- Effects of adding Y(NO3)3·6H2O on the phase change behavior and thermal conductivity of Aluminum Nitride ceramics

Jun Ki Chunga,*, Seongmin Jub and Tae Kwon Haa

aCenter for Industrial Technologies of Non-Ferrous Metals, Gangneung-wonju National University, Gangneung 25457, Korea

bSchool of Electrical Engineering and Computer Science, Gwangju Institute of Science and Technology, Gwangju 61005, Korea

The phase change behavior and

thermal conductivity of Aluminum nitride (AlN) ceramics with Y(NO3)3·6H2O

and Y2O3 as an additive were studied. Sintering was

performed in the temperature of 1,900 oC for up to 3 h under a N2

atmosphere to optimize the sintering conditions for each composition. The

microstructure and assemblage of the secondary phase have a significant effect

on the final thermal conductivity of the sintered AlN. The mechanical property

and thermal conductivity of the AlN composition of using the Y2O3

additive were improved by adding Y(NO3)3·6H2O,

which decreased the porosity. At 13.56 wt% Y(NO3)3·6H2O,

the AlN ceramic exhibited the highest strength of 375 MPa, the highest hardness

of 10.60 GPa, and the highest thermal conductivity of 200.2 W/m·K.

Keywords: AlN, Y(NO3)3·6H2O, Phase change behavior, Thermal conductivity, Mechanical property

Aluminum nitride (AlN) may be highly suitable as

substrates and packages for IC/LSI because of its high thermal conductivity

(theoretical value of 320 W/m·K), low dielectric constant (8.0 at 1 MHz), and

thermal expansion coefficient (4.8 × 10−6 K−1 at 20-500 ℃)

that is close to that of silicon [1-3]. However, because of its high

covalent bonding, it is difficult to sintering. Several sintering

additives, such as CaO, CaC2, C, CaO-Al2O3,

and Y2O3, were reported to be useful for the fabrication

of high densification and thermal conductivity AlN ceramics

[4-6]. Y2O3 is widely used as a sintering additive

because it forms binary eutectics at temperatures around of

~1,800 ℃ with native Al2O3, which is present

on the surface of AlN particles, resulting in a material with high density and

high thermal conductivity [7, 8]. A typical feature in ceramic processing

is the addition of a limited fraction of sintering additives, typically oxides,

to promote densification. However, an associated disadvantage

is that non-negligible alterations may occur of the bulk property for which the

ceramic phase has been originally selected. The thermal conductivity of poly

phase ceramics is strongly affected by internal phase geometry and other

microstructural details [9-11]. High thermal conductivity constitutes an

attractive property of AlN ceramics for high-power semiconductor

devices [12, 13]. However, the usual preparation of dense polycrystalline

AlN bodies involves the additive Y2O3 which, by virtue of

its good wet-ability of the AlN grain surface, enables ready densification by

pressureless sintering [4, 14, 15]. As substrates and packages, the

thermal conductivity of AlN ceramics is very important. Most studies look at

the influence of different sintering additives on the thermal conductivity of

AlN ceramics.

In this work, we studied to

compare the sintering behavior and crystalline phases change related with the

densification of AlN with Y2O3 and Y(NO3)3·6H2O

additives.

Commercially available AlN powders (Grade H, Tokuyama

Soda, Japan) was used as a starting material. First, the

Y(NO3)3·6H2O (99.99%, High Purity Chemicals,

Japan) or Y2O3 (99.9%, High Purity Chemicals, Japan) was

dissolved in ethanol, and the AlN powders were dispersed in the solution using

ultrasonic technology. The Y(NO3)3·6H2O and Y2O3

were added into a AlN suspension and then sonicated for 24

h to obtain a metal ion doped AlN suspension via surface adsorption.

After dried and calcinated (500 ℃), the mixed powders were

densified by hot pressing at 1,900 ℃ for 3 h under a pressure

of 20 MPa in flowing N2. The sintering additive

of Y(NO3)3·6H2O was added in the following

amounts: 10.1198, 11.8684, 13.5638, and 15.2594 wt% (equivalent to

6, 7, 8 and 9 wt% Y2O3 respectively), referred to here

after as A-6YP, A-7YP, A-8YP and A-9YP for the sintered samples. For

comparison, monolithic AlN was also prepared in the same process. The

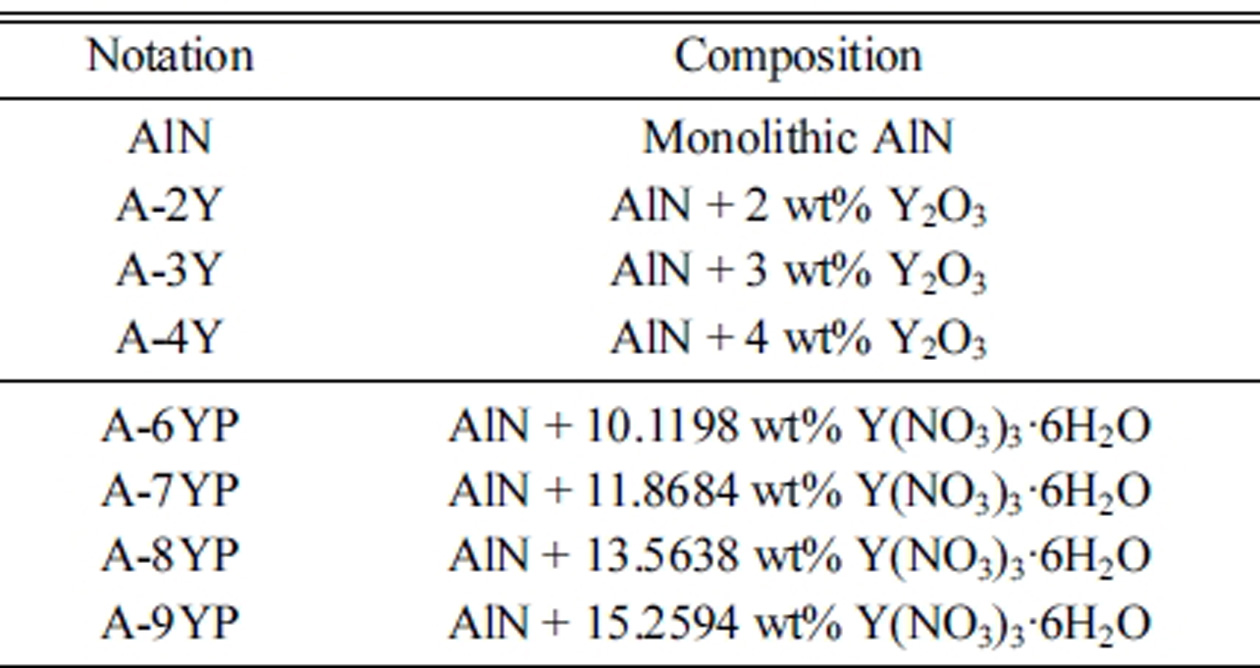

composition of powder mixture was indicated in Table 1.

Crystalline and 2nd

phases were identified with X-ray diffraction

pattern (D/MAX-2500V, RIGAKU) with Cu Kα

radiation (λ = 1.5406 Å). All the samples for mechanical test were prepared by diamond saw and

then grinded by diamond disc. Mechanical properties of specimen were evaluated

by four-point flexural strength (5882, Instron, USA) with a cross head speed of

0.5 mm/min and micro vickers hardness tester (HM124, Akashi, Japan) at a

load 9.8 N for 5 sec. The dimension of mechanical test specimen was

3 × 4 × 40 mm (width × length × height)

and the inner span and outer span were 10 and 30 mm, respectively. Fracture

surfaces of the pellets were observed by Field emission scanning electron microscopy (FE-SEM, S-4700, HITACHI, Japan). Thermal diffusivity measurement

(LFA 457, NETZSCH, Germany) at room temperature is measured by the laser flash

method. Thermal conductivity (K) is calculated using a heat capacity (Cp)

of AlN at room temperature where λ and d are the thermal

diffusivity and the density, respectively [16].

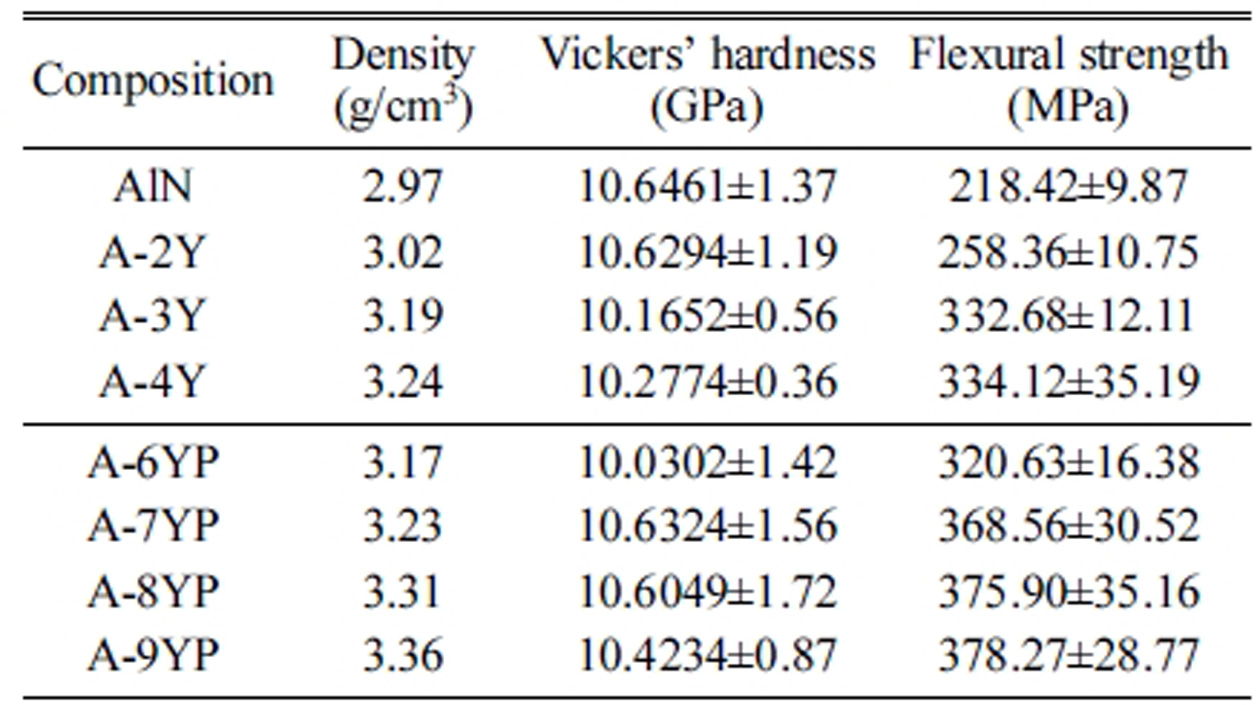

The densities and mechanical

properties of the sintered AlN ceramics are summarized in Table 2. The density

increases with the additive content. Compared with AlN when the additive is Y2O3,

better mechanical properties, such as Vickers’ hardness, flexural strength, are

obtained for sintered samples when the additive is ≤8 wt% Y(NO3)3·6H2O,

A-8YP exhibits the highest strength of 375 MPa, hardness of 10.60 GPa. This

high density is due to the formation of an aluminum oxy nitride (Al–O–N) liquid

by reaction between surface alumina and AlN. The addition of Y2O3

promotes more extensive liquid formation due to reaction to form a quaternary

liquid (Y–Al–O–N) at lower temperature.

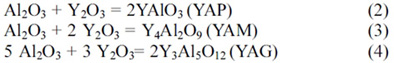

Fig. 1 gives the X-ray powder

diffraction patterns for the all samples after sintering at 1,900 ℃

for three hours. Each composition shows strong peaks associated with AlN in

addition to minor peaks associated with the secondary grain boundary phase.

Fig. 1(a) showed peaks for AlN, YAlO3 (YAP) on

the 2 wt% of Y2O3. The YAP phases

disappeared with increasing Y2O3 content and then Y3Al5O12

(YAG) phases (3 wt% of Y2O3) Y4Al2O9

(YAM) phases (4 wt% of Y2O3) appeared.

But Fig. 1(b) showed peaks for AlN, YAP and YAG phases with increasing Y(NO3)3·6H2O

content. Because compared with AlN when the additive is Y2O3,

the improved dispersion properties are attributed to the increase in reactivity

between Al2O3 and Y(NO3)3·6H2O.

Al2O3 peaks were not detected

because the amount of residual Al2O3 is very small and

below the detection limit of the equipment. Moreover, Al2O3

occurs as a thin surface layer on AlN grains. Because of this surface layer and

residual spinel, thermal conductivity is very low for this sample, as can be

seen in Fig. 3. This means that the amount of added Y2O3

was insufficient to fully react with residual Al2O3 and

to purify the AlN and to complete the oxygen removal from both the lattice and

the surface.

From previous reports [17, 18], the Y2O3

decomposed from Y(NO3)3·6H2O reacts

with Al2O3, which is also present on the surface of AlN

particles, to form yttrium aluminates:

The formation of liquid phase (Y4Al2O9

and/or Y3Al5O12) during sintering process will

play an important role in the densification of the AlN ceramics.

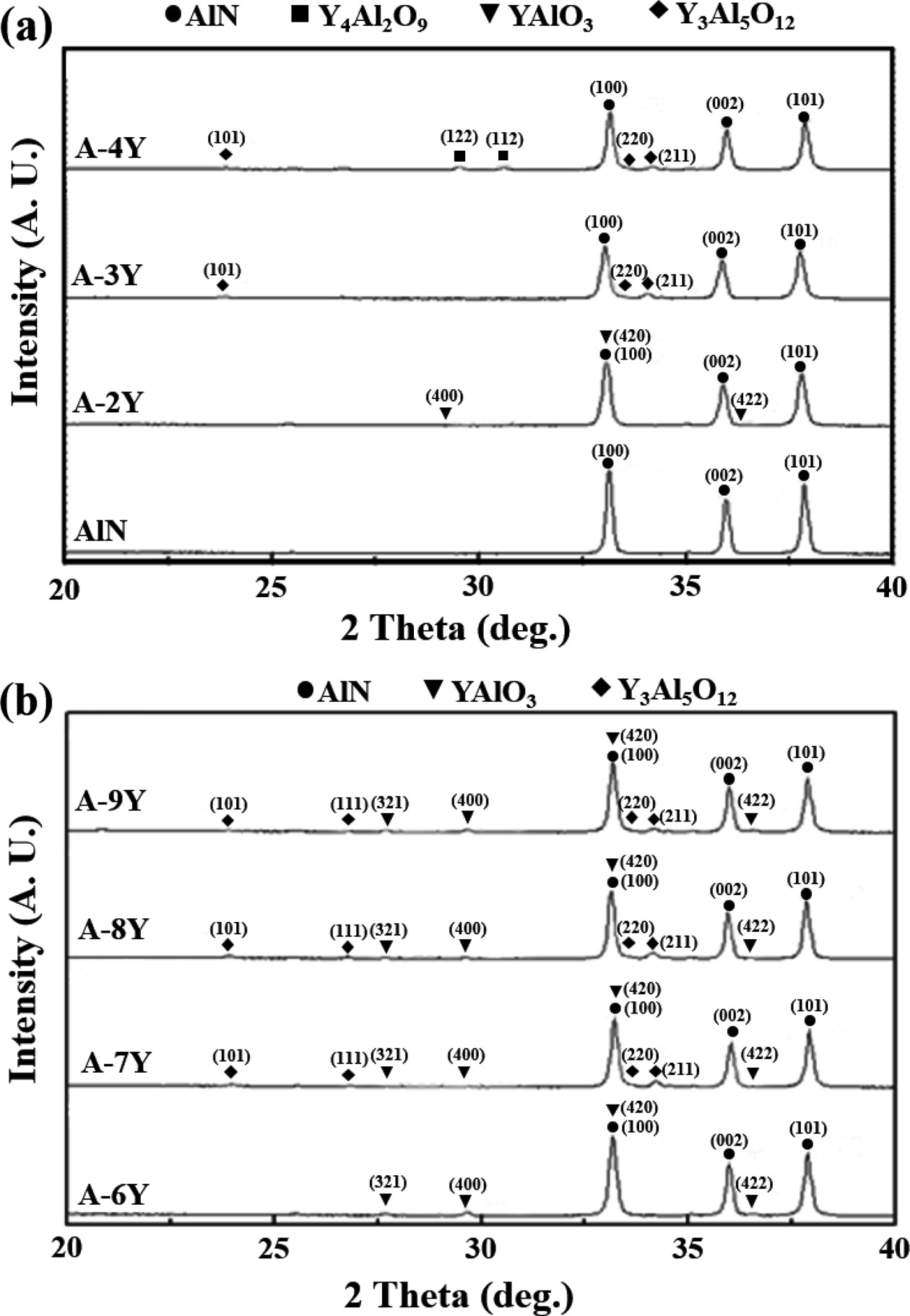

The FE-SEM microstructure of composition containing Y2O3

and Y(NO3)3·6H2O is shown in Fig. 2. The

secondary phase (white) shows up at the grain junctions only and not along

grain edges. Compared with AlN when the additive is Y2O3,

the addition of Y(NO3)3·6H2O appears to have a

further effect of changing the wetting behavior of the liquid phase with

respect to the AlN grains. Indeed, the dihedral angle of the secondary phase at

the grain junction is high. This has a significant effect on the thermal

conductivity (k).

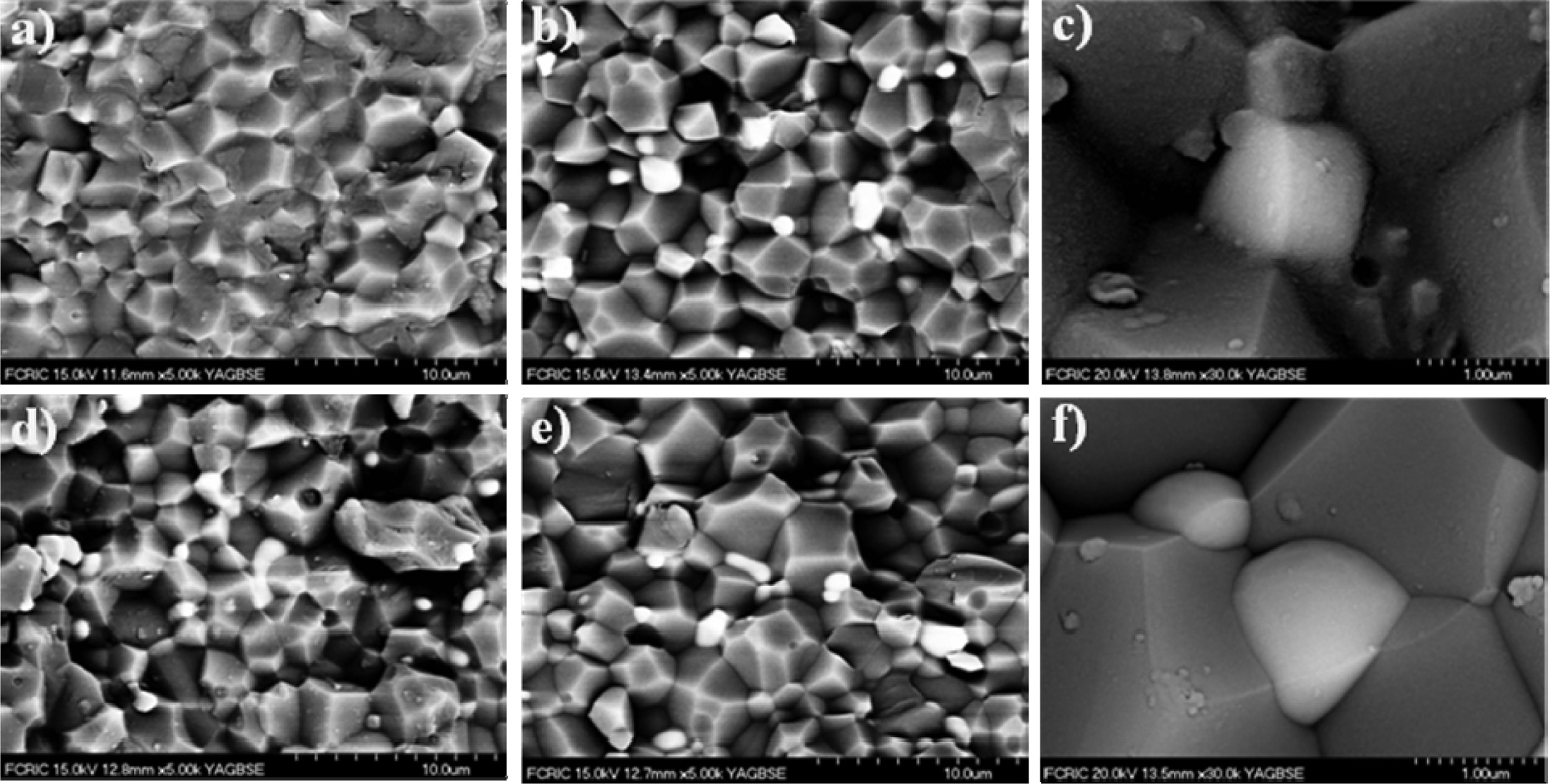

Jackson et al. [19]

suggest that thermal conductivity rises to a maximum and then decreases due to

the increase in volume fraction of aluminates with further Y2O3

addition.

|

Fig. 1 X-ray powder diffraction patterns of AlN addition of Y2O3 and Y(NO3)3·6H2O. |

|

Fig. 2 Back-scattered electron SEM fractured surface images of AlN specimens sintered at 1,900 ℃ : (a) AlN, (b) A-3Y, (c) high magnification of (b), (d) A-6YP, (e) A-8YP, (f) high magnification of (e). |

|

Fig. 3 Variation in thermal conductivity of AlN addition of Y2O3 and Y(NO3)3·6H2O. |

Fig. 3 shows the trend in thermal conductivity of the compositions.

The thermal conductivity of the aluminate phase

is low (<10 W/m·K), hence as the volume fraction increases,

a decrease in the overall thermal conductivity is

expected. The thermal conductivity of AlN sintered without sintering additives

has a significantly low value of 92.2 W/m·K. Therefore, the effect of the

additive has a major impact on the conductivity in two ways: (a) it removes

oxygen from particle surface and (b) a micro structural change occurs as the

aluminates de-wets the grain boundaries and segregates to the grain junctions

leading to AlN–AlN grain boundary contact. Also, this figure shows, that

compositions of using the Y(NO3)3·6H2O

additive have higher thermal conductivity than composition of using

the Y2O3 additive. Because of

the oxide layer was consumed to produce YAP, YAG as secondary phases.

Furthermore, it was shown by the experimental work of Medraj et al. [20]

that YAP wets the surface of AlN more than YAG or YAM if all

the experimental conditions are considered. Also,

the presence of YAP phase will prevent AlN–AlN surface contact. But higher YAP

content is associated with lower thermal conductivity.

Aluminum nitride (AlN) ceramics were prepared by

hot-pressing with Y(NO3)3·6H2O and Y2O3

as sintering additive. When increasing Y2O3 content, the

YAlO3 (YAP) phase disappeared and then Y3Al5O12

(YAG) phase (3 wt% of Y2O3) Y4Al2O9(YAM)

phase (4 wt% of Y2O3) appeared. But increasing Y(NO3)3·6H2O

content showed peaks for AlN, YAP and YAG phase. Because compared with AlN when

the additive is Y2O3, the improved dispersion properties

are attributed to the increase in reactivity between Al2O3

and Y(NO3)3·6H2O. The mechanical properties

and thermal conductivity are obtained for sintered samples when the additive is

≤13.5638 wt% Y(NO3)3·6H2O, A-8YP specimen

exhibits the strength of 375 MPa, hardness of 10.60 GPa and the highest

thermal conductivity of 200.2 W/m·K. The addition of Y(NO3)3·6H2O

appears to have a further effect of changing the wetting behavior of the liquid

phase with respect to the AlN grains. It was confirmed that AlN using Y(NO3)3·6H2O

showed relatively higher thermal conductivity and mechanical properties than

the Y2O3.

This work was financially supported by Ministry of Science

and ICT(MSIT) in Korean government and Korea Industrial Technology Association

(KOITA) as “A study on the programs to support collaborative research

among industry, academia and research institutes”

- 1. L.M. Sheppard, Am. Ceram. Soc. Bull. 69 (1990) 1801-1812.

- 2. G.A. Slack, J. Phys. Chem. Solids 34 (1973) 321-335.

-

- 3. R.R. Tummala, J. Am. Ceram. Soc. 74 (1991) 895-908.

-

- 4. Y. Kurokawa, K. Utsumi, and H. Takamizawa, J. Am. Ceram. Soc. 71 (1988) 588-594.

-

- 5. P.S. de Baranda, A.K. Knudsen, and E. Ruh, J. Am. Ceram. Soc. 76 (1993) 1751-1760.

-

- 6. E. Hagen, Y. Yu, T. Grande, R. Høier, and M.-A. Einarsrud, J. Am. Ceram. Soc. 85 (2002) 2971-2976.

-

- 7. L.A. Qiao, H.P. Zhou, H. Xue, and S.H. Wang, J. Eur. Ceram. Soc. 23 (2003) 61-67.

-

- 8. W.J. Tseng and C.J. Tsai, J. Mater. Process. Technol. 146 (2004) 289-293.

-

- 9. F.M. Xu, Z.J. Zhang, X.L. Shia, Y. Tana, and J.M. Yang, Journal of Alloys and Compounds 509 (2011) 8688-8691.

-

- 10. R.C. Progelhof, J.L. Throne, and R.R. Ruetsch, Polym. Eng. Sci. 16 (1976) 615-621.

-

- 11. H.J. Ott, Plastic Rubber Process. Appl. 1 (1981) 9-14.

- 12. W. Werdecker and F. Aldinger, IEEE Trans. C.H.M.T. 7 (1984) 399-404.

-

- 13. L.M. Sheppard, Am. Ceram. Soc. Bull. 69 (1990) 1801-1815.

- 14. Komeya, K., Inoue, H., and Tsuge, A., Yogyo-Kyokai-shi 89 (1981) 330-333.

-

- 15. Kuramoto, N., Taniguchi, H., Numata, Y., and Aso, I., Yogyo-Kyokai-shi 93 (1985) 517-521.

-

- 16. R. Koba, J. Harris, R. Youngman, M. Mallinger, and L.B. Max, Microwave RF (1997) 156-166.

- 17. A.V. Virkar, T.B. Jackson, and R.A. Cutler, J. Am. Ceram. Soc. 72 (1989) 2031-2042.

-

- 18. K. Watari, M. Kawamoto, K. Ishizaki, J. Mater. Sci. 26 (1991) 4727-4732.

-

- 19. T.B. Jackson, A.V. Virkar, K.L. More, R.B. Dinwidie, and R.A. Cutler, J. Am. Ceram. Soc. 80[6] (1997) 1421-1435.

-

- 20. M. Medraj, M. Entezarian, and R.A.L. Drew, Sintering 99 Conference Proceedings (2000) 307-312.

This Article

This Article

-

2020; 21(1): 1-4

Published on Feb 28, 2020

- 10.36410/jcpr.2020.21.1.1

- Received on Dec 31, 2018

- Revised on Nov 18, 2019

- Accepted on Dec 9, 2019

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jun Ki Chung

-

Center for Industrial Technologies of Non-Ferrous Metals, Gangneung-wonju National University, Gangneung 25457, Korea

Tel : +82-33-640-3018 Fax: +82-33-640-2245 - E-mail: junki@gwnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.