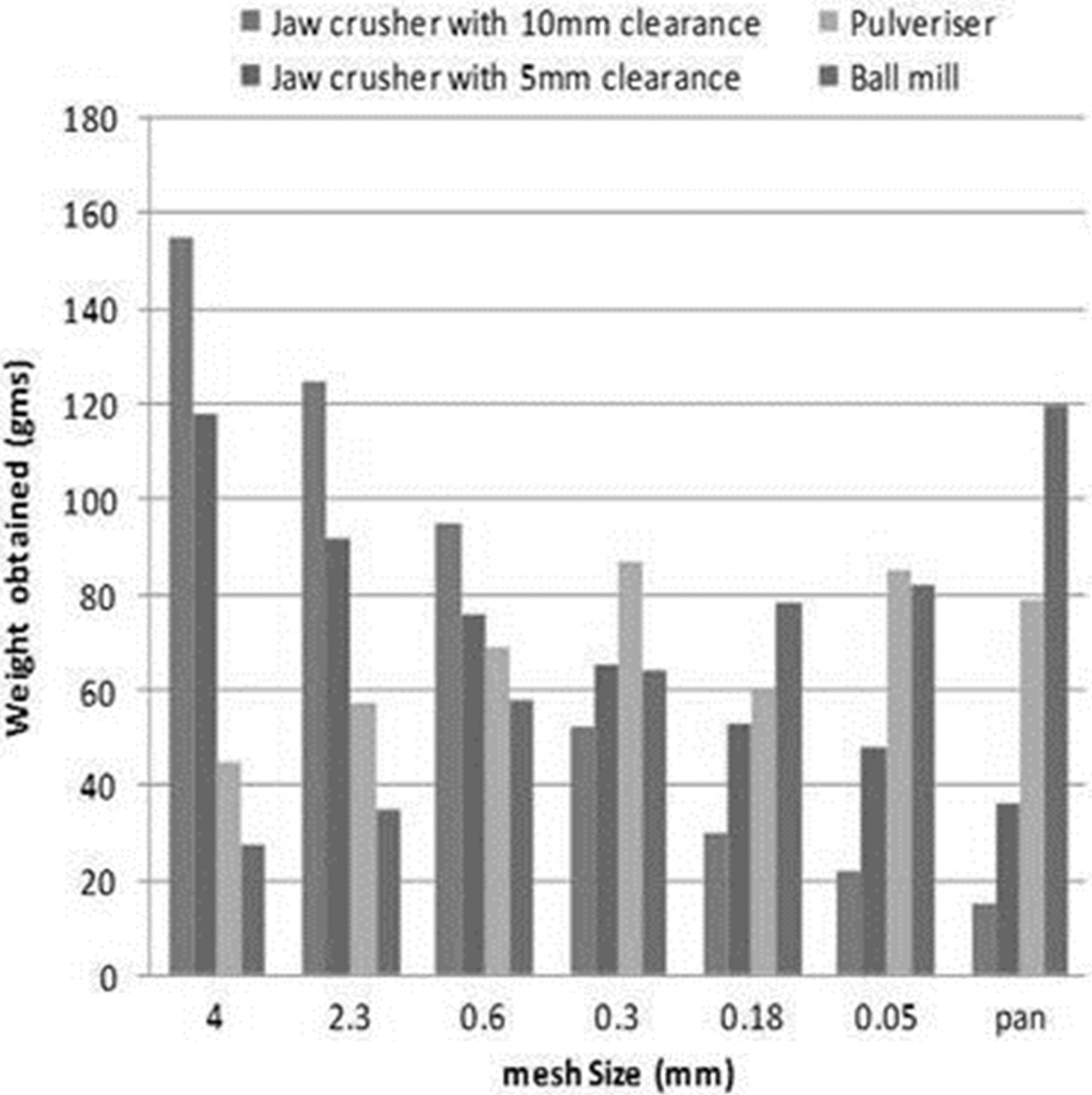

[26, 39]. Therefore, Fig. 1 showed that, Primary Raw PCBs; in to

stepwise size reduction under the various mechanical operations (Jaw

crusher, Roll crusher, thermal heater and pulverized mills

produced small sizes between 4mm-0.05mm).

Methods

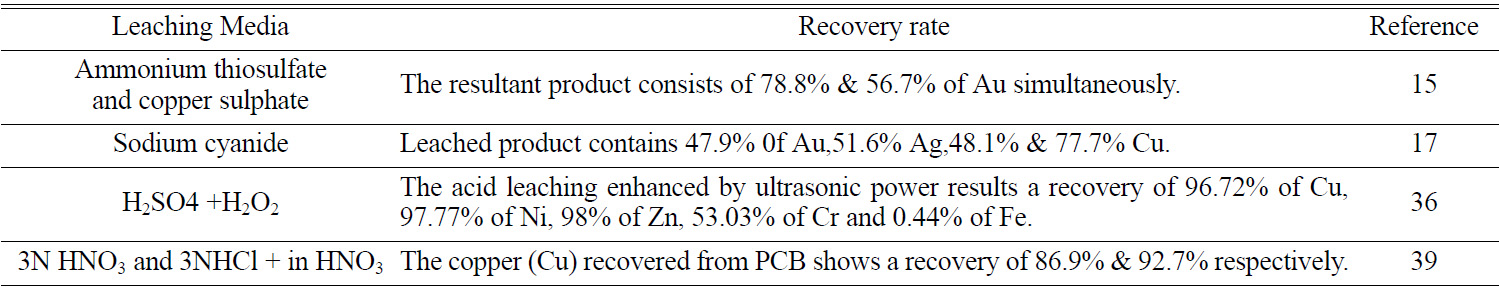

Aqua Regia preparation and Metals leaching

The leaching media is an important factor that should be

considered while extracting heavy metals such as Zn2+, Sn2+,

Cu2+ and Pb2+ etc from PCBs. Different sort of leaching

agents given various leaching rates with respect to

the type of metal were deliberated in previous

studies [25]. The Previous studies have resulted in significant metal recovery;

the copper (Cu) recovered by 3N HNO3 and 3N HCL+ in HNO3

from PCB shows a recovery of 86.9% & 92.7% respectively [40]. It also

possesses demerits such as targeted extraction of specific metal leads to loss

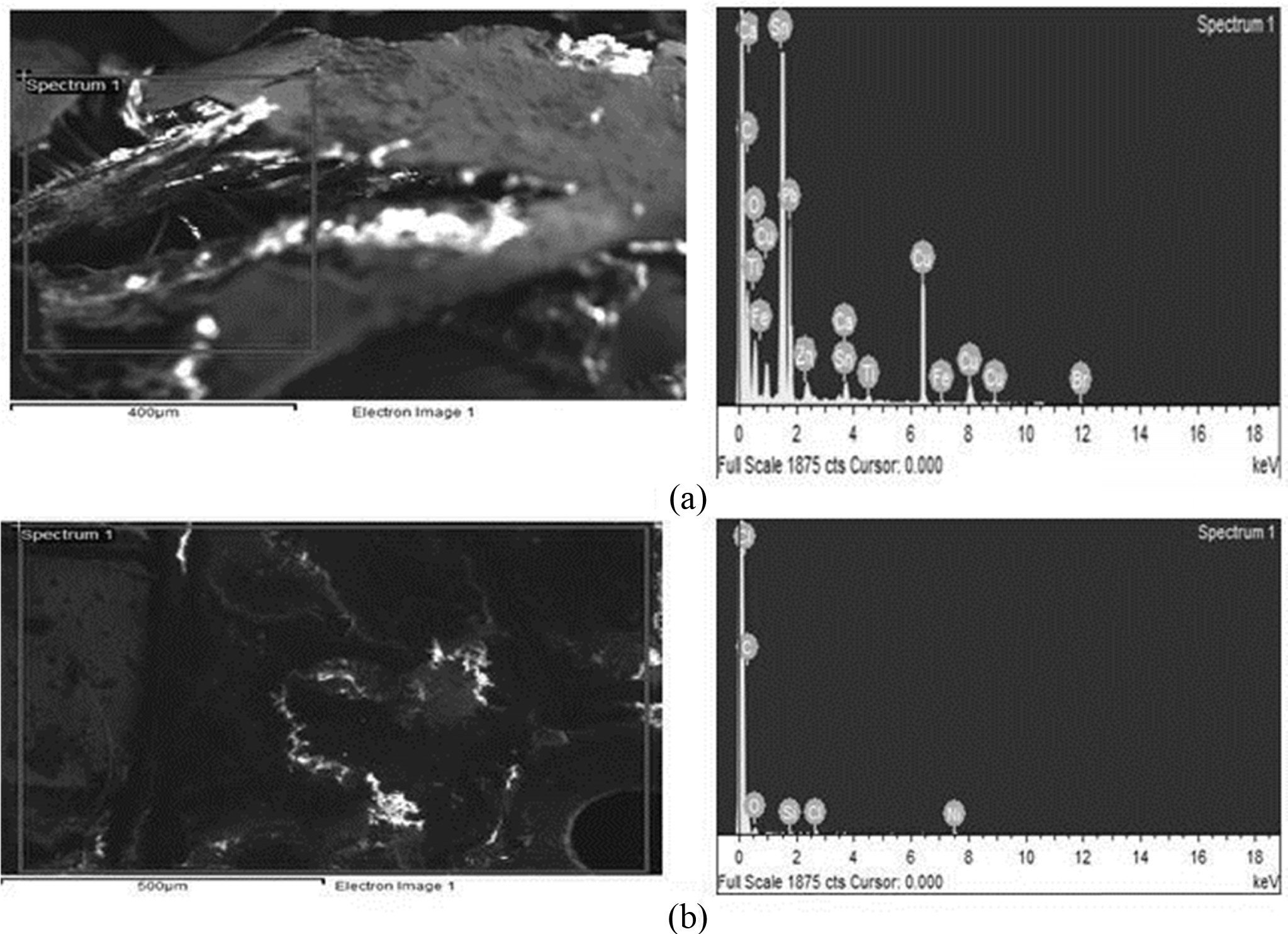

of several other valuable metals (Table 1). By using aqua regia as leaching

reagent by two stages (first stage HCL and HNO3 and second stage HCL

and H2SO4) heavy metals can be extracted from PCBs with

various operating conditions and samples were analyzed by Energy-dispersive

X-ray Spectroscopy EDXs [41, 42]. The dissolution of metal ions having PCBs

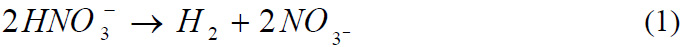

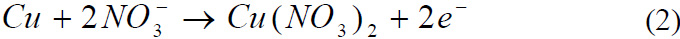

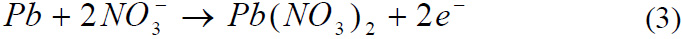

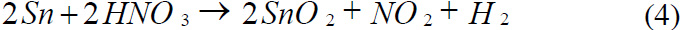

takes place according to the following reaction mechanisms:

Reaction of copper with Nitric acid

Reaction of Lead with Nitric acid

Reaction of Tin with Nitric acid

Reaction of Tin with Hydrochloric acid

Reaction of with Hydrochloric acid

Reaction of Tin with Sulphuric acid

Reaction of Zinc with Sulphuric acid

Adsorbentactivation

Bent clay carbon and peanut shell carbon were used as

adsorbents. Chemical and physical treatments are given to the

adsorbents initially. 250 g of both adsorbents were

taken in the thermal crucible and were dried for about five hrs for thermal

activation at 900 ℃. Therefore, the samples obtained are

of 1 µm to 5 µm. The higher specific surface area was obtained due to the

removal of unwanted gaseous molecules from the Non-activated adsorbents (NAC).

The C-A Bent & C-A PSC was prepared by using concentrated HCL and HNO3.

Then, it was shaken at 200 rpm for 5 hrs. The

acid-activated adsorbent was recovered and washed with deionized

water. After drying, both samples were grinded and

sieved. The preparedsamples were tested by the help of Scanning

Electron Microscope (SEM-FEI-Quanta FEG 200F) [41, 43].

Adsorption studies

The adsorption of heavy metals on PSC & Bent was

carried out in a batch system in both activated and NAC. 2 g of adsorbent was added to

20 ml of leached solution in a conical flask.

The mixture was shaken at 200 rpm for 5 hrs at 80 ℃ temperature.

After complete adsorption, the

samples were filtered and metals concentration was analyzed by using EDXs. It

is performing elemental analysis characterization of a sample in conjunction

with SEM. The energy of the beam

current is typically in the range of 100 Na, Schottky emitter

ranges between (-200 v – 30 kv), magnifications ranges 12X-105 X and resolution as 2

nm (Gold Nano-particles suspended on

carbon substrate). Then, adsorption efficiency of an adsorbent (PSC & Bent) was

determined by the following the

equation.

Removal efficiency (%) =

(Co - Ce)/Co × 100 (9)

Co is initial concentration of

metal ions from leached samples. Ce is the metal ions

concentration at the completion of adsorption operation [30].

Influence of various parameters on recovery

The studies carried out on recovering of metal ions from

leached solution with specified metals ions recovered by

PSC & Bent. Experiments were conducted with

pristine, thermally activated, chemically activated adsorbents to recover Zn2+,

Sn2+, Cu2+ and Pb2+ ions by varying the

operating parameters like adsorbent dosage (0-10 g), concentration (0-40 ml),

sizes of adsorbent (10-0.5 μm) contact time (0-4 hrs) and temperature (0-120 ℃) [25, 34, 35, 43]. Optimization studies were carried out to find the

maximum recovery.

|

Fig. 1 Image of Primary Raw PCBs; in to stepwise size reduction under the various mechanical operations (Jaw crusher, Roll crusher, thermal heater and pulverized mills produced small sizes between 4 mm-0.05 mm). |

Analysis

of printed circuit board

The primary samplefollowed three size reduction operations

namely crushing, pulverizing and milling and the weight fractions were

collected. The graphical representation (Fig. 2) of size analysis shows that

the fraction of the sample obtained in the sieves with larger mesh size has

been decreasing when subjected to a sequence of size reduction operations. From

the sieve analysis data of each operation, the sample obtained from ball mill

has many fractions of weight in the pan which is less than 0.05 mm [22]. The

sample sizes are most important for dilution of metal ions from leaching agent.

Here the minimum sizes of samples were used to recover the metals ions for

better dilution. Therefore, the results showed in graphical representation of

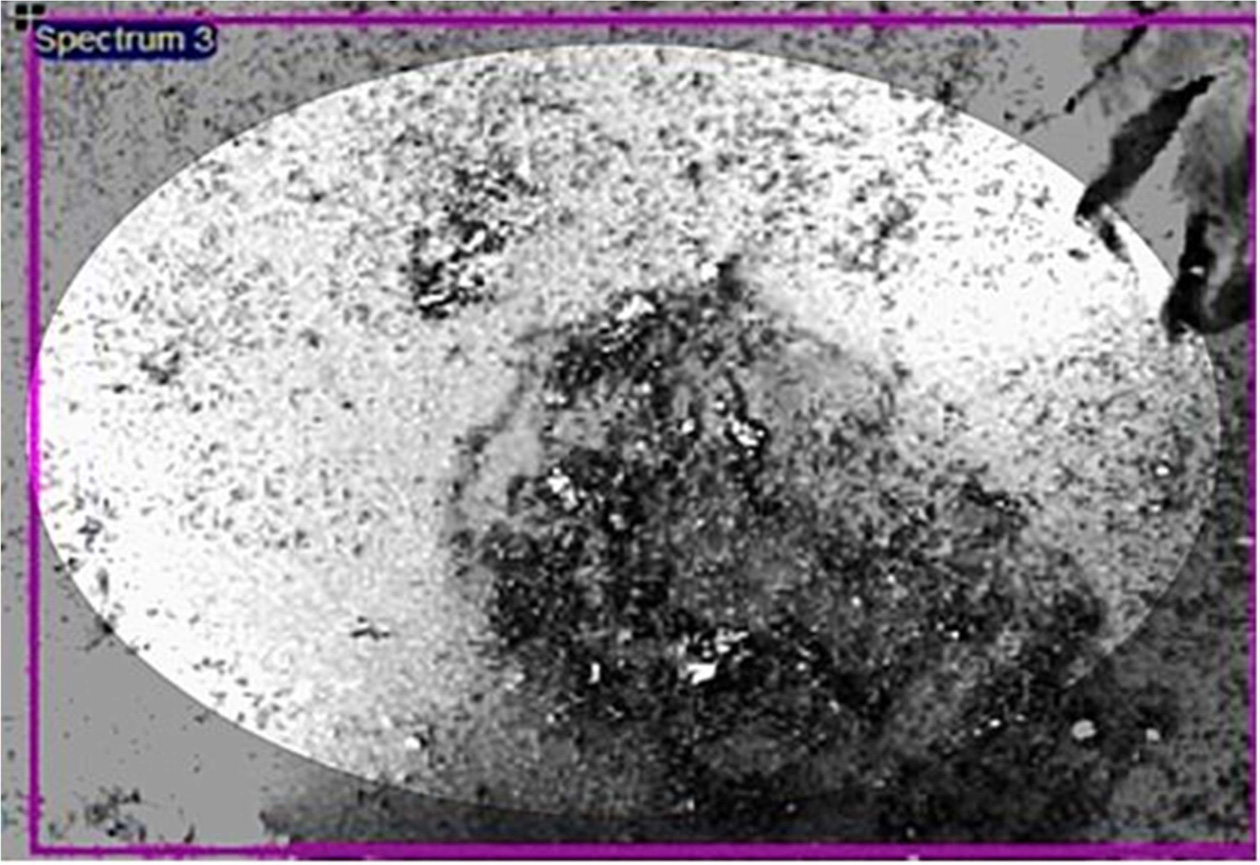

various size reduction operations (sizes up to 4-0.05 mm). The SEM images of

crushed samples were shown in (Fig. 3). Few studies were carried out based on

the effect of particle size to recover the metal ions from waste PCBs under

bioleaching and chemical leaching techniques. Present research comprises of

leaching used particle size 0.05 mm that is the sample retained just above the

pan.

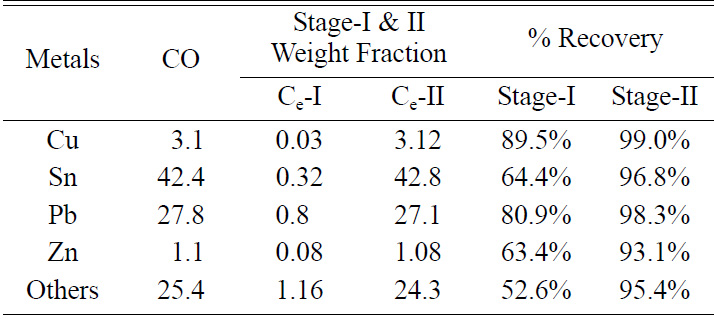

Leaching

The optimization of leaching experiments carried out by

keeping optimized variable parameters based on previous

studies. The electro deposition method recovered 98% of hazardous metals (Cu, Pb, Zinc (Zn), Tin (Sn), Nickel (Ni),

Silver (Ag) and Gold (Au) etc.) from PCBs. It was done by using leaching

(acetic aqueous chloride) and electrodeposition method [44, 45] in

specific conditions of 80 ℃ of temperature, 0.05 mm of thickness, 3

hrs of contacting time, 80 rpm shaking speed and pulp density of PCB sample 20

g mL-1,

in bothstages having 3:1 ratio of HCL and HNO3

prepared as a leaching agent. The experimental results were

obtained under the above mentioned conditions and have been shown in (Table 2)

and (Fig. 4). Results found the optimum recovery rate for Cu 97.06%, Sn 94.66%,

Zn 96.64% and Pb 96.89% respectively.

Adsorbent characterization and studies

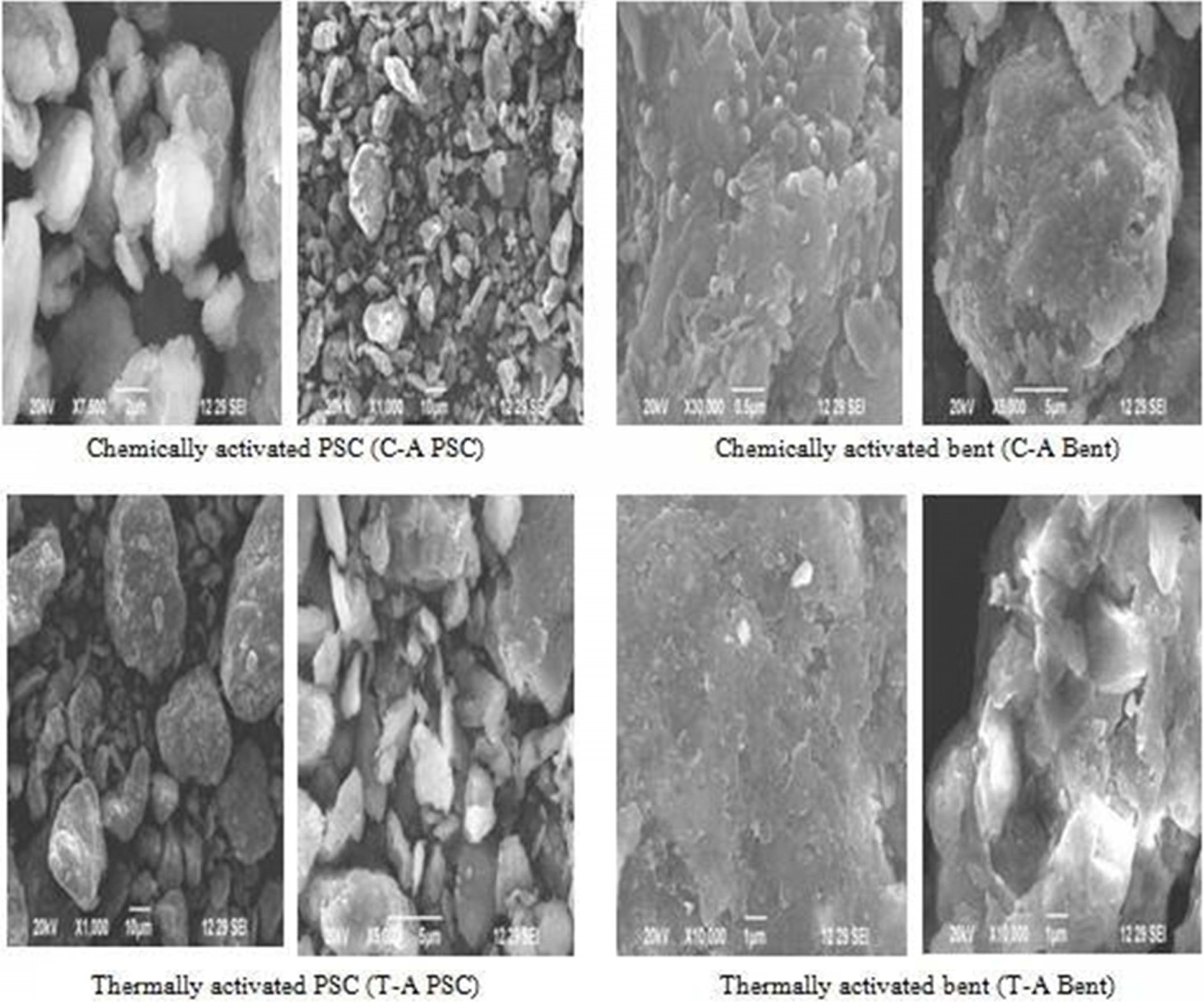

The SEM images of crushed and pulverized samples of Bent

and PSC subjected to thermal treatment and chemical treatment as shown in

Fig. 5 and it seems the C-A Bent particles

were slightly smaller compared with C-A PSC particles. It has been found by the

image of SEM. It reports the removal of moisturized contents and unwanted ions

from the adsorbents. In this regard, adsorbents improve the pore sizes and

enhance the recoverability rate. The adsorbent activation test were realized in

a experimental work, where the C-A bent and PSC are given maximum numbers of

pores like 2 μm of PSC and 0.5

μm of bent it should be comparatively

more rate of pores are created. The thermally activated adsorbents gave minimum

pore rates like 5 μm of PSC (T-A PSC) and 1 μm of bent (T-A Bent) due to the

recovery rate of unwanted minerals. Acid activation was more effective due to

the dissociation of both adsorbents by concentrated HCL and HNO3.

From the result shown in (Fig. 5), we observed that HCL and HNO3 are

strong acid to be able to improve the surface area of both adsorbents.

Therefore, many studies carried on the adsorption to recover of Zn2+,

Sn2+, Cu2+ and Pb2+ from various samples using

bent and PSC. During our tests, specified parameters were deliberate to see

their effects on the adsorbent performance in to the adsorbate (leached

solution) adsorption.

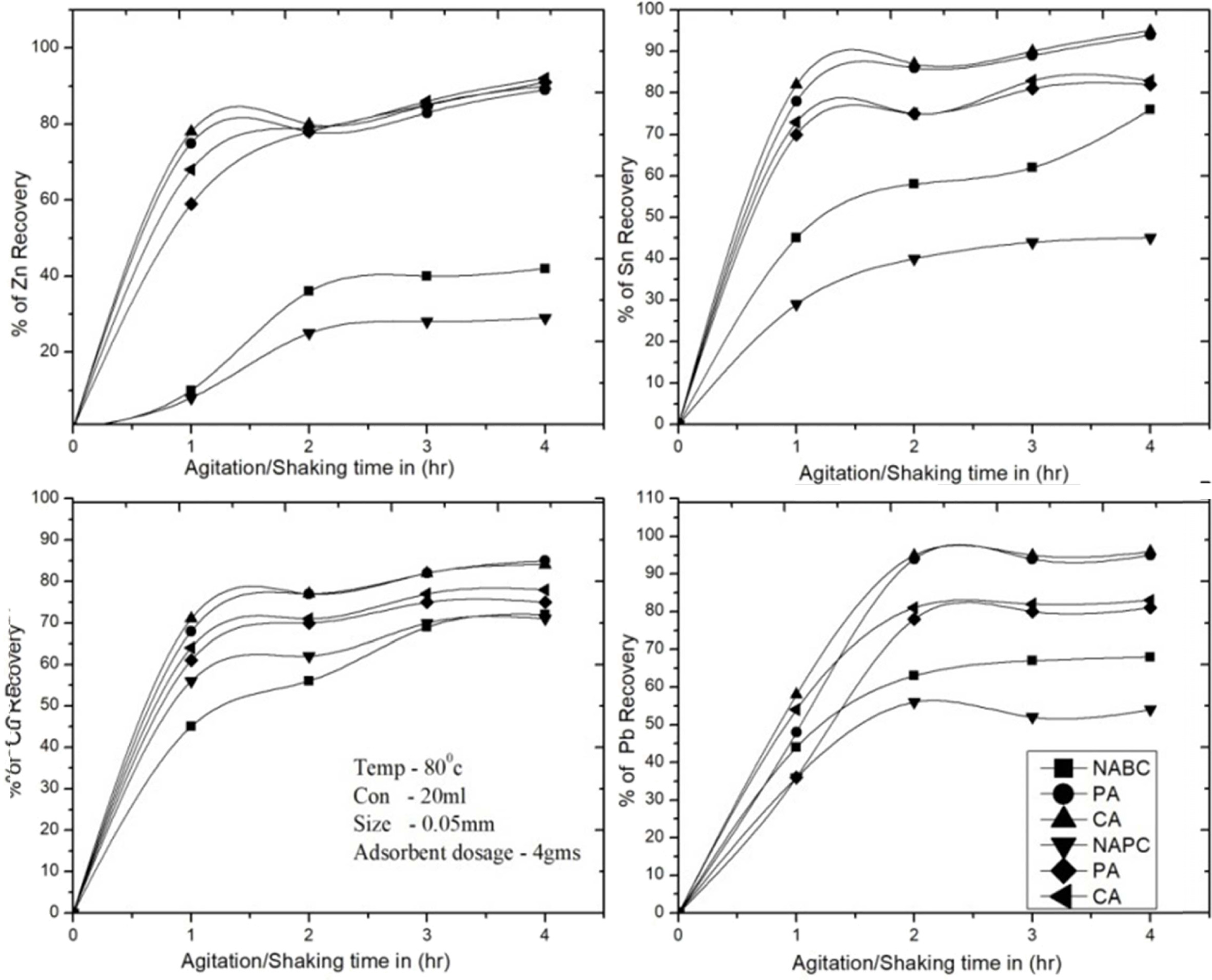

Effect

of contact time in the removal of metals

The contact time is an important factor affecting the

adsorption efficiency by agitation. To determine the effective time

ofadsorption, the sampleswere allowed to be leached for different interval of

time based on previous studies. The persistent condition was

maintained at 5 g sample adsorbents, size 0.05 mm shaken with 0.5

litter of aqua regia in a conical flask and shaking speed of 200 rpm while

temperature maintained at 34 ℃ for all category of adsorbents (C-A

Bent & C-A PSC and T-A Bent & T-A PSC). It is followed to be leached

for 1, 2, 3, 4 and 5 hrs respectively. The test reported 1 to 4 hrs, for

adsorbent NAPC and NABC are adsorbed Zn 20-40%, Sn 35-65%, Cu 70% and Pb

40-60%, T-A PSC & T-A Bent are adsorbed Zn 83%, Sn 70-85%, Cu 70-80% and Pb

80-85%, C-A Bent & C-A PSC are adsorbed more recovery rate due to higher

surface area of adsorbents were the results as a both adsorbents are recovered

the metal ions at1 to 4 hrs more than 83% of Zn, 88% of

Sn, 89% of Cu and Pb 80-85% respectively. Therefore,

the tests are identified 1 to 3 hrs are gradually increased

adsorption rate and then linearly attain equilibrium.The optimum values for

removal of metal ions were determined at 2 to 4 hrs. Therefore, (Fig. 6) shows

that higher efficiency for Zn2+, Sn2+, Cu2+

and Pb2+ ions adsorption can be obtained at the time intervals

between 2 to 4 hrs. All remaining experiments were carried out at 4 hrs contact

time. The result shows at 3 hrs the maximum recovery of metals as 91.46%,

90.56%, 86.56% and 89.91% of Cu, Sn, Zn and Pb respectively.

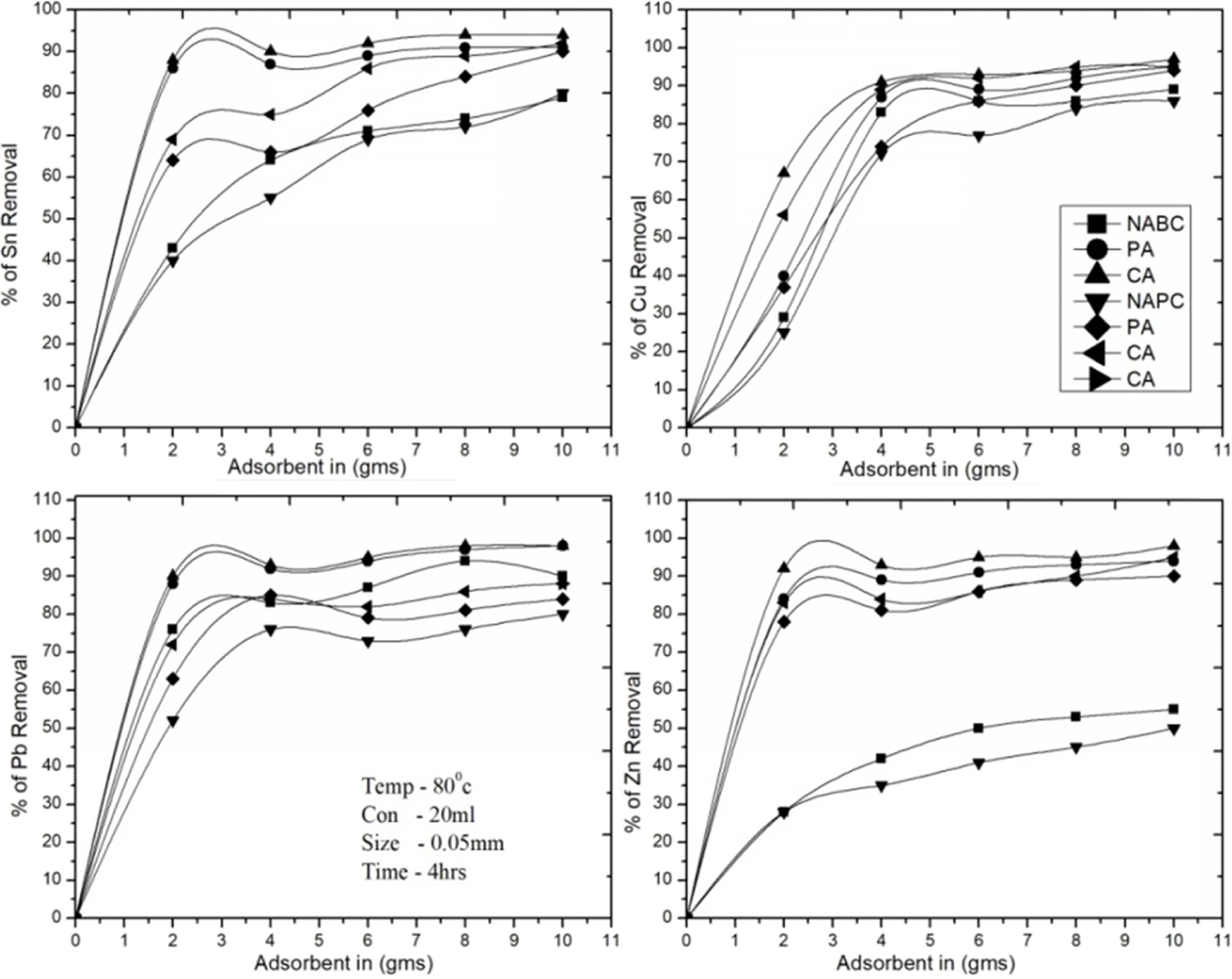

Effect

of adsorbent dosage in the removal of metals

The experimental studies were carried out in the ratios

1:2, 1:4, 1:6, 1:8. 1:10 of leached solution and adsorbent. The adsorption rate

increased linearly with dosage and attained equilibrium. In order to determine

the optimum value of adsorbent dosage during the adsorption process, parameters

like contact time, concentration and temperature were kept constant. The

increased adsorbent dosage increased the surface area of adsorbent. This can be

attributed to the increase in the adsorption efficiency of adsorbent [42, 46, 47].

The experimental results were found with the dosage of both adsorbents at the

ranges from 0-10 g, NAPC and NABC are adsorbed linearly up to 5 g, after that

attain equilibrium, and finally 75% of Sn, 80-85% of Cu, 75-80% of Pb and

30-42% of Zn, T-A PSC & T-A Bent are studied and the results as 82-25% of

Sn, 85-92% of Cu, 85-88% of Pb, 80-89% of Zn and C-A Bent & C-A PSC are

much effective at 1-5 g of both adsorbent were found maximum recovery rate of

valuable metals like 93-95% of Sn, 96% of Cu, 94% of Pb, and 91-95% of Zn. The

present tests were analyzed linearly increased adsorbent dosage rate as well as

increased Zn2+, Sn2+, Cu2+ and Pb2+

ions recovering media it was increased adsorption

rate. Therefore, (Fig. 7) shows the adsorption efficiency

of activated and NAC adsorbents and optimum values

are found to be at 4 g per 20 ml of PCBs leached solution.

CA-Bent adsorbents were found maximum recovery of metallic composition as

95.06% of Cu, 97.87% of Sn, 92.39% of Zn and 96.60% of Pb.

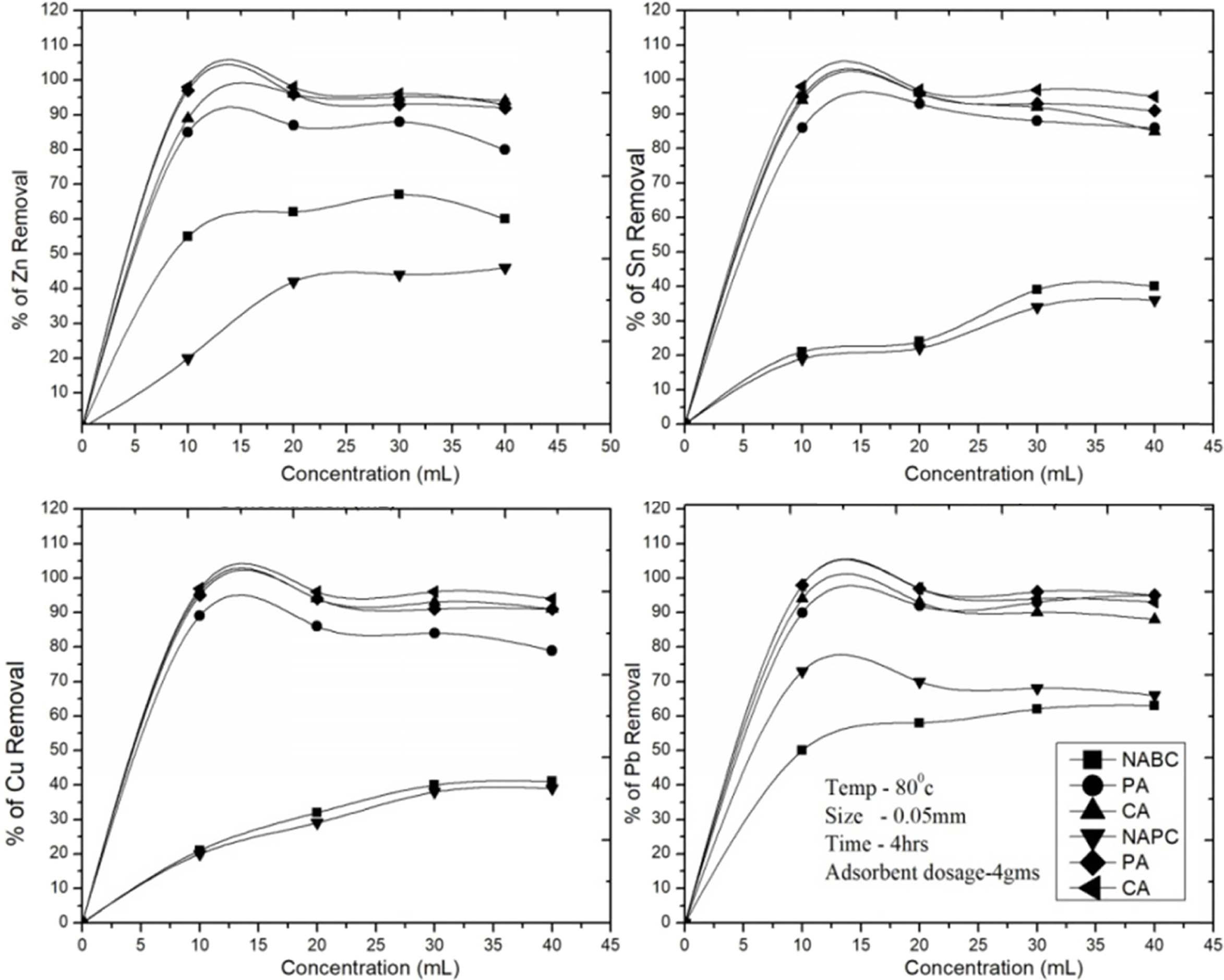

Effect

of leached solution concentration

The effect of concentration on the adsorption of Zn2+,

Sn2+, Cu2+ and Pb2+ ions was carried out with

the con- centrations of 10, 20,

30, 40 and 50 ml under the operating temperature of 80 ℃, agitating

speed of 200 rpm and 0.5 μm of particle sizes within the equilibrium contact

time of 4hrs and adsorbent dosage of 4grams. As shown in (Fig. 8), the removal

quantity was increased with increasing themetal ions concentration until the

equilibrium at the adsorption. After that, leached solution metal ions will not

be adsorbed due to many more metal ions fully covered in the adsorbent surface.

The previous studies [27, 43] reported, the leached solutions 0 to 40 ml were

used in adsorption for heavy metals adsorption as aresult provides linearly

increase in the adsorption rate and attain saturation condition. The initial

metal concentration providesthe essential driving force to get over the

resistance tothe mass transfer between the aqueousand the solid phases. At

lower initial metal concentration, more sorption sites were available for metal

adsorption. Higher initial metal ion concentrations are enhances the

interaction among the adsorbate and adsorbent, hence the result was found

higher adsorption efficiency. Our results indicated

that 10-20 ml were the optimal concentrations for

Zn2+, Sn2+, Cu2+ and Pb2+ ions

removal, respectively. All the

studies carried out with the optimal concentration at 20 ml/4 g

of adsorbent. Bent (C-A sample) showed the maximum removal rate due to higher

pores and surface area. After the saturation time of 4 hrs, the removal of Sn

decreased from more than 96% to 85% at 20 ml of leached sample because of metal

recover ability reduction from both adsorbent. The same behavior

was observed with other metals ions removal Zn2+ (96-94%), Cu2+

(94-91%) and Pb2+ (98-93%), respectively. In comparison with PSC

(C-A sample) samples, the Bent (C-A sample) samples removed

maximum amount of metal ions but the treated PSC (C-A) and

untreated samples are showed much lower removal efficiency (Fig. 8). Thus,

it was clearly observed that the removal of metal ions

was strongly influenced by the concentration and

adsorbent surface recover ability rate.

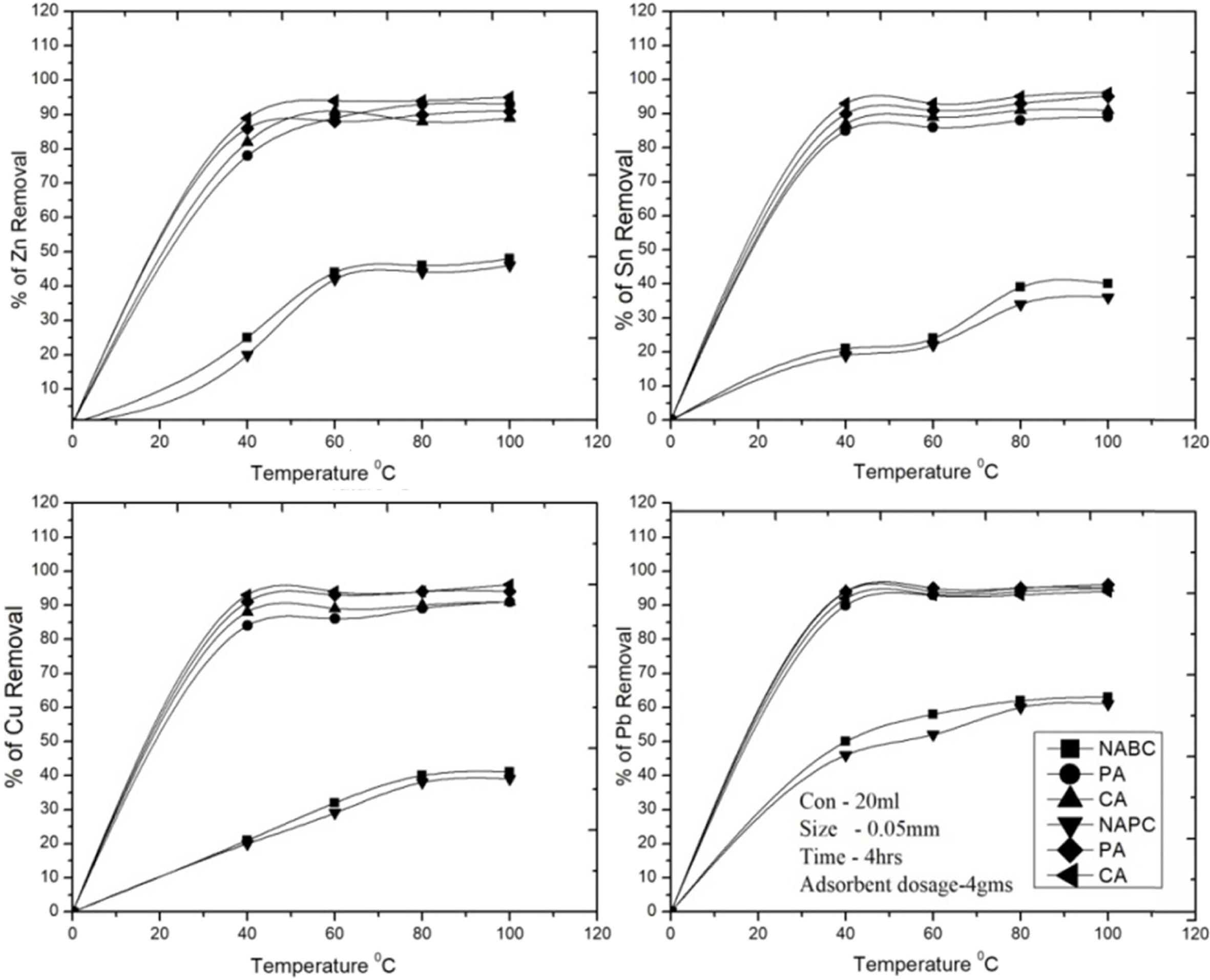

Effect

of temperature on the adsorption

The study was carried out for the effect of temperature

on the adsorption of Cu2+, Zn2+, Sn2+ and Pb2+

ions on to Bent and PSC samples at 20, 40, 60, 80 and 100 ℃ with

other parameters kept constant with respective equilibrium conditioned level.

The adsorption capacity of metal ions by the both adsorbents increased as temperature

increases from 20 to 60 ℃ and then attained

equilibrium for endothermic sorption process. After attain

the equilibrium/saturation, adsorption rate decreased continuously and

stopped (temperature suggested

an exothermic sorption process) it were reported [29, 48]. The (Fig. 9) shows

the removal quantities of heavy metal ions by the activated and non activated adsorbent samples at highest removal

efficiency with respective

temperature. In this study shows that, the removal rate of C-A PSC

adsorbent has presence of results as Cu2+

(91%), Zn2+ (94%), Sn2+ (93%), Pb2+ (95%) and

C-A Bent presence of result as Cu2+ (88%), Zn2+ (82%), Sn2+ (86%), Pb2+

(94%) respectively. These results

demonstrate that the Bent is not effective for removal of metals byendothermic

temperature at 60 ℃. 20-40 ℃ temperature range was used

to get a good removal efficiency of about 90% for Pb removal. As a result of

increased adhesiveness in C-A Bent & C-A PSC adsorbents, both adsorbents

are showed higher adsorption rate at higher temperatures compare to T-A Bent

& T-A PSC adsorbents.

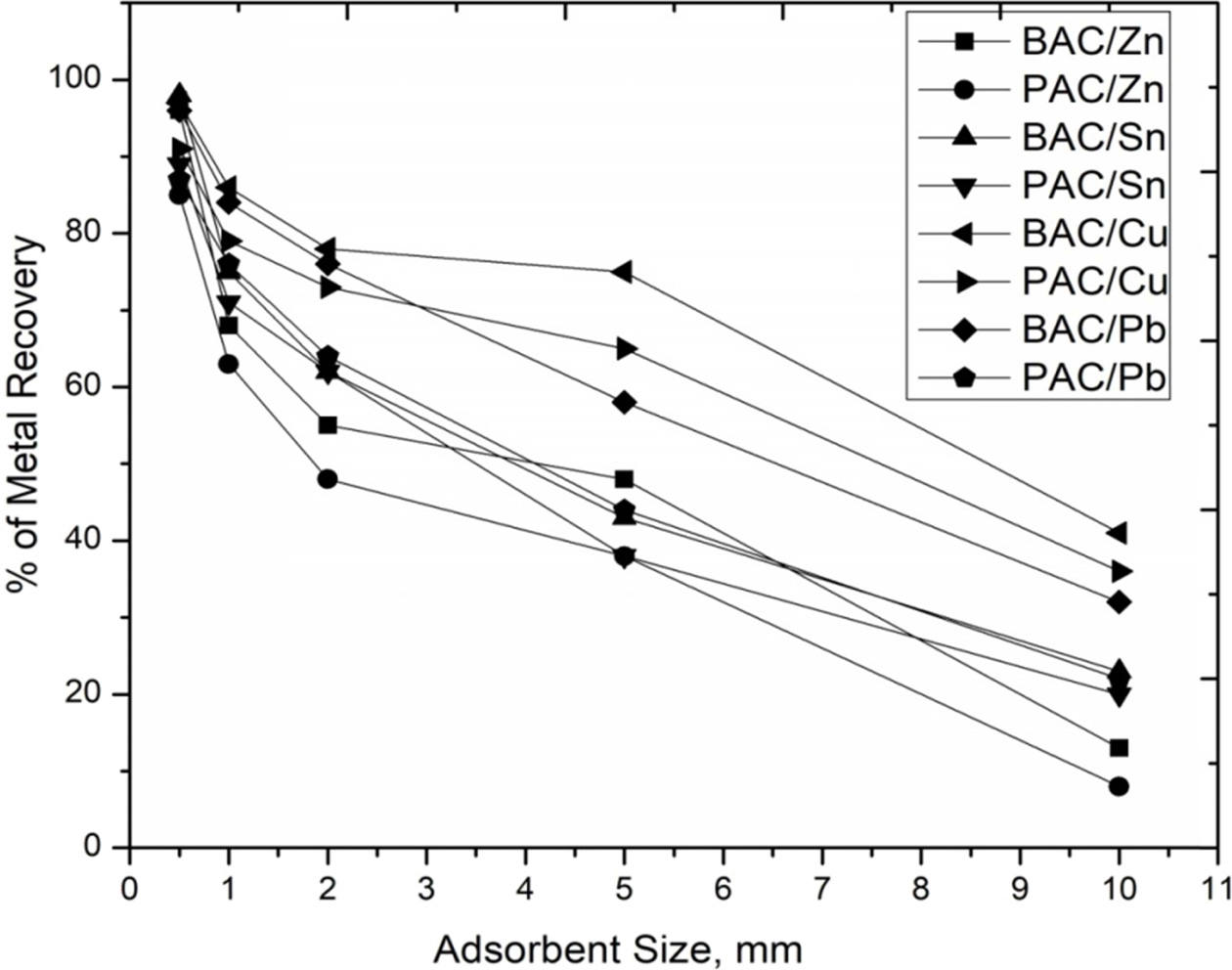

Effect

of particle size of the adsorbent

Effects of various sizes of adsorbents for both adsorbents

were studied. The different particle sizes of adsorbents such as 10 μm, 5 μm, 2

μm, 1 μm, and 0.5 μm were performed for metal ions adsorption and keeping

same operating procedure with studied parameters like

agitation contact time 4 hrs, adsorbent dosage 4 g, leached solution metal ion

concentration 20 ml and temperature 60 ℃ [49-51]. This study

analyzed adsorption rate with respect to various particle sizes for both

adsorbents. The small particle size of adsorbent gives maximum surface area so

that metal ions easily adsorbed. Fig. 10 shows 0.5 μm

particle size adsorbent’s removal rate of BAC. It gives Zn

96%, Sn 98%, Cu 97%, Pb 96% and PAC gives Zn 85%, Sn 89%, Cu 91%, Pb

87%. Therefore, particle size is more important to recover

the heavy metals through adsorption.The previousresult also indicatesthat C-A

Bent samples gave the better removal efficiency [53-55]. The study revived

the recovery of heavy metal ions like Pb and Cu by different clay minerals.

Therefore, in this experimental work also confirm their beneficial

use for the removal of copper, tin, lead and zinc from heavy metals having

leached solution.

|

Fig. 2 Graphical representation of size reduction and analysis in various operations (jaw crusher, pulverize and Ball mill) sizes obtained 0.05 to 4 mm. |

|

Fig. 3 SEM images of metals present in powdered PCBs. |

|

Fig. 4 EDXs spectrum analysis for metal ions obtained before (a) Metals composition in before treatment of (PCBs) and after (b) Metals composition in after treatment of (PCBs) PCBs by Leaching. |

|

Fig. 5 SEM Microphotograph Surface images analysis of adsorbents (C-A Bent & C-A PSC and T-A Bent & T-A PSC). |

|

Fig. 6 Effect of contact time in various operating conditions for removal of Zn2+, Sn2+, Cu2+ and Pb2+. |

|

Fig. 7 Effect of adsorbent dosage on the removal of Zn2+, Sn2+, Cu2+ and Pb2+. |

|

Fig. 8 Effect of concentrations in various operating conditions for removal of Zn2+, Sn2+, Cu2+ and Pb2+. |

|

Fig. 9 Effect of temperature various operating conditions for removal of Zn2+, Sn2+, Cu2+ and Pb2+. |

|

Fig. 10 Effect of sample sizes in various operating conditions for removal of Zn2+, Sn2+, Cu2+ and Pb2+. |

|

Table 2 Metallic composition of leached PCBs at optimum conditions by stage-I & II. |

Heavy metals in waste PCBs were leached into corresponding

reagents during the two-stage leaching operations. The effectiveness of two leaching

media (HCL; HNO3, H2SO4; HCL) for recovery of

heavy metals during the treatment of PCBs was evaluated. The recovery rate was

nearly obtained for Cu - 99.04%, Sn - 96.88%, Pb - 98.34%, Zn - 93.1%, others -

95.44% (Ni, Mn, and Mg…) by aqua regia leaching. Hence the

leached metal ions were treated by adsorption. Activated

and NAC adsorbent (Bent & Peanut shell) were utilized to recover the heavy

metal ions (Zn2+, Sn2+, Cu2+ and Pb2+)

from PCBs and investigated by different significant parameters. The

experimental results showed that adsorption rate was linearly increasing

and later itbecomes stable due to changes in operating conditions. From the

result of this study, C-A Bent adsorbentsassist in effective separation of

heavy metal ions. Hence, it was concluded that the combination of aqua regia

leaching and bent adsorption is a more effective and economic way for the

elimination of heavy metals from PCBs.

PCBs : Printed

circuit boards

Bent : Bentonite

Clay

AC : Activated carbon

NAC : Non-activated

Carbon

NABC : Non-activated

Bentonite Clay

PSC : Peanut

Shell Carbon

C-A

Bent : Chemically

activated bent

C-A

PSC : Chemically

activated Peanut shell carbon

Co : Initial

concentration of metal ions from leached samples

Ce : Metal

ions concentration at the completion of adsorption operation

T-A

Bent : Thermally

activated bent

T-A

PSC : Thermally

activated Peanut shell carbon

Ce-I&Ce-II : Metal

ions concentration at the completion of adsorption in stage I & II

This study was carried out with utilization of the

laboratory facilities in Erode Sengunthar Engineering College and Kongu

Engineering College. The author would like acknowledge and thank his parents

for the support rendered.

- 1. D.-R. Pangavhane, M.Sadhana, A. Khandekar, and M. Rashmi, Ind. J.Res. 2(2013) 138-140.

- 2. D. Pant, D. Joshi, M.K. Upreti, and R.K. Kotnala, Waste Manag. 32 (2012) 779- 979.

- 3. S. Jaibee, N. Hisyamudin, B.M. Nor, A. Khalil, A. Rahim, F. Mohammad, S. Chee Kiong, F. Ahmad, S. Jamian, and Y. Seiji, ARPN J.Eng. Appl. Sci. 11 (2016) 2332-2335.

- 4. Monika and J. Kishore, Indian J. Community Med. 35 (2010) 382-385.

-

- 5. C.-S. Poon, Waste Manag. 28 (2008) 1449.

-

- 6. N. Padiyar, P. Tandon, and S. Agarwal, Int. J. Contemporary Dentistary. 2 (2011) 80-83.

- 7. Y.-C. Chien, H. Paul Wang, K.S. Lin, Y.J. Huang, and Y.W. Yang, Chemosphere. 40 (2000a) 383-387.

-

- 8. L.-M. Plum, L. Rink, and H. Hajo, Int. J. Environ. Res. Public Health. 7 (2010) 1342-1365.

-

- 9. H. Mattila and T. Virtanen, Chemosphere 25 (1992) 1599-1609.

- 10. N. Menad, B. Björkman, and E.G. Allain, Resour. Conserv. Recycl. 24 (1998) 65-85.

-

- 11. Y.-C. Chien and H.P. Wang, J. Environ. Sci. Heal. - Part A Toxic/Hazardous Subst. Environ. Eng. 4 (2000) 635-644.

- 12. Y. Ikushima, K. Hatakeda, N. Saito, and M. Arai, J. Chem. Phys. 108 (1998), 5855-5860.

-

- 13. Y.-J. Huang, H. Paul Wang, C.T. Li, and Y.C. Chien, Chemosphere. 40 (2000) 347-349.

-

- 14. Y.-C. Chien, H.P. Wang, K.S. Lin, and Y.W. Yang, Water Res. 34 (2000b) 4279-8283.

-

- 15. E. Kantarelis, W. Yang, W. Blasiak, C. Forsgren, and A. Zabaniotou, Appl. Energy. 88 (2011) 922-929.

-

- 16. I. Masavetas, A. Moutsatsou, E. Nikolaou, S. Spanou, and A. Zoikis-Karathanasis, Global Nest J.11 (2009) 241-247.

- 17. R. Montero, A. Guevara, and E. De La Torre, J. Earth Sci. and Eng. 2 (2012) 590-595.

- 18. M. Kerolli Mustafa, L. Ćurković, M. Ujević Bošnjak, and T. Rezić, Chem. Biochem. Eng. 31 (2017) 403-415.

-

- 19. J. Cui and L. Zhang, J. Hazard. Mater. 158 (2008) 228-256.

-

- 20. P. Xiang, Y. Zhang, and Q. Liu, IOP Conference Series: Mater. Sci. Eng. 394 (2018) 022001.

-

- 21. W. Lu, Y. Lu, F. Liu, K. Shang, W. Wang, and Y. Yang, J. Hazard. Mater. 186 (2011) 2166-2170.

-

- 22. H. Yang, J. Liu, and J. Yang, J. Hazard. Mater. 187 (2011) 393-400.

-

- 23. B. Bayat and B. Sari, J. Hazard. Mater. 174 (2010) 763-769.

-

- 24. P.-P. Sheng and T.H. Etsell, Waste Manag. Res. 25 (2007) 380-383.

-

- 25. B.-I. El-Eswed, O.M. Aldagag, and F.I. Khalili, Appl. Clay Sci. 140 (2017) 148-156.

-

- 26. M. Kumar, J.C. Lee, M.S. Kim, J. Jeong, and K. Yoo, Environ. Eng. Manag. J. 13 (2014) 2601-2607.

-

- 27. J.-P. Choudhury and M.A. Hashim, Chem. Biochem. Eng. 18 (2004) 295-302.

- 28. S.-A. Aljlil, Fares, and D. Alsewailem, Athens J. Sci. 1 (2014) 21-30.

-

- 29. A.-T. Sdiri and T.J.F. Higashi. Int. J. Environ. Sci. Technol. (2013) 1-23.

- 30. N. Abdennebi, M. Bagane, and C. Chtara, J Chem Eng Process Technol. 4 (2013) 166-170.

-

- 31. S. Budsaereechai, K. Kamwialisak, and Y. Ngernyen, KKU Res. J. 17 (2012) 800-809.

- 32. M.-F. Brigatti, L. Medici, and L. Poppi, Appl. Clay Sci. 11 (1996) 43-54.

-

- 33. S. Veli, and B. Aly, J. Hazard. Mater. 149 (2007) 226-233.

-

- 34. E. Helios-Rybicka and R. Wójcik, Appl. Clay Sci. 65 (2012) 6-13.

-

- 35. R. Sjöblom, H. Bjurström, and R. Pusch, Appl. Clay Sci. 23 (2003) 187-193.

-

- 36. Y. Kim, J. H. Kim, K. G. Lee, and S. G. Kang, J. Ceram. Process. Res., 6 (2005) 25-30.

- 37. E.-Y. Yazici and H. Deveci, Hydrometallurgy. 139 (2013) 30-38.

-

- 38. L. Flandinet, F. Tedjar, V. Ghetta, and J. Fouletier, J. Hazard. Mater. 2132 (2012) 485-490.

-

- 39. J. Hanafi, E. Jobiliong, A. Christiani, D.C. Soenarta, J. Kurniawan, and J. Irawan, Procedia - Soc. Behav. Sci. 57 (2012) 331-338.

-

- 40. R. Vijayaram, D. Nesakumar, and K. Chandramohan, Res. J. Eng. Sci. 2 (2013) 11-14.

- 41. Y. Chehade, A. Siddique, H. Alayan, N. Sadasivam, S. Nusri, and T.I.A., Int. Conf. Chem. Civ. Environ. Eng. 24 (2012) 226-234.

- 42. R. Souag, N. Kamel, M. Hammadi, Z. Kamel, D. Moudir, F. Aouchiche, Y. Mouheb, and S. Kamariz., J. Ceram. Process. Res., 16 (2015) 150-155.

- 43. T. -H. Ahn, K.B. Shim, K.H. So, and J.S. Ryou, J. Ceram. Process. Res., 15 (2014) 539-544.

-

- 44. R. Umapriya, V. Manisha, S. Vidyavathy, G. Arthanareeswaran, J. Rohan, and A.R. Poorna., J Ceram Process Res., 20 (2019) 291-300.

- 45. J. Zhu, V. Cozzolino, M.Fernandez, R.M.T. Sánchez, M. Pigna, and Q. Huang, Appl. Clay Sci. 52 (2011) 339-344.

-

- 46. F. Anjum, H. N. Bhatti, M. Asgher, and M. Shahid, Appl. Clay Sci. 47 (2010) 356-361.

-

- 47. N. Gomathi and I. Sridevi, Der Pharma Chem. 7 (2015) 219-224.

- 48. D.-H. Kwak and M. S. Kim, Mater. Sci. Appl. 4 (2013) 12-17.

-

- 49. P. Vanegas, J.R. Peeters, F. Plessers, D. Cattrysse, and J.R. Duflou, Kenya, in: Procedia CIRP. 15 (2014) 283-288.

-

- 50. B. Abeln and S. J. Lombardo, J. Ceram. Process. Res., 12 (2011) 515-520.

- 51. V.-L. Grudic, I. Boskovic, and A. Gezovic, Chem. Biochem. Eng. 32 (2018) 299-305.

-

- 52. S.-P. Kumar, S. Govindaradjane, and T. Sundararajan, Int. J. Eng. Res. Appl. (IJERA). 3 (2013) 469-473.

- 53. W.-E. Marshall and E.T. Champagne, J. Environ. Sci. Heal. Part A Environ. Sci. Eng. 30 (1995) 241-261.

-

- 54. A.- A. A Saad, Appl. Sci. Res. 5 (2010) 138-145.

- 55. V.-K. Gupta P.J. M. Carrott, M. Ribeiro Carrot, and M.L. Sauhas, Crit Rev Environ Sci Technol 39 (2009) 783-843.

-

This Article

This Article

-

2020; 21(1): 75-85

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.75

- Received on Aug 27, 2019

- Revised on Nov 19, 2019

- Accepted on Dec 9, 2019

Services

Services

- Abstract

introduction

material and methods

results and discussion

conclusions

nomenclature

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Murugesan Manikkampatty Palanisamy

-

Department of Chemical Engineering, Kongu Engineering College, Perundurai, Erode, Tamil Nadu 638060, India

Tel: +9566604416 - E-mail: engineermurugesh@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.