- Characterization of some selected Ghanaian clay minerals for potential industrial applications

B. Onwona-Agyemana, N. Lyczkob, D. P. Minhb, A. Nzihoub and A. Yayaa,*

aDepartment of Materials Science & Engineering, School of Engineering Sciences, University of Ghana, Legon, Ghana

bUniversité de Toulouse, IMT Mines Albi, RAPSODEE CNRS UMR-5302, Campus Jarlard, F-81013 Albi cedex 09, France

The aim of this work was to

study five (5) selected local raw clay materials from Ghana using different

characterization techniques such as Thermogravimetric/Differential Thermal

Analysis (TG/DTA), X-ray diffraction (XRD), Fourier Transform Infra-red

Spectroscopy (FTIR), Scanning Electron Microscopy equipped with Energy

Dispersive X-ray Spectroscopy (SEM-EDX) and Nitrogen Desorption (Brunauer-Emmett-Teller, BET) specific surface

area analysis. The clay samples

studied are; Nkroful kaolin (NK), Amanfrom kaolin (AK), Ball clay (BC), Akyem

Feldspar (AF) and Akwatia silica (AS). SEM and EDX show the morphological

features of the five clay samples and also confirm the presence of some

dominant elemental compositions such as aluminium and silicon in all the

samples. FTIR show that the vibrations spectra in the region around 3,600-3,700

cm-1 and 700-800 cm-1 are due to M-OH groups and

that at 900-1000 cm-1 corresponds to Si-O-Si modes.

BET analysis gives specific surface area of the clay samples as NK (4.6 m2/g),

AK (21.9 m2/g), BC (25.50 m2/g), AS (0.79 m2/g)

and AF (0.49 m2/g). X-ray diffraction pattern

confirm the presence of quartz as the major reflection in all the samples

analysed and only kaolinite reflections appeared in three of the samples (NK,

AK and BC). All the kaolinite clays (NK, AK and BC) are suitable starting materials for the fabrication of

electroporcelain insulators, catalytic converters and diesel particulate

filters.

Keywords: Clay, Specific surface area, Electro-porcelain

Clay refers to the finest fraction of sediments that

consist of accumulations of different minerals such as quartz, feldspar and

many more which is formed by the weathering of silicate minerals in/on the

earth’s crust [1]. Clay has many vast benefits in medicine and

industrial purposes which has gained extensive research interest due

to its abundance and low cost [2]. In Africa, clay is mainly used in making

pots for storing water or food and earthen ware bowls for cooking.

Prehistoric practices such as geophagy, which is the

practice of ingesting earth materials or substances such as clay [3, 4] to

augment a scanty mineral deficient diet (for example; iron, copper, calcium,

zinc and manganese) [5], as part of a culture, or to stimulate a healing response

to sooth an infected and inflamed gastrointestinal lining [6] is still

prevalent in the 21st century.

Clays such as smectites, kaolinite and fibrous clay

minerals have been applied widely for drug delivery systems because of their

large specific surface area, pore volume and uniform porosity for sustained

release [7]. Smectites in particular are frequently used as substrate, because

it can retain large amounts of drug due to its cation exchange ability [7].

Others such as palygorskite, kaolinite and talc are extensively used in

pharmaceutical formulations because of their high specific

surface area, good rheological properties, chemical inertness,

low toxicity and good biocompatibility which is

highly suitable for patients [8]. The adsorptive properties of some clay

materials such as high pore volume, fine particles size and cation ion exchange

allows the removal of oils, toxins and contaminants from the skin, which makes

clay suitable for formulations in the

cosmetic industry [6, 9, 10]. Therapeutic uses of clay includes

mixing variable amounts of clay with different sea or salt lake mineral waters

to form pastes for fighting chronic rheumatism and bone muscle diseases

[9, 11-13]. Many studies have proven that clays can be used for

biomaterials and other medical devices such as biosensors [14-18]. In

agriculture, sepiolite and palygorskite clay suspensions have been used as a

tool to reduce the amount of cadmium (Cd) concentration in the soil. This was

done to solve the pollution of soil by this heavy metal. It has also been used

as fertilizer because of its nutrients content, thereby increasing crop yield

[19].

Kaolin is widely used in the paper industry to coat the

surface of paper for brighter colors, as filler in many composite

materials to add strength and to improve the abrasion resistance, and rigidity

to both natural and synthetic rubber products at a low cost. It is also used in

the ceramic industry as an insulator and paint industry due to its high

covering power, low cost and high resistance to chemical attack [20-24].

Recently, research has shown that archeological clay

obtained in Komaland, from the Northern Region of Ghana has prospects to

enhance human fetal osteoblast cells growth in vitro [25]. Also, other

research has shown that treated kaolin from natural clay using chemical and

thermal reactions inhibit Hela cervical cancer cells in vitro [26]. Some

modified clay minerals with lidocaine and silver have been exploited in burn

wounds and antisepsis respectively [27]. In Africa, several kaolin deposits are

not utilized effectively and may serve as assets in economic gains and research

opportunities [28]. Natural clay has been inadequately exploited to know their

chemical composition, their characteristics and applications as compared to

those that are modified, synthetic or refined. In Ghana, although the clay

industry is huge, the properties that inform their usage are limited.

This work seeks to explore various clay deposits from five

different geographical locations, that is; Amanfrom Kaolin (AK),

Ball clay (BC), Nkronful Kaolin (NK), Akyem Feldspar (AF), and Akwatia silica

(AS) and characterize them using techniques such as TGA/DSC, XRD, FTIR, SEM

equipped with EDX and BET so as to better understand their

characteristics for future industrial applications such as electroporcelain insulators, diesel particulate filters and as washcoat materials in catalytic

converters.

The raw materials for this

study were collected from kaolin deposits in Ghana located in the Western and

Central regions.

Powder samples were prepared for this study using a 400 g

quantity of lumpy kaolin deposits, Nkroful and Amanfrom, which were first

ground using a Thomas grinding machine to break up the agglomerates. The samples

were each further milled for 13 h in a cascading ball mill

using alumina balls to obtain fine powders. These were

sieved through a gradient sieve with aperture size of 63 μm.

The specific surface area of the clay materials was determined

using BET method with a MICROMERITICS ASAP 2010 apparatus.

Fourier transformed infra-red spectroscopy (FTIR) was carried

out with a Shimadzu spectrophotometer (FTIR-8400S) scanning between 4,000 and

500 cm−1. Each clay sample was finely ground in a mortar and then

mixed with potassium bromide (KBr) powder. The powder mixture was put in a

mould and pressed at high pressure to form thin pellets. In order to minimize

the amount of water adsorbed, the pellets were heated in a furnace overnight at

130 ºC.

XRD analyses were performed using a Philips diffractometer

(PANalytical, X’pert Pro MPD model) with a Bragg-Brentano configuration with

voltage of 45 kV and current of 40 mA. The measurement was done at room

temperature using a filtered Cu Kα (λ = 0.15418 nm) radiation and scanning from

10 to 70 degrees with scan speed of 0.042°/sec.

The morphology and microchemical features of the clay

samples were observed with a Field Emission Scanning

Electron Microscope (FE-SEM Philips XL30) equipped

with an energy dispersive x-ray spectroscope. Particles images were obtained

with a secondary detector.

Thermal analyses were carried out with a TGA/DSC apparatus,

SDT Q600 by TA Instruments. 15 mg of solid samples were

heated over the temperature range from ambient to 1,000 oC at a

heating rate of 5 oC/min in air atmosphere with a 100 mL·min-1

flow rate. Samples were analyzed in alumina crucibles and the reference was an

empty alumina pan.

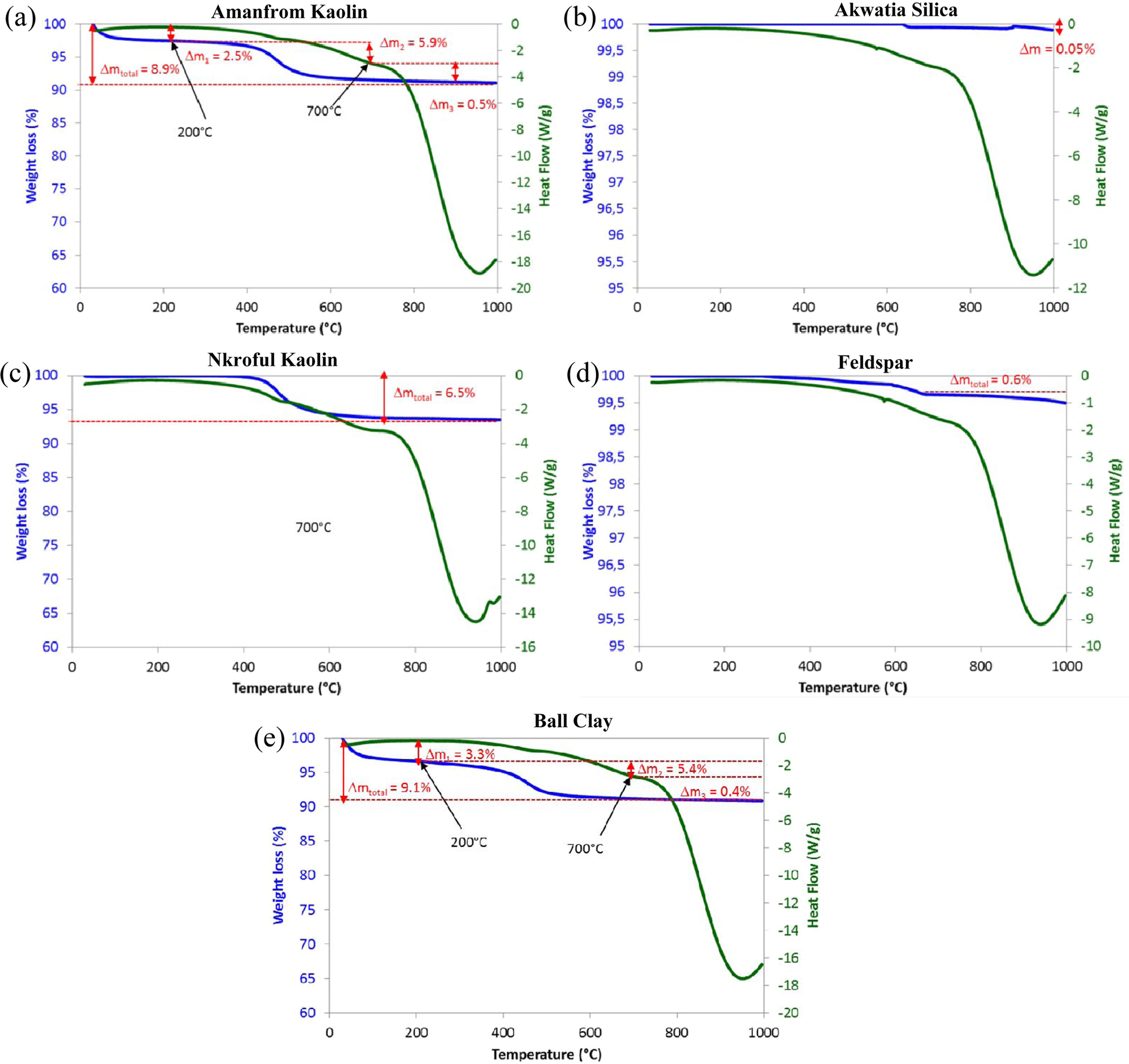

The results for the TGA/DSC curves for all the samples

(AK, BC, & NK, AF, and AS) are given in Fig. 1 for the temperature range

0-1000 oC. As evident in the TGA/DSC peaks, there is some

weight losses observed in the samples.

For samples AK & BC,

weight loss occurred in the temperature

ranges of 200-700 oC which are 2.5%, 5.9% & 3.3%, 5.4%

respectively. After 700 oC, the weight loss in AK and BC are

0.5% and 0.4% corresponding to total weight

loss of 8.9% & 9.1% respectively. The difference in mass loss between the

two samples is about 0.2% which is an indication of similar heating pattern

(i.e, AK & BC) as seen in their TGA/DSC curves, while NK gave a total mass

loss of 6.1% at 700 oC. The endothermic peak at 200 oC

indicated the removal of water and other hydroxylated functional groups

attached to the clay minerals. As temperature

is increased to 700 oC, α-β quartz transition occurs without further mass loss which

is in agreement with earlier reports for quartz transitions [29]. For AS and

AF, total weight losses are relatively insignificant compare to the three

kaolinite materials. Additionally, there appears to be an exothermic peak in

all the samples at 980 oC and this is attributed to the

formation of a spinel phase at higher temperatures [17, 26].

|

Fig. 1 TGA/DSC curves for (a) Amanfrom kaolin, (b) Akawtia silica, (c) Nkroful Kaolin, (d) Akyem-Akroso Feldspar and (e) Ball Clay. |

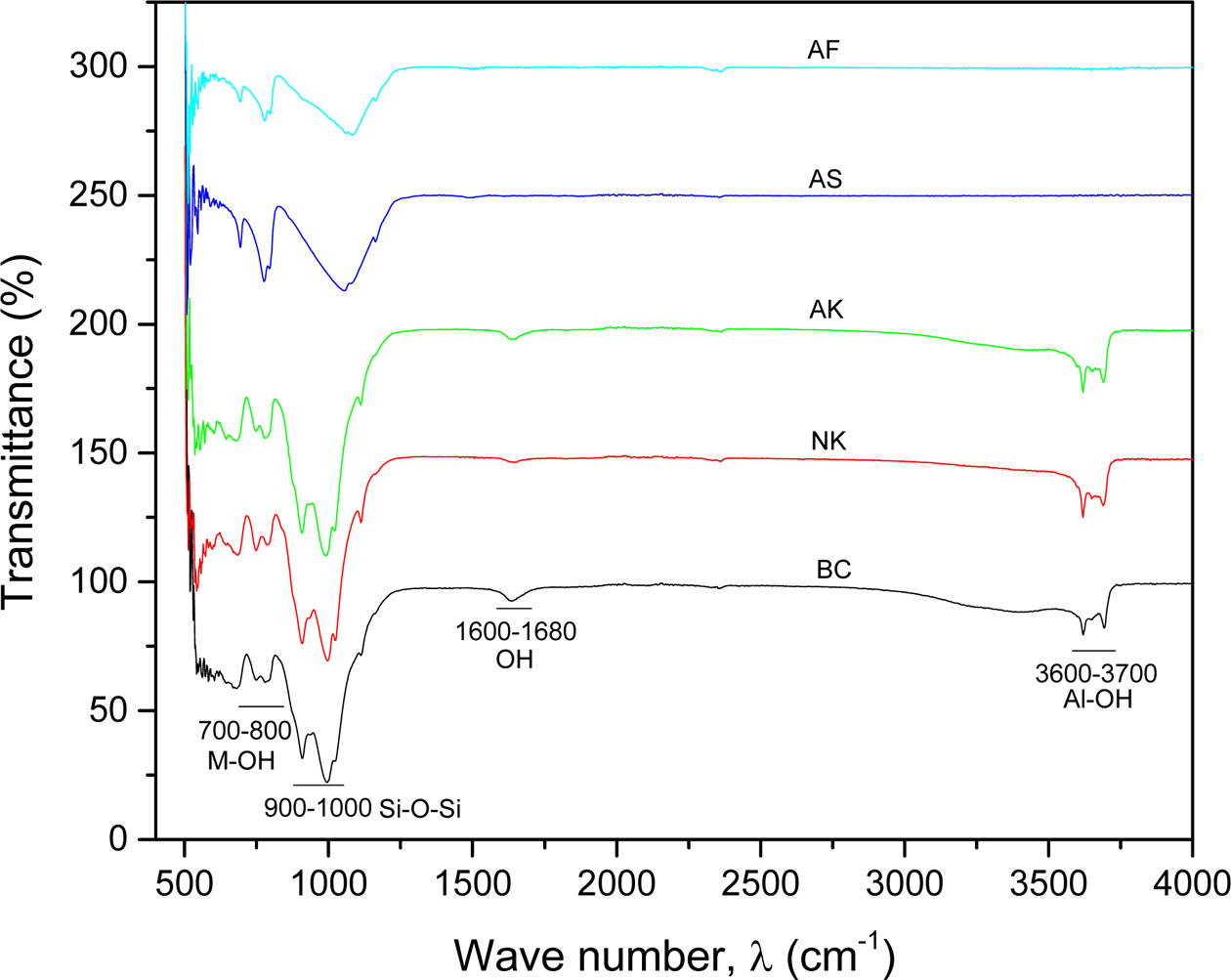

FTIR spectroscopy has been used extensively to

characterize clay and clay based minerals [30, 31]. Fig. 2 is the FTIR for

the various samples used in this study. The stretching and bending vibrations

found in the region of 3,600-3,700 cm-1

and 700-800 cm-1

respectively are due to M-OH groups [32]. Also, the weak band around

1,600-1,631 cm-1

is ascribed to the bending modes of physisorbed water molecules with other OH

groups present in the clay minerals. These stretching and bending vibrations

occurs in all the kaolinites (AK, NK & BC) but not observed in the

silica-based, AS and AF as shown in Fig. 2. The bands around

900-1,000 cm-1

are attributed to Si-O-Si stretching vibrations, see Fig. 2.

Additionally, the appearance of medium intensity bands around

500-650 cm-1 is

attributed to the presence of quartz in all the samples,

(showing intense band for AK and AF). The sharp peaks observed in the spectra

for NK & AK, suggest a well order kaolinite phases in these two clay

samples. The FTIR analysis closely agrees with the studies of S. Mahmoudi et

al. on clay materials from Cameroon [33].

|

Fig. 2 FTIR analysis for Ball clay (BC), Nkroful (NK), Amanfrom (AK), Akwatia Silica (AS) and Akyem Feldspar (AF). |

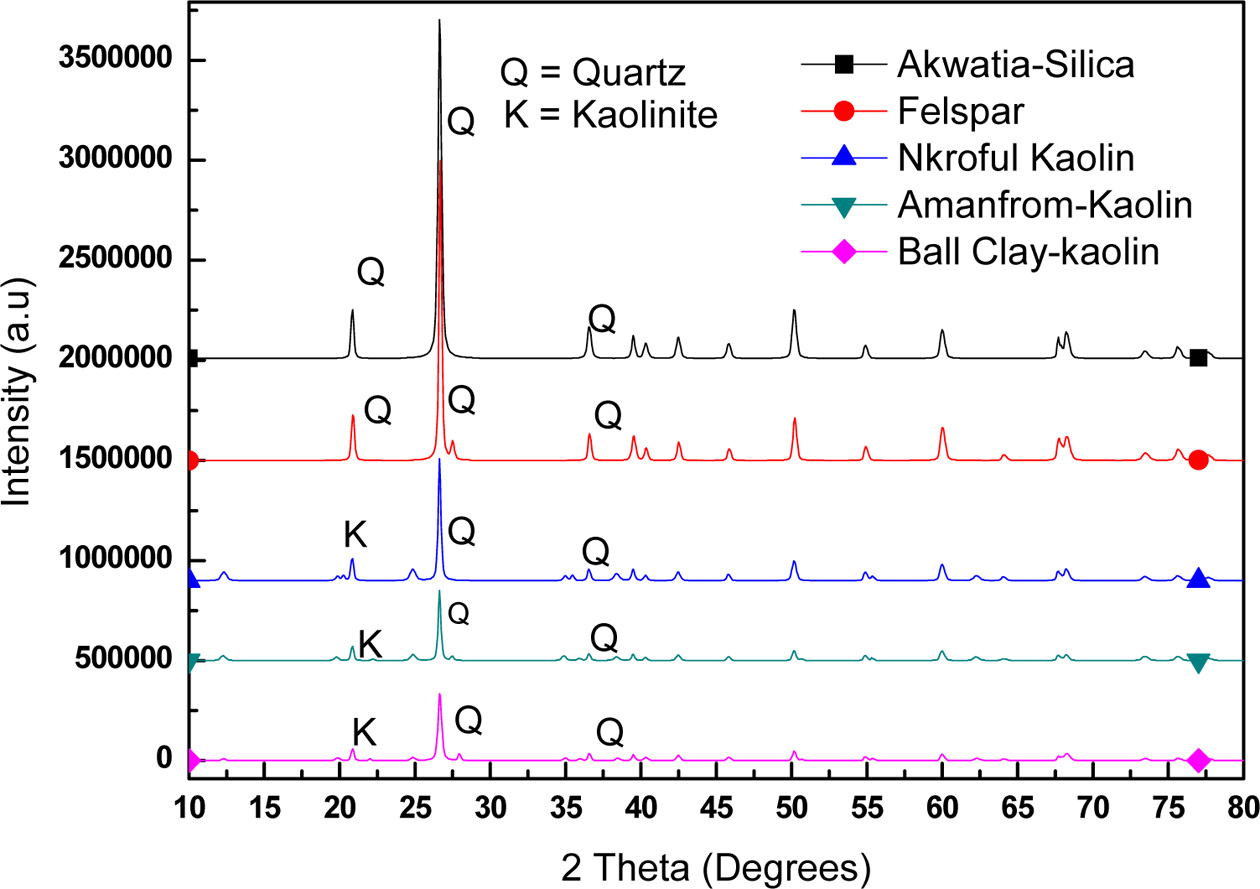

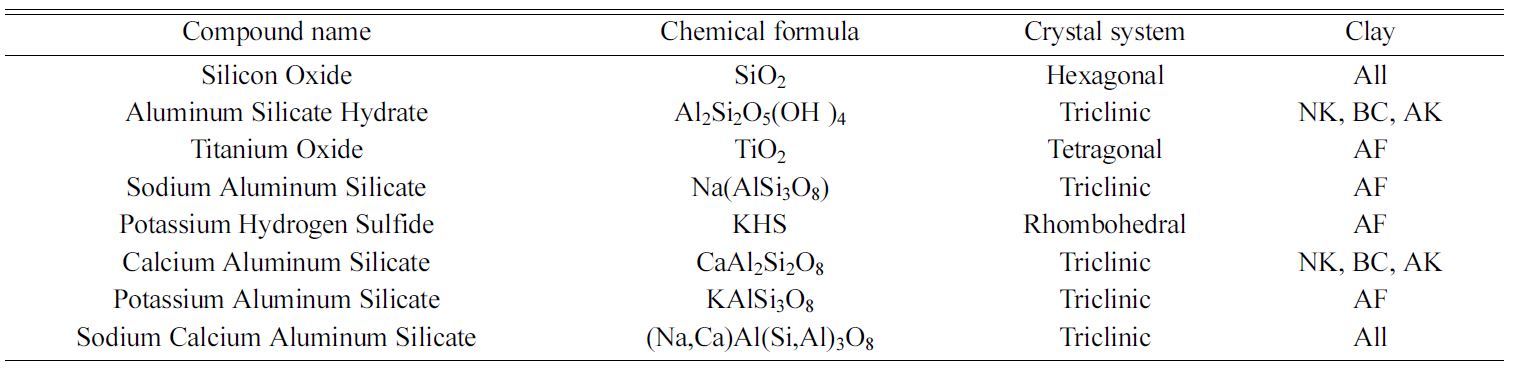

The minerals structure in

clays can successfully be determined through the use of X-ray diffraction. This

can also be used to validate FTIR analysis. XRD was used to identify the

structural phases present in the samples. The XRD patterns for the AS and AF are

very similar with the dominant phase present being SiO2, whereas that of NK, AK and BC

contains Al2Si2O5(OH)4 and Na (Al Si3 O8)

as major components in addition to some traces of SiO2 as shown in

Fig. 3 and also in Table 1. Furthermore, AF was found to contain some traces of

potassium, hydrogen and sulphur suggesting that, it is a potash feldspar (see

Table 1). This also goes to confirm the identification of the stretching

frequencies observed in the FTIR in

which similar vibrations frequencies were found for the three kaolinite groups

at about 3,600-3,700 cm-1 and that of the silica and

feldspar also having same frequency

|

Fig. 3 X-ray diffraction patterns of the various samples. |

|

Table 1 Identified crystalline phases from X-ray diffraction studies on the five (5) clay samples. |

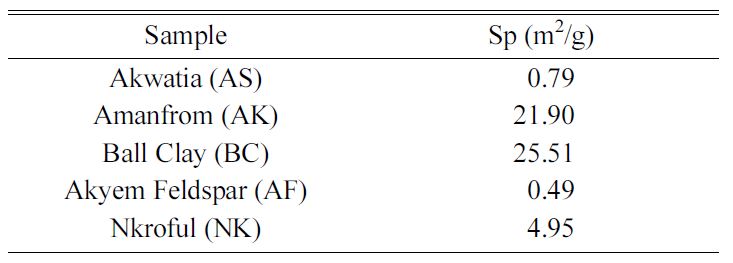

Table 2 shows the BET specific surface area measure-ments for the

various samples. It is clear that, BC has the highest surface area of 25.51 m2/g

which explains why it can absorb large amount of water making it plastic

because of large pore volumes and its finer particle sizes. Similarly, AK has

surface area of about 21.90 m2/g but is not as plastic as ball clay.

Nkroful kaolin has a surface area of 4.9 m2/g making it the least of

the kaolinite groups which becomes hard when dry. The other silica-based have

the least surface area; AF with 0.49 and AS 0.79 m2/g respectively,

which have nearly similar pores and show why they are non-absorbers

and have a larger particle size than the others.

The high specific surface area

of BC and AK can be applied in the areas of wash-coat materials for catalytic converters used in purifying

exhaust gasses from internal combustion engines [30]. The catalyst wash-coat is a

carrier for the catalytic materials, which is used to disperse catalyst

materials over a high surface area. The catalytic materials are suspended in

the washcoat before application to the core body and the washcoat have rough,

irregular surface to increase surface area, which helps to maximize the catalytically active

surface available to react with the

engine exhaust gasses.

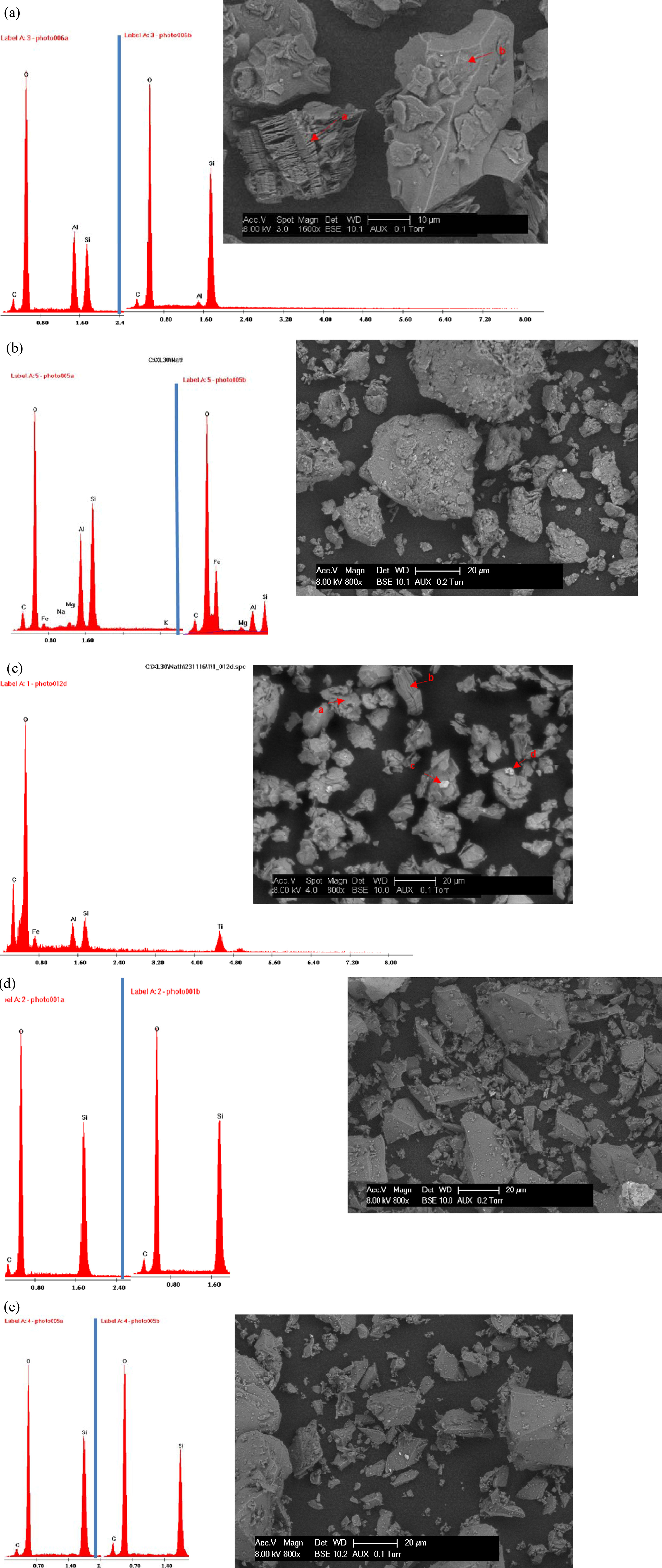

The SEM images and EDX analysis of the samples are given

in Fig. 4. Morphological features show that, NK is made up of well-developed

kaolinite crystals with layered morphology (Fig. 4a). For AK and BC, both show

a relatively porous aggregate morphology. The porous aggregates consist of

stacks of hexagonal kaolinites plates and some individual crystals (Fig. 4b-c).

The EDX analysis of the various peaks also reveals Si & Al as the dominant

elements with some traces of other elements which agrees with the FTIR and XRD

studies reported earlier. On the other hand, AS and AF show a platelet crystals

with their characteristic EDS spectra (see Fig. 4d-e) giving Si as the most

dominant elements which is in agreement with the FTIR and XRD studies. The high

silica content in AS and AF can be exploited by heating the samples in the

presence of a carbon source in an inert or vacuum chamber at high temperatures

to form silicon carbide [31]. Since SiC has good oxidation, wear

resistance, high hardness and thermal stability it can be used as protective

coatings on ceramic components in the aerospace industry [32] and as diesel

particulate filter [33].

|

Fig. 4 Scanning electron microscopy images with resolution of 20 μm and EDX spectra for; (a) Nkroful kaolin, (b) Ball clay, (c) Amanfrom, (d) Akwetia silica and (e) Akyem feldspar. |

In this work five types of Ghanaian clays have been evaluated

for their potentials in; diesel particulate filters, electroporcelain

insulators and catalytic converters. Different characterization

techniques such as XRD, SEM equipped with EDX, BET, FTIR and TG-DTA were used

extensively to study the clay samples from different locations in Ghana. XRD

patterns showed the presence of quartz as the dominant phase in all the samples

examined whilst the EDX confirmed the presence of silicon and

aluminium as the major elemental compositions. These

characterisations have revealed very important features of these minerals that

could be tailored towards specific industrial applications.

All authors declare no conflicts of interest in this

paper.

- 1. A. Yaya, E.K. Tiburu, M.E.Vickers, J.K. Efavi, B. Onwona-Agyeman, and K.W. Knowles, Appl. Clay Sci. 150 (2017)125-130.

-

- 2. J.H. Choy, S.J. Choi, J.M. Oh andTaeun Park, Appl. Clay Sci. 36 (2006) 122-132.

-

- 3. M.J.Wilson, J. Chem. Ecol. 29 (2003)1525-1547.

-

- 4. R.E. Ferrell, Clays Clay Miner. 56(2008) 751-760.

-

- 5. J.M. Hunter, Geogr. Rev. 63 (1973)170-1953.

-

- 6. M.I. Carretero, Appl. Clay Sci. 21(2002) 155-163.

-

- 7. R.B. Asamoah, E. Nyankson, E.Annan, B. Agyei-Tuffour, J.K. Efavi, K. Kan-Dapaah, V.A. Apalangya, L.N.W.Damoah, D. Dodoo-Arhin, E.K. Tiburu,S.K. Kwofie, B. Onwona-Agyeman, and A. Yaya, Orient. J. Chem. 34 (2018) 4.

-

- 8. C. Aguzzi, P. Cerezo, C.Viseras, and C. Caramella, Appl. Clay Sci. 36 (2007) 22-36.

-

- 9. M.I. Carretero and G. Lagaly,Appl. Clay Sci. 36 (2007) 1-3.

-

- 10. C.S.F. Gomes and J.B.P. Silva,Appl. Clay Sci. 36 (2007) 4-21.

-

- 11. F. Tateo and V. Summa, Appl. Clay Sci. 36 (2007) 64-76.

-

- 12. C. Viseras, C. Aguzzi, P.Cerezo et al., Appl. Clay Sci. 36 (2007) 37-50.

-

- 13. F. Veniale, A. Bettero, P.G.Jobstraibizer et al., Appl. Clay Sci. 36 (2007)141-147.

-

- 14. M. Ghadiri, W. Chrzanowski,and R. Rohanizadeh., Roy. Soc. Chem. Adv. 5 (2015) 29467-29481.

-

- 15. N. An, C. Hui, X. Yu et al.,Appl. Clay Sci. 114 (2015) 283-296.

-

- 16. I. Aksu, E. Bazilevskaya, andZ. T. Karpyn, Geo. Res. J. 7 (2015) 1-13.

-

- 17. M.I. Carretero and M. Pozo,Appl. Clay Sci. 46 (2009) 73-80.

-

- 18. M.H. Kim, G. Choi, A.Elzatahry, A. Vinu, Y. Bin Choy, and Jin-Ho Choy, Clay and Clay Minerals 64[2]2016 115-130.

-

- 19. X. Liang, J. Han, and Y. Xu,Geoderma, 235-236 (2014) 9-18.

-

- 20. H.H Murray, Clays, and ClayMinerals 10[1] 1961 291-298.

-

- 21. H.H. Murray, Appl. Clay Sci.17 (2000) 207-221.

-

- 22. H. Celik, Appl. Clay Sci. 50(2010) 245-254.

-

- 23. P. Melgarejo, J.J. Martínez,F. Hernández, R. Martı́nez-Font, P. Barrows, and A. Erez,Sci. Hortic. (Amsterdam) 100 (2004) 349-353.

-

- 24. C. Volzone, Appl. Clay Sci. 36(2007) 191-196.

-

- 25. E.K. Tiburu, B.W. Kankpeyeng,S.N. Nkumbaan, A. Salifu, and J. Q. Zhuang, J. Biomimetics, Biomater. Biomed.Eng. 30 (2017) 45-60.

-

- 26. E. Annan, B. Agyei-Tuffour, Y.D. Bensah, D.S. Konadu, A. Yaya, B. Onwona-Agyeman, and E. Nyankson, CogentEngineering 5 (2018) 1476017. https://doi.org/10.1080/23311916.2018.1476017.

-

- 27. J. Santaren, E. Ruiz-hitzky,P. Aranda, A. Antonio, and A. Esteban, Development in Clay Science 3 (2011)393-452.

-

- 28. G.I.E. Ekosse, Appl. Clay Sci.50 (2010) 212-236.

-

- 29. A.N. Duowona, E. Nyankson J.K.Efavi, L.N.Damoah, E. Tiburu, D.Dodoo-Arhin, V. Apalangya, T. Tomychiek, and A.Yaya, Journal of Ceramic Processing Research 19[2] (2018) 95-100.

- 30. B. Onwona-Agyeman, R. Suzuki,H. Yano, and H. Tomoda, SAE Int. J. Engines 1[1] (2008) 1341-1346.

-

- 31. P.D. Miller, J.G. Lee, and I.B. Cutter, J. Am. Cer. Soc. 62[3-4] (1979) 147-149.

-

- 32. B.S. Sung and Y. H. Yun,Advances in Materials Science and Engineering (2017).

-

- 33. A. Itoh, K. Shimato, T. Komoriet al., SAE Transactions 102[3](1993) 505-513.

This Article

This Article

-

2020; 21(1): 35-41

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.35

- Received on Jul 12, 2019

- Revised on Nov 18, 2019

- Accepted on Nov 22, 2019

Services

Services

- Abstract

introduction

materials and methodology

results and discussions

conclusion

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- A. Yaya

-

Department of Materials Science & Engineering, School of Engineering Sciences, University of Ghana, Legon, Ghana

Tel : +233559278551 - E-mail: ayaya@ug.edu.gh

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.