- Modifications of structural and optical properties of copper oxide thin films by thermal annealing

In-Sub Han, Ji-Soo Park and Il-Kyu Park*

Department of Materials Science and Engineering, Seoul National University of Science and Technology, Seoul 01811, Korea

The structural modification of

copper oxide thin films was investigated by controlling the thermal annealing

atmosphere and temperature, which in turn affected their optical and electrical

properties. Copper oxide thin films were deposited by spray pyrolysis

deposition at 300 oC to give a uniform surface consisting of

submicron-size grains with cubic Cu2O crystalline structure. As the

Cu2O thin films were thermally annealed at less than 700 oC,

they were transformed into the CuO phase. However, a mixed phase of CuO and Cu2O

was observed at temperatures above 800 oC. As the thermal

annealing temperature was increased from 400 to 700 oC, the

optical bandgap energy of the copper oxide thin films was decreased from 2.54

to 1.91 eV and the electrical charge carrier concentration was decreased

gradually due to the improved crystalline quality. In this way, the crystalline

structure of the copper oxide and its corresponding optical and electrical

properties could be controlled by thermal annealing.

Keywords: CuO, Cu2O, Spray pyrolysis deposition, Thermal annealing

Copper oxide semiconductors have received strong attention

for application to optical, electrical, and chemical devices

such as solar cells, light-emitting diodes, transparent

heaters, thin film transistors, and photocatalysts [1-7].

Copper oxide forms two stable crystalline phases: CuO

and Cu2O [5-7]. Cu2O has a direct energy bandgap

between 2.1 and 2.6 eV [8-10]. The many advantages offered by Cu2O

thin films include a long minority carrier diffusion length, a high hole

concentration of 1016-1019 cm-3,

and a high hole mobility of 50-100 cm2/V·sec at

room temperature [8-10]. Therefore, they have been applied

to the light absorbing layer or hole transport layer of solar cells

and of photoelectrochemical cells for

water decomposition [8-10]. The other crystalline phase, CuO,

exhibits n-type semiconductor properties with a

bandgap energy of 1.3-2.1 eV and offers chemical stability,

non-toxicity, and low cost processing [11-14]. These characteristics make these

oxides a promising material system for optoelectronic applications.

Recent research on the fabrication of copper oxide thin

films has included hydrothermal processing, electro- deposition, sputtering

deposition, atomic layer deposition, and

ultrasonic-assisted spray pyrolysis deposition (SPD) [8-13].

SPD has received strong attention because it provides

comparatively low cost processing and offers a larger area for mass production

compared to other vacuum technologies [12, 13]. In principle, SPD is a

hybrid method of a wet process and chemical vapor deposition. Metal compounds

dissolved in a source solution are transferred in the form of a spray and are

thermally decomposed on the substrate surface to nucleate and grow the thin

film [12, 13]. The structural and optical properties of the copper oxide

thin films in the SPD system are influenced by the source flow rate, growth

atmosphere, and substrate temperature [12]. For copper oxide,

the formation of Cu2O with a cubic structure and CuO with

a monoclinic structure is sensitive to the deposition temperature and

atmosphere, which makes it difficult to control these two crystalline phases

[12]. In addition, the effect of post thermal annealing on the structural,

electrical, and optical properties of the copper oxide thin

films has not been fully elucidated. In this paper, we investigated the effect

of thermal annealing atmosphere and temperature on the structural properties of

the copper oxide thin films deposited by SPD and their corresponding effects on

the films’ optical and electrical properties.

Fabrication

Copper oxide thin films were deposited on glass substrates

using ultrasonic-assisted SPD. The glass substrates were cleaned in acetone,

methanol, and deionized (DI) water for 5 min to remove organic pollutants and

then loaded into a commercial SPD system (Nano SPD-TV500, Ceon, Korea). The

source solution was prepared by dissolving 2 mM of copper acetylacetonate (Cu(acac)2, Sigma Aldrich), used

as a chelating agent to improve the Cu(acac)2 solubility, and 4 mM of ethylenediamine (C2H4(NH2)2), Sigma

Aldrich) in methanol. The solution was stirred at room temperature for 4 hrs

and finally changed to a clear and homogeneous solution. The copper oxide thin films were

deposited at 300 oC using an N2 carrier gas for 60,

120, and 180 min. The N2 flow rate was

maintained constant at 15 L/min. To investigate the effect of thermal

annealing on the optical and electrical properties of the copper oxide thin

films, rapid thermal annealing (RTA, ECOPIA RTP-1300) was performed at

temperatures between 400 and 800 oC in the N2 and O2 atmosphere. The thermal annealing

time was fixed at 5 min with a ramping rate of 25 oC/min.

The flow rate of the atmosphere gas was 10 L/min.

Characterization

The morphologies of the copper

oxide thin films were observed by scanning electron microscopy (SEM,

Hitachi S-4800). The crystalline structure of the

copper oxide thin films was measured by X-ray

diffraction (XRD, PANalytical Empyrean). The electrical

properties of the copper oxide thin films were characterized using

Hall effect measurement (HMS-3500, ECOPIA).

The transmittance and UV-visible absorption spectra of the copper oxide thin

films were measured by using a UV-Vis-NIR spectrophotometer (Cary 5000,

Agilent).

The copper oxide thin films were deposited at 300 oC

to fabricate the Cu2O crystalline structure. Previous results

reported for the SPD-growth of copper oxide thin films showed that the divalent

Cu2O was preferentially deposited rather than the CuO

phase at temperatures lower than 400 oC [12]. To investigate

the structural evolution during the deposition, the deposition time was varied

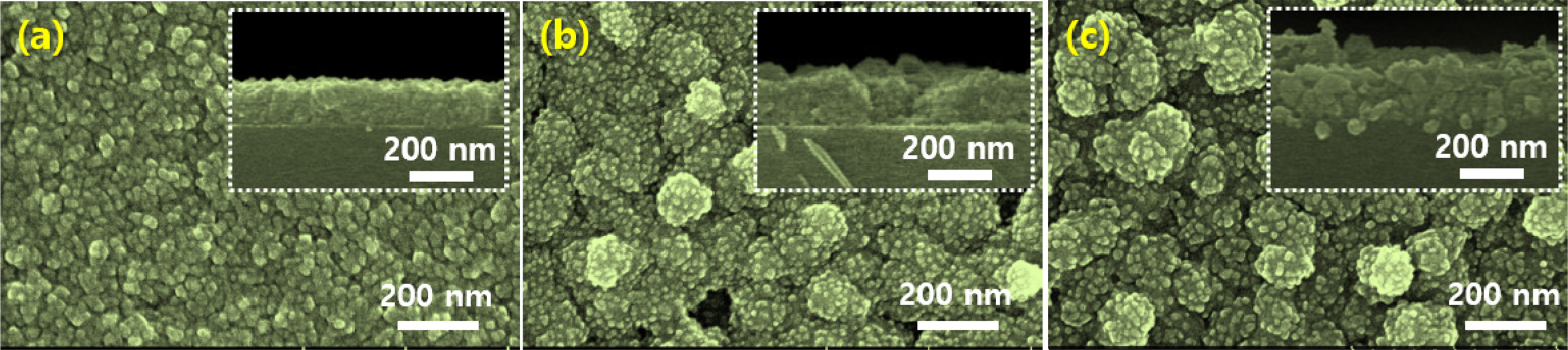

from 60 to 180 min. Figure 1 shows the surface and cross-sectional SEM images

of the copper oxide thin films deposited on the glass substrate with variation

of the deposition time. As shown in Fig. 1(a), surface of

the copper oxide thin films showed a uniform morphology

consisting of nano-crystalline grain. Because the growth

temperature was lower than 400 oC, the atomic mobility on the

substrate surface can be very low. This results in the formation of

nano-crystalline grains. As the growth time was increased from 60 to 120

and to 180 min, larger grain size consisting of nano-crystalline

particulates were observed. The limited surface atomic

diffusion enabled the small grain size to be maintained even as the deposition

time was increased, as shown in Figs. 1(b) and (c).

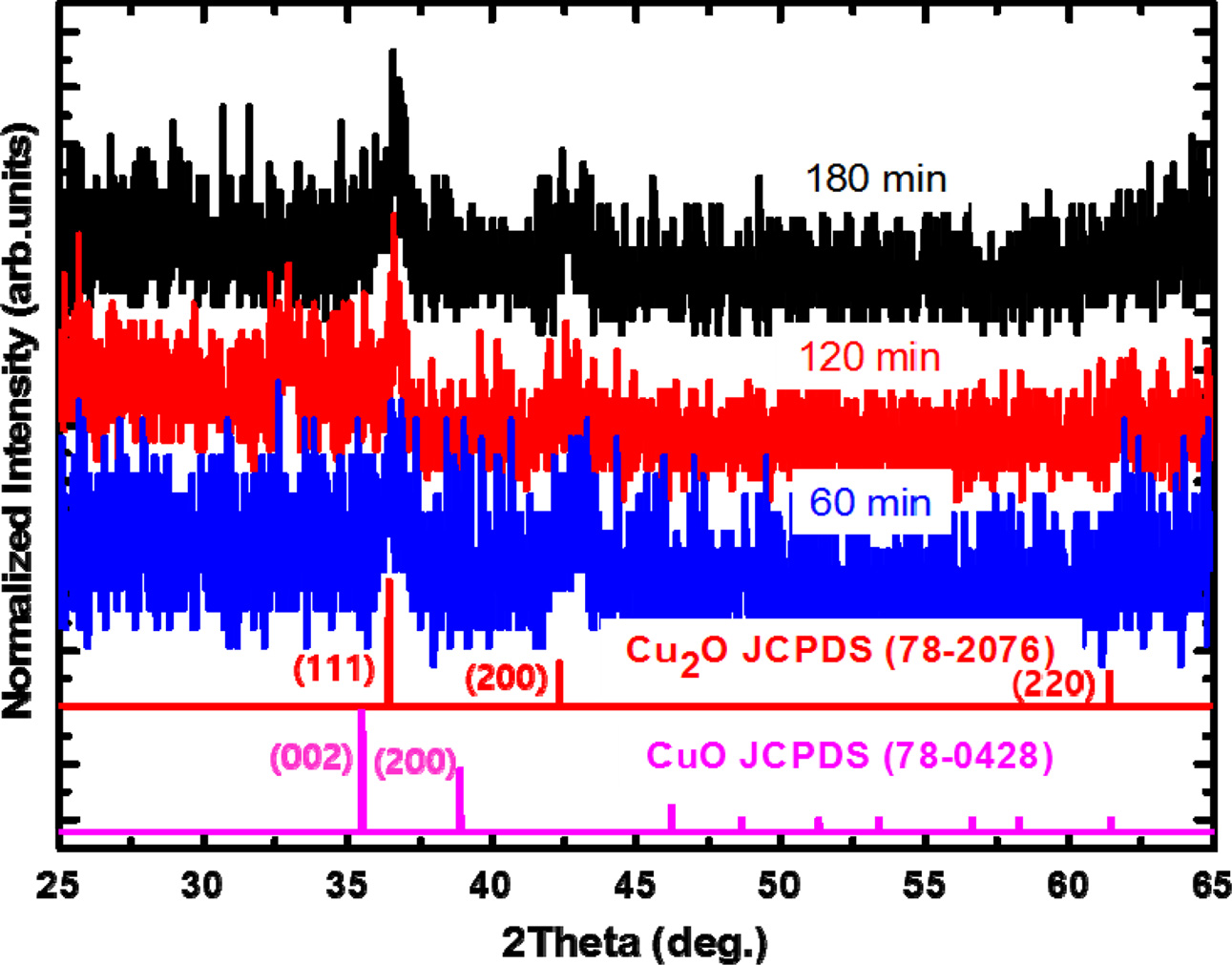

To investigate the crystalline structure of the

copper oxide thin films, XRD was measured for the samples with different

deposition times. As shown in Fig. 2, the XRD results for the samples mainly

showed two peaks at 36.44o and

42.32o, which correspond to the (111)

and (200) planes of the cubic Cu2O (space group: Pn-3m; a

= 0.428 nm, JCPDS 78-2076) crystal, respectively. Because the thin

films comprised small domains of Cu2O sized less than 20 nm, the

diffraction peaks were broad, which can be expected

from the Scherrer equation relating the XRD peak

broadness and the domain size. The absence of any additional

peaks in the diffraction results indicates that no unintentional chemical

species, such as CuO or Cu metallic compounds, were formed even with increasing

deposition time. The overall reactions for the formation of the nanostructures

can be summarized by the following reactions. The copper acetylacetonate

[Cu(acac)2; Cu(C5H7O2)2]

used as the copper source is dissolved in the aqueous solution via the following reactions [12, 15]:

Cu(acac)2 + H2O

→ Cu(acac)·(OH) + H(acac) (1)

Cu(acac)·(OH) → Cu(acac)+

+ OH- (2)

Cu(acac)+ + OH- → Cu(OH) + (acac) (3)

2Cu(OH) → Cu2O + H2O (4)

The chelating agent, ethylenediamine

(C2H4(NH2)2), increases the

solubility of the copper acetylacetonate by chelating the

Cu cations by two amine-based ligands. The agent also promotes the

uniform deposition of Cu2O thin films on the substrate by preventing

the random reaction between Cu cations and OH- anions even at low

temperature around 300 oC [16].

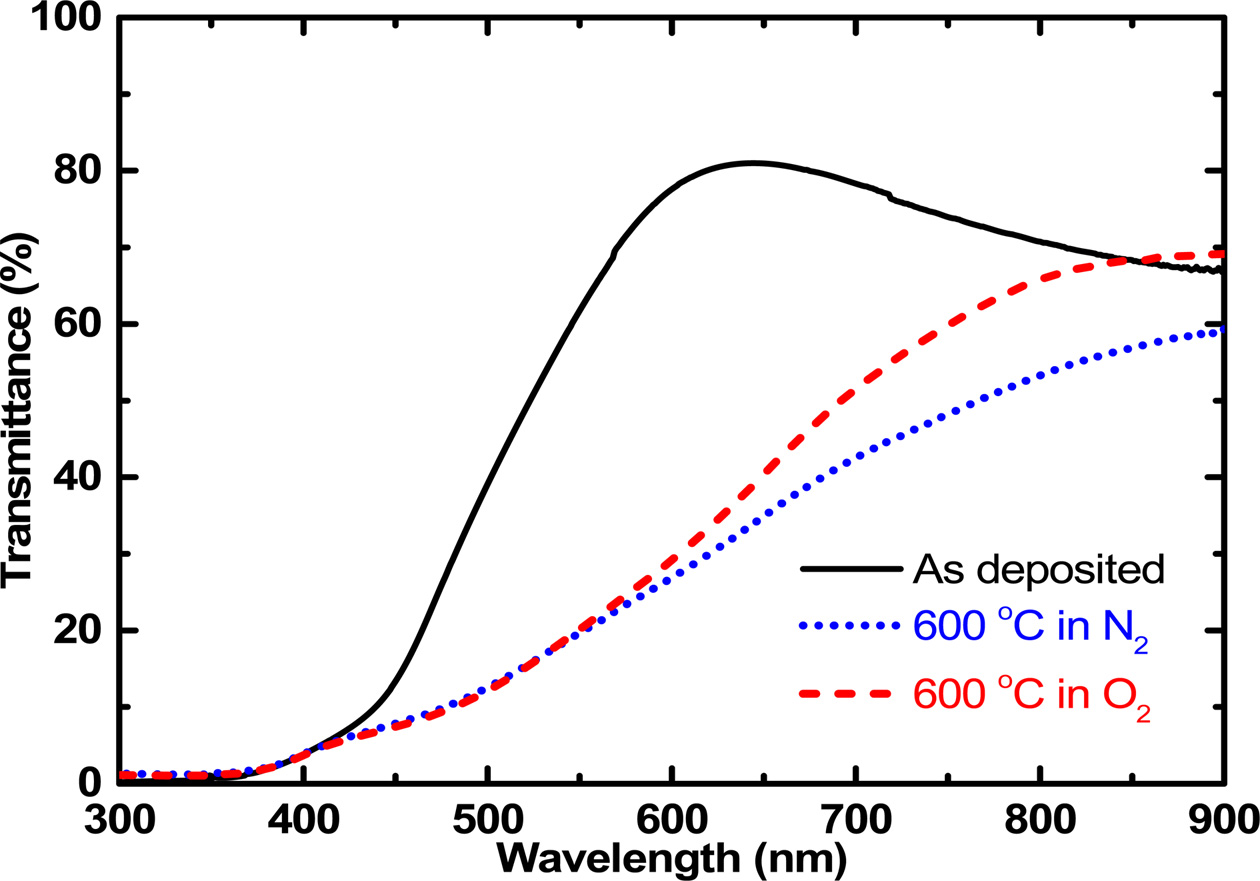

To investigate the effect of thermal annealing on

the structural and optical properties of the CuO2 thin films, the

deposited thin films were annealed in the RTA system. Figure 3 shows the

optical transmittance results of the Cu2O thin films for the

as-deposited film and for that thermally annealed at 600 oC in N2 and O2 gas atmosphere. The as-deposited Cu2O

thin film showed a transmittance over 80% at the wavelength around 600 nm.

After the Cu2O thin film was thermally annealed at 600 oC in N2 and O2 gas atmosphere, the transmittance

decreased drastically in the visible spectral range and was maintained in the

infrared spectral range. In general, the increase of the light absorption in

the oxide thin film is originated from the phase transformation or increased

defect formation. In this case, the increase of absorption would be attributed

to the increased point defect during the annealing process. The optical

transmittance decreased further when the annealing atmosphere was in the N2

gas, which was attributed to the increased generation of oxygen vacancy-related

point defects in the N2 atmosphere because of high vapor pressure of

oxygen atoms. The oxygen vacancy-related point defects produce free charge

carriers to increase the absorption of light

[17]. This result indicates that thermal

annealing in O2 atmosphere is better for avoiding the generation of

oxygen vacancy-related point defects.

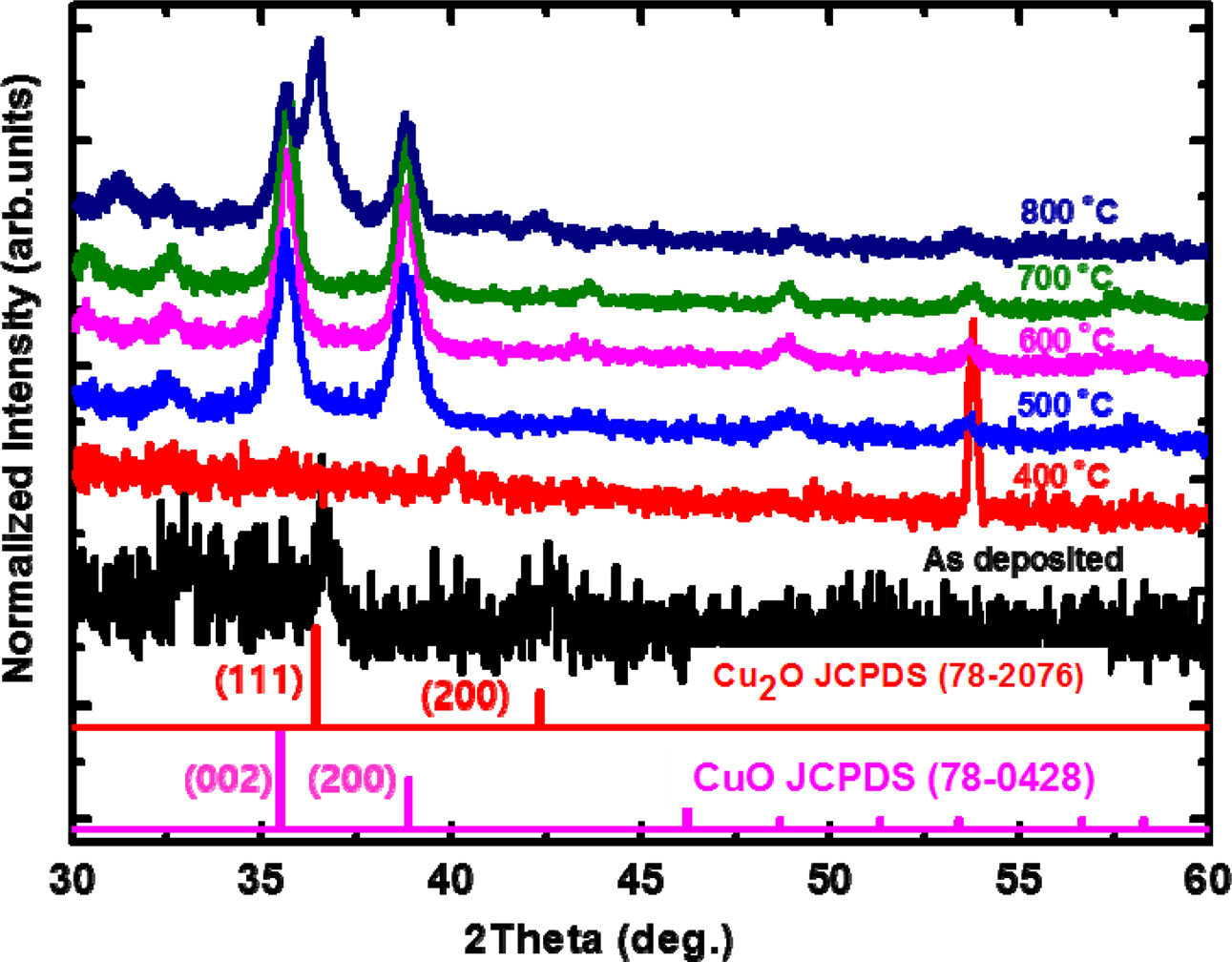

To investigate the dependence of the optical and structural

properties on the thermal annealing temperature, the Cu2O

thin films were thermally annealed between 400 and 800 oC in O2 atmosphere. Figure 4 shows the temperature-dependent

structural evolution of the Cu2O thin films. At an

annealing temperature of 400 oC, the peaks corresponding to Cu2O

phase disappear. As the temperature

is increased from 500 to 700 oC, new peaks appear at 35.5o and 38.9o, which correspond to the (002) and (111) planes of the monoclinic CuO phase (space

group: C2/c; a = 0.32501 nm, b = 0.343 nm, c = 0.5131 nm, β = 99.549o,

JCPDS 78-0428) [18]. This was attributed to the ionization of the Cu

element into the Cu+ ion to form a Cu2O phase at

temperatures lower than 400 oC, but

into the divalent Cu2+ ions to form a CuO phase at temperatures higher than 500 oC. The full-width at half maximum of the peak became narrower as the

temperature was increased to 700 oC, which indicates the improved crystalline quality of the copper oxide thin

films. At temperatures higher than 800 oC, another peak corresponding to the (111) plane of the Cu2O

phase starts to appear, which leads to the formation of a mixed phase of CuO

and Cu2O. As the temperature is increased

further, the CuO phase becomes unstable and is transformed

into the Cu2O phase by evaporation of the oxygen atoms.

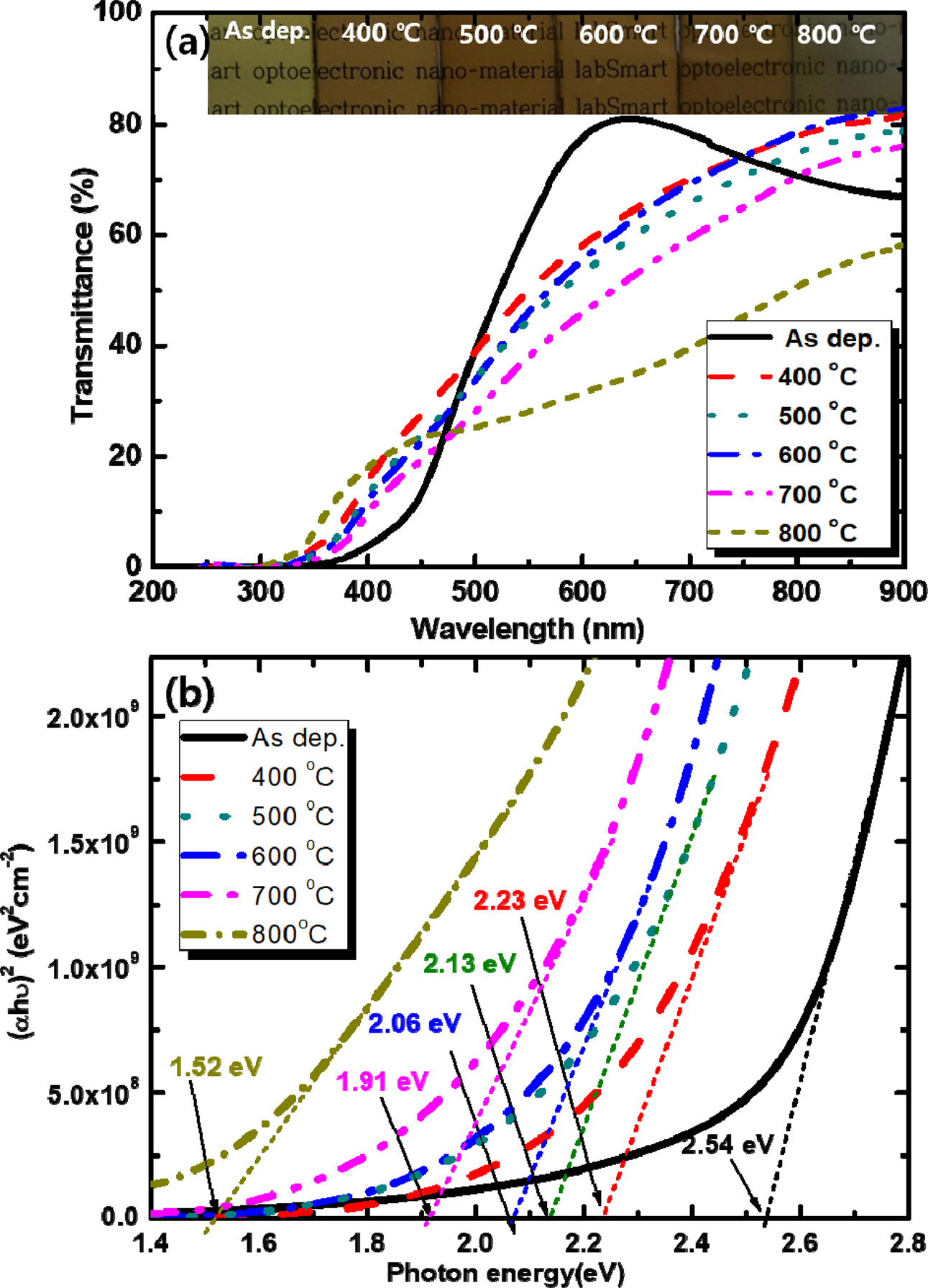

Figure 5 shows the dependence of the optical properties

of copper oxide thin films on temperature. As shown in the inset of Fig. 5(a),

the as-deposited Cu2O thin film shows a brown surface because the

energy bandgap of Cu2O is 2.1-2.6 eV. As the annealing temperature

is further increased up to 700 oC, the

sample becomes reddish. The transmittance decreases gradually as the annealing

temperature is increased from 400 to 700 oC. The bandgap energy of the samples was estimated by plotting

the photon absorption coefficient (α) versus the photon energy (hv),

as shown in Fig. 5(b). The optical bandgap energy was estimated by the Tauc and

Davis-Mott expression [19]:

(αhν)1/n = A(hν-Eg) (5)

In the equation, A and Eg are the

proportional constant and the bandgap energy, respectively,

and n is a characteristic constant that determines whether the

electronic transition is direct (n=0.5) or indirect (n=2) [19].

The plots were well fitted for n=0.5, indicating that the copper oxide

was a direct bandgap material. The bandgap energy of the as-deposited Cu2O

thin film was determined to be 2.54 eV, which is similar to the reported

bandgap energy of the bulk Cu2O [7-10]. As the annealing temperature

is increased from 400 to 800 oC, the

estimated optical bandgap energy decreases from 2.23 to 1.52 eV. The bandgap

energy of the CuO is 1.3~2.1 eV [10-12].

Therefore, these results indicate that the

as-deposited Cu2O phase changes to CuO phase as the annealing temperature is increased. This result is consistent with the XRD structural investigations.

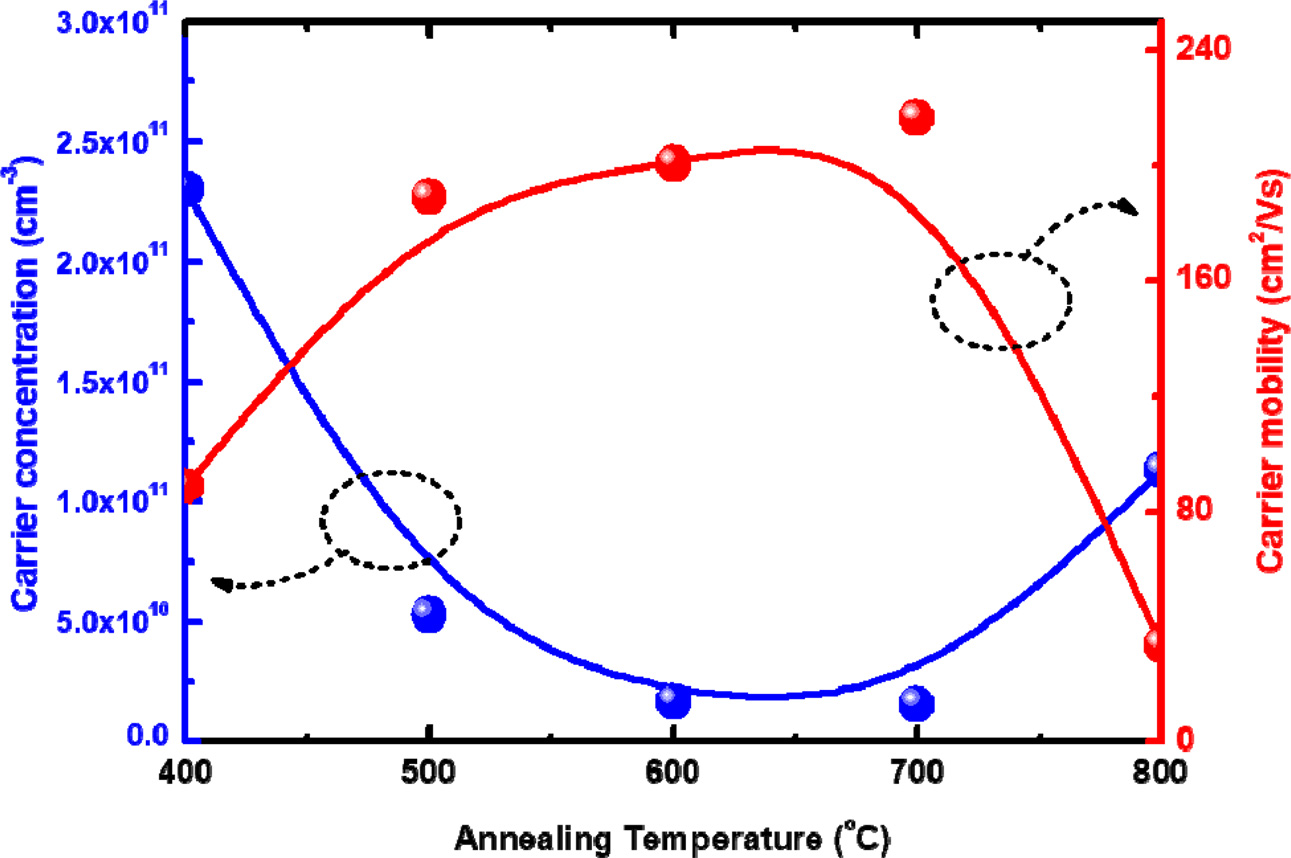

To investigate the effect of thermal annealing on the

electrical properties of Cu2O thin films, Hall effect measurement

was performed at room temperature. The copper oxide thin films showed highly

resistive n-type characteristics with only a small amount of charge carrier

concentration in the order of 1011 cm-3.

As shown in Fig. 6, the charge carrier concentration decreases

while the carrier mobility increases, as the annealing temperature

is increased up to 700 oC. This was attributed to the improved crystalline

quality of the CuO as the annealing temperature was increased. Because the copper oxide thin films were annealed in an oxygen

atmosphere, their crystalline quality was improved without evaporation of

oxygen from the thin film, as shown in the XRD results. As the thermal

annealing temperature is increased further up to 800 oC, the charge carrier

concentration increases but the mobility decreases, because the decomposition of the CuO crystalline phase above this

temperature leads to the formation of various point defects. Therefore, the

copper oxide phase can be modified by thermal annealing, which enables their

optical and electrical properties to be controlled.

These findings will support the development of improved copper oxide-based optoelectronic devices.

|

Fig. 1 Plane-view and cross-sectional-view SEM images of the copper oxide thin films with different deposition times: (a) 60 min, (b) 120 min, and (c) 180 min. |

|

Fig. 2 Normalized θ-2θ XRD patterns of the copper oxide thin films with different deposition times. |

|

Fig. 3 Transmittance spectra of the copper oxide thin films that were thermally annealed at 600 oC in N2 and O2 atmosphere. |

|

Fig. 4 Normalized θ-2θ XRD patterns of the copper oxide thin films according to the thermal annealing temperature in O2 atmosphere. |

|

Fig. 5 (a) UV-vis optical absorption spectra of the copper oxide thin films according to the thermal annealing temperature in O2 atmosphere. The inset shows the sample images observed by the naked eyes. (b) Specific absorption band edges calculated from Tauc-plot studies. Variation of (αhν)2 as a function of the photon energy (hν) to obtain the direct band gap of the copper oxide thin films. |

|

Fig. 6 Charge carrier concentration and carrier mobility of the copper oxide thin films according to the thermal annealing temperature. |

In conclusion, we investigated the structural evolution

of copper oxide thin films by controlling the thermal annealing, which in turn

affected their optical and electrical properties. The XRD and

SEM results showed that the as-deposited copper oxide thin films were

composed of small grains with Cu2O phase. As these Cu2O

thin films were thermally annealed between 500 and 700 oC, they

were transformed into the CuO phase. Thermal annealing at 800 oC

resulted in the formation of a mixed phase of CuO and Cu2O. As the

thermal annealing temperature was increased from 400 to 800 oC,

the optical bandgap energy of the copper oxide thin films

decreased from 2.54 to 1.52 eV. The electrical charge

carrier concentration of the copper oxide thin films was decreased gradually as

the thermal annealing temperature was increased from 400 to 700 oC

due to the improved crystalline quality. Therefore, the

crystalline structure of the copper oxide thin

films could be modified by thermal annealing, which enabled

their optical and electrical properties to be controlled. Considering the

optical and electrical properties of copper oxide thin films, the temperature

between 500 and 700 oC in the O2 gas atmosphere can

provide the optimal thermal annealing condition.

This study was supported by the Research program funded by

the Seoultech (Seoul National University of Science & Technology).

- 1. R. N. Briskman, Sol. Energy Mater. Sol. Cells 27 (1992) 361-368.

-

- 2. B. P. Rai, Sol. Cells 25 (1988) 265-272.

-

- 3. X. Deng, Q. Zhang, E. Zhou, C. Ji, J. Huang, M. Shao, M. Ding, and X. Xu, J. All. Comp. 649 (2015) 1124-1129.

-

- 4. R. Laskowski, P. Blaha, and K. Schwarz, Phys. Rev. B 67 (2003) 075102-075110.

-

- 5. J. T. Zhang, J. F. Liu, Q. Peng, X. Wang, and Y. D. Li, Chem. Mater. 18 (2006) 867-871.

-

- 6. H. Zhu, J. Wang, and G. Xu, Cryst. Growth Des. 9 (2009) 633-638.

-

- 7. A. S. Zoolfakar, R. A. Rani, A. J. Morfa, A. P. O’Mullane, and K. Kalantar-zadeh, J. Mater. Chem. C 2 (2014) 5247-5270.

-

- 8. R. Wick and S. D. Tilley, J. Phys. Chem. C 119 (2015) 26243-26257.

-

- 9. J. Luo, L. Steier, M.-K. Son, M. Schreier, M. T. Mayer, and M. Grätzel, Nano Lett. 16 (2016) 1848-1857.

-

- 10. Y. Yang, D. Xu, Q. Wu, and P. Diao, Sci. Rep. 6 (2016) 35158.

-

- 11. Md. A. Hossain, R. Al-Gaashani, H. Hamoudi, M. J. A. Marri, I. A. Hussein, A. Belaidi, B. A. Merzougui, F. H. Alharbi, and N. Tabet, Mat. Sci. Semicon. Proc. 63 (2017) 203-211.

-

- 12. I. S. Han and I. K. Park, Kor. J. Mater. Res. 28 (2018) 516-521.

-

- 13. C. Y. Kim, S. G. Cho, S. Park, and D. K. Choi, J. Ceram. Process. Res. 10 (2009) 851-854.

- 14. M. Y. Lee, S. H. Kim, and I. K. Park, Physica B 500 (2016) 4-8.

-

- 15. Y. C. Zhang, J. Y. Tang, G. L. Wang, M. Zhang, and X. Y. Hu, J. Crystal Growth 294 (2006) 278-282.

-

- 16. K. Chen, C. J. Chiang, and D. Ray, Mater. Lett. 95 (2013) 172-174.

-

- 17. L. Wang, Y. Yang, and T. J. Marks, Appl. Phys. Lett. 87 (2005) 161107.

-

- 18. I. Kaya, C. Cetin, H. Aydin, Z. Katircioġlu, B. Z. Bűyűkbekar, M. S. Yavuz, M. Uyaner, V. Kalem, and H. Akyildiz, J. Ceram. Process. Res. 16 (2015) 648-655.

- 19. J. Tauc, Opt. Acta Int. J. Opt. 17 (1974) 952-952.

This Article

This Article

-

2019; 20(6): 660-664

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.660

- Received on Aug 5, 2019

- Revised on Sep 30, 2019

- Accepted on Oct 7, 2019

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Il-Kyu Park

-

Department of Materials Science and Engineering, Seoul National University of Science and Technology, Seoul 01811, Korea

Tel : +82-2-970-6349 Fax: +82-2-973-6657 - E-mail: pik@seoultech.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.