- Improved performance of barium cobalt-based perovskites materials: Influence of B-site substitution and metal oxide supported perovskite on oxygen desorption property and reactivity

Shian Lia, Rongqiang Wei, Yuhang Jiang, Qiuwan Shena,*, Guogang Yanga,* and Naibao Huangb

aMarine Engineering College, Dalian Maritime University, Dalian, China

bCollege of Transportation Engineering, Dalian Maritime University, Dalian, China

Oxy-fuel combustion is one of

the proposed technologies which have the potential to achieve a zero CO2

emission. To enhance the oxygen production performance of the oxygen carrier,

different LaBO3-δ (B=Co, Ni, Fe, Cr) and metal oxide (CeO2,

Al2O3, ZrO2) supported BaCoO3-δ perovskites

have been successfully synthesized by the EDTA sol-gel method and further

applied for producing oxygen. The oxygen desorption/production performance of

synthesized perovskites were studied in a fixed-bed reactor system.

Furthermore, the effects of H2O and air as regeneration gas of metal

oxide supported BaCoO3-δ perovskite oxygen carrier were investigated

in detail. Results shows that the oxygen desorption amount of different B-site

substituted LaBO3-δ (B=Co, Ni, Fe, Cr) perovskites decrease in the order

of LaNiO3-δ > LaCoO3-δ > LaCrO3-δ >

LaFeO3-δ.While compared with pure BaCoO3-δ and different

metal oxide supported BaCoO3-δ, CeO2 supported BaCoO3-δ

features higher production amount of oxygen. Multiple cycles demonstrated that

BaCoO3/CeO2 displays higher stability and regeneration

capacity, which is the key factor to provide stable O2/CO2

gas stream for oxyfuel combustion application. In short, the novel BaCoO3/CeO2

oxygen carrier developed in this work exhibits high oxygen desorption

capacity and stability. In addition, it provides a promising potential for

oxygen production in industrial application.

Keywords: CO2 capture; Oxygen carrier; Supported-perovskite; Oxygen production

The combustion of fossil fuels contributes to the emission

of carbon dioxide into the atmosphere, leading to

global warming [1, 2]. Oxyfuel combustion technology is

a very effective technology path to reduce carbon dioxide emissions [3-5]. This

type of combustion requires a high concentration of oxygen. The current

cryogenic process is the only commercially available way to provide large-scale pure

oxygen, but the large investment in oxygen production and high

energy consumption is its major economic challenge and drawback. For oxyfuel

combustion, only an O2/CO2 mixture gas with an oxygen

concentration of 30% ~40% is required for the fuel combustion but not the pure

oxygen.

Perovskite-like oxides-ABO3 (where A and B are usually

rare earth and transition metal cations, respectively) can be

tailored to create a wide family of catalysts by varying either the A-site or

the B-site metal ion. Perovskite-type oxides have been investigated intensively

as functional materials because of their potential technology in

the applications such as fuel cells, a component of

capacitors, microwave technology, electrodes, and immobilization of

nuclear wastes, as well as being catalysts for oxidation

and hydrogenation [6-12].

A new application of producing pure O2 or O2/CO2

gas streams by using perovskite-type oxygen carriers for oxyfuel

combustion is proposed by Lin et al. [13]. The reversible

adsorption/desorption processes based on the perovskite-type oxygen carrier is

described as below:

Where VO··

is the oxygen vacancy, OO×

and □· denote

lattice oxygen and electronic-hole, respectively.

A relatively low oxygen desorption amount may be a major

drawback of this technique. This problem may pose a challenge to the high

efficiency of the oxygen product volume in practical applications. Therefore,

the development of perovskite-type oxygen carrier materials

with excellent oxygen desorption performance and cyclic performance is

necessary.

A

common approach to improve the properties of perovskite-type

oxygen carrier is using A/B site substitution in the metal oxides. Our previous study demonstrated that barium cobalt-based (Ba-Co-O) perovskites

oxygen carriers present higher oxygen

desorption capability and oxygen

releasing rate [3, 4]. As La-based perovskites are the most common perovskites, LaBO3-δ (B=Co, Ni, Fe, Cr)

and BaCoO3-δ are selected as candidate oxygen carrier in this study

[14, 15]. CeO2-based materials are of intensive interest because of their outstanding

oxygen storage capacity, and CeO2

can supply active oxygen species to

perovskite [16, 17]. To support BaCoO3, zirconia (ZrO2) is particularly adopted because ZrO2

remains highly stable under oxidizing

and reducing atmospheres, making ZrO2

as a promising support [18, 19].

Moreover, Al2O3 is another typical support, and the use of a load material having high thermal

conductivity can reduce the sintering of the oxygen carriers. The additives can improve reaction performance and

stability for perovskites materials

in the oxygen-permeable membrane application [20, 21]. However, there is

rare research about using supports to improve the reaction performance of

perovskites. The effect of the supports on the reaction and the oxygen

desorption capability are still unclear, and the durability of the supported

perovskites has not yet been developed.

The current work aimed to

study the effects of B-site (B=Co, Ni, Fe, Cr) substitution on oxygen

desorption performance for La-based perovskites and the effect of supports on

oxygen production/cyclic performance of metal oxide supported BaCoO3-δ.

All the perovskite-type oxides were synthesized

by EDTA sol-gel combustion method. The reactivity and performance of different

pure and supported perovskites were investigated in a fixed-bed reactor system.

Oxygen

carrier preparation

The pure LaBO3-δ (B=Co, Ni, Fe, Cr) and BaCoO3-δ

perovskite samples were synthesized by EDTA sol-gel method as shown in our

previous study [5]. And metal oxide supported perovskite oxygen carriers in

this study were prepared also by a sol-gel synthesis method. The detail

preparation process for BaCoO3-δ /ZrO2 for example is as

follows: Metal nitrates Ba(NO3)2 and Co(NO3)2 · 6H2O

were used as the raw materials and all of analytical purities. A design amount

of metal nitrates and citric acid were dissolved in the NH3-EDTA

solution. The mole ratios of EDTA: citric acid: total metal ions

were controlled as 1:1.5:1. A desired amount of ZrO2 was added in

the string precursor solution. The solution was then gently heated and stirred

at 70 oC for 5 h and further dried at 105 oC

for 10 h, respectively. Then the dry residual was calcined at 850 oC

for 8 h. Finally, the resultant black powders were characterized and tested.

Experimental

procedure

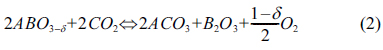

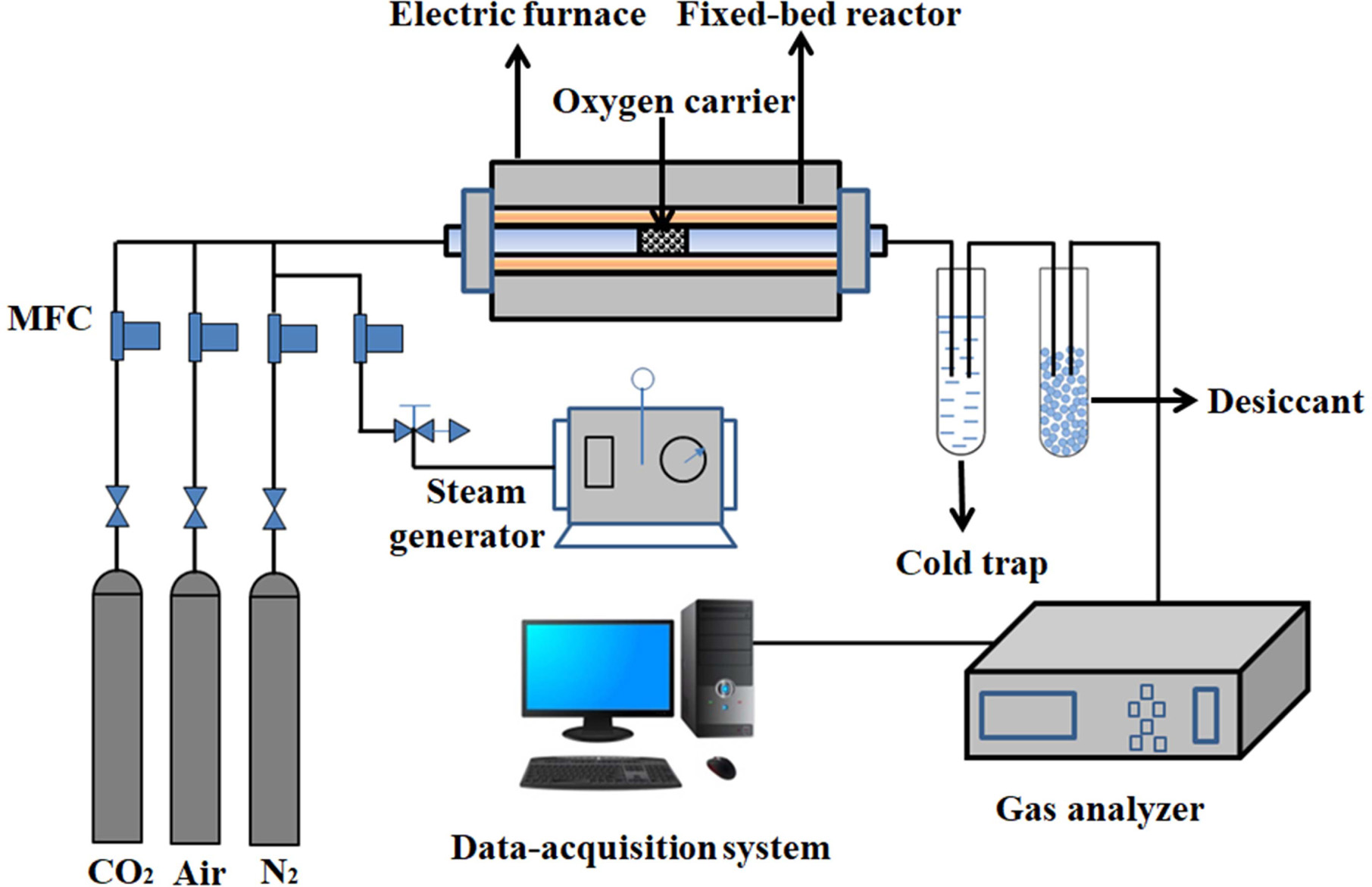

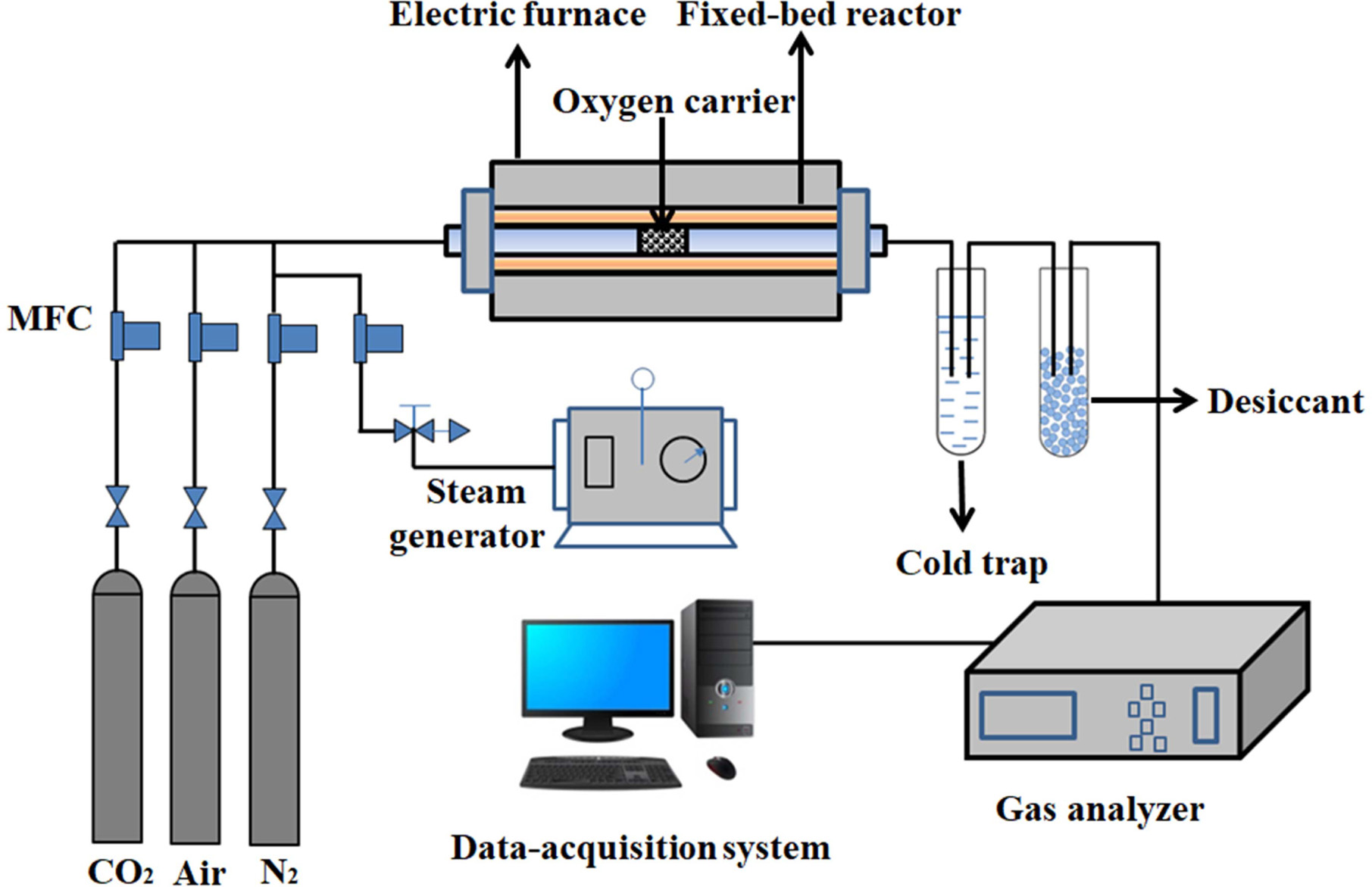

Oxygen adsorption/desorption experiments were performed in

a fixed-bed reactor system as shown in Fig. 1. It consisted of a gas feeding

system (including N2, air, CO2 and a steam

generator), an electric furnace with a quartz reactor, a gas analyzer and a

computerized data-acquisition system.

About 5.0 g of synthesized perovskite powder is filled in

the middle of the quartz reactor. Air/H2O and CO2 are

used as the feed gas for the adsorption step and the purge gas for the

desorption step, respectively.

Output

calculation

The total oxygen desorption amount calculation is

performed by an integration scheme based on the obtained oxygen concentration

distribution. And the following formula can be used:

where ΣCO2 is the integration of the entire oxygen

concentration during the desorption, Fout (L/s) is the flow

rate of desorption effluent, m (g) is the mass of perovskite powders, VO2 (mL/g · sample)is

the oxygen desorption amount for 1 g of the perovskite sample.

|

Fig. 1 Schematic diagram of fixed bed reactor system. |

Effects

of B-site substitution on oxygen desorption performance for la-based

perovskites

The effects of different B-site substitution by different transition

metal ions on the oxygen production performance of LaBO3-δ

were investigated. Fig. 2 demonstrates the comparison of the oxygen desorption

performance for LaBO3-δ (B = Co, Ni, Fe, Cr). It is obvious that

B-site total substitution has significant effect on the oxygen desorption performance

of LaBO3-δ. It shows that the oxygen desorption amount of B-site

total substitution for LaBO3-δ is in the following order:

LaNiO3-δ > LaCoO3-δ > LaCrO3-δ

> LaFeO3-δ. It indicates that LaNiO3-δ has

the optimum oxygen desorption performance among the above

B-site-substituted LaBO3-δ perovskite. The oxygen desorption amount

for LaNiO3-δ is about 13 ml O2/g×perovskite.

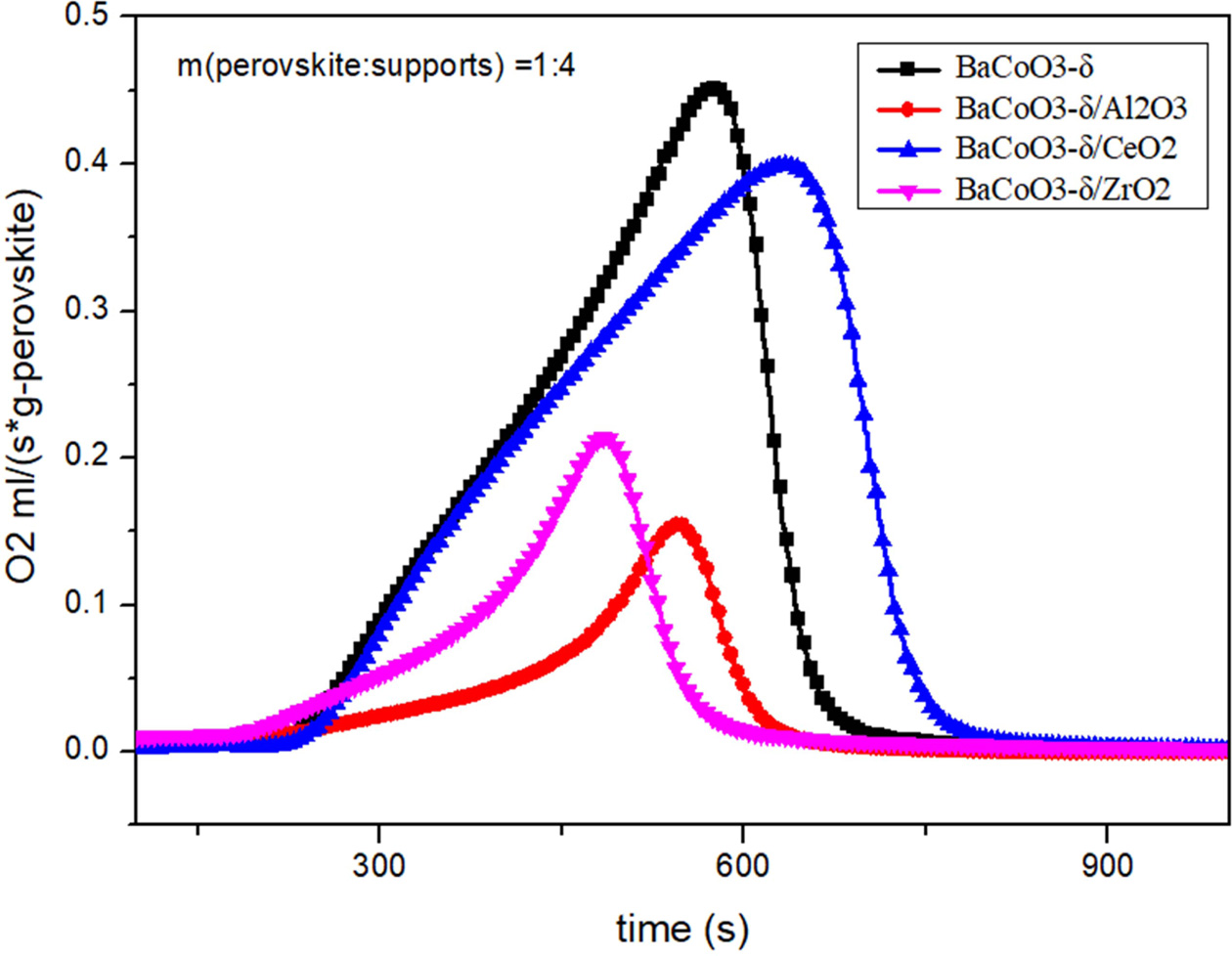

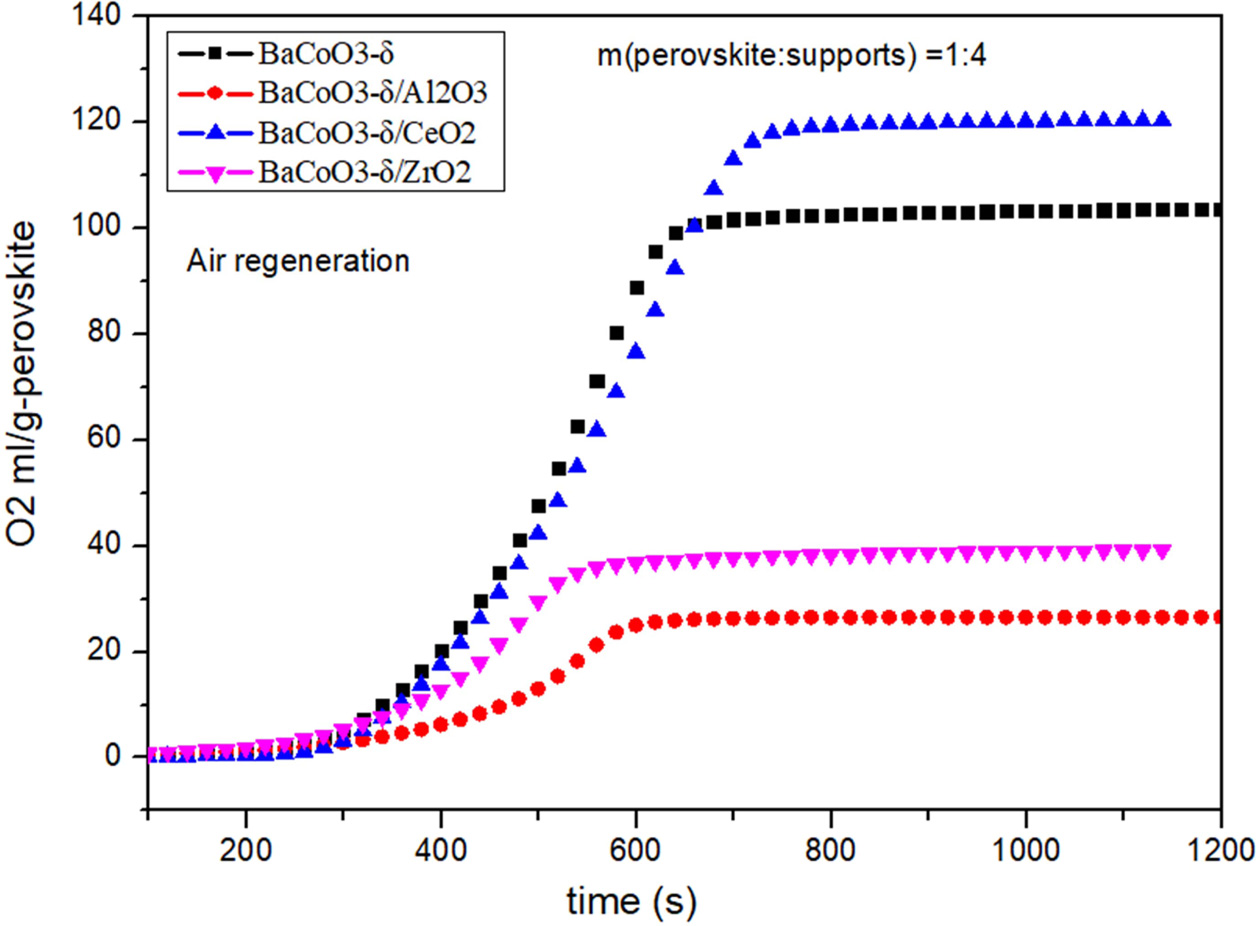

Effect

of metal oxide supported perovskite oxygen carriers on oxygen desorption

performance

The performance of metal oxide supported BaCoO3−δ

oxygen carriers was studied in the fixed-bed reaction. The absorption and

desorption temperature are 800 oC and 850 oC

respectively.

Its performance was compared with the pure BaCoO3−δ

oxygen carriers. Comparison of oxygen desorption curves

and oxygen desorption amount of pure BaCoO3−δ, BaCoO3−δ/CeO2

(BCC), BaCoO3−δ/Al2O3 (BCA) and BaCoO3−δ/ZrO2

(BCZ) are shown in Fig. 3 and Fig. 4. Results showed that the order of oxygen

production amount was as follows:

BCC > BC > BCZ > BCA. That

is to say, BCC perovskite has the improved oxygen desorption performance. On

the other hand, the Al2O3 and ZrO2 reduced the

oxygen desorption property of BaCoO3−δ oxygen carrier.

The results showed that CeO2-supported

perovskite has better oxygen production performance in the desorption process.

As an oxygen storage material, CeO2 exhibits high oxygen mobility

and oxygen capacity at high temperatures. The lattice oxygen in CeO2

can be supplied to perovskites in the high temperature process [22-24].

Therefore, CeO2 is an excellent support material for

oxygen carriers, which can enhance

the performance of BaCoO3−δ nanoparticles.

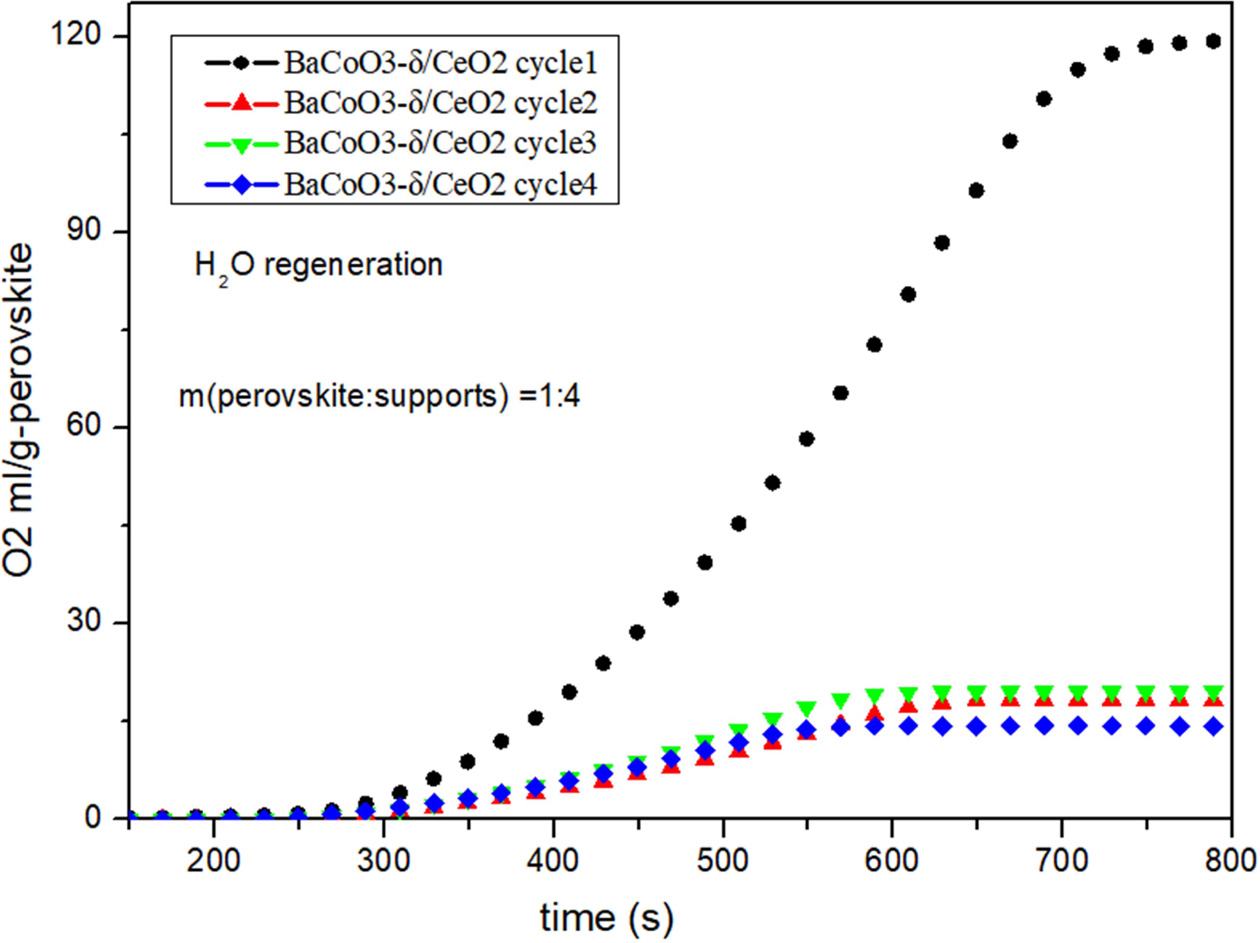

Effects

of H2O regeneration gas on oxygen desorption performance and cyclic

performance

Main feature of this type of perovskites is that they can

adsorb O2 from air at high temperature to restore its perovskite

structure. In order to study the self-recovery ability of perovskite carriers,

water vapor and air are chosen to compare their recycling regeneration capacity.

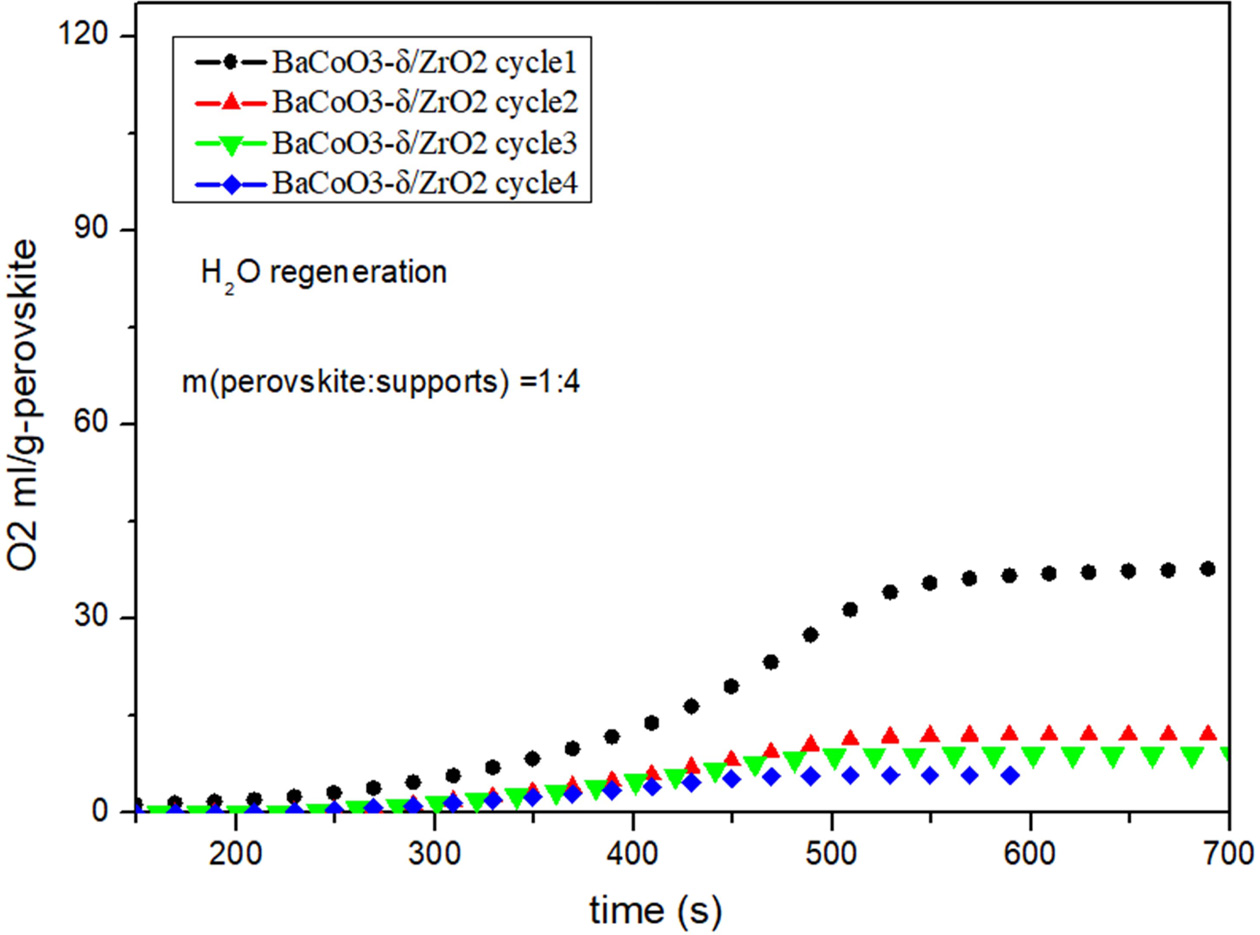

Fig. 5, Fig. 6, Fig. 7 and Fig. 8 show the cyclic

performance of pure BaCoO3−δ and supported BaCoO3−δ

oxygen carrier under the H2O instead of Air as regeneration gas

conditions. Results show that all the perovskite oxygen carriers

have good oxygen desorption performance in

the first cycle. However there is a significant drop during cycle 2 to cycle 4

for all the samples. It is indicated that H2O as

regeneration adsorbent does not appropriate for perovskite

recovery.

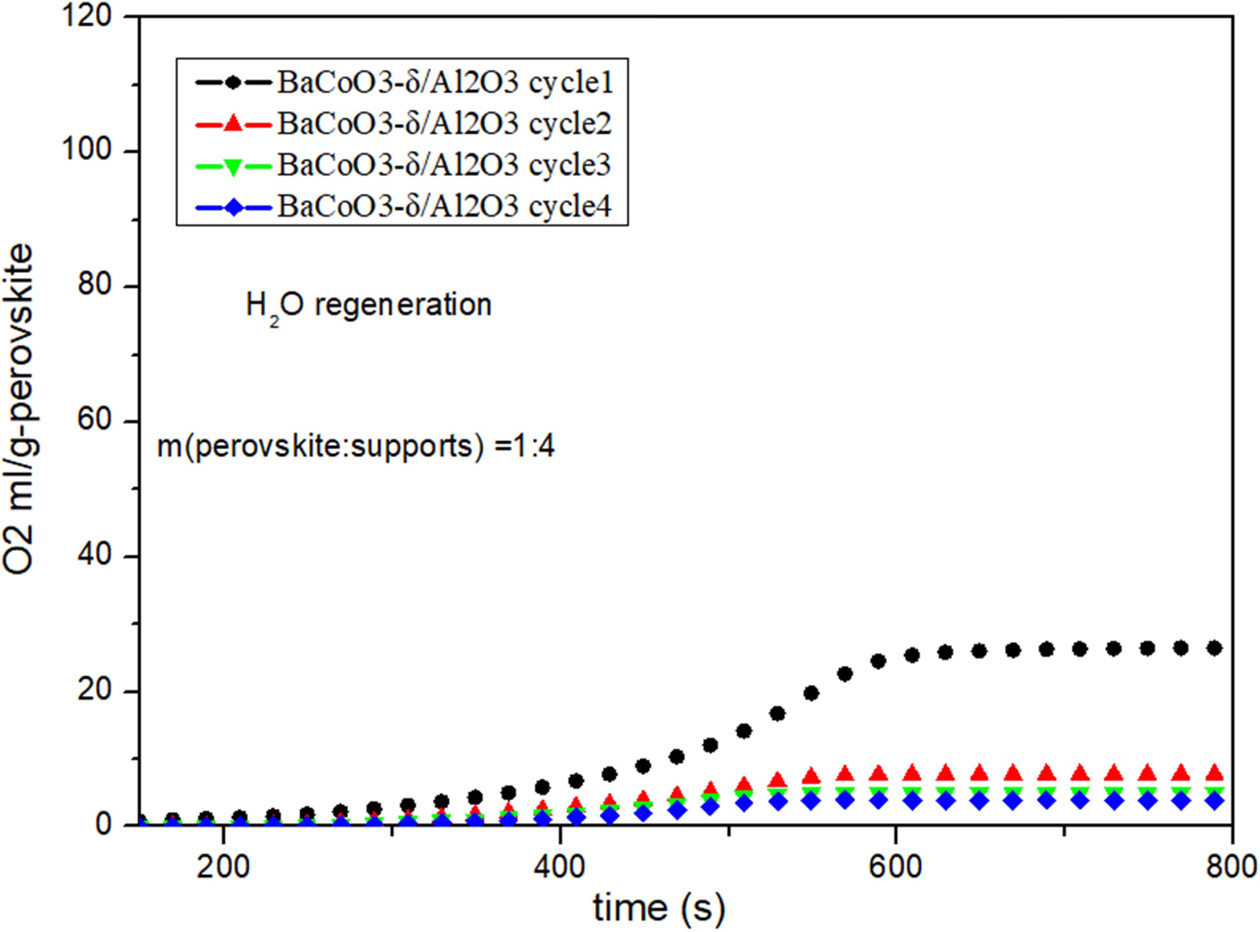

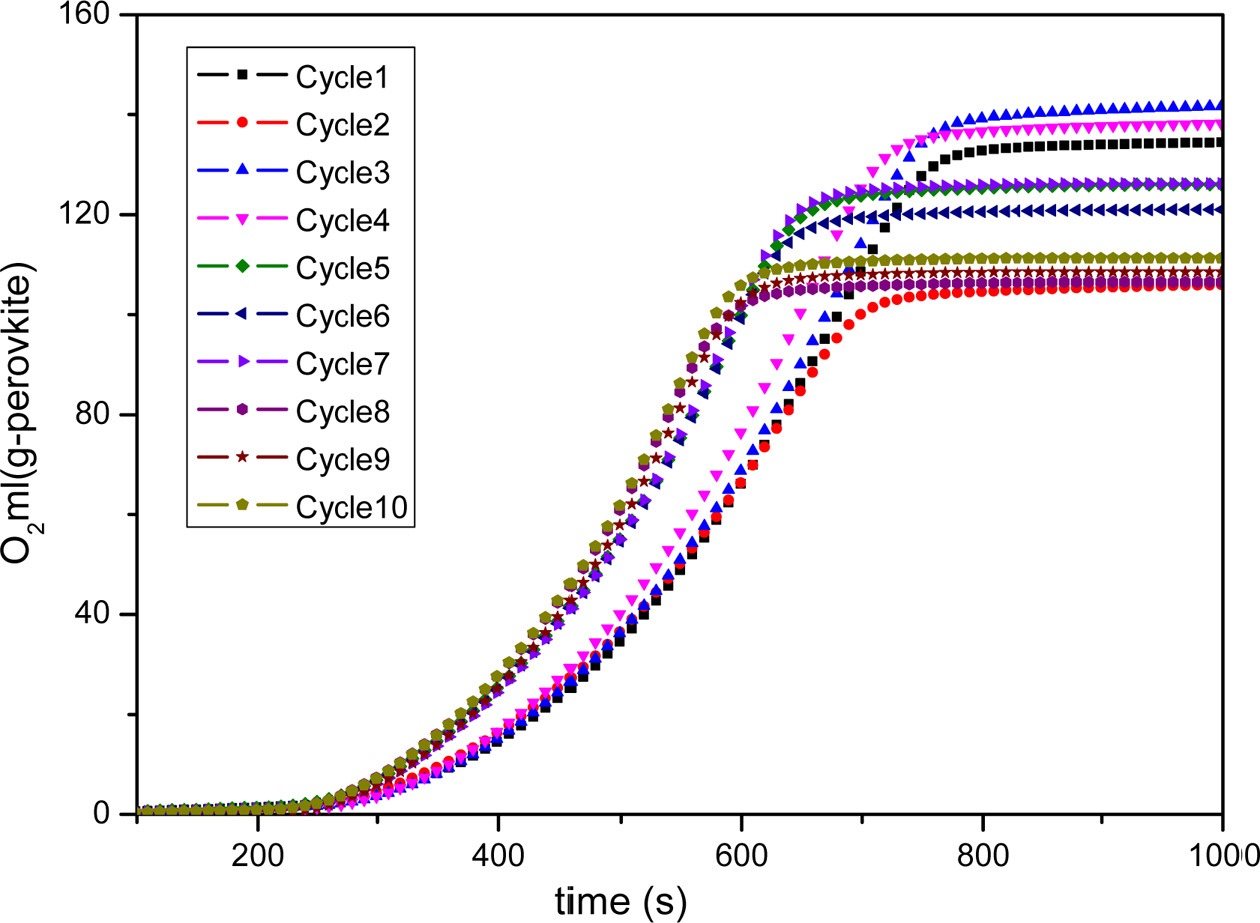

Cyclic

performance

Stability is a key parameter

for the performance of oxygen carriers, providing a stable O2/CO2

recycle gas for oxyfuel combustion

applications. This work evaluated the stability of the proposed BaCoO3-δ/CeO2

perovskite oxygen carrier and applied it for 10-cycles long-term testing. Fig.

9 and Fig. 10 shows the cyclic capacity of BaCoO3−δ/CeO2 perovskite

oxygen carrier. It indicates that the oxygen desorption performance does not

show an obvious decrease during the

1-7 cycles. After cycle 7, there is a litter decrease of the oxygen desorption

amount for BaCoO3−δ/CeO2.

The oxygen desorption amount of BaCoO3−δ/CeO2 could still

achieve 110 ml/g sample after 10 cycles. Therefore, the novel perovskite-type oxygen carrier BaCoO3−δ/CeO2 has

excellent regeneration capacity in cyclic use, which is very important for practical

application.

|

Fig. 2 Oxygen desorption curves for LaBO3-δ (B=Sr, Ba, Mg, Ca). |

|

Fig. 3 Comparison of oxygen desorption curves for pure and supported BaCoO3−δ. |

|

Fig. 4 Comparison of oxygen desorption amount of pure and supported BaCoO3−δ. |

|

Fig. 5 Cyclic performance of pure BaCoO3−δ (H2O as regeneration adsorbent). |

|

Fig. 6 Cyclic performance of BaCoO3−δ/CeO2 (H2O as regeneration adsorbent). |

|

Fig. 7 Cyclic performance of BaCoO3−δ/ZrO2 (H2O as regeneration adsorbent). |

|

Fig. 8 Cyclic performance of BaCoO3−δ/Al2O3 (H2O as regeneration adsorbent). |

|

Fig. 9 Long-term testing of BaCoO3−δ/CeO2 oxygen carrier. |

|

Fig. 10 Comparison of cyclic oxygen desorption amount of BaCoO3−δ/CeO2 oxygen carrier. |

In this study, different LaBO3-δ

(B=Co, Ni, Fe, Cr) and metal oxide (CeO2, Al2O3,

ZrO2) supported BaCoO3-δ perovskites have been successfully prepared by the EDTA sol-gel method and

applied for oxygen production. Results show that B-site total substitution has

significant effect on oxygen desorption

properties of LaBO3-δ. LaNiO3-δ has the optimum oxygen desorption

performance among the B-site-substituted LaBO3-δ

perovskite. Effects of H2O regeneration gas on oxygen

desorption performance and cyclic performance indicated that H2O

as regeneration adsorbent comparing to air

does not appropriate for perovskite recovery.CeO2 supported

perovskite featured better oxygen production

performance. Furthermore, BaCoO3−δ/CeO2 exhibits an

excellent regeneration capacity in cyclic use which is very important for practical

application.

The authors gratefully acknowledge the financial supports from National Natural Science Foundation of China (No.51606013 and No.51779025). This work is also funded by the Fundamental Research Funds for the Central Universities of China (No.3132019191, No. 3132019187 and No. 3132019327), China Postdoctoral Science Foundation (No.2019M651097 and No.2019M 651094) and Natural Science Foundation of Liaoning Province (No.2019-BS-026 and No.2019-ZD-0154).

- 1. Q.W. Shen, S.A. Li, G.G. Yang, J.L. Yuan, and N.B. Huang, J. Ceram. Process. Res. 20 (2019) 152-157.

- 2. Q.W. Shen, S.A. Li, G.G. Yang, S. Bengt, and J.L. Yuan, Energies, 12 (2019) 410-420.

- 3. Q.W. Shen, Y.D. Zhang, H. R. Ding, Y.Q. Xu, B.C. Shi, B.C. Y. Zheng, and J.L. Yuan, Energies, 10 (2017) 164-174.

-

- 4. Q.W. Shen, Y. Zheng, C. Luo, and C.G. Zheng, Chem. Eng. J. 225 (2014) 462-470.

-

- 5. Q.W. Shen, Y. Zheng, S.A. Li, H. R. Ding, Y.Q. Xu et al., J. Alloys Compd. 658 (2016) 125-131.

-

- 6. Q.W. Shen, L.N. Sun, and B.W. Wang, Int. J. Electrochem. Sci. 14 (2019) 1698-1712.

- 7. M. Siddique, S. K. Durrani, and E. Ahmed, J. Ceram. Process. Res. 16 (2015) 515-518.

- 8. H. W. Jin, J. H. Kim, Y. M. Park, C. Choi, H.J. Kim, and H. Kim, J. Ceram. Process. Res. 13(2012) 286-290.

- 9. H. Hashimoto, T. Kusunose, and T. Sekino, J. Ceram. Process. Res. 12(2011)223-227.

- 10. Q. Liao, Y.Chen, Y.Y.Wei, L.Y.Zhou, and H.H. Wang, Chem. Eng. J. 237(2014)146-152.

-

- 11. S. Boldrini, C. Mortalo, and S. Fasolin, Fuel Cells, 12(2012) 54-60.

-

- 12. J.Q. Zheng, Y.J. Zhu, and J.S. Xu, Mater. Lett. 100(2013)62-65.

-

- 13. Z. Yang, and Y.S. Lin, Ind. Eng. Chem. Res. 41 (2002) 2775-2784.

-

- 14. G. Guo, K. Lian, L. Wang, F. Gu, D. Han, and Z. Wang, RSC Adv. 4 (2014) 58699-58707.

-

- 15. Y. Wang, X. Yang, L. Lu, and X. Wang, Thermochim. Acta. 443 (2006) 225-230.

-

- 16. D. Tian, C. Zeng, H. Wang, X. Cheng, Y. Zheng, C. Xiang et al., Appl. Surf. Sci. 416 (2017) 547-564.

-

- 17. R. Zhang, Y. Wang, and R.C. Brown, Energy Convers. Manage. 48 (2007) 68-77.

-

- 18. T. Yamaguchi, Catal. Today 20 (1994) 199-217.

-

- 19. A.L. Kustov, O.P. Tkachenko, L.M. Kustov, and B.V. Romanovsky, Environ. Int. 37 (2011) 1053-1056.

-

- 20. B.C. Enger, R. Lødeng, and A. Holmen, Appl. Catal. A-Gen. 346 (2008) 1-27.

-

- 21. S. Pavlova, N. Sazonova, V. Sadykov, S. Pokrovskaya, V. Kuzmin, and G. Alikina, Catal. Today. 105 (2005) 367-371.

-

- 22. M. Alifanti, M. Florea, S. Somacescu, and V.I. Parvulescu, Appl. Catal. B-Environ. 60 (2005) 33-39.

-

- 23. R. Zhang, W. Yang, N. Luo, P. Li, Z. Lei, and B. Chen, Appl. Catal. B-Environ. 146 (2014) 94-104.

-

- 24. T.H. Shin, S. Ida, and T. Ishihara, J. Am. Chem. Soc. 133 (2011) 19399-19407.

-

This Article

This Article

-

2020; 21(1): 64-68

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.64

- Received on Aug 20, 2019

- Revised on Nov 8, 2019

- Accepted on Nov 22, 2019

Services

Services

- Abstract

introduction

materials and methods

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Qiuwan Shen

-

Marine Engineering College, Dalian Maritime University, Dalian, China

Tel : +86-13971559130, +86-13050561150 Fax: +0411-84728659 - E-mail: shenqiuwan@dlmu.edu.cn, yanggg@dlmu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.