- Process parameters and properties of electric resistance spot welded AISI304-AISI1020 dissimilar weldments

Mathi Kannaiyana, Jinu GowthamiThankachi Raghuvaranb,*, Karthikeyan Govindanc and Elaya Perumal Annamalaid

aAssistant Professor, Department of Mechanical Engineering, University College of Engineering, Kancheepuram, Tamil Nadu

bAssistant Professor, Department of Mechanical Engineering, University College of Engineering, Nagercoil, Konam, Tamil Nadu

cAssistant Professor, Department of Mechanical Engineering, University College of Engineering, Pattukkottai, Rajamadam Tamil Nadu

dResearch Scholar/SRF (UGC), Department of Mechanical Engineering, University College of Engineering, Nagercoil, Konam, Tamil Nadu

In this present work, an

attempt was made on optimising the Resistance Spot Welding (RSW) process

parameters for joining two dissimilar combinations of AISI 304 and AISI 1020

grade steel with each other. Experiments were conducted by varying the three

weld process parameters such as welding current, pressure and welding time. The

integrity of the weld joints was evaluated mechanically and metallurgically.

Tensile shear fracture, nugget diameter, and hardness properties were examined.

Macrostructure, Microstructure, and Scanning Electron Microscopy (SEM) analysis were carried out on the tested

samples to validate the type of fracture occurred. Maximum nugget

diameter and maximum tensile fracture of 6.666 mm and 10.5 kN were achieved

respectively. The experimental results confirmed the validity of the used

Response Surface Methodology applied for optimising the welding process

parameter in the RSW process. The Response Surface Methodology (RSM) results

show that the weld current is the most significant factor for Tensile Shear

Fracture Load (TSFL) and nugget diameter, followed by weld pressure and time.

Keywords: Resistance spot welding, Tensile shear fracture, Nugget diameter, Response surface methodology

The RSW process is widely used for joining sheet metals in

automobile sectors due to the increase in the demand for

welding. In automobiles industries fabrication of sheet

metals are ideally suited for mass production due to inexpensive and effective

way to join metal sheets [1, 2]. In RSW process the two sheet metals are joined

in the form of a spot or continuous faying method. The process

of joining the sheet can be completed in three stages namely squeeze time, weld

time/heating time and hold time. In this welding process a

substantial electric current is allowed to flow on the sheets which

are placed together, and pressure is applied with the help of two copper

electrode tips. Due to the flow of welding current against the sheets, the

resistive path is generated at the area to be joined, which creates localized

heating. When the flow of current is stopped, it gets solidify to join the

sheets. The efficiency of the joints was based on the weld process parameters

such as welding current, welding time as well as electrode pressure between the

two water-cooled copper-based electrodes [3]. Vuril et al. investigated

the effect of nugget diameter on mechanical and metallurgical properties of galvanised steel and AISI304 welded lap joints

[4]. Bouyousfi et al. [5] carried out experiments to investigate the

effect of spot welding process on mechanical characteristics of AISI 304

similar joints. They revealed that

the applied load is a major controlling

factor for the mechanical characteristics of weld joint compared to the welding

duration and current intensity of welding. Oscar Martin et al. [6]

carried out spot welding on

austenitic stainless steel(304), and the results revealed that the tensile shear load bearing capacity (TSLBC) increased

initially by increasing weld time and weld current, but when the pressure

increases continuously the TSLBC was decreased. Yoon et al. [7]

identified the optimal weld process parameters for spot welding of AA7075- T6

aluminium alloy sheets using Taguchi method. They found that Electrode force

1323 N, Welding current 14 kA, Welding time four cycles is the optimum process

parameter for obtaining higher tensile shear strength.

Austenitic stainless steel and low carbon steel possess

an excellent combination of mechanical properties, formability, weldability and

corrosion resistance. This combination of steels is extensively used in the

marine industry [8, 9]. Stainless steel is an iron-based alloy having

excellent corrosion resistance due to the passive films on the surface

[10, 11]. This type of materials is used in

several applications due to its superior properties such as high

corrosion resistance, good toughness, high energy absorption, weldability, and

high strength [12]. Stainless steel has been widely used in automotive and aerospace

industries due to its higher corrosion resistance and

workability [13, 14]. Jae Hyung Kima investigated the impact of weld input

process parameters like weld time and current of resistance spot welding with

output responses like tensile strength and nugget diameter on Low Carbon and

High strength Low Alloy (HSLA) Steel [15]. Dawei Zhao [16] investigated the

effect of the specific transition resistance on sheet-sheet contact. They

revealed that the sheet to sheet contact posses ten times higher specific

transition resistance than between electrodes to sheet contact. They also

concluded that the local contact temperature is the most significant

influencing factor for the specific transition resistance. Aslanlar et al.

[17] analysed the effect of variation in dynamic resistance across electrodes

for the nugget growth by varying the RSW parameters such as

electrode force and welding current. They identified that for

higher weld, current and electrode force improves the rate of nugget growth.

From the literature survey, it is identified that several

researchers have shown a keen interest in resistance spot welding process for

welding of various similar and dissimilar joints using duplex

stainless steel, HSLA steels, AA 7075. The various mechanical and

metallurgical investigations were also carried out on the resistance

spot-welded joints based on its applications. No work was carried out for

identifying the optimum RSW process parameters in welding of AISI 304 and AISI

1020 dissimilar joints.

Therefore in this work, Electrical Resistance spot welding

of single lap joint was carried out on AISI 304 and AISI 1020 materials by

varying the weld process parameters such as welding power, welding pressure and

weld time. The various mechanical tests, such as tensile shear fracture and

hardness, were conducted on the welded samples to find the relationship between

weld input process parameters and the resulting weld nugget strength. In this

work RSM was used to predict the tensile shear strength/failure modes of welded

joint at various RSW process parameters.

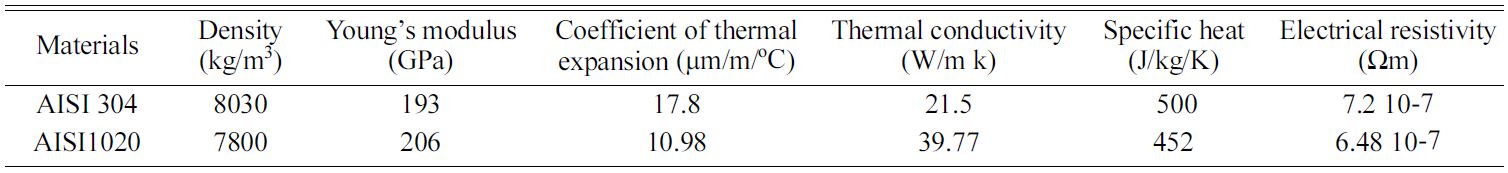

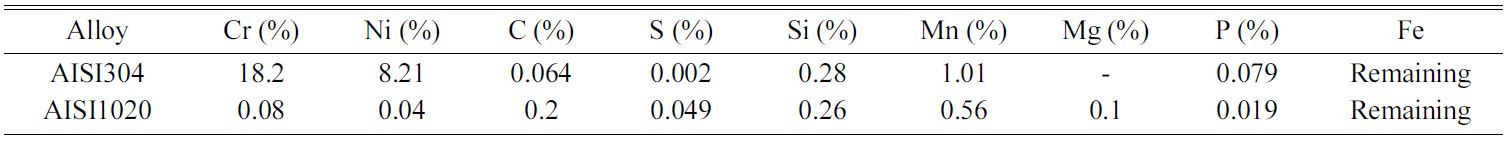

In this work AISI 304 with chromium as an alloying element

and AISI 1020 with manganese as an alloying element of

1.5 mm as thickness were used in this present investigation

as shown in Fig. 1(a) and (b). The mechanical, thermal

properties and chemical composition of these alloys are given in Table 1 and 2.

The joining of metal sheets was carried out in Resistance spot

welding machine with the configuration of pedestal type

inverter base and medium frequency DC machine (Model PACI TECH-ERSW) of

capacity 90 kV. It has the flexibility of welding sheets up to 6 mm thickness

with a maximum current of 20 kVA capacities shown in Fig. 1(c). The electrode

used in this welding consists of a shank of diameter 16 mm with a conical cap

having a tip diameter of 5 mm shown in Fig. 1(d), which is made up of Cu-Cr-Zr

alloy and is water-cooled during the welding process. The electrodes are made

to hold the sheet specimens under pre-determined pressure, and at that time the

current is passed through it, to fabricate the joints. Three process parameters

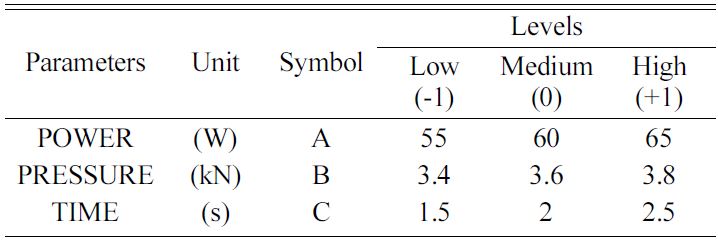

with three levels of experiments were selected as given in Table

3. The welded samples are shown in Fig. 1(e). The tensile

shear test was conducted on the welded samples as per the

ISO14273 standards. The width of the samples is

calculated as 41.285 mm, and it was rounded to 42 mm by using the equation

w ≥ wcr = 13:4 + 18:59 t (1)

The nugget diameter was measured by a digital calliper.

Investigating the weld nugget resistance was carried out with the help of

computerised Micro Vickers hardness tester under the application of load 200

gms for 15 seconds of dwell period. The optical system, which is used for

measuring of nugget zone, has a range of 200 µm at 0.01 µm of resolution by a

light source of 12 V/20 W ARTRAY Camera.

For microstructural analysis, the welded samples were

polished by different grit papers and etched to reveal microstructure. A Carl

Zeiss Ultra Plus Gemini FESEM model SEM was used to characterise the weld zones

of the welded samples.

|

Fig. 1 (a) base metal specimen, (b) specification of base metal, (c) resistance spot welding machine, (d) copper electrode, and (e) welded specimen. |

Heat input is one of the main criteria for obtaining the

efficiency of the joint. Also, the capability is based upon the differences in

the melting temperature of the two dissimilar metals. The adequate heat

generation depends on the variation of the three parameters. (1) The current,

(2) the resistance of the conductor and (3) the duration of the current. The required

heat generated through the electrical resistance of the two bodies to be joined

specified in Eq. (1) [18, 19].

Q = I2Rt (2)

where t = Time to current flow

in -s

I = Current in-

A

R = Electrical

resistance in- ohm

Q = Heat

generated in- J

According to Joule's law as welding current decreases

with increasing electrical resistance and induction of constant second voltage.

When heat input is increased weld nugget also increased similar reports were

identified in [19-22].

Based on previous literature’s and by conducting

feasibility weld trials, it is identified that the most influencing process

parameter for RSW process is power, pressure and weld time. Similarly, from the

feasibility study the range of parameters were identified

to obtain defect-free joints. The selected weld process parameters and their

levels are listed in Table 3, by applying those values in Box-Behnken

(three-parameter and three levels).

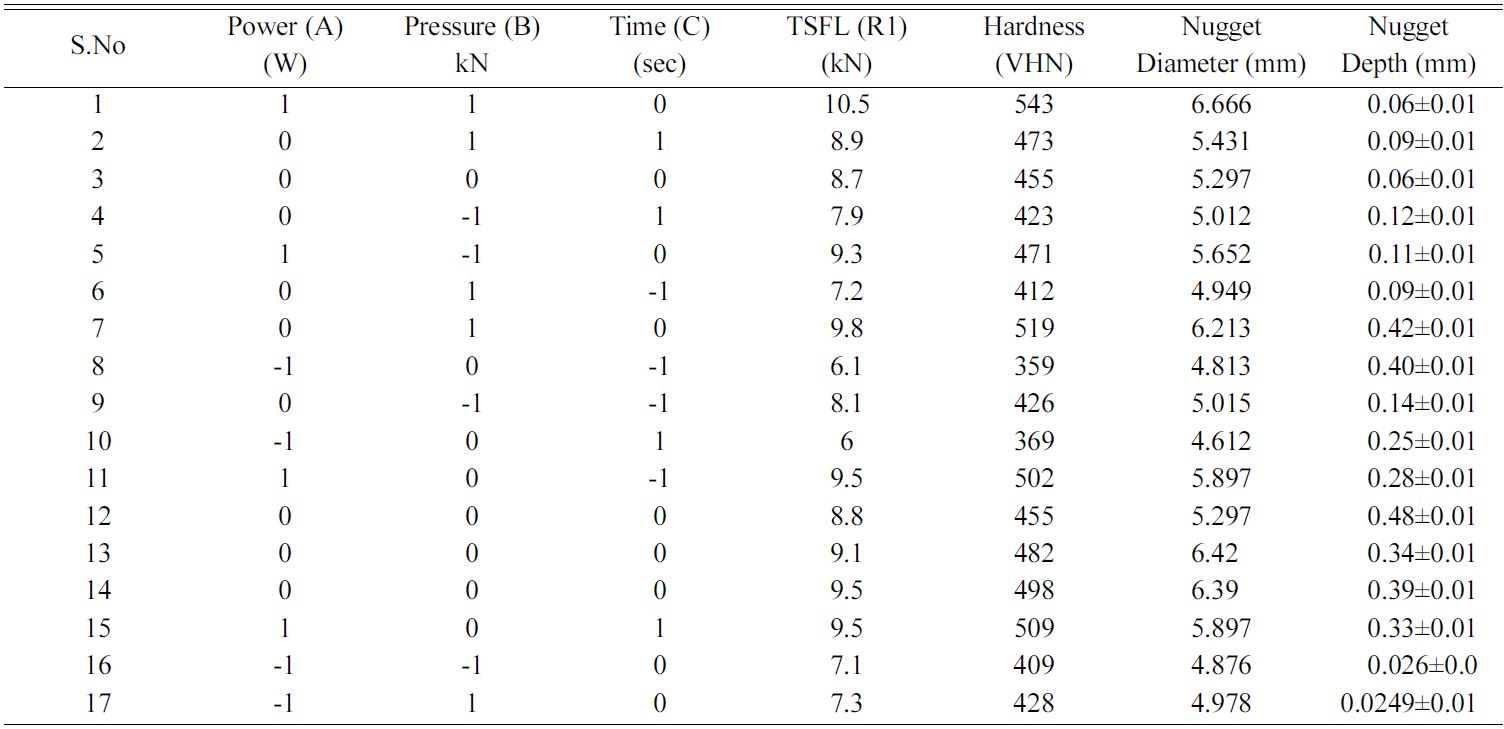

The 17 combinations of weld process parameters were

collected as given in Table 4; the weld trials were conducted. From the welded

samples the TSFL and hardness test was carried out, and the results are given

in Table 4. The nugget diameter and depth was also measured and given in Table

4.

From the Table 4, it is identified that the maximum TSFL

of 10.5 kN and hardness 543 VHN was obtained for the joint welded at the power

of 65 watts, the pressure of 3.8 kN and the weld time of 2 seconds. The main

parameter in this research is the nugget diameters which decide the joint efficiency,

and it is measured by a video measuring instrument, and the results are

tabulated in Table 4. The maximum efficiency of the joint depends on increasing

the weld time and current. The nugget diameter is varied from 4.612 mm to 6.666

mm. This varied nugget diameter will affect the change in tensile shear

fracture [23].

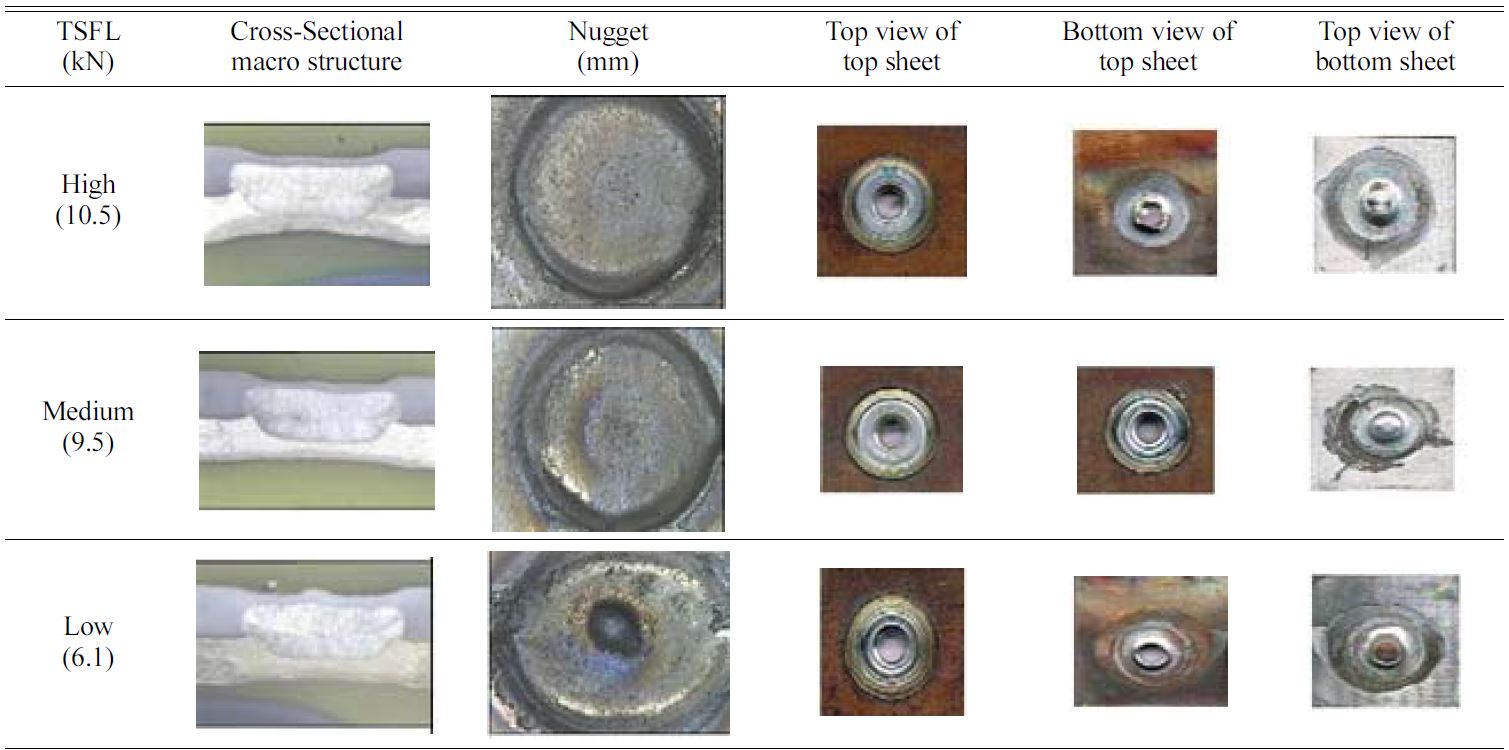

In resistance spot welding, the pressure and current

applied on the lap joined metals and which will attain molten metal and

solidified into nugget after quick cooling. The low, medium, high TSFL values

obtained samples are subjected to macro-structural evaluation, and the

corresponding macro images are given in Table 5. Vural and Akku [4] also

reported that the heat input increases with increasing weld time and current

the varied macrostructure which are shown in the figures and presented in Table

5. reveal that the shearing and tearing occurred on the welded joints.

|

Table 5 Macrostructure evaluations for Resistance spot welded Joints at high, medium and low levels. |

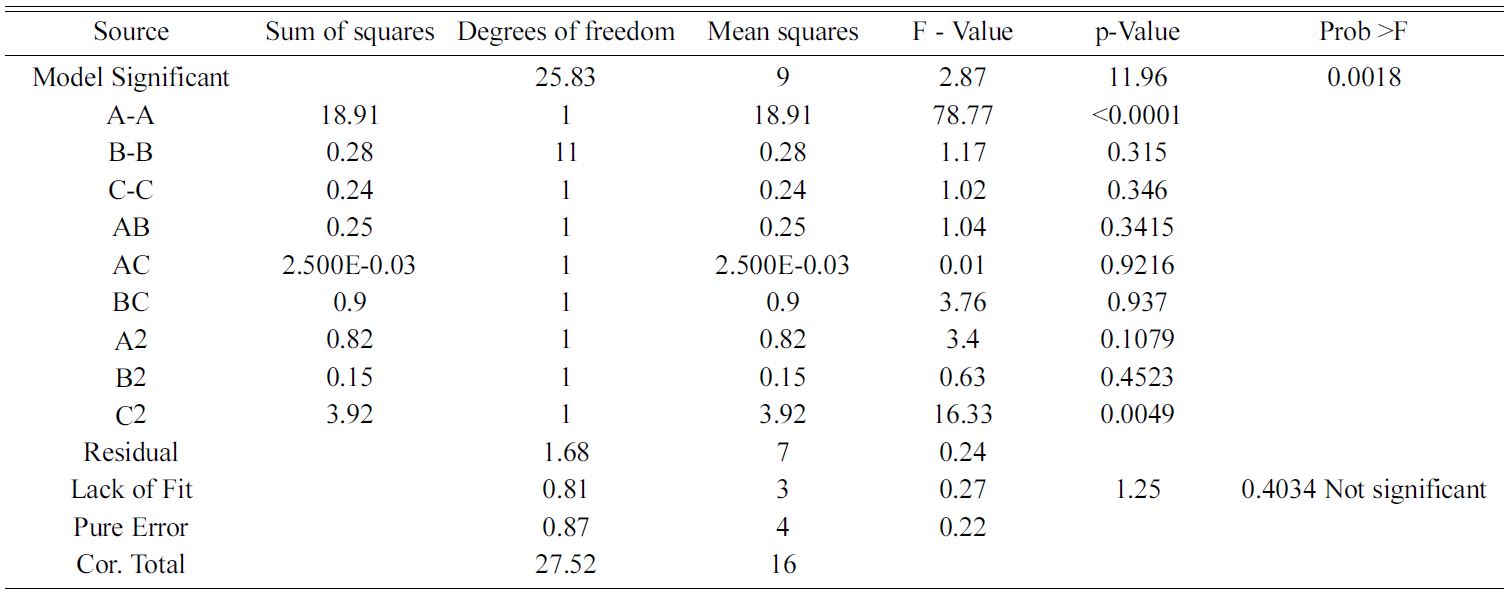

In order to identify the influence of weld process

parameters on the quality of weld joints. It is necessary to find out the

optimal condition of process parameter levels, which were done with the help of

ANOVA. ANOVA was performed based on the experimental data at a confidence

interval of 95%. The obtained results from the ANOVA analysis are given in

Table 6. From Table 6, it is identified that the model P-value of 11.96 implies

that the model is an important one. Similarly, the R- squared value of 0.9389

and the adjacent R squared value of- 0.8304 reveal the same results. From Table

6, it is identified that the weld current is the most significant factor for

TSFL and nugget diameter, followed by the weld pressure. Weld time is the least

significant factor for the above output parameters.

|

Table 6 ANOVA for response surface quadratic model analysis of variance of partial sum of squares type III. |

RSM gives the mathematical relationship between the output

response and the independent variables are unknown [23].

T. Kim et al. [24-29] studied the response surface

methodology by employing it in steel. The second-order model was used in the

resistance spot welding process. The Box-Behnken design was adopted to

formulate a useful regression model. Optimum welding conditions

were determined by desirability approach. Among 17 experimental Runs, 8

Residues lie in the centre and almost all the residue lie in the trend line.

Two outliers present in the normal probability.

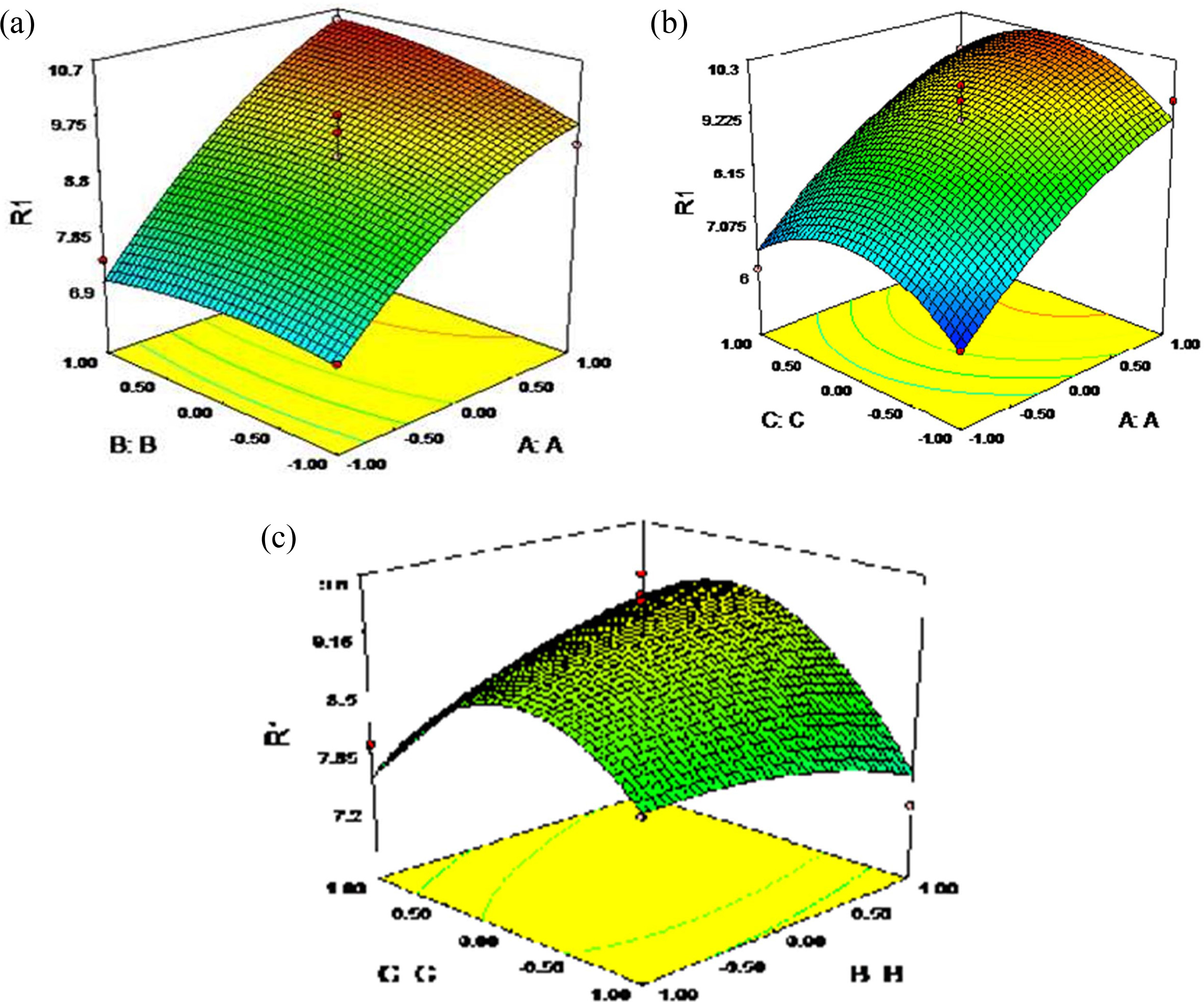

The Response surface of tensile shear fracture load was

obtained for the analysis of the interaction effects. Fig.

2(a), 2(b) and 2(c) show that, when there is an increase in factor A and B,

there will be an increase in 10.5 kN. Fig. 2(a), 2(b) and 2(c) also show that

the peak value is attained during higher A and higher B. At lower and higher

levels of A and C shows dip in the response, whereas in the middle level of A

and C, Steep increase of response as noticed. It is due to Peak Value as

attained in the highest level of A and middle level of C. In the middle level

of B and C, Maximum Response is obtained.

|

Fig. 2 Three dimensional plot for the resistance welding parameter with TSFL as response. |

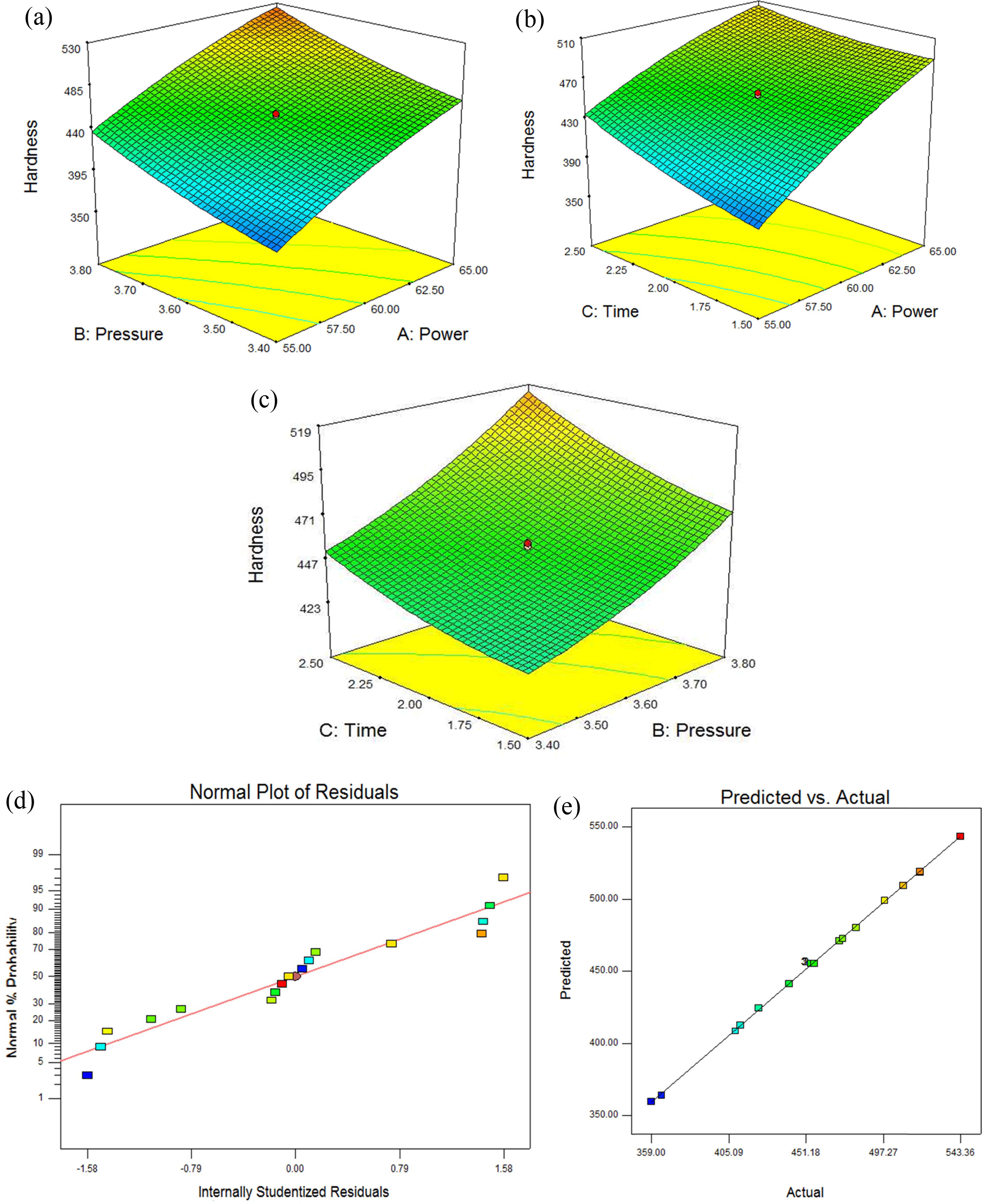

The interaction of hardness values is plotted in Fig.

3(a), (b) and (c). The similar results were obtained for the response plots for

hardness. After the regression model of shear tensile strength and hardness was

developed, the model adequacy examination was performed

in order to substantiate the regression analysis. Fig. 3(d) shows the standard

probability plot of the residual shows the proper sign and the experimental

values are very closer to the straight-line pattern. It is concluded that all

the data’s are normally distributed and the final response equation to predict

the tensile shear strength (R1) is depicted as follows in Eq. (2)

R1 (TSFL) = +9.18+1.54 * A+0.19 * B+0.18

* C+0.25 * A * B+0.025 * A * C+0.47

* B * C-0.44 * A2-0.19 * B2-0.96 * C2

(3)

Fig. 3(e) demonstrates the relationship between the

predicted and experimental values for shear, tensile strength which indicates

that both the results are very closer to the straight-line pattern.

|

Fig. 3 (a), (b) and (c) The distinct relation among hardness on pressure, power, time. (d) and (e) Normal plot for predicted and actual values. |

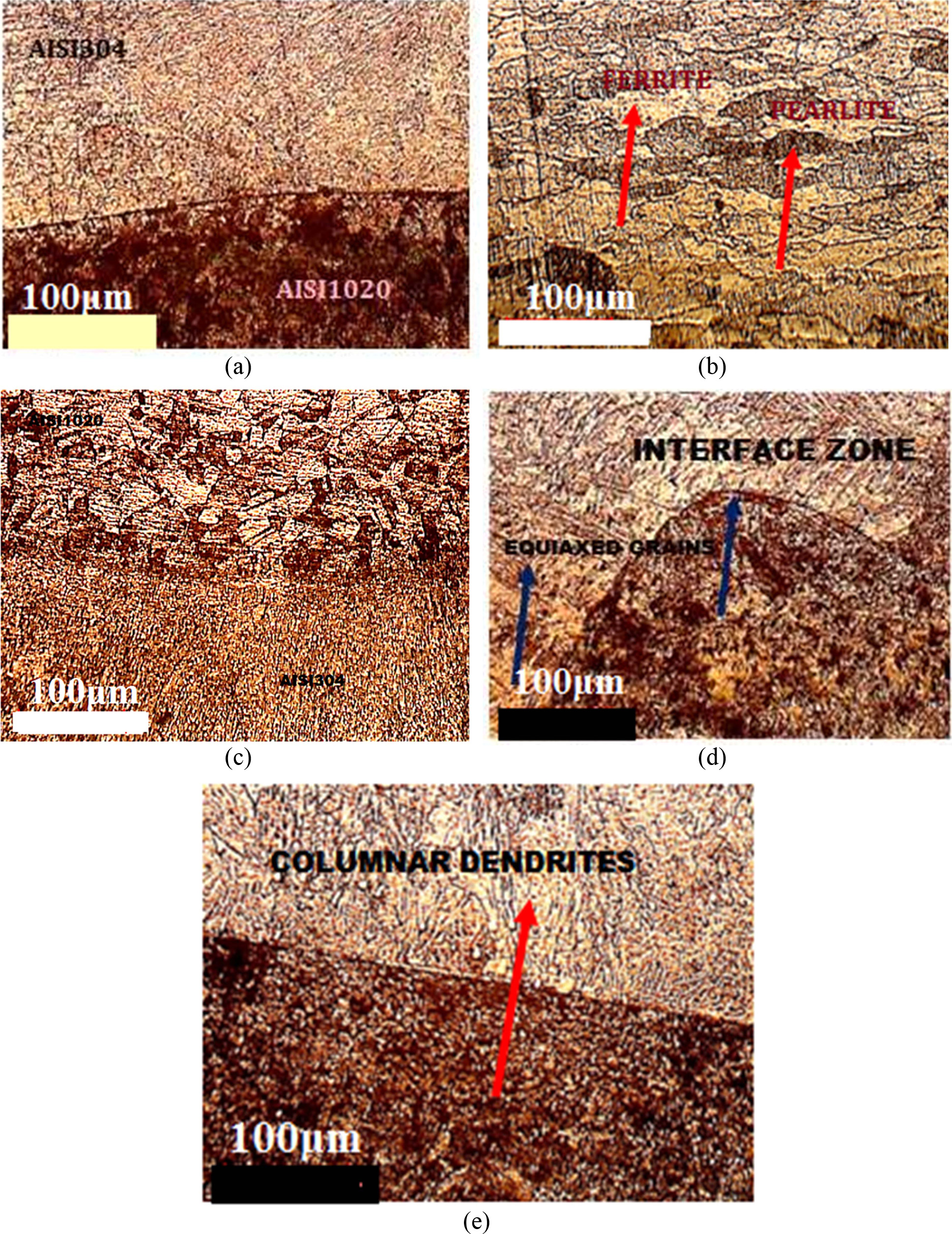

The interfacial zone of AISI 304 and AISI 1020 are shown

in Fig. 4(a), which reveals the fabricated

joints were highly inhomogeneous solidification mode. Fig. 4(b)

shows the interfacial zones of fabricated resistance-welded AISI

304 and AISI1020 materials. It can be observed that the zones consist of coarse

austenite and ferrite modes of solidification occurred. In addition to that

presence of high chromium content in AISI 304 promoted more ferrite content.

The substrate was marginally melted and re-solidified however unmixed where

higher ferrite was examined as shown in Fig. 4(c). The temperature on the

interface reached near to melting point attributed a formation of dendrite

ferrites on the interfacial zone. These dendrite ferrites were almost normal to

each weld interface as presented in Fig. 4(d) because the heat flow takes place

in the same direction in each welding pass. However, when moved to weld

centerline, the temperature gradient was fewer consequences

equiaxed dendrites into columnar dendrites. The visual

appearance of columnar dendrites at the centerline of the weld is as presented

in Fig. 4(e).The flow of elements of AISI 304 in the form of grains is

transferred.

|

Fig. 4 Scanning Electron Microscope images of resistance spot welded joints. |

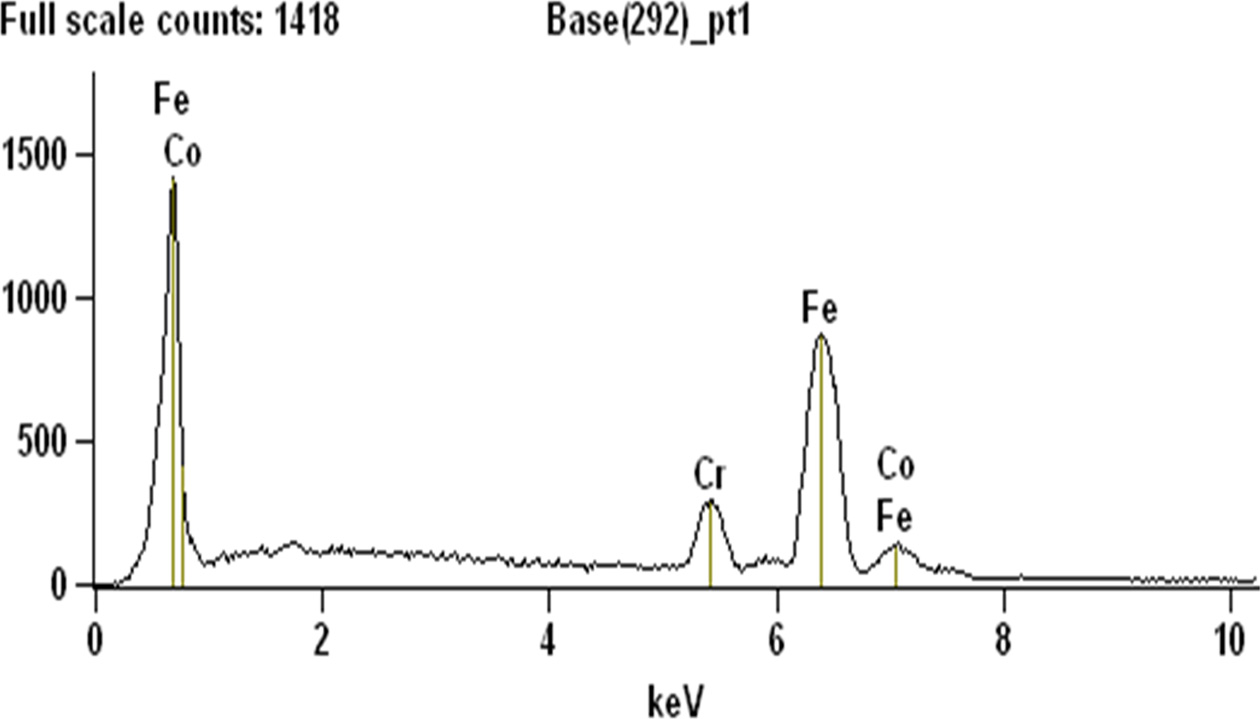

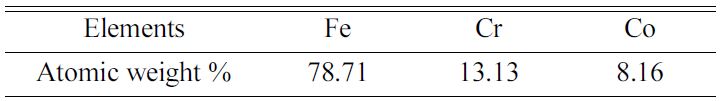

Fig. 5 shows the EDS graph which concluded that the mild

steel has highest scale counts and there is no rise in counts of mild steel

before 1 keV, but after the 1 keV there is a drastic change in the rise of

scale counts of AISI 304 elements. Also the presence of all elements which in

the form of the weight of all atoms present and net counts of all the atoms

present in the specimen [30]. Amount of atoms present in the

specimen after the spot welding also listed by the application of

EDX. The presence of chromium of about 13.13% and Fe content of 78.71% as shown

in Table 7.

|

Fig. 5 EDS plot for the spot welded sample. |

Based on the objective of this work RSW process was used

for welding of AISI 304/AISI 1020. From the Box-Behnken analysis was carried

out for ANOVA and RSM models were developed for identifying the

optimal parameter to study the most influencing parameter.

From this study, the following conclusions were drawn

accordingly.

The TSFL values recorded in different parameters such as

pressure, time and welding current. The highest values of TSFL is 10.5 kN and

the hardness of AISI 304-AISI 1020 combination is 543 VHN. The nugget diameter

and Tensile strength are proportional to weld time, pressure and current. With

the increase in heat input during welding, the shear -

tensile strength increases within the adequate weld range due

to the enlargement of nugget size.

From the RSM, it is identified that the nugget diameter and tensile strength are influenced by weld

current, followed by time and weld pressure.

The microstructural studies reveal that the welded joints

are in high in homogeneous solidification mode. The weld zone consists of

coarse austenite and ferrite mode, and similarly the presence of high chromium

content in AISI304 promotes the formation of ferrite content.

The chemical characterisation and elemental analysis of

certain samples were welded at optimum condition are executed by EDX analysis,

which shows that the presence of iron, chromium and cobalt in the spot-welded

joints.

- 1. H. Zhang, F. Wang, T. Xi, J.Zhao, L. Wang, and W. Gao, Mechanical System and Signal Processing.,62-63 (2015) 431-443.

-

- 2. P.De Tiedra, Ó. Martín, and M. López, Corrosion. Sci. 53 (2011) 2670-2675.

-

- 3. JanVinas, Lubos Kascak, and Miroslav Gres, De Gruyter Open. 6[1] (2016) 504-510.

-

- 4. M.Vural, A. Akkus, and B. Eryurek, Journal of Materials Processing Technology 176(2006) 127-132.

-

- 5. B.Bouyousfi, T. Sahraoui, S. Guessasma, and K.T. Chaouch, Materialsand Design 28 (2007) 414-419.

-

- 6. O.Martin, P.D. Tiedra, M. Lopez, M. San-Juan, C. Garcia, F. Martin, and Y.Blanco, Materials and Design 3 (2009) 68-77.

-

- 7. <!--[endif]-->H.-K.Yoon, B.-H. Min, C.-S. Lee, D.-H. Kim, Y.-K. Kim, and W.-J. Park, InternationalJournal of Modern Physics B. 20[25-27] (2006) 4297-4302.

-

- 8. N. Charde and R. Rajkumar, Journal of Engineering Scienceand Technology. 8 (2013) 69-76.

-

- 9. M.Ishak, L.H. Shah, I.S.R. Aisha, W. Hafizi, and M.R. Islam, Journal ofMechanical Engineering and Sciences 6 (2014) 793-806.

-

- 10. T.K. Mori, T.Masachika, E. Yamazaki, and Y. Watanabe, Journal of Material Processing andTechnology 143-144(2003) 242-248.

-

- 11. N.Kahraman, B. Gülenç, and H. Akça, Journal of the Faculty of Engineering andArchitecture of Gazi University 17 (2002) 75-85.

-

- 12. R.Shashanka and D. Chaira, Powder Technology 278 (2015) 35-45.

-

- 13. H.Ma, G. Qin, P. Geng, F. Li, B. Fu, and X. Meng, Materials & Design 86(2015) 587-597.

-

- 14. A.Fattah-Alhosseini and S. Vafaeian, Egyptian Journal of Petroleum.24 (2015) 333-341.

-

- 15. J.H. Kim, Y. Cho, and Y.H.Jang, Journal of Manufacturing Systems 32[3] (2013) 505-512.

-

- 16. D. Zhao, Y. Wang, S. Sheng,and Z. Lin, Measurement 46[6] (2013) 1957-1963.

-

- 17. S. Aslanlar, A. Ogur, U.Ozsarac, E. Ilhan, and Z. Demir, Materials & Design 28 (2007) 2-7.

-

- 18. L.P. Conner, WeldingHandbook, 8th edition, Vol. 1, P.16, American Welding SocietyMiami, FL, USA (1987).

- 19. A SM Handbook, Welding Brazing and Soldering, Vol.6, P.2062, ASMInternational, Materials Park, OH, USA (1993).

- 20. A.M. Pereira, J.M. Ferreira,A. Loureiro, J.D.M. Costa, and P.J. Bártolo, Materials and Design 31 (2010)2454-2463.

-

- 21. M. Hessamoddin and S.F. Iradj.Journal of Material Processing Technology 212 (2012) 347-354.

-

- 22. Z. Hongqiang, Q. Xiaoming, B.Yang, X. Fei, Y. Haiyan, and S. Yanan, Materials & Design 63 (2014)151-158.

-

- 23. G.Karthikeyan and G.R. Jinu, Transactions of the Canadian Society for MechanicalEngineering 40[3] (2016) 351-369.

-

- 24. K.Danial, M. Amir, and A.A. Ahmad, Materials & Design 61 (2014) 251-263.

-

- 25. T. Kim, H. Park, and S.Rhee, International Journal of ProductionResearch 43[21] (2005) 4643-4657.

-

- 26. A. Şenaras,in “Sustainable Engineering Products and Manufacturing Technologies” (AcademicPress is an imprint of Elsevier, 2019) p.187-197.

-

- 27. S.K. Beheraa, H. Meenaa, S. Chakrabortya, and B.C. Meikapab, International Journal of Mining Scienceand Technology 28 (2018) 621-629.

-

- 28. YongWang, Layun Deng, and Youhua Fan, Advances in Materials Science and Engineering2018 (2018) 1-8.

-

- 29. Shuo Deng, Yinguang Chen,Water Sci Technology, 79[1] (2019) 188-197.

-

- 30. G. Karthikeyan, G.R. Jinu, and P. Vijayalakshmi, Matéria (Rio de Janeiro) 22[3] (2017) 1-12.

-

This Article

This Article

-

2020; 21(1): 26-34

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.26

- Received on Jul 12, 2019

- Revised on Nov 5, 2019

- Accepted on Dec 9, 2019

Services

Services

- Abstract

introduction

experimental procedure

result and discussions

microstructural studies

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jinu GowthamiThankachi Raghuvaran

-

Assistant Professor, Department of Mechanical Engineering, University College of Engineering, Nagercoil, Konam, Tamil Nadu

Tel : +919443994330 Fax: 04652-260510 - E-mail: grjinu1980@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.