- Electrochemical properties of Ni-Mn hydroxide and carbon cryogel composite electrodes for supercapacitors

Deuk Yong Leea and Young-Jei Ohb,c,*

aDepartment of Biomedical Engineering, Daelim University, Anyang 13916, Korea

bOpto-electronic Materials & Devices Research Center, Korea Institute of Science and Technology, Seoul 02792, Korea

cDepartment of Nano Material Science and Engineering, Korea University of Science and Technology, Daejeon 34113, Korea

The Ni-Mn hydroxide/carbon

cryogel (20 to 80 wt%) composite electrodes were synthesized by freeze-drying

to improve electrochemical properties of the Ni-Mn hydroxide. XRD results

revealed that the composite electrode showed a distorted spinel-like structure

similar to the Ni-Mn hydroxide plus the graphitized carbon. The crystallinity

of carbon cryogel in composite electrode was improved dramatically with

increasing the carbon cryogel content. The presence of the carbon cryogel

played a significant role in inhibiting the crystal growth of Ni-Mn hydroxide

on the surface of carbon cryogel. Electrochemical properties of the composite

electrodes, such as capacitance, power density, and energy density, were observed

to be always higher than those of the Ni-Mn electrodes. The highest specific

capacitance of 221 F/g was observed for the electrodes containing 20 wt% of

carbon cryogel at a scan rate of 5 mV/s and an electrode loading amount of 15

mg/cm2 due to easy transport of the ions into pores. However, the

highest energy density of 10.8 Wh/kg and power density of 927 W/kg were

observed for the composite electrodes containing 80 wt% of carbon cryogel.

Experimental results suggested that tunable electrochemical properties of the

composite electrodes can be adjusted by varying the carbon cryogel content.

Keywords: Ni-Mn hydroxide, Carbon cryogel, Capacitance, Power density, Energy density, Supercapacitor

Lithium secondary battery and electrochemical

supercapacitor can be used as a portable power source as an energy storage

system using electrochemical principle [1-7]. Although the secondary battery

has excellent energy density (the amount of energy that can be accumulated per

unit weight or volume), there is still room for improvement in terms of usage

time, charging time, and amount of energy available. Although

the electrochemical supercapacitor has a smaller energy density than the

secondary battery, it exhibits superior characteristics to the secondary

battery in terms of use time, charging time, and output density [6]. Manganese

and nickel electrode materials display considerable electrochemical activity

not only in low discharge rates applied in conventional secondary batteries but

also under the usual harsh conditions for the electrochemical supercapacitors

[8-11]. Ni-Mn oxide and hydroxide-based electrodes reveal a significant

reversible electrochemical activity in the alkaline

electrolytes and an extended operating voltage window (~1.8 V)

[8]. Ni-Mn ilmenite-based electrode materials demonstrate a low fade

rate and high specific electrochemical capacity values at high

discharge rates (up to 70 mAh/g at I = 70 mA/cm2) that

makes feasible their application in high rate batteries and

electrochemical supercapacitors. These metal oxides are widely

used as active electrode with polypyrrole, polyaniline, and polythiophene for

supercapacitors due to the availability of dual metal cations [8, 12-16]. Carbon-based

materials such as activated carbon, carbon black,

carbon aerogels, graphene, carbon fiber materials, porous

nanocarbon, carbon nanotubes, and multiwalled carbon

nanotubes have been widely used in the electrode materials

for supercapacitors [6, 12-20]. Carbon aerogels are

considered as a promising candidate material for the application of

supercapacitors because of high porosity, low electrical resistivity, and high

surface area [6]. However, the cost of supercritical drying limits a widespread

use. Nowadays, carbon cryogels are emerging as the

material of choice for the electrode materials of supercapacitors due to the

simplicity because the use of activated carbon or carbon nanotube mixed with

the metal oxide powder and the polymer binder may cause the complexity of the

process and the deterioration of the electrical conductivity [1-7, 12-20].

The purpose of this study is

to solve the problems of the complexity of the process and the deterioration of

the electrical conductivity of the composite electrode as a result of the use

of the mixed carbon with the metal oxide powder and the polymer binder. In

order to improve the power density, the energy density, and the capacitance of

electrochemical capacitors, we have studied electrodes by adding the

freeze-dried carbon cryogel, which has excellent specific surface area and

electrical conductivity, to the coprecipitated Ni-Mn hydroxide possessing high

specific capacitance and energy density. Carbon cryogels are synthesized by

sol-gel polycondensation of resorcinol with formaldehyde, followed by a freeze

drying and subsequent pyrolysis in an inert atmosphere [1-7]. Electrochemical

properties of the carbon cryogel

electrode mixed with Ni-Mn metal oxide are then evaluated.

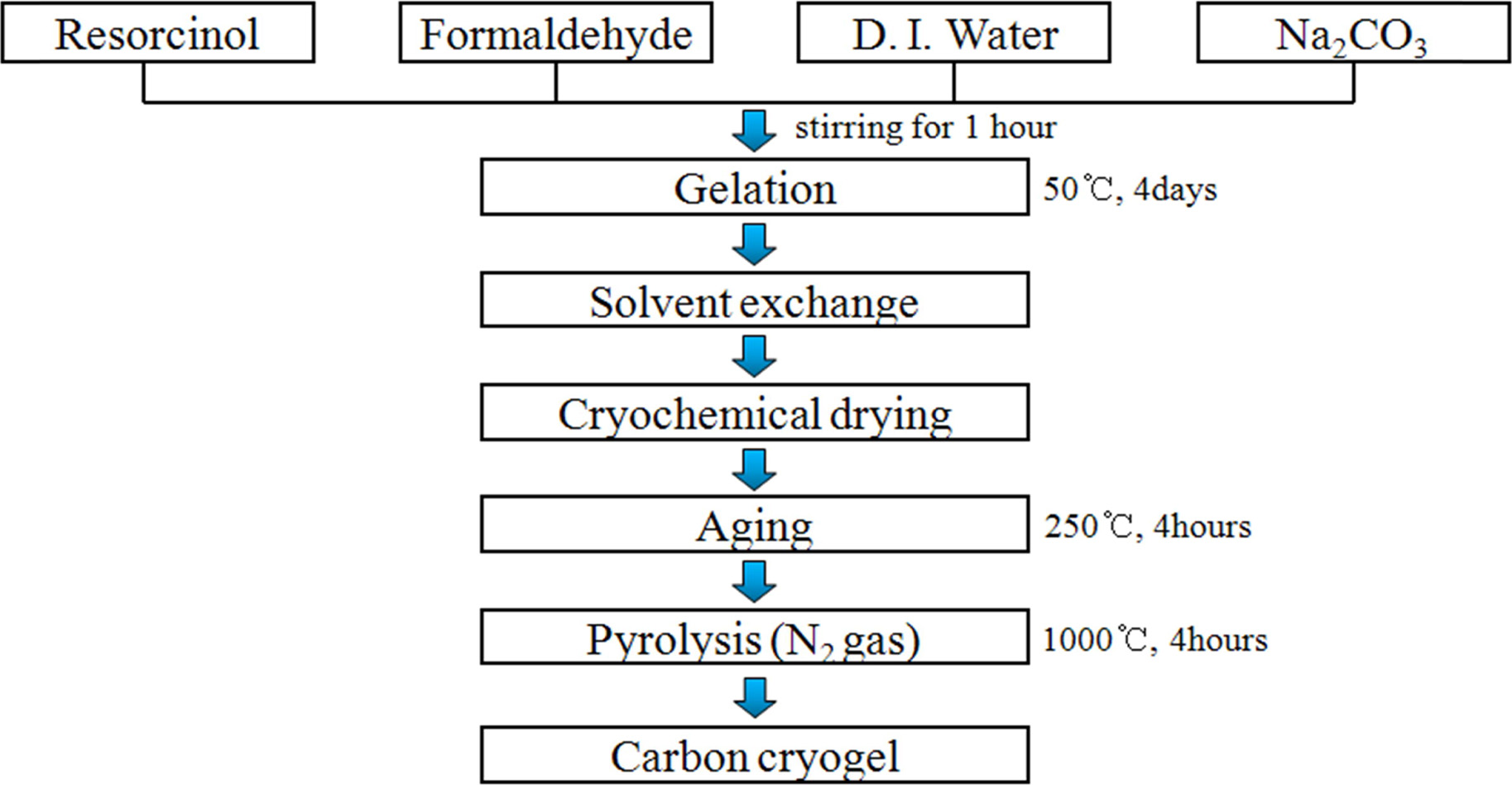

Carbon

cryogel

Carbon cryogel possessing a large specific surface area

and pore size was prepared to compensate for the drawbacks (low specific

surface area and electrical conductivity) of Ni-Mn hydroxide, which is shown in

Fig. 1. The aqueous polycondensation of resorcinol (R) with formaldehyde (F)

were prepared from resorcinol (Sigma-Aldrich), formaldehyde

(Sigma-Aldrich, 37 wt% solution in water), sodium

carbonate (Na2CO3, Sigma-Aldrich), and distilled water.

After stirring for 1 h, the solution was gelled by curing for 4 days at

50 oC. This gel was washed by immersing the gel in t-butanol

for 1 day. The as-washed gels were frozen for 1 h at -30 oC and

then dried for 3 days to obtain the RF cryogel [6, 21, 22]. After aging

the RF cryogel for 4 h at 250 oC, carbon

cryogel was prepared by pyrolysis of the cryogel for 4 h at

1,000 oC, as depicted in Fig. 1. Details of the experimental

process is described elsewhere [6]

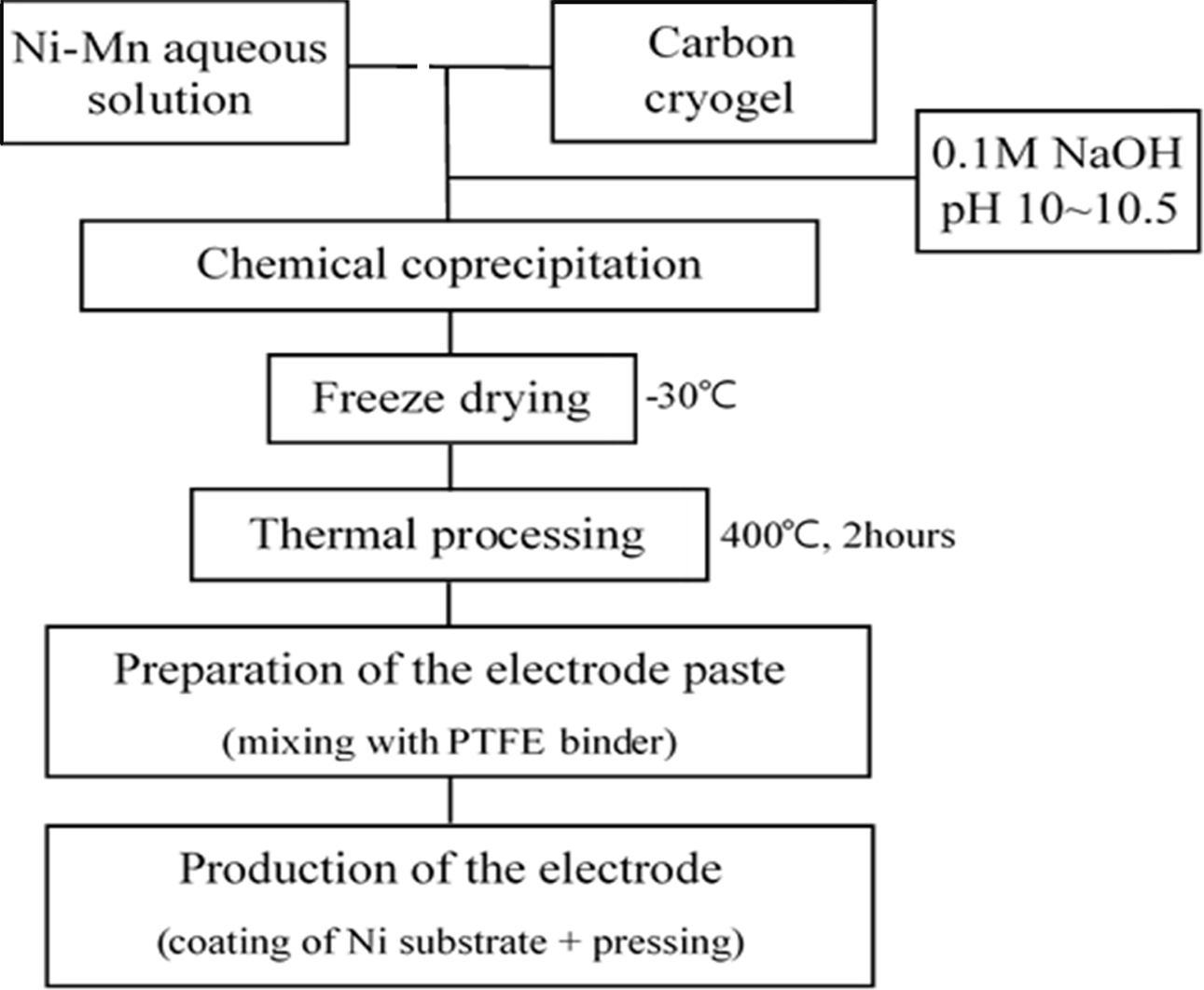

Ni-Mn

hydroxide/carbon cryogel composite electrode

The composite electrode was prepared by mixing Ni-Mn

aqueous solution and carbon cryogel (0~80 wt%), as displayed in Fig. 2. Ni-Mn

hydroxides were coprecipitated from aqueous solutions followed by

freeze drying. The freeze-dried powders were isothermally processed for 2 h at 400 oC. The electrode paste

was prepared by mixing them with

polytetrafluoroethylene (PTFE) binder.

The paste was pressed into the nickel foam substrate and then dried for 12 h at

100 oC [6, 8].

Electrochemical

properties

The electrochemical properties of the composite electrodes

were examined at room temperature with a three-electrode apparatus

consisting of a working electrode, a Pt counter electrode, and an Hg/HgO

reference electrode in KOH solution with

different concentrations [6].

Electrochemical properties of carbon

cryogel as electrode material in supercapacitor was evaluated using cyclic voltammetry (CV), a

galvanostatic charge-discharge test,

and electrochemical impedance spectroscopy (EIS). The CV measurements were

performed at various scan rates in the range of 5 mV/s and 50 mV/s. Galvanostatic

charge-discharge behavior was performed under various constant current

densities in a potential between 0 and 1.0 V. Impedance analysis was done with

10 mV amplitude in the frequency range of 100 kHz to 10 mHz using a

two-electrode system [13]. Prior to the experiment, carbon cryogel electrodes

were immersed in electrolyte for 24 h to diffuse the aqueous electrolyte

solution into the pores of carbon cryogel [6, 8, 14-20].

|

Fig. 1 Fabrication procedure of carbon cryogel. |

|

Fig. 2 Manufacturing procedure of Ni-Mn hydroxide+carbon cryogel composite electrode. |

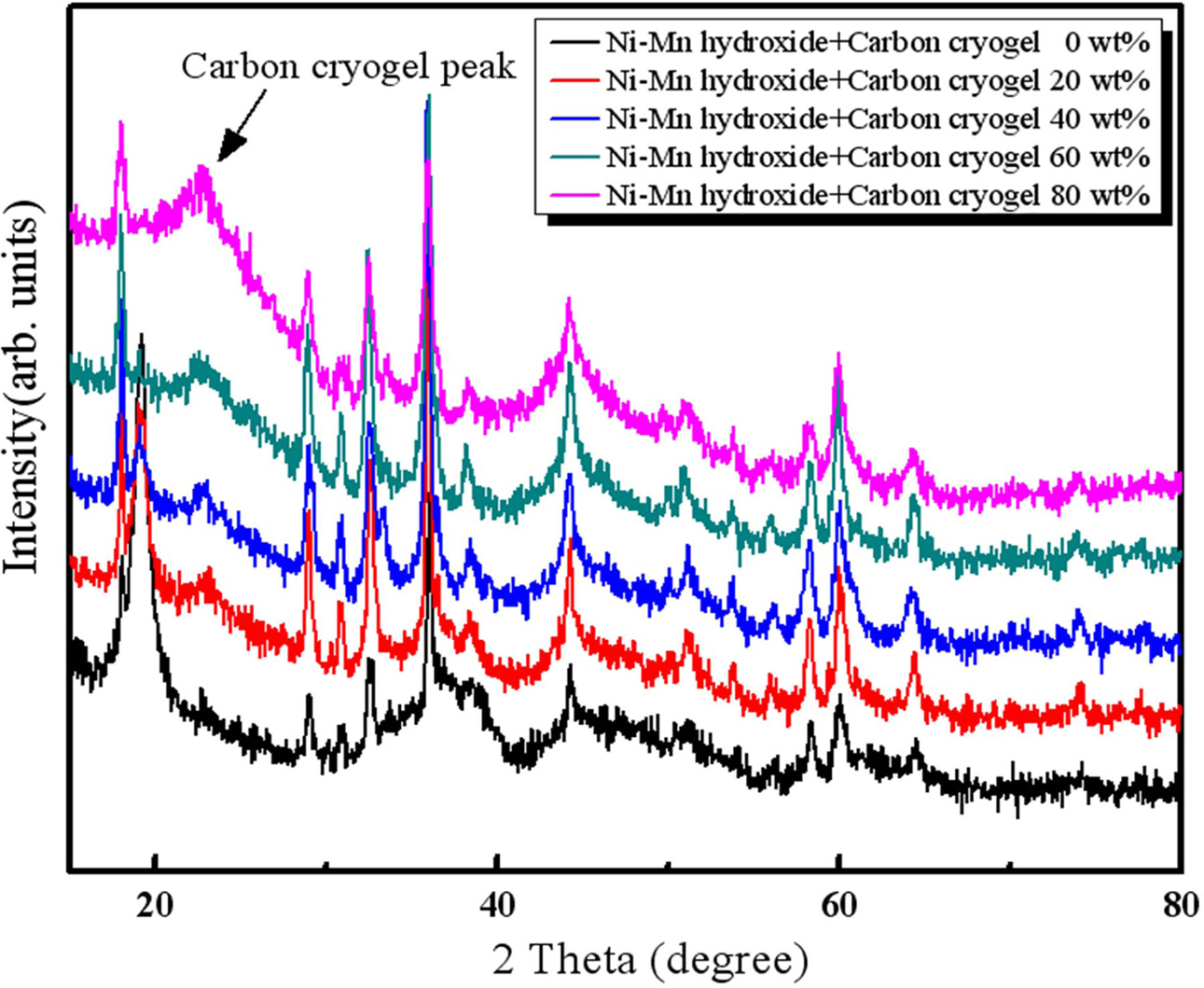

Our previous studies revealed that carbon cryogels had a high

surface area of 1264 m2/g, large mesopore volumes of 0.63 cm3/g,

and average pore diameter of 20 Å [6]. XRD peaks of the carbon

cryogels were reported to be located at 2θ of 23.5o and 43.8o,

exhibiting the strong (002) and weak (101) diffraction

lines, respectively, implying that the carbon cryogels were composed of most

amorphous and small amount of graphitized carbons [6]. In the present study,

the effect of the amount of carbon cryogel on the electrochemical properties of

Ni-Mn and carbon cryogel composite electrodes was investigated. Fig. 3

exhibited that the composite electrode showed a distorted spinel-like structure

similar to the Ni-Mn hydroxide plus the carbon cryogel peaks located at 2θ

of 23o [8]. As the amount of carbon cryogel increased from 0 to 80

wt%, the peak intensity of graphitized carbon rose dramatically

without any second phases, implying that the carbon cryogel can be regarded as

graphitized carbon rather than carbon. In addition, the XRD peak of Ni-Mn was

slightly shifted to lower angle due to the formation of distorted spinel-like

structure [13].

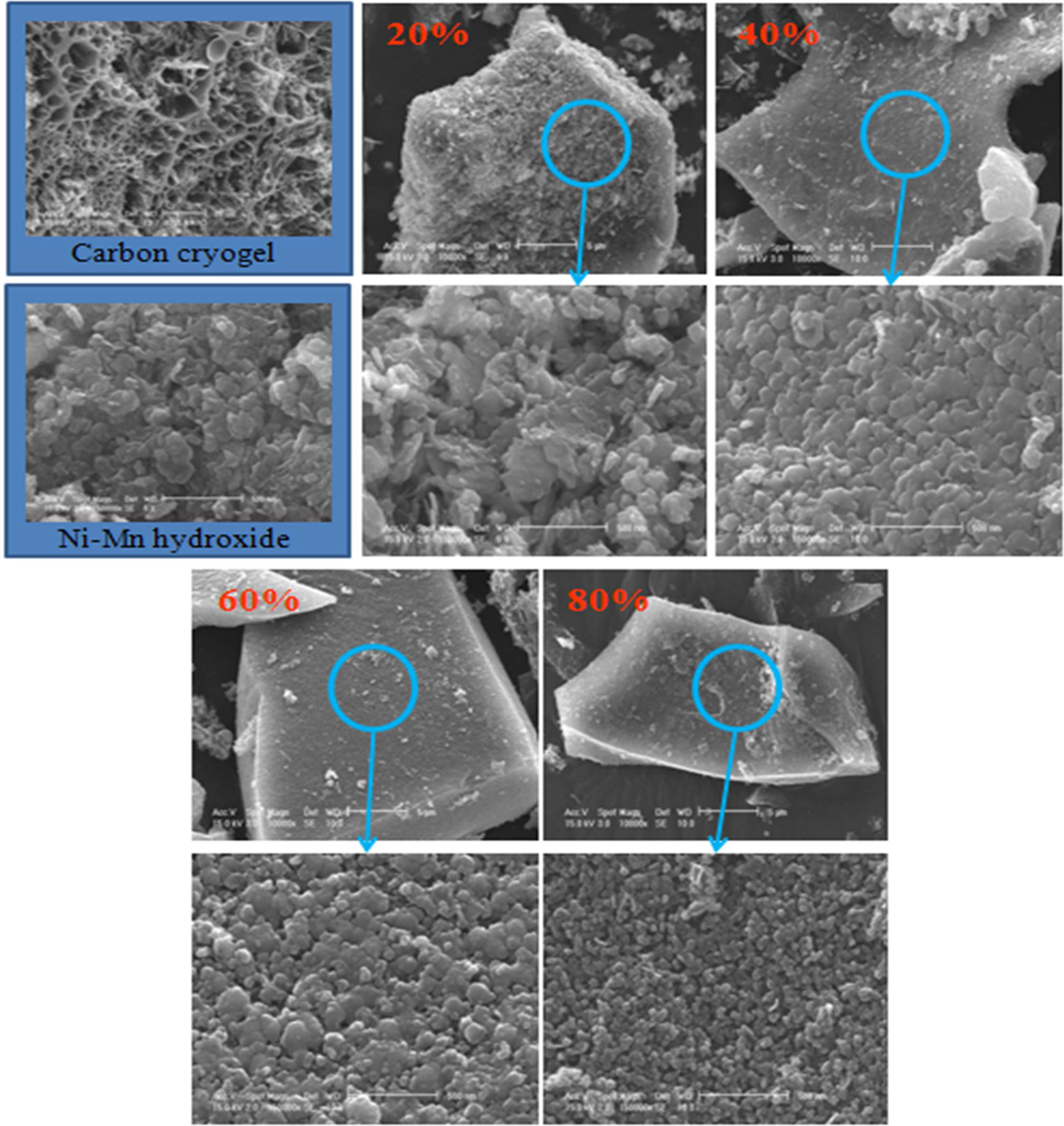

Microstructure of the composite electrode as a function of

carbon cryogel concentration was examined as shown in

Fig. 4. As the carbon cryogel concentration increased,

Ni-Mn hydroxides were uniformly distributed on the

surface of carbon cryogel having higher specific surface area. And the particle

size of Ni-Mn hydroxide on the surface of carbon cryogel

decreased dramatically with increasing the content of

carbon cryogel from 20% to 80%. Although physical mechanisms involved are not

yet completely understood, the presence of the carbon cryogel played a

significant role in inhibiting the crystal growth of Ni-Mn hydroxide.

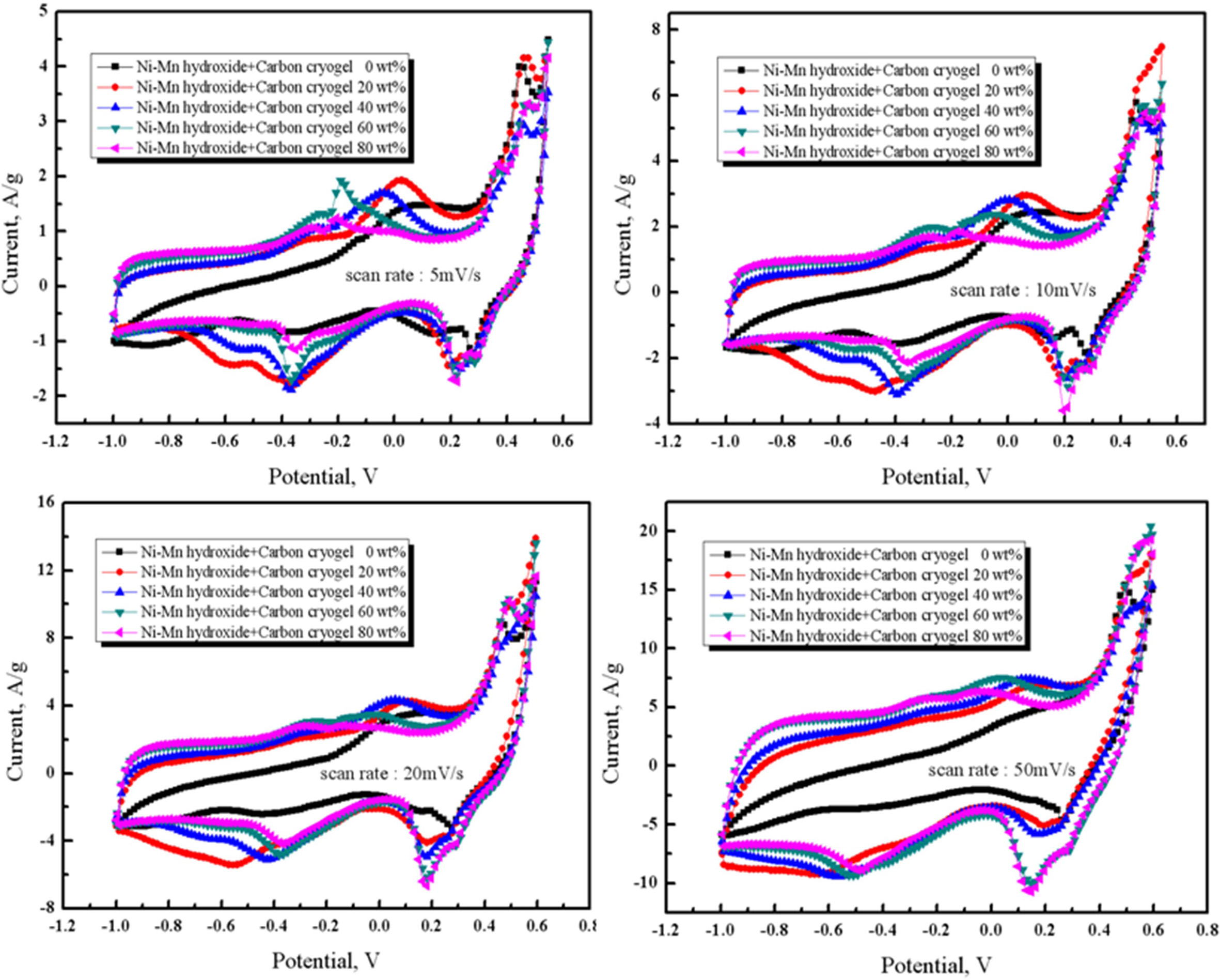

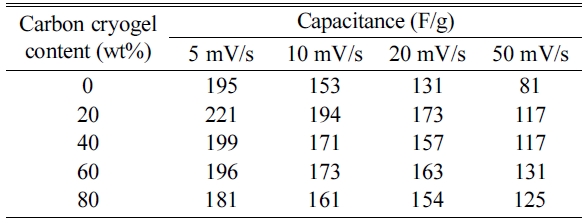

The CV curves were examined in 6M KOH electrolyte

to investigate the variation of capacitance with various scan rates in the

range of 5 mV/s to 50 mV/s, as shown depicted in Fig. 5. The specific

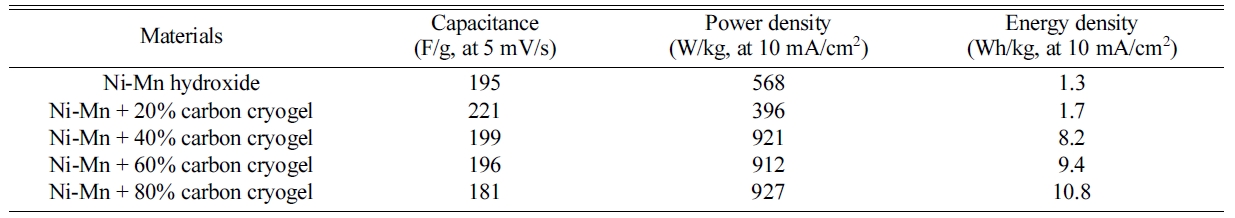

capacitances of the electrodes (C), as summarized in Table 1,

were estimated from the equation of C = {(Ia + |IC|) / 2W(dV/dt)},

where Ia, Ic, W,

and dV/dt are the current of anodic and cathodic voltammetric curves on

positive and negative sweeps, mass of the composite, and the sweep rate,

respectively [6, 23]. As can be seen in Fig. 5 and Table 1, the

capacitance started to decrease with increasing the scan rate

from 5 mV/s to 50 mV/s. Excellent capacitances were observed for

the composite electrode containing 20 wt% of carbon cryogel when the scan rates

were in the range of 5 mV/s and 20 mV/s. As the carbon cryogel concentration

rose from 20 wt% to 80 wt%, the capacitance decreased from 221 F/g to 181 F/g

due to the decrease in the amount of Ni-Mn hydroxide. In

addition, the specific capacitance of the composite electrode

containing 20 wt% of carbon cryogel decreased from 221 F/g

to 117 F/g with increasing the scan rate from 5 mV/s to 50 mV/s. It is reported

that the ions can transport into pores more easily at low scan rate, however,

they had a difficulty in diffusing into pores when scan

rates were above 5 mV/s [6]. It is conceivable that the low

scan rate (5 mV/s) and the content of carbon cryogel (20 wt%) are mainly

attributed to higher capacitance of the composite electrodes.

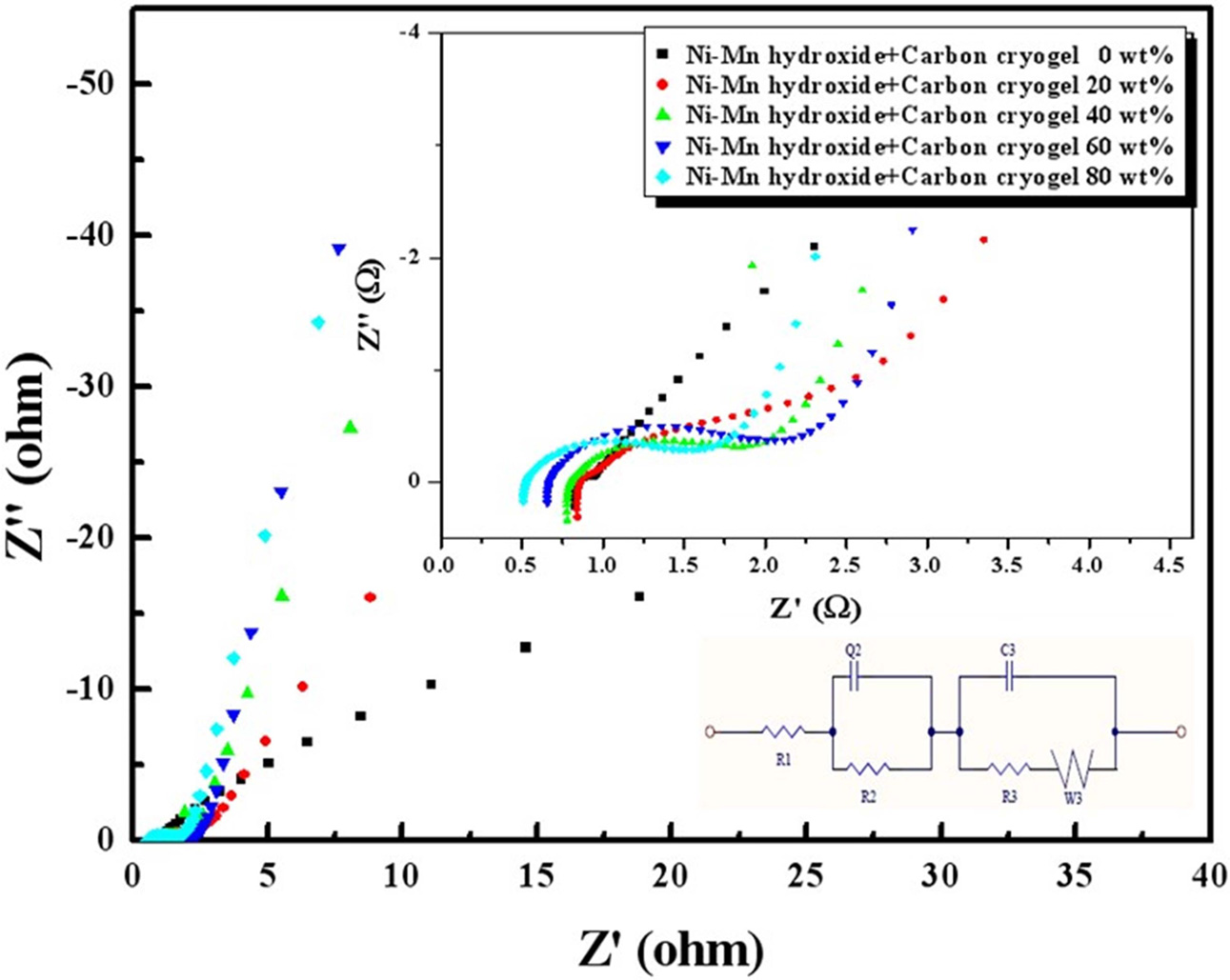

The imaginary part of the impedance is plotted as a function

of real part to compose the impedance spectrum (Nyquist plot), as displayed in

Fig. 6. The capacitance can be calculated from the imaginary part of the

impedance spectrum according to the equation of Z'' = 1/2πfC,

where f and Z” are the applied frequency and the imaginary

impedance, respectively [6, 12-20]. Electrochemical

impedance spectroscopy of the composite electrodes

in 6 M KOH electrolyte with different concentrations of carbon cryogel in the

range of 0 to 80 wt% revealed that the variation in carbon cryogel

concentration can be found in the impedance plot of the composite electrodes.

This phenomenon can be evaluated by an equivalent circuit model (Fig. 6). R1

is the electrolyte resistance. R2, R3, and Q2,

represent the contact resistance, the reaction resistance, and the capacitance

between carbon cryogel and Ni-Mn hydroxide particles,

respectively. C3 and W3 are the capacitance of double

layer on the surface and the Warburg impedance, respectively

[13]. R1 decreased gradually with increasing the content

of carbon cryogel probably due to the use of carbon aerogel and Ni-Mn oxide

instead of activated carbon, as displayed in Fig. 6. In the low frequency region,

the impedance plot of these capacitors increases, implying

that it is purely capacitive. The intersection with the real axis and the first

semicircle indicates the internal resistance of the capacitor,

which is an equivalent series resistance (ESR) of the

electrolyte in contact with the current collector and composite electrode. The higher

the content of carbon cryogel, the lower the ESR. The

combination of resistive and capacitive behaviors of the ions penetrating into

the electrode pores leads to a Warburg diffusion line and a capacitive line.

The stiffer slope in Fig. 6 implies that the ions can be penetrated into the

pores of the composite electrodes more easily with increasing the content of

carbon cryogel.

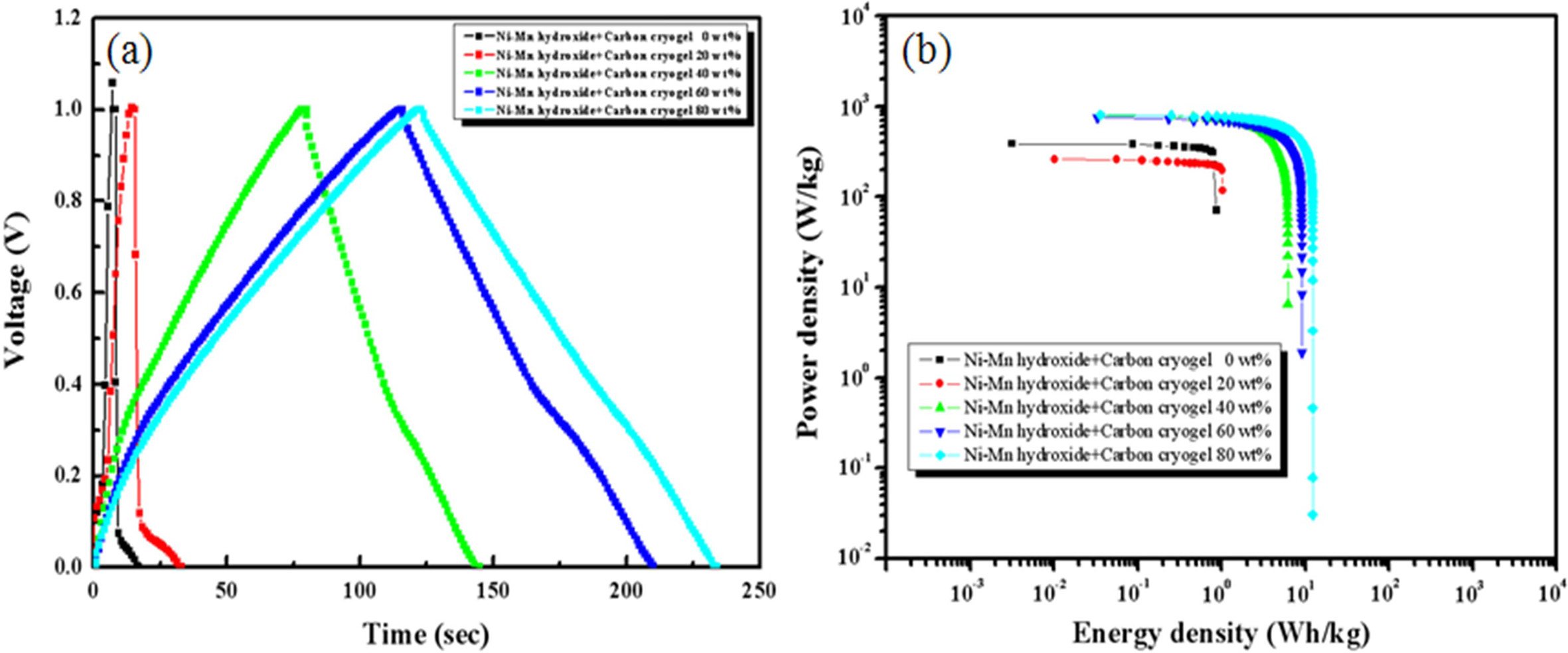

The charge-discharge curves and Ragone plot of the

composite electrodes measured in 6 M KOH at current density of 10 mA/cm2

are shown in Fig. 7(a). As the carbon cryogel concentration increases, the IR

drop occurring at the initial state of discharge decreases and the

discharge time becomes longer, suggesting that it can store more energy. The

carbon cryogel content is mainly attributed to excellent

charge-discharge characteristics and energy density. The energy density rose

from 1.7 Wh/kg to 10.8 Wh/kg with increasing the carbon cryogel content from 20

wt% to 80 wt%. The specific capacitance and power density are calculated using

the charging/discharging characteristics. As a result of Ragone plot (Fig. 7(b)

and Table 2), the power density of

the electrodes regardless of the carbon cryogel content reached a

plateau and then decreases dramatically at a certain value

of energy density. The composite electrodes with 80 wt%

of carbon cryogel exhibited much better power output of 927 W/kg. In addition,

capacitance, power density, and energy density of the composite electrodes can

be tailored through the adjustments of the experimental parameters (the content

of carbon cryogel, scan rate, and energy density) for

supercapacitors.

|

Fig. 3 XRD patterns of Ni-Mn hydroxide and carbon cryogel composite electrodes. |

|

Fig. 4 SEM images of the surfaces of Ni-Mn hydroxide and carbon cryogel composite electrodes. Note that the particle size decreased with increasing the content of carbon cryogel from 20 wt% to 80 wt%. |

|

Fig. 5 Cyclic voltammogram of the Ni-Mn hydroxide and carbon cryogel composite electrodes with various scan rates in 6M KOH electrolyte. |

|

Fig. 6 Electrochemical impedance spectroscopy of carbon cryogel electrode in KOH electrolyte with different carbon cryogel concentration. |

|

Fig. 7 (a) Charge-discharge curves and (b) Ragone plot of Ni-Mn hydroxide and carbon cryogel composite electrodes. |

|

Table 1 Capacitance of the Ni-Mn hydroxide and carbon cryogel composite electrodes with various scan rates in 6 M KOH electrolyte. |

|

Table 2 Capacitance, power density, and energy density of Ni-Mn hydroxide and carbon cryogel composite electrodes. |

To improve electrochemical properties of Ni-Mn hydroxide,

20 to 80 wt% of carbon cryogels with high specific surface area and electrical

conductivity were added to Ni-Mn hydroxide electrode. XRD results of the

composite electrodes revealed that the composite electrode

showed a distorted spinel-like structure similar to the Ni-Mn

hydroxide plus the graphitized carbon. The electrolyte resistance (R1)

decreased gradually with increasing the content of carbon cryogel.

Although the power density and the energy density of the composite

electrodes increased with increasing the carbon cryogel concentration, the

highest capacitance was observed for the electrodes containing 20 wt% of carbon

cryogel due to the reduction in Ni-Mn hydroxides. The Ni-Mn hydroxide and carbon

cryogel materials demonstrated sufficient electrochemical activity and high

capacitance of 221 F/g at an electrode loading amount of 15

mg/cm2, implying that the composite electrodes are suitable

for supercapacitors.

- 1. J.R. Miller and P. Simon, Science 321[5889] (2008) 651-652.

-

- 2. G. Wang, L. Zhang, and J. Zhang, Chem. Soc. Rev. 41[2] (2012) 797-828.

-

- 3. A.M. Saleem, V. Desmaris, and P. Enoksson, J. Nanomater. 2016 (2016) 1537269.

-

- 4. O.A. Shlyakhtin, S.H. Choi, Y.S. Yoon, and Y.-J. Oh, Electrochim. Acta 50[2-3] (2004) 511-516.

-

- 5. O.A. Shlyakhtin and Y.-J. Oh, J. Electroceram. 23 (2009) 452-461.

-

- 6. M. Song, S. Nahm, and Y.-J. Oh, J. Korean. Ceram. Soc. 45[11] (2008) 662-666.

-

- 7. N.M. Shinde, J.M. Yun., R. S. Mane, S. Marthur, and K.H. Kim, J. Korean. Ceram. Soc. 55[5] (2018) 407-418.

-

- 8. O.A. Shlyakhtin, A.M. Skundin, Y.S. Yoon, and Y.-J. Oh, Mater. Lett. 63[1] (2009) 109-112.

-

- 9. J. Cao, S. Yuan, H. Yin, Y. Zhu, C. Li, M. Fan, and H. Chen, J. Sol-gel Sci. Technol. 85 (2018) 629-637.

-

- 10. M.-S. Jeong, B.-K. Ju, Y.-J. Oh, and J.-K. Lee, Korean J. Mater. Res. 21[6] (2011) 309-313.

-

- 11. O.A. Shlyakhtin, A.M. Skudin, S.J. Yoon, and Y.-J. Oh, Mater. Lett. 63[1] (2009) 109-112.

-

- 12. J.L. Figueiredo, J. Sol-gel Sci. Technol. 89 (2019) 12-20.

-

- 13. H.S. Min, S. Kim, W.-K. Choi, Y.-J. Oh, and J.K. Lee, Korean J. Mater. Res. 19 (2009) 544-549.

-

- 14. J.Y. Hwang, M. Li, M.F. El-Kady, and R.B. Kaner, Adv. Funct. Mater. 27 (2017) 1605745.

-

- 15. S. Ramesh, D. Vikraman, K. Karuppasamy, H.M. Yadav, A. Sivasamy, H. Kim, J. Kim, and H. Kim, J. Alloy Comp. 794 (2019) 186-194.

-

- 16. J. Theerthagiri, G. Durai, K. Karuppasamy, P. Arunachalam, V. Elakkiya, P. Kuppusami, T. Maiyalagan, and H. Kim, J. Ind. Eng. Chem. 67 (2018) 12-27.

-

- 17. J.Y. Hwang, M.F. El-Kady, Y. Wang, L. Wang, Y. Shao, K. Marsh, J.M. Ko, and R.B. Kaner, Nano Energy 18 (2015) 57-70.

-

- 18. S. Chun, B. Evanko, X. Wang, D. Vonlanthen, X. Ji, G.D. Stucky, and S.W. Boettcher, Nat. Commun. 6 (2015) 7818.

-

- 19. Y. Shao, M.F. El-Kady, J. Sun, Y. Li, Q. Zhang, M. Zhu, H. Wang, B. Dunn, and R.B. Kaner, Chem. Rev. 118 (2018) 9233-9280.

-

- 20. M.F. El-Kady and R.B. Kaner, ACS Nano 8 (2014) 8725-8729.

-

- 21. Y. Kim, S. Son, C. Chun, J. Kim, D.Y. Lee, H.J. Choi, and T. Kim, Biomed. Eng. Lett. 6 (2016) 287-295.

-

- 22. O.A. Shlyakhtin, Y.S. Yoon, S.H. Choi, and Y.-J. Oh, Electrochim. Acta 50 (2004) 505-509.

-

- 23. X. Wang, X. Wang, W. Huang, P.J. Sebastian, and S. Gamboa, J. Power Sources 140 (2005) 211-215.

-

This Article

This Article

-

2019; 20(6): 649-654

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.649

- Received on Jul 12, 2019

- Revised on Oct 1, 2019

- Accepted on Oct 7, 2019

Services

Services

Shared

Correspondence to

Correspondence to

- Young-Jei Oh

-

bOpto-electronic Materials & Devices Research Center, Korea Institute of Science and Technology, Seoul 02792, Korea

cDepartment of Nano Material Science and Engineering, Korea University of Science and Technology, Daejeon 34113, Korea

Tel : +82-2-958-5553 Fax: +82-2-958-5554 - E-mail: youngjei@kist.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.