- Comprehensively utilizing waste coal gangue to fabricate high strength glass-ceramics

W. Danga and H.-Y. Heb,*

aXi'an Aeronautical University, Xi'an 710077, China

bCollege of Material Science and Engineering, Shaanxi University of Science and Technology, Xi'an 710021, China

Waste coal gangue was utilized for the fabrication of strength glass-ceramics for

environmental management. The optimal utilization rate of

coal gangue is 55 wt.% when the utilization rate of another mineral material bauxite is 35 wt.%. The mullite showing high strength is the main crystal

phase in the sintered glass-ceramics. The effect of various processing

parameters on the microstructure and mechanical performances of the sintered

glass-ceramics was systematically studied. Mineralization agent BaCO3

and MnCO3 resulted in remarkable enhancement of the mechanical

properties of the sintered glass-ceramics. The strength of 148.36-156.12 MPa, water absorption of 0.17-0.02%, and a

density of 2.66-2.68 g/cm3 were achieved for the sintered glass-ceramics. The process of forming and sintering also showed a remarkable

effect on the microstructural and mechanical properties. By optimization experiments,

optimal processing parameters were also determined.

Keywords: Coal gangue; Glass-ceramics, Waste management, Maximal utilization ratio, Process optimization, Mechanics property

Glass-ceramics are attractive materials used in various applications

such as building materials, cooking ceramics, machinable

ceramics, bio-ceramics, electrical ceramics, glass semiconductors in thermal

insulation, optical materials, etc. [1-6]. From a point of the raw material,

utilizing the industrial solid wastes were widely used to fabricate the g;ass-ceramics and cecrents

et al. [7-10].

Coal gangue is a category of solid industrial waste. This

waste material is largely produced in coal production. The amount

produced in China is reached above several million tonnes and increases by

about one million tonnes per year. To prevent its pollution to air and river

environments and save natural resource, the comprehensively utilizing the coal

gangue are urgent for efficient environmental management.

However, the ratio of utilizing coal gangue is greatly limited. The coal gangue contains a

high alumina of ~30 wt.% and a high silica of ~62

wt.%, and so has been used to produce cement [11-13], cement [14], ceramics

[15, 16], glass-ceramics [17, 18], brick [19, 20], zeolite [21], lightweight

aggregate [22], and so on. The glass-ceramics mainly contains the crystals and

amorphous phase that is composed of SiO2, Al2O3,

CaO, and/or MgO. The mullite and some other crystals composed of both alumina

and silica are favorable for the high strength of the glass-ceramics. The high

content of SiO2 and Al2O3 makes the coal

gangue is very suitable to fabricate the glass-ceramics having high mechanical

properties.

For sintering high strength glass-ceramics, the crystal

phase and its size and content are critical factors. In general, mullite and

other crystals composed of both aluminium and silicon will be favorable for the

high strength of the glass-ceramics. Meanwhile, the nucleating agent

and some process parameters are the deterministic factors for

the size and content of the formed crystal phase as well as the density of the

sintered glass-ceramics.

This work focuses on the fabricating the glass-ceramics by

utilizing waste material coal gangue and the optimizing coal gangue utilization

ratio, nucleating agent, and processing parameters. The glass-ceramics with the mullite as main crystal phase were successfully obtained by selecting the

reasonable prescriptions of the glass-ceramics in the

condition of considering the maximal utilization rate of

the coal gangue. The optimization of nucleating agent and process parameter

were also focused to further realize the enhancement of property of the

sintered glass-ceramics.

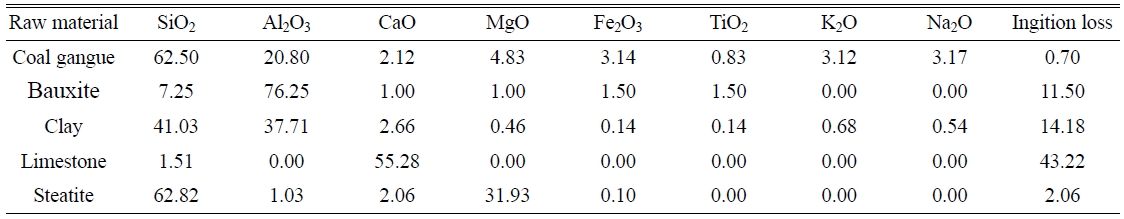

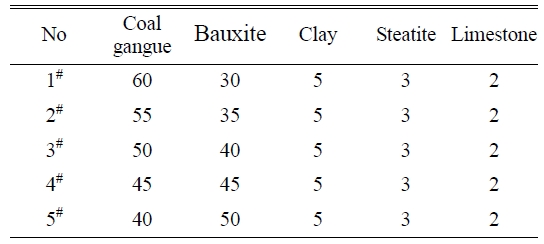

Mullite (Al6Si2O13) generally has high strength and so was designed as the main crystal phase. The mullite (Al6Si2O13) contain higher alumina than the

coal gangue (Table 1). Thus, the bauxite

with high alumina content was utilized to be in favor of the formation of

mullite crystal phase. Clay as an adhesive was utilized to enhance slurry formability. Besides,

small amounts of steatite and limestone were used as

additives; and BaCO3, MnCO3, and MgCO3

were used as mineralizers. The sodium

tripolyphosphate (STPP) and methylcellulose

(CMC) as water reducers were utilized to

decrease the slurry

viscosity. The chemical composition of the bauxite and clay together with coal gangue

and some mineral minerallizers is listed in Table 1. In consideration of the utilization ratio of the coal gangue, the basic

prescriptions were designed

as listed in Table 2.

Typical sintering processes of the

designed glass-ceramics are mentioned below: the raw materials were first mixed

according to the designed prescriptions. The mixtures were filtered through 10 mesh,

wet-milled at the ratio of raw materials : ball : water

= 1 : 2.5 : (0.3-0.5) for 15-25 min and then filtered through 120 mesh (Aperture: 0.045 mm, ASTM). As prepared mixtures were undergone a 3-5 h drying of 50-70 oC. The 200 g

each of the dried mixtures was mixed with 5 g STPP and 5 g CMC and ball-milled using the appropriate

amount of water for 12 min. The formed slurries were sifted

with a serve (80 mesh, aperture: 0.180 mm, ASTM). The ~0.1% residue above the

sieve only remained. The slurries were dried at 50-70 oC for 3-5 h. The formed powders

underwent a pulverization and then sifted with a sieve (55 mesh, aperture: 0.280 mm, ASTM). The fine powders were sprayed by

water and sintered to form prilled grains. The prilled grains were sifted with

a sieve (20 mesh, aperture: 0.850 mm, ASTM). The fine grains were undergone

re-spraying water and then processed to be the samples for the measurement of flexural strength. The formed

samples were then pressed at 25-35 MPa and dried at 50-100 oC for 24 h. The large grains on the

sieve were dried at 80 oC for 4 h. The dried samples and large grains were finally sintered at 1290-1430 oC for 30-90 min at a heating rate of 5-10 oC/ min.

The sintered glass-ceramics samples were characterized with

D/Max-2200PC X-ray diffractometer (XRD, CuKα1, λ=0.15406

nm), S-570 scanning electron microscopy (SEM), and the flexural strength measurement on 401/3

strength tester. The water absorbance (Aw) was measured

on the sintered grain samples. On the measured Wd and Wh,

the Aw was specified by the following relation:

In which, Wd

is the weight of some grains that undergone the drying at 110 oC

for 3 h, Wh is the weight of the above-used grains undergone

the soaking in the water for 36 h at room temperature followed by erasing the

surface water with a wet towel. The density (d) was measured on the

sintered grain samples, and specified with the following relation:

Where m0 is the mass of some grain

samples that undergone the 3 h drying at 105-110 oC, m1 is the mass of the above-used grain

samples when immersed in the water at room temperature. The withdrawn grains underwent the erasion of the surface water with a wet towel.

All the property measurements were

repeated three times to obtain accurate results.

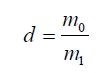

The five samples with the basic

prescriptions listed in Table 2 were first tested to determine

optimal utilization ratio of the coal gangue. Fig. 1 shows the variations of flexural strength and water

absorbance of glass-ceramics fabricated with basic prescriptions as a function of sintering temperature. The

glass-ceramics fabricated with prescription 2# shown a maximal strength and minimal water

absorbance in the sintering temperature range of 1290-1430 oC. Therefore, the utilization ratio

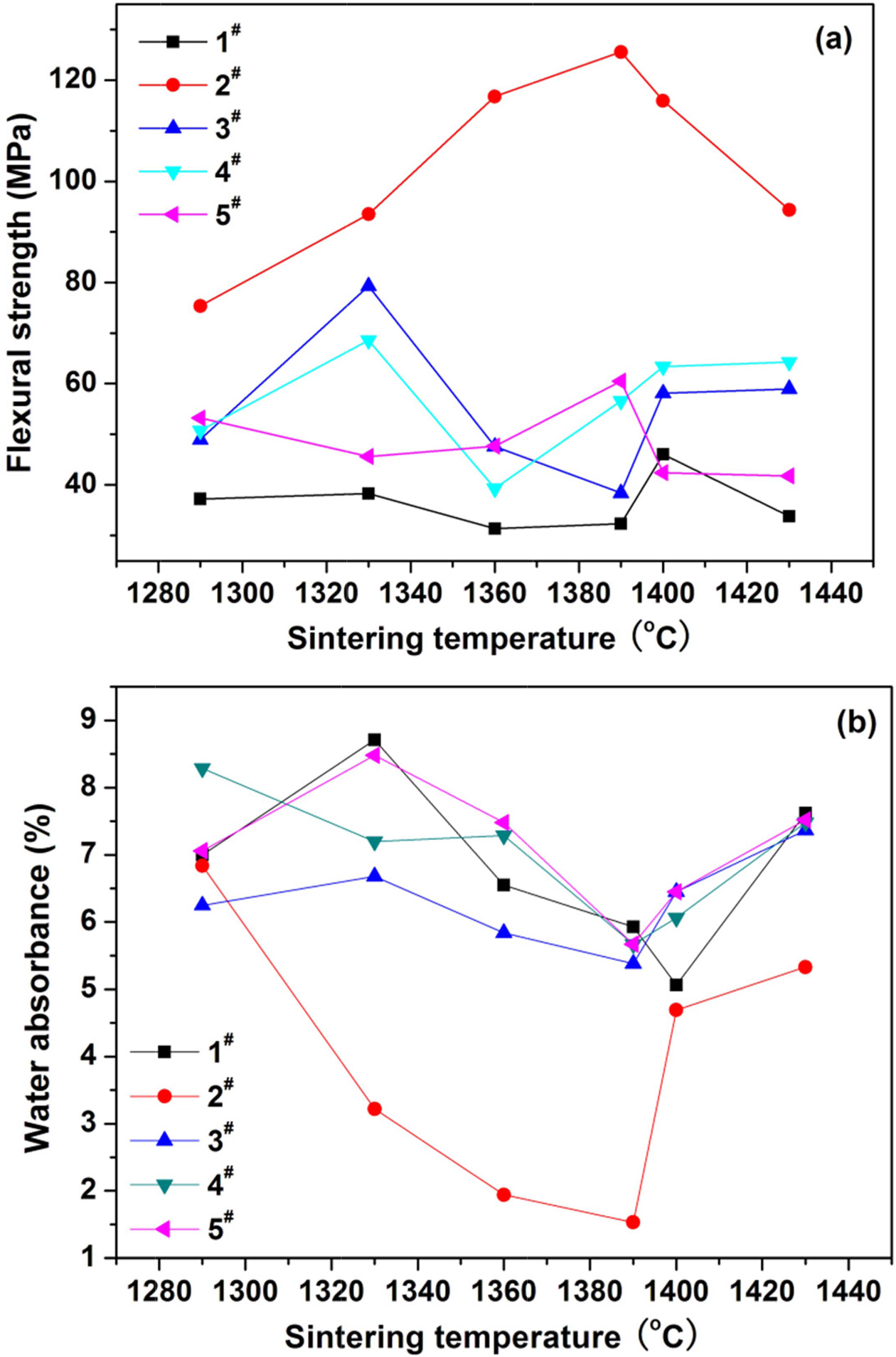

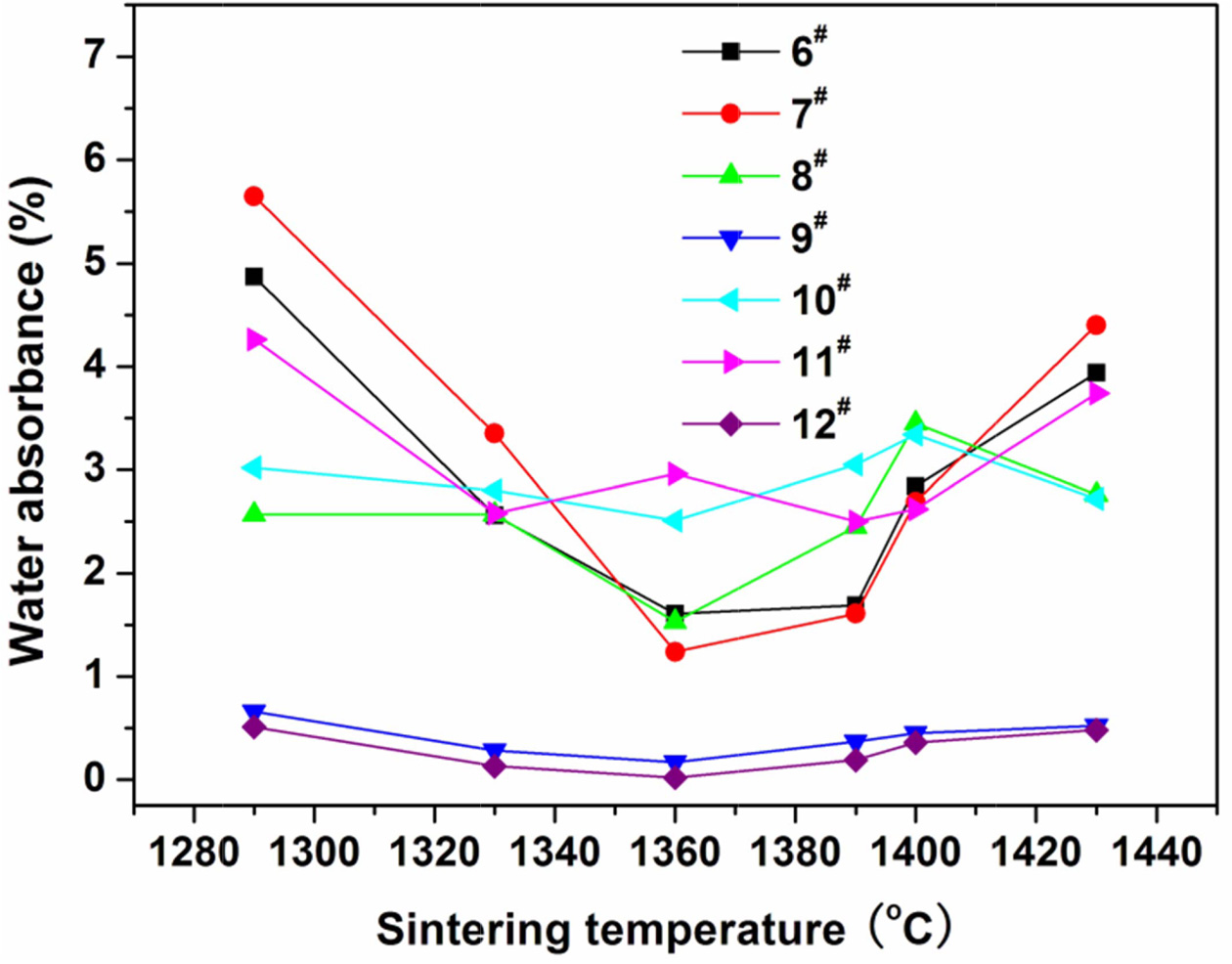

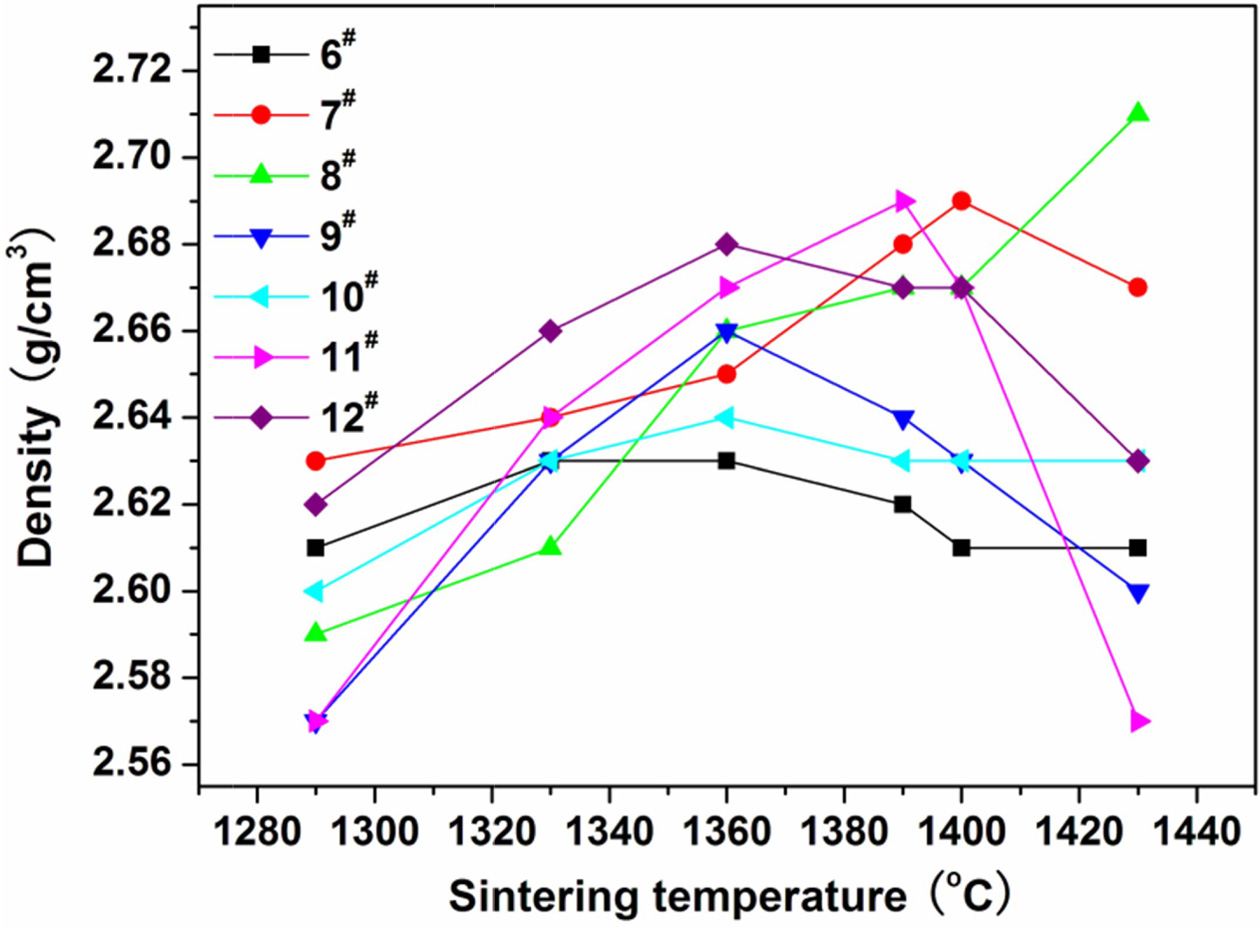

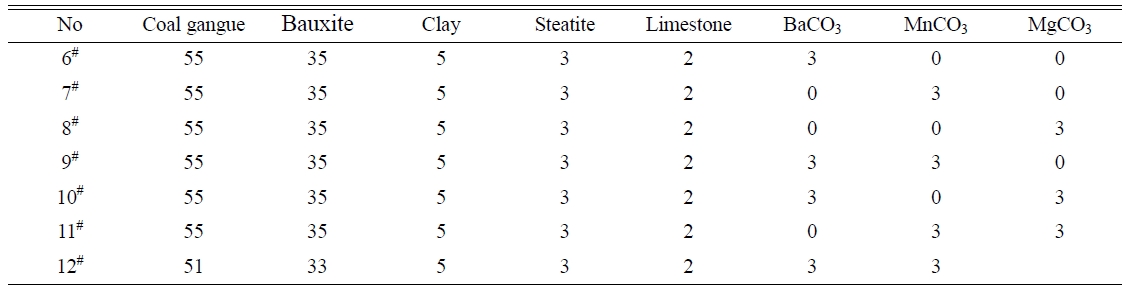

of 55% is determined for the coal gangue. The prescription 2# was further studied by adding various mineralizers. Table 3 lists the new prescriptions. Fig. 2, 3, and 4 illustrate the properties of the glass-ceramics

formed at the

press of 30 MPa and sintered at different temperatures for 30 min. BaCO3

and MnCO3 co-adding (prescription

9#) lead to better effect, achieving

a minimal water absorption (0.17%), maximal flexural strength (148.36 MPa), and maximal density (2.66

g/cm3) at sintering temperature of

1360 oC. Whereas, the BaCO3 and MnCO3 co-substitution for the small amount of coal gangue

(prescription 9#) lead to an optimal effect. That is, minimal water absorption (0.02%),

maximal flexural strength (156.12

MPa) and density (2.68 g/cm3) are achieved at sintering temperature of 1360 oC. The optimal sintering

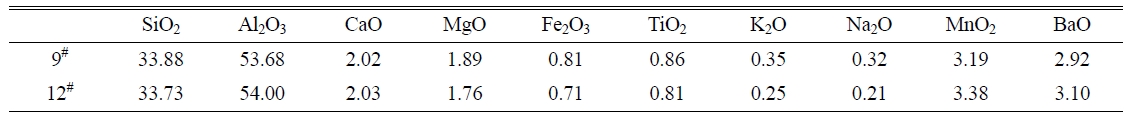

temperature for these samples is 1360 oC. The chemical compositions of the

prescription 9# and 12# are listed in Table 4.

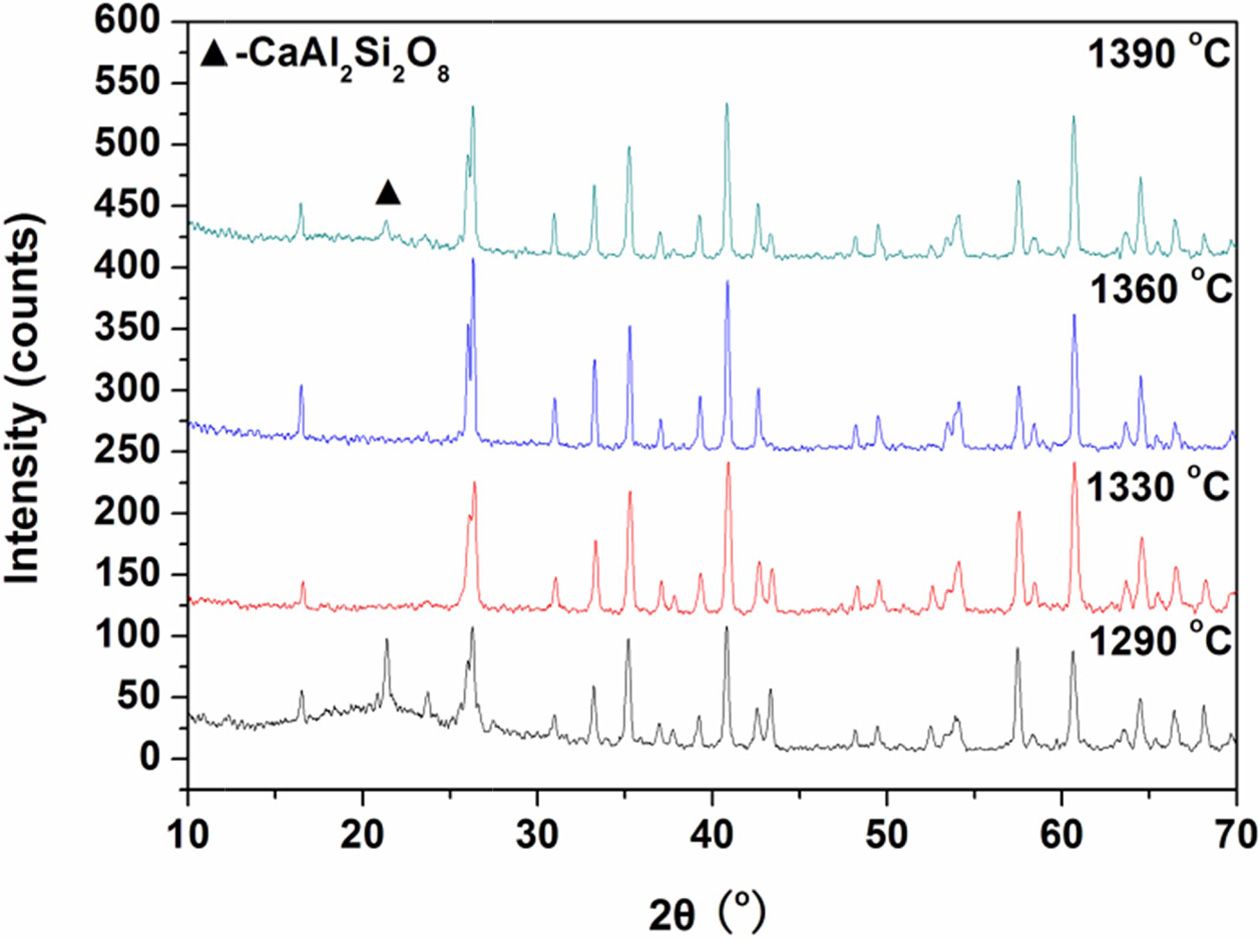

Fig. 5 shows the XRD patterns of the

samples fabricated with prescription 12#. The glass-ceramics sintered at 1330 oC and 1360 oC only contain mullite (Al6Si2O13) (JCPDS: 15-0776). When sintered at 1290 oC and 1390 oC, second phase svyatoslavite (CaAl2Si2O8) (JCPDS:

46-1266) appeared. The mullite is generally formed at the higher

temperature, such as above 1320 oC as reported in previous

literature [23]. The formation of mullite in the glass-ceramics at

the sintering temperature

of 1290 oC may be due to fine raw materials, fluxing actions of minerals

additives and mineralizers, and nucleation of Fe2O3 and TiO2 existing in the raw materials [24]. The mullite shows a compressive strength

(0.69 GPa) larger than many other crystals including the cordierite (0.32 GPa),

the boron nitrate (0.32 GPa), and the forsterite (0.55 GPa) [25]. This makes

the glass-ceramics samples high-strength. Thus, the glass-ceramics sintered at

1330 oC and 1360 oC show better properties.

Furthermore, the XRD peaks are enhanced as the increase in sintering

temperature from 1330 oC to 1360 oC, indicating the increase in the content of the mullite crystal. This

results in the optimal sintering temperature of 1360

oC.

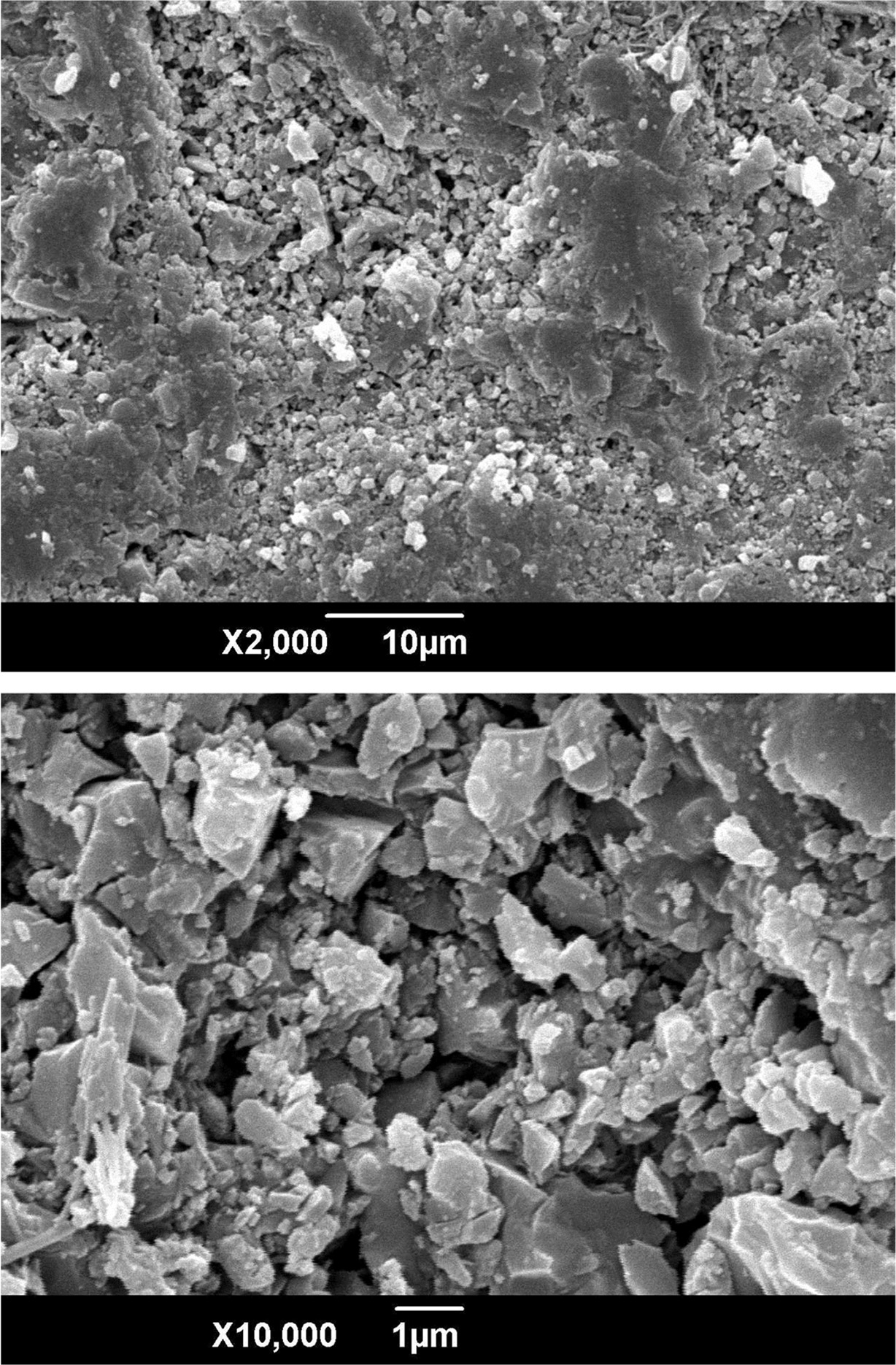

Fig. 6 shows the SEM micrographs of

the glass-ceramics fabricated with prescription 12# at sintering temperature of 1360 oC. The small and compact crystals with polygonal morphology can be

observed.

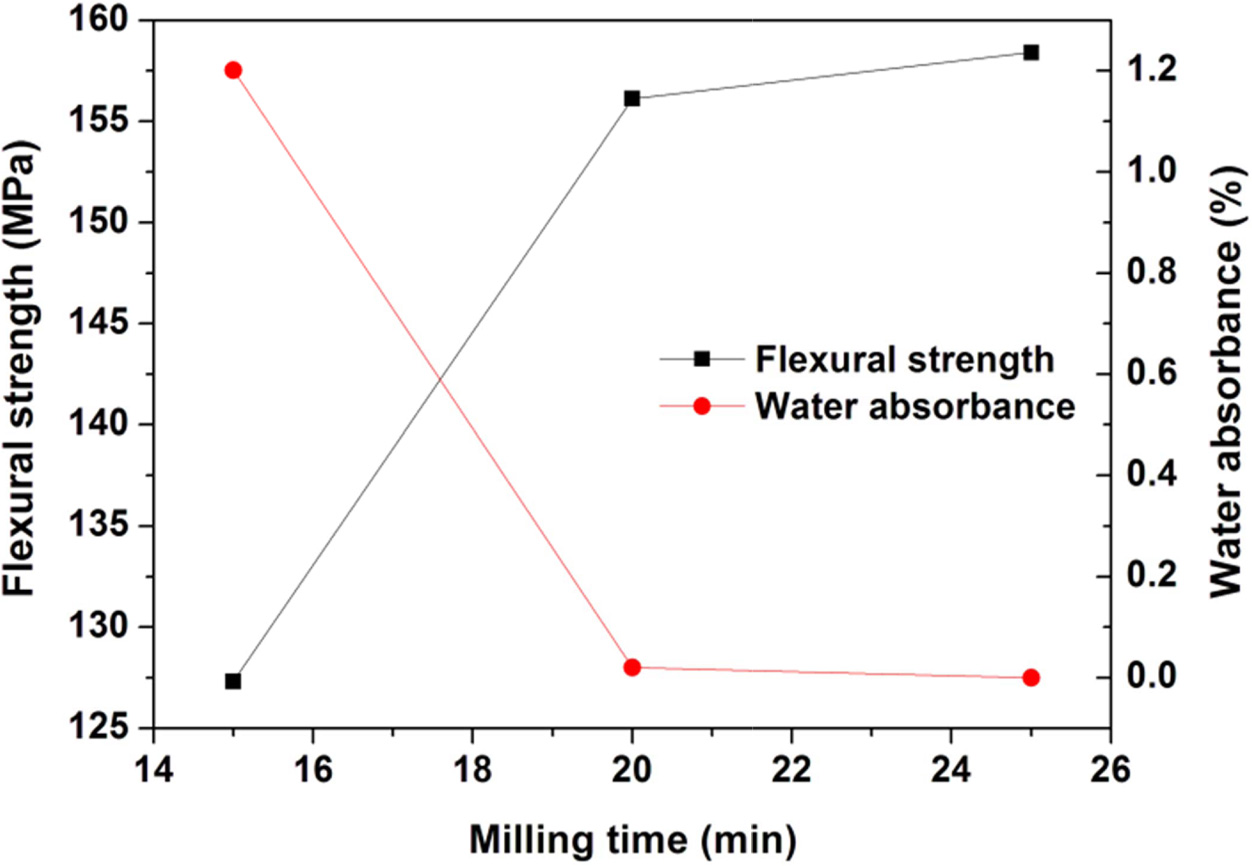

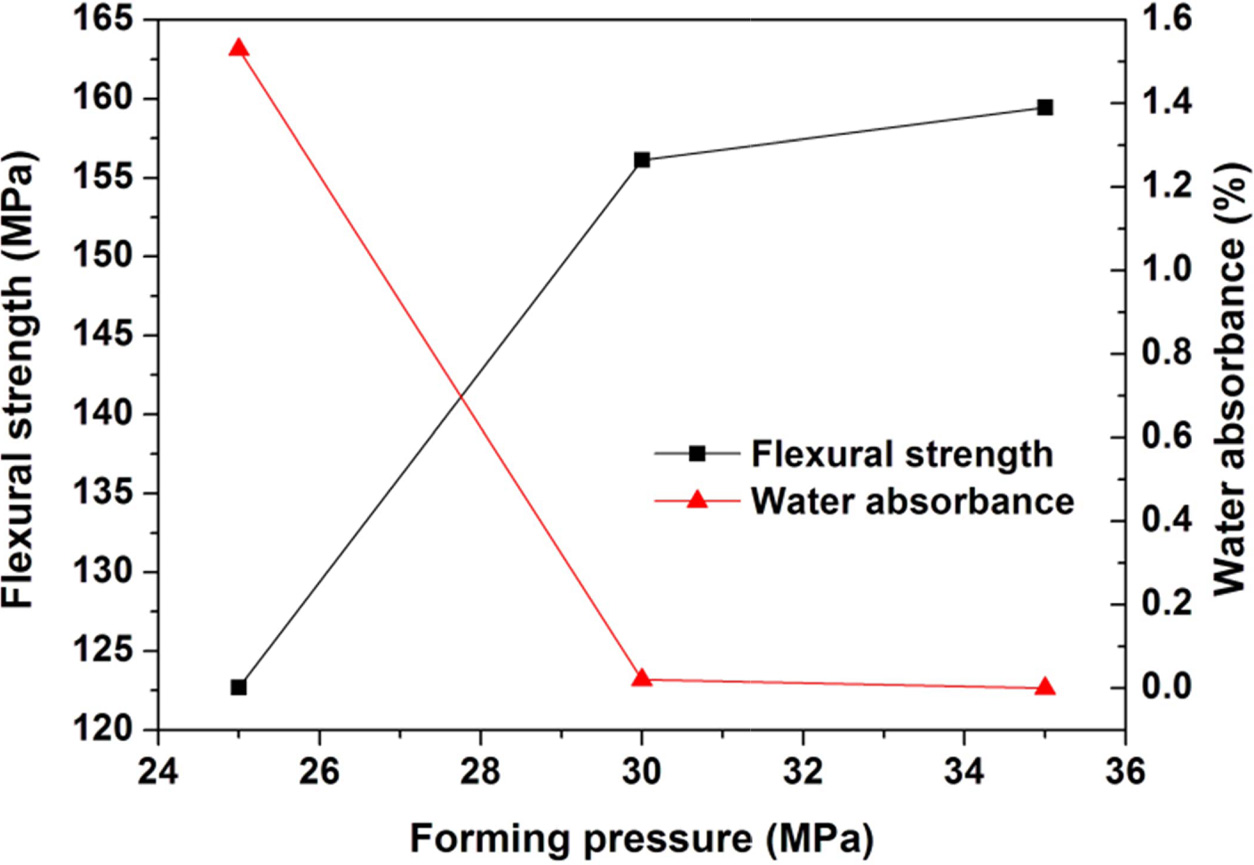

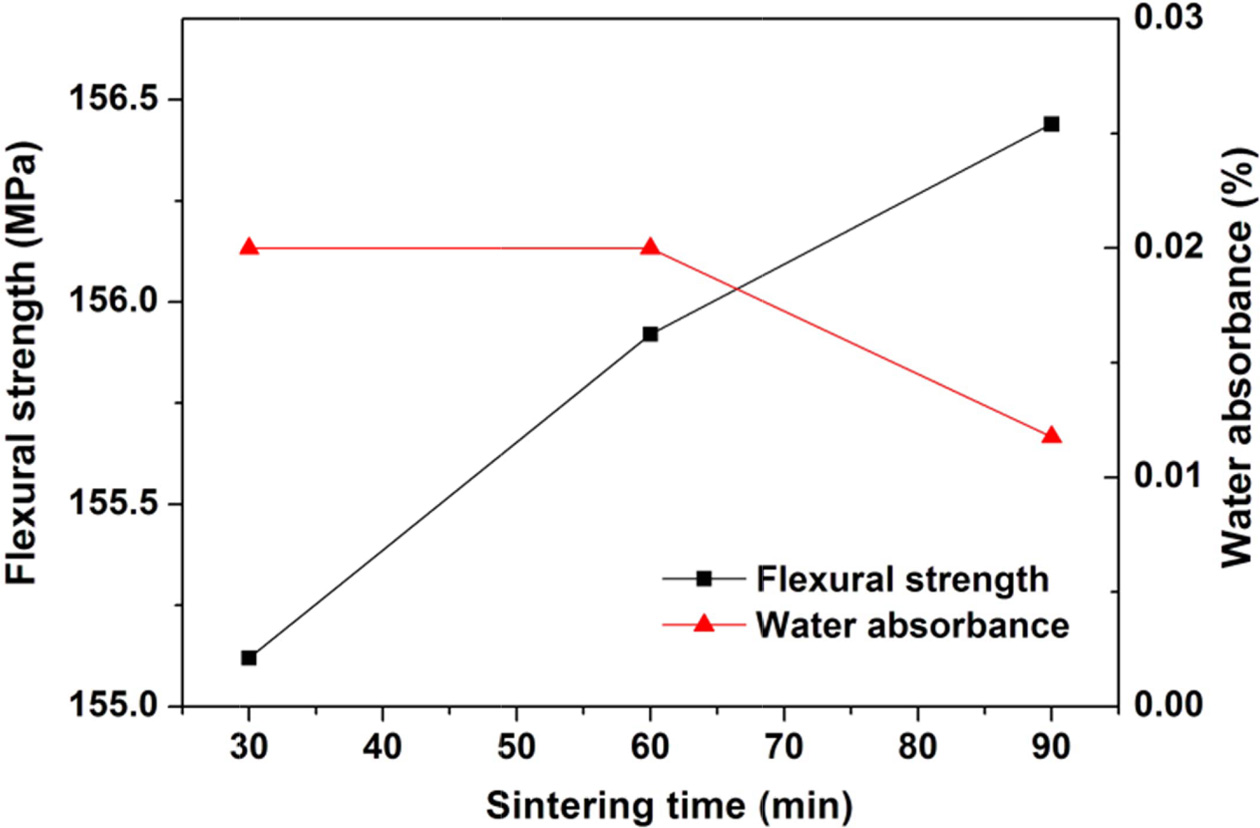

To optimize the processing parameter, the prescription 12# was further studied in various

processing parameters including milling time, forming pressure, and sintering time. The

results are shown in Fig. 7, 8, and 9. The increase of milling time from 15 to

20 min leads to great enhancement of the properties,

however further increase of milling time only shows a slight effect on the properties. Similarly, the

increase of forming pressure from 25 to 30 min leads to great enhancement of the properties

of the glass-ceramics, however further increase of forming

pressure only shows a slight effect. The increasing sintering time from 30 min

to 90 min only results in slight increase (~1.4 MPa) of flexural strength and a slight decrease

(0.01%) of water absorbance.

Many researchers have fabricated the glass-ceramics with various waste minerals [26-32]. Their glass-ceramics generally had the flexural

strength in the range of 30-130 MPa [26-32] and the density in the range of

~1.8-3.0 g/cm3 [26, 27, 30-32]. The glass-ceramics fabricated with coal gangue contained the

gehlenite as a main crystal phase and nepheline as the next crystal phase [18]. The glass-ceramics only

showed a bending strength of 28 MPa [18]. The mullite glass-ceramics fabricated with coal

gangue and γ-Al2O3 showed the bending strength from

64 MPa to 218 MPa as adding the La2O3 from

0 mol% to 10 mol% [16]. The porous mullite ceramic fabricated from coal gangue and bauxite showed the flexural

strength of 66.06 to 133.61 MPa varied with corn starch content [22]. The crystal phases different from mullite and their sizes and densities

are the key factors. By comparison, our glass-ceramics have higher strength. Fig. 3 Fig. 4 Fig. 8 Fig. 9

|

Fig. 1 Variations of (a) flexural strength and (b) water absorbance of the glass-ceramics fabricated with basic prescription 1-5# with sintering temperature (Sintering time: 30 min; milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 2 Variations of flexural strength of the glassceramics fabricated with prescription 6-12# with sintering temperature (Sintering time: 30 min; milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 3 Variations of water absorbance of the glassceramics fabricated with prescription 6-12# with sintering temperature (Sintering time: 30 min; milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 4 Variations of the density of the glass-ceramics fabricated with prescription 6-12# with sintering temperature (Sintering time: 30 min; milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 5 XRD patterns of the glass-ceramics fabricated with prescription 12# at different sintering temperatures for 30 min (Milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 6 SEM micrographs of the glass-ceramics fabricated with prescription 12# at sintering temperature of 1360 oC for 30 min (Milling time: 20 min; forming pressure: 30 MPa). |

|

Fig. 7 Variations of flexural strength and water absorbance of the glass-ceramics fabricated with prescription 12# at sintering temperature of 1360 oC for 30 min with wetmilling time (Forming pressure: 30 MPa). |

|

Fig. 8 Variations of flexural strength and water absorbance of the glass-ceramics fabricated with prescription 12# at sintering temperature of 1360 oC for 30 min with forming pressure (milling time: 20 min). |

|

Fig. 9 Variations of flexural strength and water absorbance of the glass-ceramics fabricated with prescription 12# at sintering temperature of 1360 oC with sintering time (Milling time: 20 min; forming pressure: 30 MPa). |

The waste coal gangue has been utilized for the fabrication of high-strength

glass-ceramics. Optimal utilization ratio of coal gangue was first

investigated. The effects of mineral additives, mineralizers,

processing parameters of forming and sintering of glass-ceramics were also researched. The optimal utilization ratio of the coal gangue

was determined to be 55 wt.% when the appropriate amounts of bauxite, clay, limestone, and steatite were used.

The appropriate amounts of mineralizers BaCO3, MnCO3,

MgCO3 can improve the

property of the glass-ceramics, in which BaCO3 and MnCO3

codoping and substitution show an optimal effect

as their amounts are 3 wt.%, respectively. The process optimization showed that

reasonable forming process parameters are milling time of 20 min and forming

pressure of 30 MPa, while optimal sintering temperature and time are 1360

oC and 30 min, respectively. Further increases of the milling time,

forming pressure and sintering time only lead to slight enhancements of the

properties. In the condition of these reasonable process parameters, the sintered glass-ceramics were of high strength (156.12 MPa), low density (2.68 g cm-3), and low water absorption (0.02

%). This makes the sintered glass-ceramics an excellent glass-ceramics having

potential superiority for the applications

in proppant materials, building materials, cooking ceramics, et al..

This work supported by Scientific Research Program Funded

by Shaanxi Provincial Education Department (Program No.19JK0431)

- 1. J. Temuujin, U. Bayarzul, E. Surenjav, K.D. Sung, and C.Y. Sik, J. Ceram. Proc. Res. 18[2] (2017) 112-115.

- 2. K.D.T. Kien, P. DinhTuan, T. Okabe, D.Q. Minh, and T.V. Khai, J. Ceram. Proc. Res. 19[6] (2018) 472-478.

- 3. I. Krstić, S. Zec, and V. Lazarević, Sci. Sinter. 50 (2018) 139-147.

-

- 4. O.R.K. Montedo AI.T. lves, and C.A. Faller, Mater Res Bull. 72 (2015) 90-97.

-

- 5. A. Mirza, M. Riaz, and T. Hussain, J. Alloys Compds. 726 (2017) 348-351.

-

- 6. V. Karayannis, A. Moutsatsou, and A. Domopoulou, J. Build Eng. 14 (2017) 1-6.

-

- 7. J.-B. Lee, S.-S. Kim, J.-Y. Lee, and J.-S. Ryou, J. Ceram. Proc. Res. 18[4] (2017) 291-300.

- 8. H.S. Lee and K.H. Sho, J. Ceram. Proc. Res. 19[2] (2018) 105-110.

- 9. M. Amiri Roudan, S. Ramesh, A. Niakan, Y.H. Wong, M. Akhtari Zavareh, Hari Chandran, W.D. Teng, N. Lwin, and U. Sutharsini, J. Ceram. Proc. Res. 18[1] (2017) 69-72.

- 10. T. Terzić, N. Đorđević, M. Mitrić, S. Marković, K. Đorđević, and V.B. Pavlović, Sci Sinter. 49 (2017) 23-37.

-

- 11. G. Patridge, Glass Technol. 35[3] (1994) 116-126.

-

- 12. X.Y. Cong, S. Lu, Y. Yao, and Z. Wang, Mater. Des. 97 (2016) 155-162.

-

- 13. C.-l. Wang, W. Ni, S-Q. Zhang, S. Wang, G.-S. Gai, and W.-K. Wang, Constr. Build. Mater. 104 (2016) 109-115.

-

- 14. D.-X. Li, X.-Y. Song, C.-C. Gong, and Z.-H. Pan, Cem. Concr. Res. 36[9] (2006) 1752-1759.

-

- 15. M.-Z. Liu, Z.-W. Zhu, Z. Zhang, Y.-C. Chu, B. Yuan, and Z.-L. Wei, Sep. Purif. Technol. 237 (2020) 116483.

-

- 16. H.-P. Ji, M.-H. Fang, Z.-H. Huang, K. Chen, Y.-G. Xu, Y.-G. Liu, and J.-T. Huang, Ceram. Int. 39[6] (2013) 6841-6846.

-

- 17. W. Pannhorst, J. Non-Cryst. Solids 219 (1997) 198-204.

-

- 18. M. Yang, Z.-X. Guo, Y.-S. Deng, X.-L. Xing, K.-H. Qiu, J.-P. Long, and J.-F. Li, Inter. J. Miner. Process. 102-103[25] (2012) 112-115.

-

- 19. L.-Q. Luo, K.-Y. Li, W. Fu, C. Liu, and S.-Y. Yang, Constr. Build. Mater. 232 (2020) 117250.

-

- 20. W. Ni, R-Y. Gong, and C.-W. Li, Fuel and Energy Abstracts 39[4] (1998) 304.

-

- 21. F. Fang, Fuel and Energy Abstracts 39[3] (1998) 193.

-

- 22. J.G. Rose, Resources and Conservation 9 (1982) 119-129.

-

- 23. Y. Manama, S. Aoki, N. Camshare, and K. Nina, J. Am. Ceram. Soc. 78[5] (1995) 1265-1271.

-

- 24. H.-Y. He, J. Wuhan Univ. Technol.-Mater. Sci. Ed. 14 (1999) 28-34.

- 25. A.H. Jones and R.A. Cutler, Terra Tek, Inc, US, 1980.

- 26. E. Bernardo, L. Esposito, E. Rambaldi, A. Tucci, Y. Pontikes, and G.N. Angelopoulos, J. Europ. Ceram. Soc. 29 (2009) 2921-2927.

-

- 27. T. Toya, Y. Tamura, Y. Kameshima, and K. Okada, Ceram. Int. 30 (2004) 983-989.

-

- 28. H.-Y. Liu, H.-X. Lu, D.L. Chen, H.L, Wang, H.L. Xu, and R. Zhang, Ceram. Int. 35 (2009) 3181-3184.

-

- 29. E. Bernardo, R. Castellan, and S. Hreglich, Ceram. Int. 33 (2007) 27-33.

-

- 30. Y.J. Park and J. Heo, J. Hazard. Mater. B91 (2002) 83-93.

-

- 31. D.-L. Shu, Mechanical Property of Engineering Materials, China Machine Press, Beijing, 2004, pp. 214-228.

-

- 32. W.R. Beck and R.B. Castle, Proppant for well fractures and method of making same, US 4493875, 1985, Jan. 15.

- 33. Q.-K. Lü, X-F. Dong, and Z.-Y. Zhu, J Hazard Mater. 273 (2014) 136-145.

-

This Article

This Article

-

2020; 21(1): 69-74

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.69

- Received on Aug 21, 2019

- Revised on Jan 23, 2020

- Accepted on Feb 5, 2020

Services

Services

- Abstract

introduction

experimental procedures

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- H.-Y. He

-

College of Material Science and Engineering, Shaanxi University of Science and Technology, Xi'an 710021, China

Tel: +86-15319453608 - E-mail: hehy@sust.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.