- Study on precipitation of microcrystalline boehmite from bayer process solutions

Gwang Hee Shina, Chan Woong Parka, Jong Hyeok Kangb, Sangyun Seoc, Tam Tranb and Myong Jun Kimb,*

aKorea Chemical Corp, Mokpo, Korea

bDepartment of Energy & Resources Engineering, Chonnam National University, Gwangju, Korea

cKorea Resources, Kangwon, Korea

This study was carried out to develop a process for

synthesising ultra-fine boehmite powders by precipitation from the Bayer

process liquor at a temperature within the range 85 ~ 95 oC.

The study was conducted to investigate whether boehmite produced by this

technique has the same physical properties as those prepared by hydrothermal

synthesis at elevated temperature and commercially available for use as fire

retardant in plastic making. As with gibbsite, the precipitation of boemite

requires seeding in which α-boehmite seeds were first produced by pyrolysis of

a plant ultra-fine gibbsite at 420 oC for 60 min. The boehmite

seeds of mean particle size (D50) of 0.30 μm were obtained through

subsequent hydrothermal synthesis.

This process would yield a high purity

well-crystalline boehmite of 1.30-1.47 μm mean particle size of low surface

area (2 ~ 4 m2/g) as required for commercial fire

retardants.

Keywords: Boehmite, Bayer process, Hydrolysis, Pyrolysis, Precipitation

Boehmite (α-AlOOH or Al2O3.H2O,

alumina mono- hydrate,

AMH) has found many applications in industry, including

use as a precursor for making special alumina ceramics,

as catalysts or fire retardants in plastic production. When

boehmite used as a precursor is calcined for making specialty alumina such as α-Al2O3

catalysts its crystal morphology (of different shapes such as

rhombic, hexagonal, etc.), purity and size

determine the transfor- mation

temperature and other properties of the final product [3]. As a fire retardant

boehmite decomposes to alumina (Al2O3), releasing water

and absorbing heat at a higher temperature (> 350 oC)

compared to alumina trihydrate/ATH (Al(OH)3, gibbsite) or magnesium

hydroxide (Mg(OH)2). Boehmite

fire retardants require specific particle properties (< 2 μm particles,

specific crystal shape, low BET specific surface area, and high purity, etc.).

It is well known that under hydrothermal conditions

gibbsite is converted to boehmite at a temperature in the range

100 ~ 350 oC, depending on pressure in the range

1 ~ 100 MPa [5, 15]. As an example, Panda et al. [9] could produce

nano-crystalline boehmite (crystallite size 35 ~ 75 nm) by treating

gibbsite (particle size range of P80 of 3 μm) hydrothermally at

temperatures < 350 oC and 15 ~ 55 MPa pressure.

In the temperature range 350 ~ 450 oC,

both boemite and α-Al2O3 are formed. One of many

techniques developed for the synthesis of boemite as nanowire, nanotube or as

nanoparticles (1 ~ 20 nm) of various crystallite shapes (hexagonal,

rhombic, ellipsoidal, etc.) employs hydrothermal conditions at temperature in

the range 150 ~ 250 oC under pressure for several days [7,

12-13, 16]. This was done by using different precursors as seeds,

ranging from bayerite Al(OH)3, gibbsite Al(OH)3,

to pseudo-boehmite sol gel, etc. As an example, flaky spherical boemite could

be produced from sodium aluminate (Bayer) liquor at

44.7 g/L Na2O (caustic NaOH) and alumina

set at A/C (alumina to caustic mass ratio, with A as g/L Al2O3

and C as g/L Na2O) of 1.41, using 266 g/L gibbsite seed at 180 oC

[6].

Several synthesis techniques were also proposed to produce

boehmite directly from Bayer or sodium aluminate liquors at temperatures lower

than 100 oC. Although the solubility of boehmite

(30 ~ 40 g/L Al2O3 in the temperature range

80 ~ 100 oC) is generally lower than for gibbsite

(60 ~ 120 g/L Al2O3) [6] the precipitation of

boehmite is slow and controlled via a kinetic step [14] with an

activation energy of 89 kJ/mol, compared to easier gibbsite

formation over the same temperature range 70 ~ 90 oC. To

produce pure boemite without gibbsite contamination the

precipitation has to be conducted at a very high total caustic

concentration (equivalent to 210 g/L caustic as Na2CO3)

equivalent to an A/C ratio of 0.67 [4]. Attempts to improve the

reaction rate, particle size (via promoting applomeration)

and strength (increasing via crystal growth) of boemite crystals have been made

during the crystallisation step from aluminate liquors. While

agglomeration of boemite is dependent on operating parameters

and can be enhanced by longer aging time, higher seed ratio, higher liquor

supersaturation (ie large difference of liquor Al2O3

concentration from equilibrium value), etc. crystal growth to control

crystallite size to within a certain range is difficult.

Wang and co-workers [18] found the crystal growth rate of

boehmite is independent of seed sizes or seed ratio and is in the range

0.08 ~ 2.4 μm/h at 80 oC, 4 ~ 10 times less than that

of gibbsite (2 ~ 7.2 μm/h). Panias and Krestou

[11] first precipitated nano-crystalline boehmite

(3 ~ 8 nm crystallites) by neutralising a supersaturated Bayer liquor

to pH 5 ~ 7 at 30, 60 and 90 oC using

nitric acid. Precipitates with higher crystallinity were formed

at pH 7 and 90 oC, which after aging for one week would yield

well crystalline boehmite of 22 ~ 37 μm

mean particle size. At 90 oC, nano-crystalline boemite

(30 ~ 80 nm) was produced using a concentrated sodium

aluminate liquor (120 g/L Na2O, 132 g/L Al2O3) within

24 h using 230 ~ 1200 g/L seeding with boehmite,

without which seeds the reaction is extremely slow [14]. Dash et

al. [1] found that to produce gibbsite within 8 h at a

reasonable yield (~ 10 g/L boehmite) and at atmospheric conditions

(85 ~ 95 oC, 1 atm). The Bayer liquors have to be

supersaturated at high aluminate concentration > 150 g/L Al2O3,

and the A/C ratio has to be in the range 1.0 ~ 1.2

with at least 100 g/L boehmite seeds of < 10 μm size added.

By adding an organic modifier, boehmite formation is

enhanced, minimising the co-precipitation of gibbsite. Dash et al.

[1] found that by adding 100 ~ 300 mg/L tartaric acid the nucleation

of gibbsite is prohibited and boehmite is produced at a lower temperature of

80 oC. Wang et al. [18] also realised that by adding ethanol

the activation energy of precipitation is reduced to 13.7 kJ/mol, shifting the

reaction kinetics to a diffusion control mechanism, thus promoting boehmite

formation.

The techniques studied and reported to date have been

difficult in scaling up for plant production due to long residence time

required for aging, either during hydrothermal processing or via precipitation

at 85 ~ 95 oC. These methods could not produce

microcrystalline boehmite with high

crystallinity in the narrow size range 1 ~ 2 μm nor having

a low surface area. Therefore, precipitation under Bayer

process conditions was studied to determine optimum conditions of liquor composition, temperature and reaction time for producing

micro- crystalline boehmite suitable

to be used as a fire retardant. The materials synthesised from this study are

also compared with existing commercial products currently on the market.

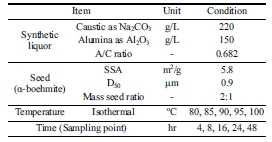

Materials

and reagents

The Bayer liquor used in this study was prepared from

a bauxite ore sample from Weipa, Australia (Table 1), the same

material has been used in the production of gibbsite/alumina trihydrate (ATH)

at the Daejoo-KC alumina refinery at Mokpo, South Korea. As in plant operation

the liquor used for the study was achieved by digesting bauxite to a caustic

solution to achieve a caustic concentration of 210 ~ 220 g/L (as Na2CO3)

and A/C ratio of 0.65 ~ 0.68.

All other reagents used in this study are of analytical

grade.

Analytical

techniques

Aluminum and caustic contents of the synthetic mother

liquors and precipitation filtrate were analysed by acid-base

neutralization/titration method. The precipitation (%) of boehmite/AMH based on

the alumina analyses of the mother liquor and the filtrate was calculated from

the following equation:

Precipitation (%) = [Alumina of mother liquor (g/L)

– Alumina in filtrate (g/L)] / Alumina of mother liquor

(g/L) × 100%

The prepared α-boehmite seeds used in this study were

analysed using a Particle Size Analyzer (PSD, S3500,

Microtrac), and the crystal phase was determined by

an X-Ray Diffractometer (XRD, Ultima IV, Rigaku). A

Surface Area Analyser (Quadrasorb-SI, Quantachrome) was used to

confirm the specific surface area of the seeds. The thermal decomposition and

composition of boemite (AMH) was evaluated using a thermal analyzer (DTG-60H,

Shimadzu). A Scanning Electron Microscope (SEM, SSX-550, Shimadzu) was also

used to evaluate the shapes of the particles produced. Chemical analysis was

performed on digested samples using an Inductively Coupled Plasma Optical

Emission Spectrometer (ICP-OES, ICPS-7510, Shumadzu).

Experimental

procedures

The following stages were conducted for the experiments:

(a) Liquor used: The Bayer mother liquor from which

boehmite was precipitated from was prepared by varying the A/C ratio, seed mass

ratio (mass of boehmite seeds/mass of Al2O3 in the

liquor),

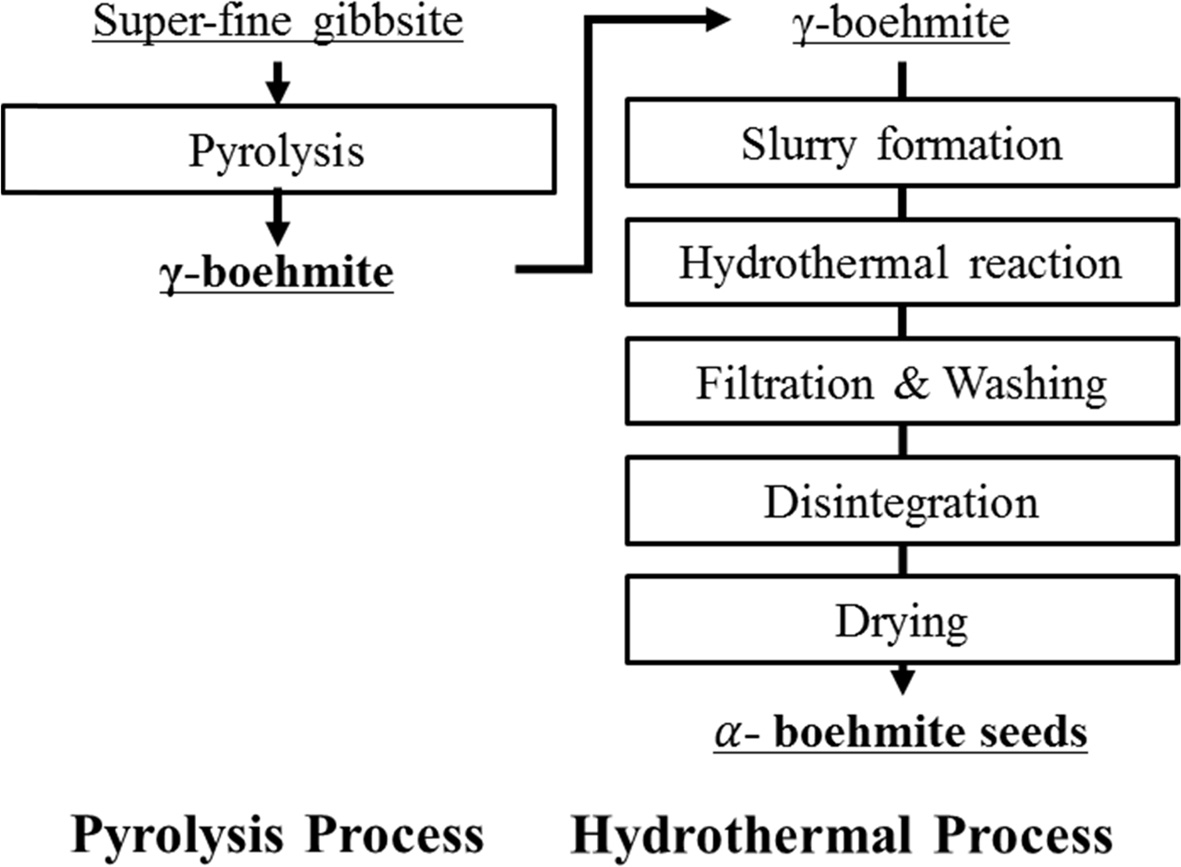

(b) Precipitation of seeds: α-boehmite seeds were

prepared for the precipitation of boehmite by calcination of a KC superfine

(< 2 μm) gibbsite/ATH product (alumina trihydrate, Al(OH)3)

at 420 oC. The calcined material was then subjected to a hydrothermal

reaction, filtered and ground to produce nano-AMH

(boemite) material as shown in Fig. 1.

(c) Boehmite precipitation – The boehmite precipitation experiments were carried out by adding the above

freshly prepared seeds into the Bayer sodium aluminate liquor at different

temperatures, caustic soda concentrations, and amounts of seeds used.

|

Fig. 1 Flowsheet of manufacturing α-boehmite seeds. |

|

Table 1 Chemical composition (%) of

the raw material (bauxite from Weipa, Australia). |

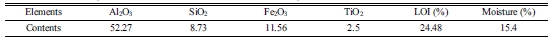

Thermodynamic

Study

A thermodynamic simulation of the precipitation conditions

was conducted using HSC program [8]. Data obtained (Fig. 2) confirm that

boehmite could be thermodynamically precipitated from 95 oC,

in preference to gibbsite. The formation of gibbsite peaks at

110 oC and decreases slowly as the temperature rises to 200 oC.

More boehmite is formed in this temperature range (95 ~ 200 oC).

Seed

preparation

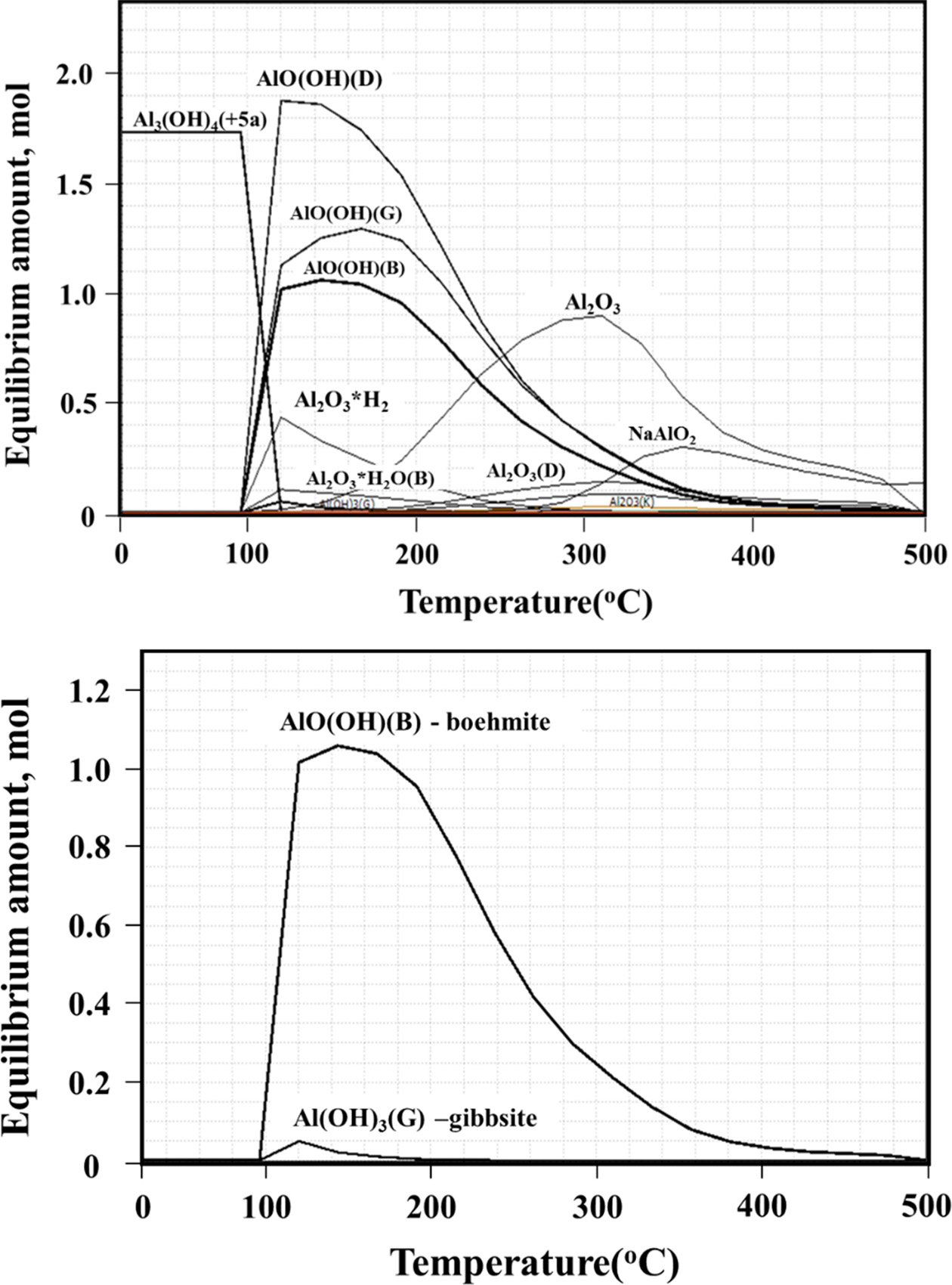

Seed preparation is a critical step for this process.

Seeds were produced by roasting gibbsite (superfine < 2 μm gibbsite/ATH

from KC plant) at different temperatures to determine the condition for making

boemite. XRD analysis (Fig. 3) shows that gibbsite remains stable at less than

350 oC during roasting. Above

400 oC γ-boehmite/AMH is formed. The pyrolysis

of superfine gibbsite to form g-boehmite seeds was therefore conducted at

420 oC subsequently for the study. After hydrolysis to

190 ~ 200 oC this material is converted to α-boemite/AMH.

Optimum

boehmite precipitation temperature

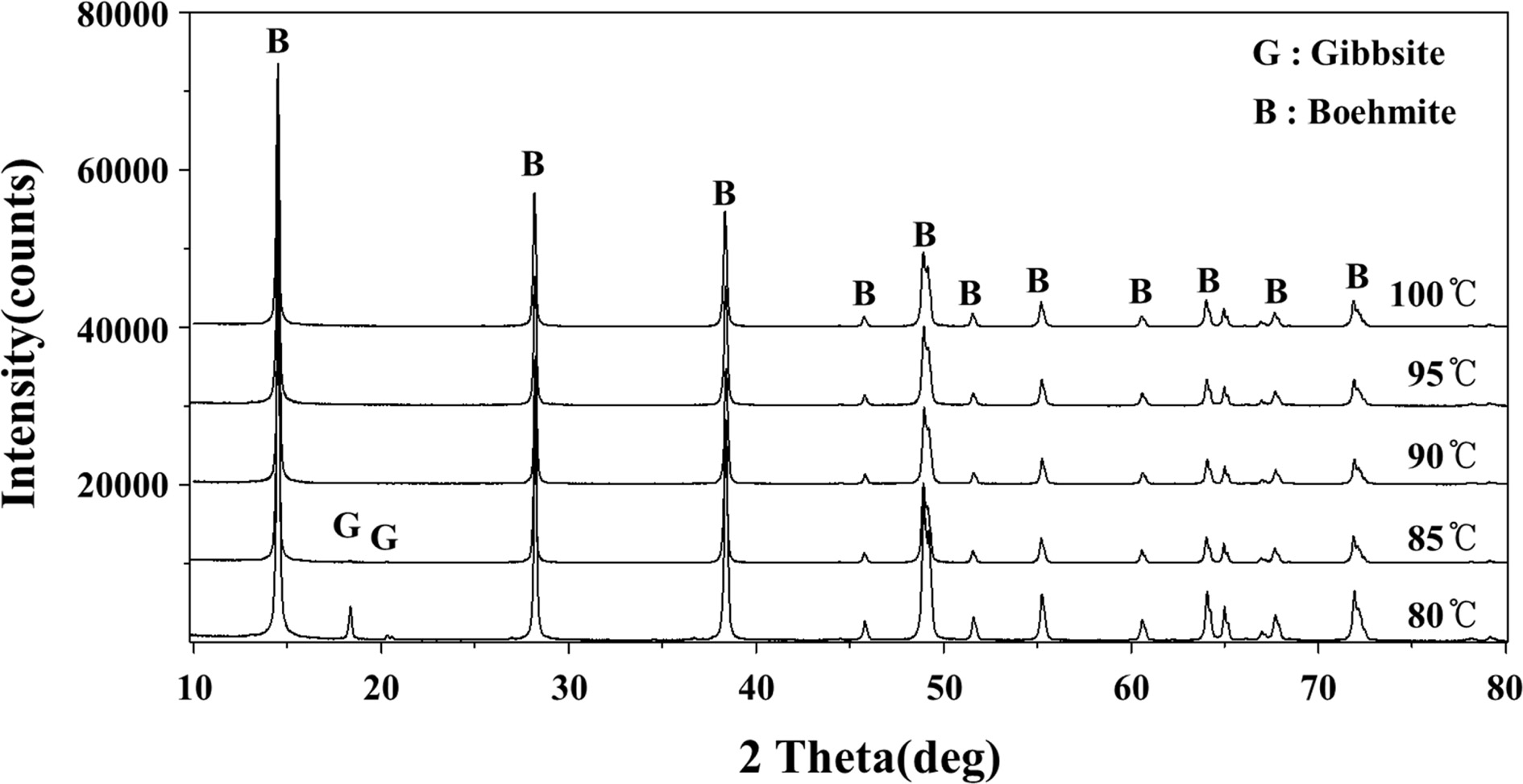

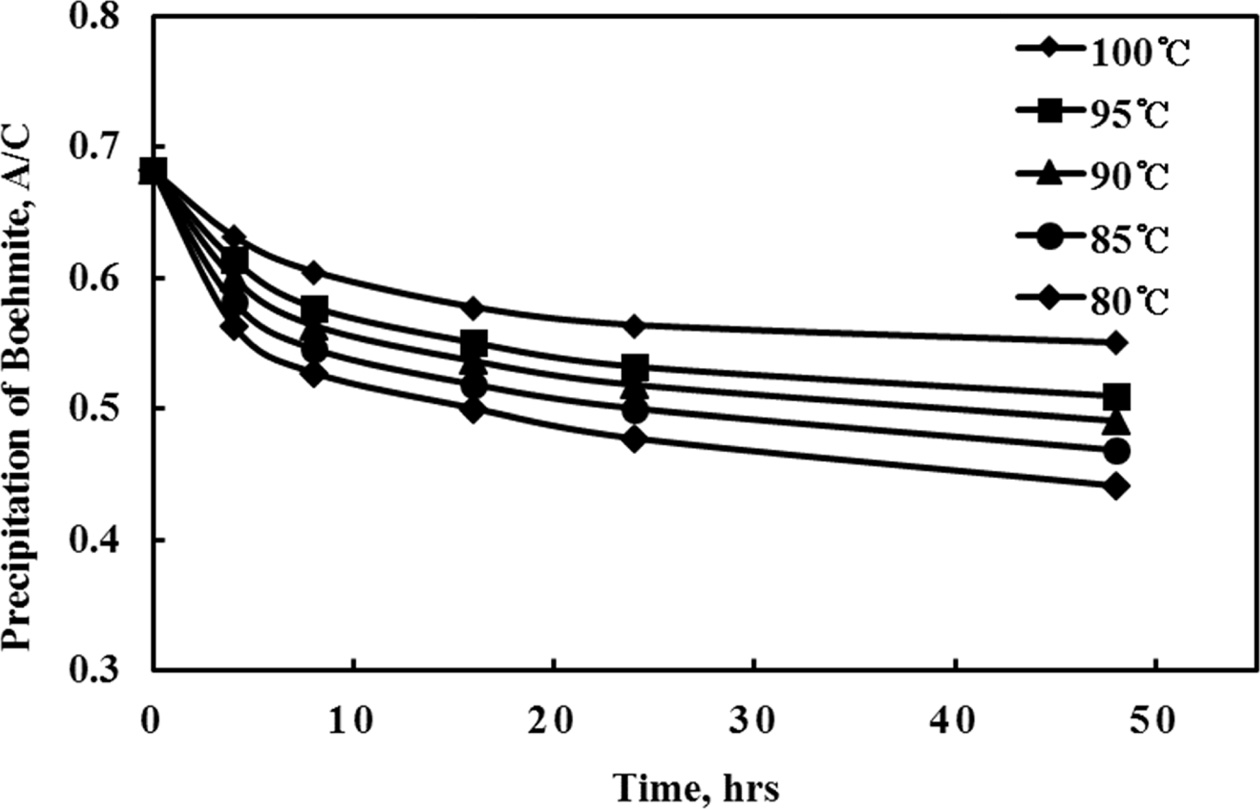

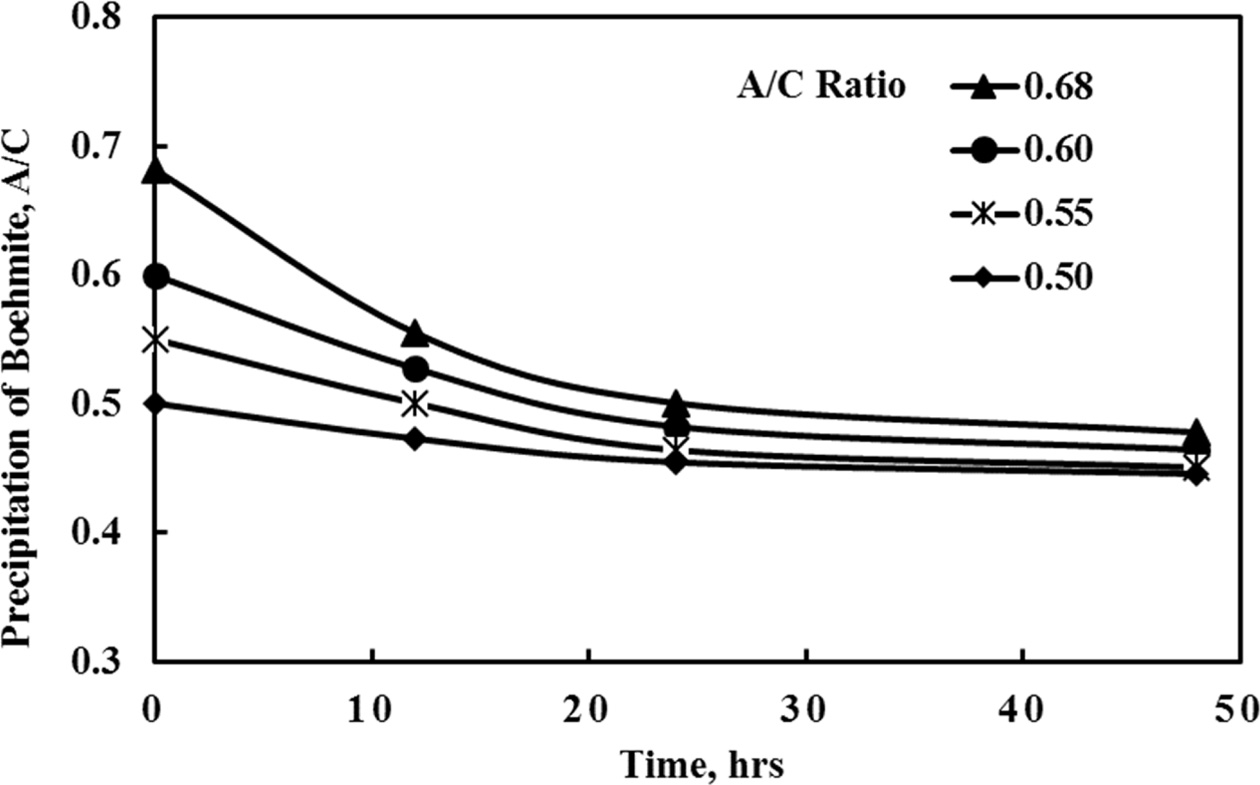

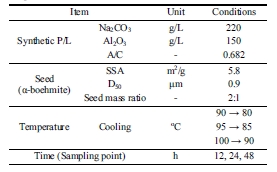

To determine the optimum precipitation temperature, tests

were conducted at the caustic NaOH concentration of

220 g/L (as Na2CO3), pregnant liquor A/C ratio 0.68,

mass seed ratio (boemite AlOOH seed/Al2O3 in the liquor,

both in g) of 2.0 with the isothermal (fixed) temperature

varying from 80 to 100 oC. It was found that gibbsite

was formed when the precipitation temperature was 85 oC or less and

boemite could only be produced when the temperature was set at higher than 90

oC. These results were confirmed by XRD analysis of the boehmite products

as shown in Fig. 4. It was also observed that the precipitation rate was very

slow, up to 48 h at which time the A/C ratio still has not reached a steady

state (ie. equilibrium has not been reached) as shown in Fig. 5.

Conditions for the tests to determine the optimum

precipitation temperature are tabulated in Table 2.

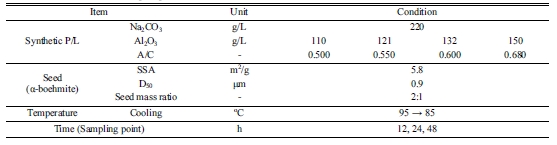

Precipitation

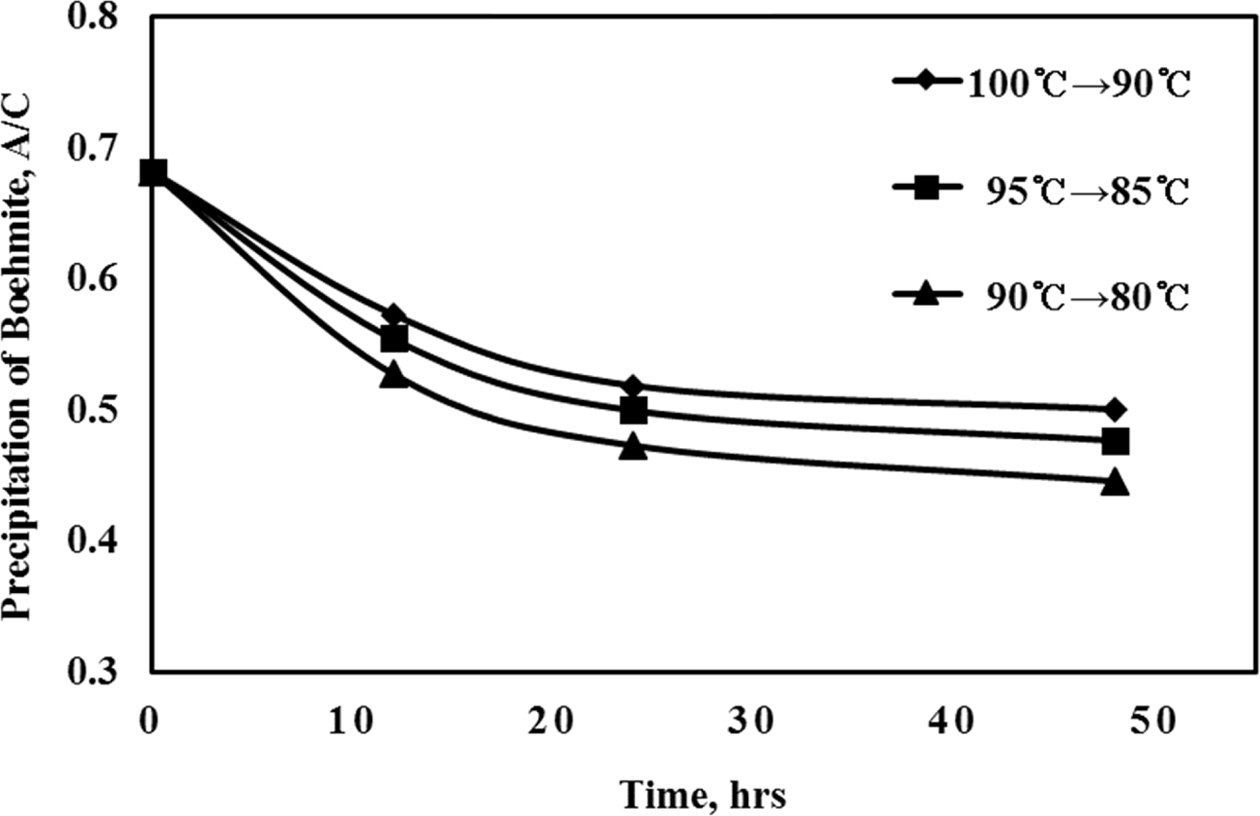

with slow cooling

In the Bayer process, the precipitation rate of

gibbsite/ATH increases depending on the difference between the initial

precipitation temperature and its final value afterwards after cooling. Based

on this, it was also applied to boehmite precipitation and the cooling

rate was 0.4 oC/hr from the starting temperature.

Conditions for this test series are tabulated in Table 3.

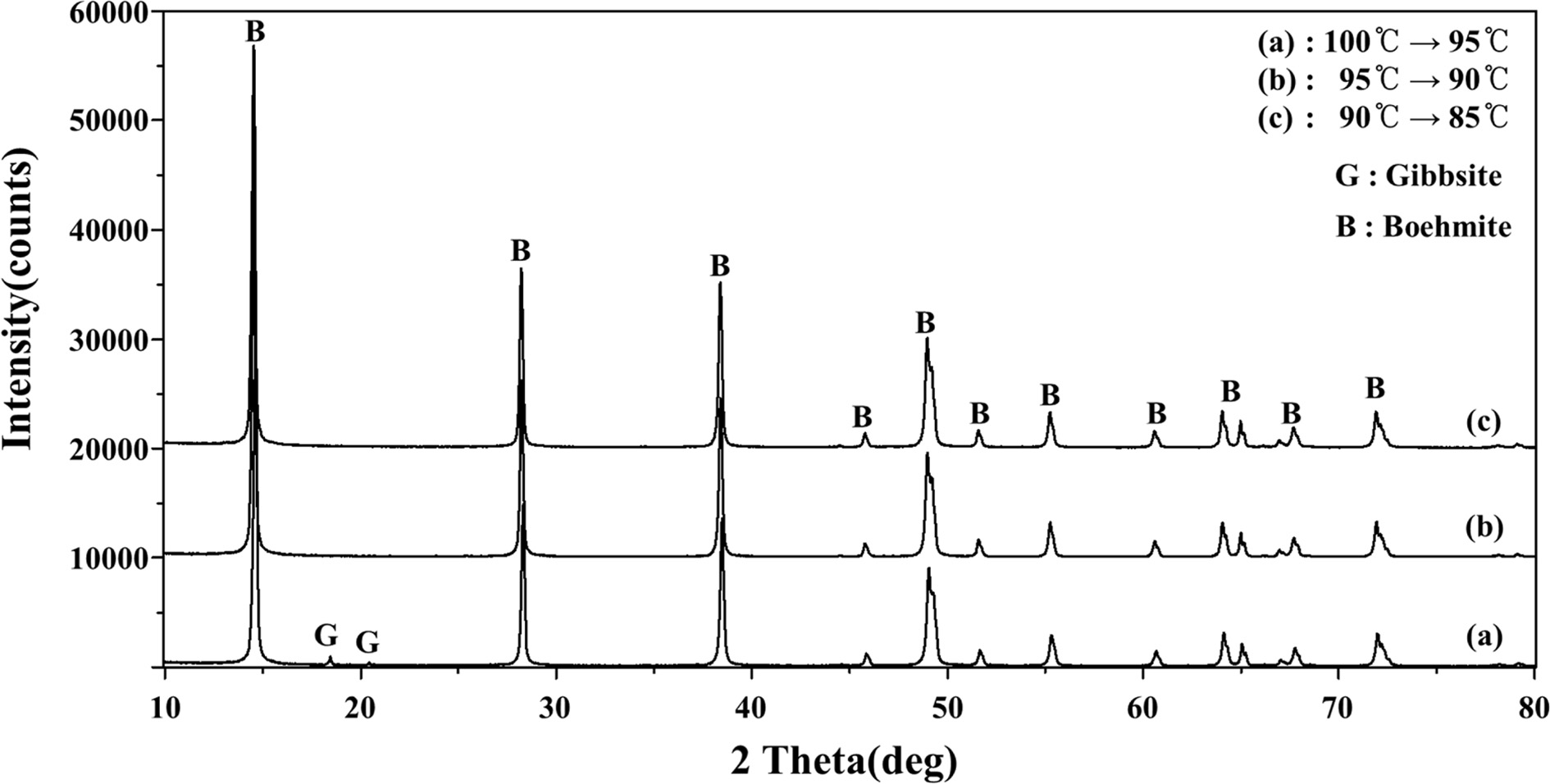

The experimental results (Fig. 6) show that the lower the

initial temperature is, the higher precipitation rate and yield, as expected

with lower final A/C ratio. It was also confirmed by XRD analysis (Fig. 7) that

gibbsite will be formed if the final temperature is less than 85 oC.

The effect of other parameters such as A/C ratios, seed

ratio, etc was also studied and results are as follows.

Precipitation

at different A/C ratios

Tests were conducted to evaluate the effect of varying A/C

ratios during boehmite precipitation according to conditions shown in Table 4.

As expected at a higher A/C ratio the precipitation rate

and yield are higher. At all conditions the steady state would be reached

slowly merging to an A/C ratio of ~ 0.45 after 48 h (Fig. 8).

It is best therefore to use a liquor having an initial A/C

ratio of 0.68 to achieve maximum product yield. This value therefore was chosen

for all tests.

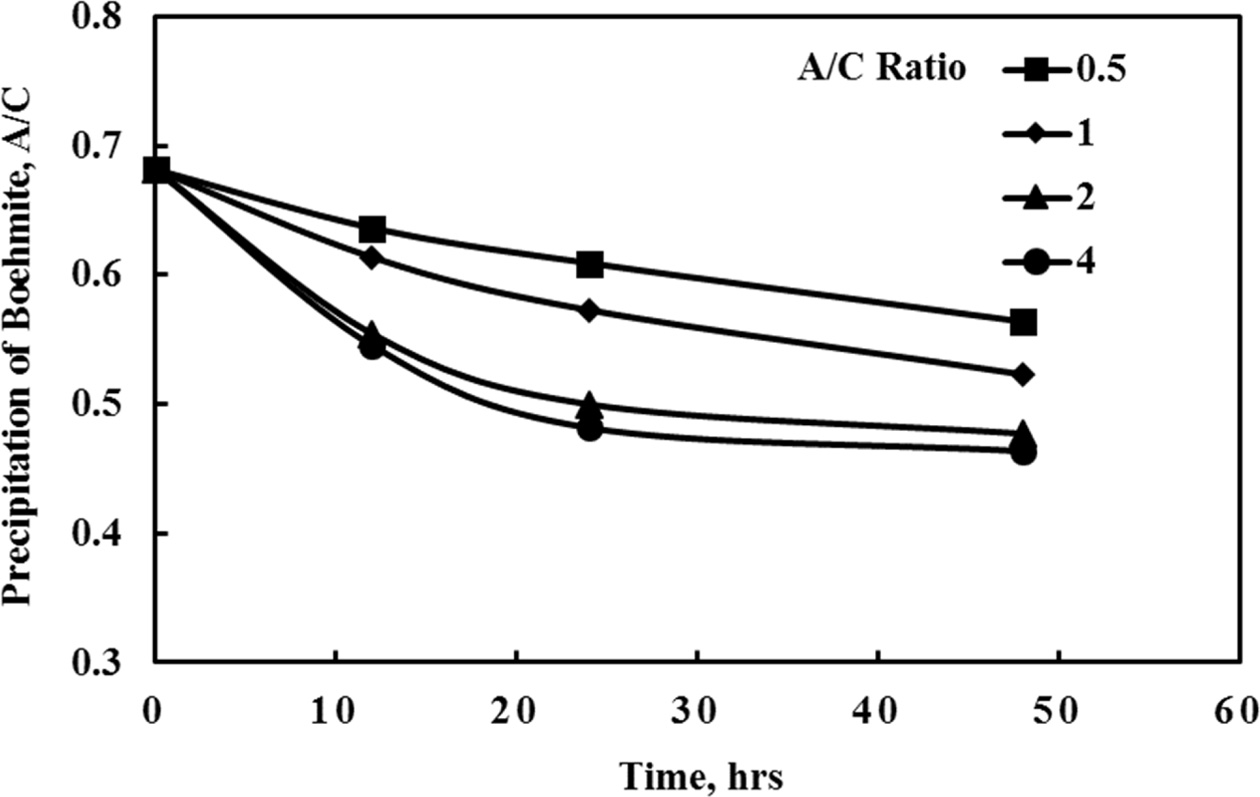

Effect

of seed mass ratio (AlOOH mass/Al2O3 mass in liquor)

Since the boehmite precipitation process requires a higher

precipitation temperature compared top gibbsite, a relatively high seed mass

ratio is required to increase the initial precipitation rate. The effect of

seed mass ratio is shown in Fig. 9, showing a higher precipitation rate at a

higher seed mass ratio in the range 0.5 ~ 2:1. Above this 2:1 ratio,

there is not much of a change of A/C ratio with respect to the seed mass ratio.

The 2:1 seed mass ratio was therefore chosen as optimum conditions as shown in

previous results.

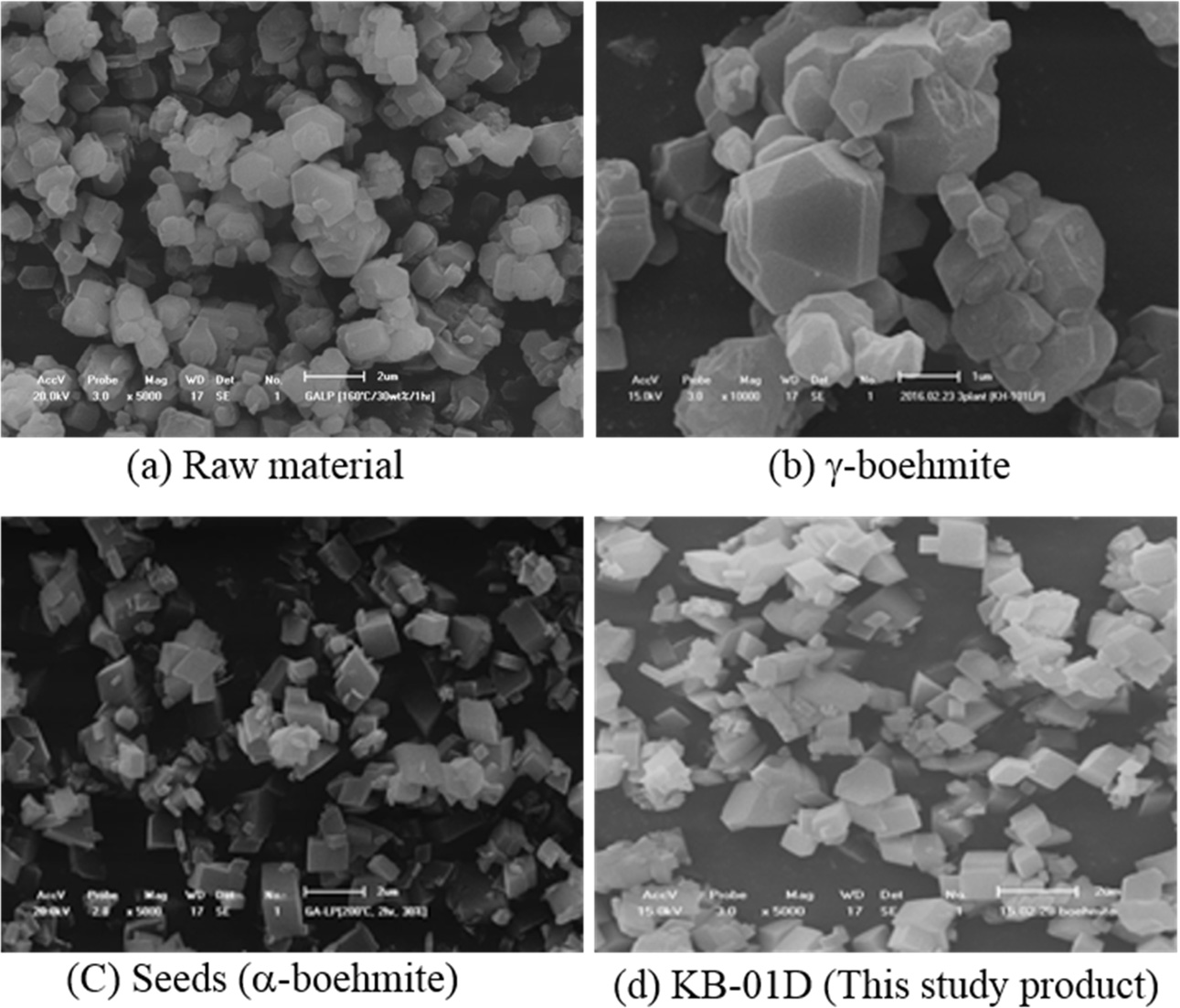

Under SEM typical materials through different stages of

the process are shown in Fig. 10. It is clear that the raw material (gibbsite)

was transformed to g-boehmite after heating to 420 oC, when the

calcined crystallites tended to sinter to hexagonal agglomerates

> 2 μm in sizes. After hydrothermal treatment at 190 ~ 200 oC

these agglomerates were broken and the a-boemite seeds became cubic in form

with reduced sizes to mostly < 2 μm. This mainly cubic shape is

maintained after precipitation into the final boemite product.

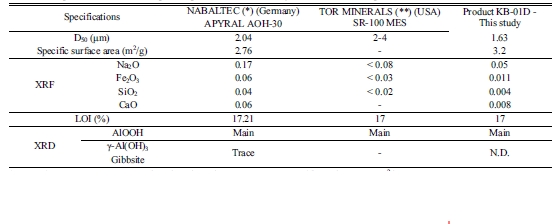

Adopting the optimum conditions for precipitating boemite, the products obtained are very compatible to typical commercial

products such as Nabaltec APYRAL AOH-30 and SR-100 MES

produced by TOR MINERALS – USA (Table 5). The boemite

produced from this study meets the specifications for particle size with D50

in between 1 ~ 2 μm, surface area 3 ~ 6 m2/g.

The purity of boehmite from this study is better than these commercial

products.

|

Fig. 2 HSC simulation of boehmite precipitation at different temperatures. |

|

Fig. 3 XRD patterns of KC superfine plant gibbsite/ATH after calcining at different temperatures in the range 250 ~ 450 oC. |

|

Fig. 4 XRD patterns of boehmite products according to different precipitation (isothermal) temperatures, showing contamination of gibbsite when precipitation was at 80 oC. |

|

Fig. 5 Change of boehmite precipitation A/C ratio with set temperature |

|

Fig. 6 Change of boehmite precipitation A/C at different cooling regimes |

|

Fig. 7 XRD patterns of boehmite product according to different cooling regimes showing boemite can only be formed at a final temperature > 85 oC. |

|

Fig. 8 Change of boehmite precipitation A/C ratio at different initial conditions. |

|

Fig. 9 Change of boehmite precipitation A/C ratio according to different seed ratio. |

|

Fig. 10 SEM analysis showing morphology of the different materials throughout the synthesis of α-boehmite. |

|

Table 2 Conditions for determining optimum temperatures for making boemite product |

|

Table 5 Comparison of the boehmite product produced from this study to other commercial products. |

*Note : (*) APYRAL AOH-30 product data sheet shows D50 1.8 μm, Specific surface area 3 m2/g |

This study was conducted to investigate the production

of 1 ~ 2 μm particle sizes required commercially as a fire

retardant. Boehmite seeds (mean particle size 0.30 μm) were first produced by

pyrolysis of a plant superfine gibbsite

(< 2 μm) at 420 oC, which was then subsequently

treated by a hydrothermal process at 190 ~ 200 oC.

These seeds were then used in a precipitation step at optimum conditions

determined from this study.

Optimum conditions for precipitation are : caustic (NaOH)

concentration of 220 g/L measured as Na2CO3,

alumina/caustic (A/C) ratio of 0.68, seed mass ratio (boemite/Al2O3

in the liquor) of 2:1 and precipitation temperature of 85 to 95 oC

and in 48 h. Following these conditions the process would yield a high quality

crystalline boehmite of 1 ~ 2 μm in sizes, 2 ~ 4 m2/g

surface area. The boemite produced from this process are

compatible to other high quality commercial products.

The authors acknowledge the support of Daejoo-KC’s

laboratories for providing analyses for this study.

- 1. B. Dash, B.C. Tripathy, I.N. Bhattacharya, S.C. Das, C.R. Mishra, and B.K. Mishra, Hydrometallurgy 95 (2009) 297-301.

-

- 2. S. Ghanizadeh, X. Bao, B. Vaidhyanathan, and J. Binner, Ceramic International 40 (2014) 1311-1319.

-

- 3. F. Karouisa, M. Boualleg, M. Digne, and P. Alphonse, Advanced Powder Technology 27 (2016) 1814-1820.

-

- 4. E. Konigsberger, L. Konigsberger, and D. Ikievski, Hydrometallurgy 110 (2011) 33-39.

-

- 5. G. Li, Y. Liu, D. Liu, L. Liu, and C. Liu, Materials Research Bulletin (2010) 1487-1491.

-

- 6. G. Liu, Z. Li, X. Li, T. Qi, Z. Peng, and Q. Zhou, International Journal of Minerals, Metallurgy and Materials 24[8] (2017) 954-963.

-

- 7. D. Mishra, S. Anard, P.K. Panda, and R.P. Das, Material Letters 42 [1-2] (2000)38-45.

-

- 8. Outotec HSC Chemistry software, available from : �https://www.outotec.com/products/digital-solutions/hsc-chemistry/?gclid=CjwKCAiAkrTjBRAoEiwAXpf9CStfCuWGa-E64 DLVhHCW4YQL-YYZQ6VqjJLL-pehH9EltjWLF5ESVBo CH74QAvD_BwE

- 9. P.K. Panda, V.A. Jalel, and S. Usha Devi, Journal of Material Science 41 (2006) 8386-9389.

-

- 10. D. Panias and I. Paspaliaris, Erzmetall 56[2] (2003) 75-81.

- 11. D. Panias and A. Krestou, Poeder Technology 175 (2007) 163-173.

-

- 12. S.P. Santos, A.C.V. Coelho, S.H. Santos, and P.K. Kiyohara, Materials Research 12[4] (2009) 437-335.

-

- 13. P.S. Santos, R.F. Neves, and H.S. Santos, Colloid and Polymer Science 271[2] (1993) 197-200.

-

- 14. C. Skoufadis, D. Panias, and I. Paspaliaris, Hydrometallurgy 68 (2003) 57-68.

-

- 15. <!--[endif]-->W.L. Suchanek, Journal of the American Ceramic Society 93 (2010) 399-412.

-

- 16. J. Yang and R. Frost, Journal of Inorganic Chemistry (2008) Article ID 602198.

-

- 17. Z. Wang, J. Zhang, R. Xu, and Z. Guo, in Light Metals 2002, edited by Carlos E.Suariez (The Minerals, Metals and Materials Society, 2002) p107-112.

-

- 19. Z. Wang, R. Xu, L. Yang, and Z. Guo, in Light Metals 2012, edited by Carlos E.Suariez (The Minerals, Metals and Materials Society, 2012) p120-125.

This Article

This Article

-

2020; 21(1): 50-56

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.50

- Received on Jul 19, 2019

- Revised on Nov 15, 2019

- Accepted on Nov 22, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

acknowledgement

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Myong Jun Kim

-

Department of Energy & Resources Engineering, Chonnam National University, Gwangju, Korea

Tel : +82 62 530 1727 Fax: +82 62 530 1729 - E-mail: junkim@jnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.