- Roles of talc-illite on phase transformation, vitrification and physical properties of a triaxial porcelain body

Suthee Wattanasiriwecha,b and Darunee Wattanasiriwecha,b,*

aCenter of Innovative Materials for Sustainability, School of Science, Mae Fah Luang University, Thailand

bCircular Economy for Waste-free Thailand Research Group, Mae Fah Luang University, Thailand

Flux forming additives have

played an important role of energy reduction in the ceramic industry for

centuries. Though there are available fluxing materials in the market, attempts

of searching for new flux systems have still been extensively done. This paper

presents the use of a combined flux system and its roles on phase

transformation and physical properties of a triaxial porcelain body. Illite was

used as the primary flux in the main recipe while talc, the supplementary flux,

was added at 0, 3, 5 weight %. In pure form, talc dissociated into enstatite

around 900 oC but when mixed in the recipe, phase changes of

talc differed. Talc and illite disappeared around 1,000 oC.

Around 1,200-1,300 oC, indialite and pyrophillite appeared only

on the body with talc addition. Early densification could be observed when talc

was present, suggesting that talc also played an important role in

vitrification. The body with 3% talc showed the greatest firing shrinkage and

flexural strength but lowest water absorption after firing at 1,200 oC,

which was ~50 oC lower than the body without talc. Further

increasing of talc content to 5% resulted in an adverse effect of these

properties.

Keywords: Triaxial porcelain, Illite, Talc, Phase transformation, Vitrification

Porcelains are vitreous ceramic whitewares which are used

extensively in table wares, dental prosthetics, and decorative wares. With the

room temperature resistivity between 1012-1014

Ω, porcelain ceramics are extensively used as an insulating material

[1].

Porcelains typically have a triaxial formulation

comprising of clay-feldspar-quartz as the main ingredients.

Quartz is partially added to reduce pyroplastic deformation

[2].

Due to the high firing temperature (>1,200 oC

for soft porcelain and 1,400 oC for hard porcelain),

flux-forming additives were generally employed in order to reduce

the energy consumption without compromising productivity and product

[3-6].

Some of the reported works are exemplified

here. Das compared densification behavior of K-and Na-feldspar-containing

porcelain bodies and found that Na-feldspar containing body exhibited maximum

densification rate at 1,171 oC

compared to 1,195 oC for the K-feldspar containing

body [7].

The Na-feldspar containing body achieved higher density,

lower water absorption and highest flexural strength at 1,200 oC.

Dana et al. have reported the enhancement in densification and

strength of triaxial porcelain when B.F. slag was used in substitution

of potash feldspar [8].

The addition of slag resulted in the diminishment of

quartz and mullite needles but development of anorthite phase (CaO·Al2O3·2SiO2).

Bragança and Berman showed that the glass-powdered porcelain in which feldspar

was replaced by recycled soda-lime glass sintered at 100 oC

lower than the traditional porcelain [9].

However, when fired at the proper

temperature, traditional porcelain exhibited higher modulus of

rupture due to the presence of secondary mullite crystals. Combined flux system

was typically used along with the aids of muscovite mineral [10].

Pyroplastic deformation, which is related to properties

of liquid phases formed during firing, was found to be influenced by ratio of

the key ions used in the formula. It was reported that that a definite

combination at SiO2/Al2O3 ratio of 5 and Na2O/K2O

ratio of 4 gave the lowest pyroplastic deformation in the porcelain body

formulations [11].

Some of the reported literatures proposed an alternative

method in energy consumption reduction such as direct sintering method whose total

processing time was reduced by a factor of

50% and the sintering temperature was

decreased from 1,200 oC to 1,175 oC [12].

In this scenario, sample was delivered

directly to the furnace pre-set at the

sintering temperatures. The samples were held for 15 min

before cooling down to 700 oC at a rate of 30 oC/min

and followed by cooling to room temperature. The use of

microwave sintering was reported to reduce sintering temperature by ~75oC

and reduce dwell time from 15 min to 5 min while retaining

comparable physical properties [13].

As previously discussed, the irreversible thermal expansion

of ceramic bodies containing ball clay started around

900 oC [14].

Most ball clay contains illite, which

is a mica- type mineral with its high potassium content in its structure, and

thus fusibility. The structure of illite is composed of two tetrahedral sheets

sandwiched to an octahedral sheet to form a 2:1 layer phyllosilicate. Illite

serves as an excellent flux because of its small particle size and being a part

of body matrix. The body porosity was, thus, reduced by the

onset of melting and the bodies began to shrink at a temperature as

low as 900 oC [14].

This result was in good agreement

with a study by Aras [15],

who used illite in substitution of kaolin. It was shown

that the high K content in illite caused a large amount of

liquids and the reduction of mullite formation temperature.

When illitic clay was fired, illite structure first collapsed around

900-950 oC resulting in liquid phase

formation [16, 17].

Another study using an in-situ high

temperature X-ray diffraction showed that transition from

illite phase to dehydroxylated phase started around 525 oC

in static air and higher at about 550 oC in vacuum.

Phase transformation from dehydroxylated to mullite occurred at above

1,100 oC [18].

It was also pointed out that transformation could be

affected by sample’s properties such as particle size, crystallinity, and

vacant type [19].

Illite was reported to gradually diminish at 600 oC

before completely disappearing at 800 oC upon firing

[19].

Our previous attempt to use illite as the primary flux

in place of a potash feldspar in a triaxial porcelain body was achieved and the

firing temperature could be lowered up to 100 oC [20].

Talc is a hydrated magnesium sheet silicate with the chemical

formula Mg3Si4O10(OH)2. Talc has a

2:1 structure with an octahedral brucite sandwiched between

two tetrahedral silicate layers [21].

Talc is typically used as a filler in composite

materials to decrease the production costs while improving the physical and chemical

properties and also providing new functionalities [22].

From literatures, talc progressively lost its hydroxyl groups

at above 900 oC and re-crystallized into different

forms of enstatite (anhydrous magnesium silicate) above

1,050 oC before melting at 1,500 oC [23].

The use of talc with other fluxes e.g.

nepheline syenite has been reported [24].

Appropriate amount of talc added to the stoneware

body was reported to give optimum properties and decrease

sintering temperature [25].

When feldspar was partly replaced by talc, the body

fired at high temperature contained more liquid of lower viscosity than

the standard body containing only feldspar flux [26].

In this study, our further

attempt to reduce the firing temperature with the aids of talc in the body

containing illite as the primary flux was performed. Phase changes and physical

properties were determined and discussed here.

China clay whose main minerals were halloysite and kaolinite

was received from Ranong province, Thailand. Quartz and

talc (Mg3Si4O10(OH)2) were

purchased from a domestic commercial supplier. The illite mineral (KyAl4Si8-yAlyO20(OH)4)

where y = 1-1.5, Green shale) was received from Ward’s Natural Science,

Rochester, New York, USA. Analysis of illite and china clay was previously

reported [20].

Analysis of talc was assessed using

standard protocols, X-ray diffraction (XRD), scanning electron

microscopy (SEM), and size analysis using laser diffraction. The lateral size

(a) of plate-like talc particle was analyzed based on the method described by

Pérez-Maqueda et al. as shown in Eq. (1) [27]:

d001 (4.67 nm or

4.67×10-9

m) was determined from the broadening of XRD peak.

esd is the equivalent spherical diameter

(m) which can be calculated from Eq. (2) as follows;

where S is the specific surface

area (6.02 m2·g-1) determined

using the BET technique and r

is the density (2.8 kg·m-3).

The body recipe contained 50 weight % china clay, 25

weight % quartz and 25 weight % illite. Talc (0, 3, 5 weight %) was finally

added and the samples were denoted as IT0, IT3 and IT5

respectively. Details of experiments were also previously addressed [20].

Summary of the experiment is given shortly here. The

starting materials were mixed, ground using a ball milling technique and sieved

through a 325-mesh sieve prior to drying in an oven overnight. The dried clay

was then pressed at a compaction pressure of 50 MPa into a rectangular bar with

the dimensions of 5 mm ´ 5

mm ´ 60 mm. Each

set of the test samples was heated in the range of 900-1,300 oC

in air atmosphere. Water absorption of the fired samples was examined based on the

Archimedes’ principle with the details of experiment reported

in ref [28].

The flexural strength was

measured using a Universal Testing Machine (Instron 2000, UK)

by the three-point bending technique. For all

measurements, the support span of 80 mm

and the crosshead speed of 5 mm/min were selected. The flexural strength was

measured using the formulae s = 3/2 [(FL)/bd2],

where is the flexural strength, F is the load at the fracture point (N), L is

the span length; b and d are the width and thickness of the specimens

respectively. These values, which were averaged from five samples, were plotted as a function of

firing temperature. Phase analysis was observed using an X-ray diffraction (XRD)

technique equipped with the software

X’pert High Score Plus (X’pert Pro MPD, Philips, Netherlands).

Microstructural development of the fired bars

was examined with scanning electron microscope (SEM: LEO 1450 VP). The fired

test bars were etched with 4% hydrofluoric acid (HF) before the microscopical

examination.

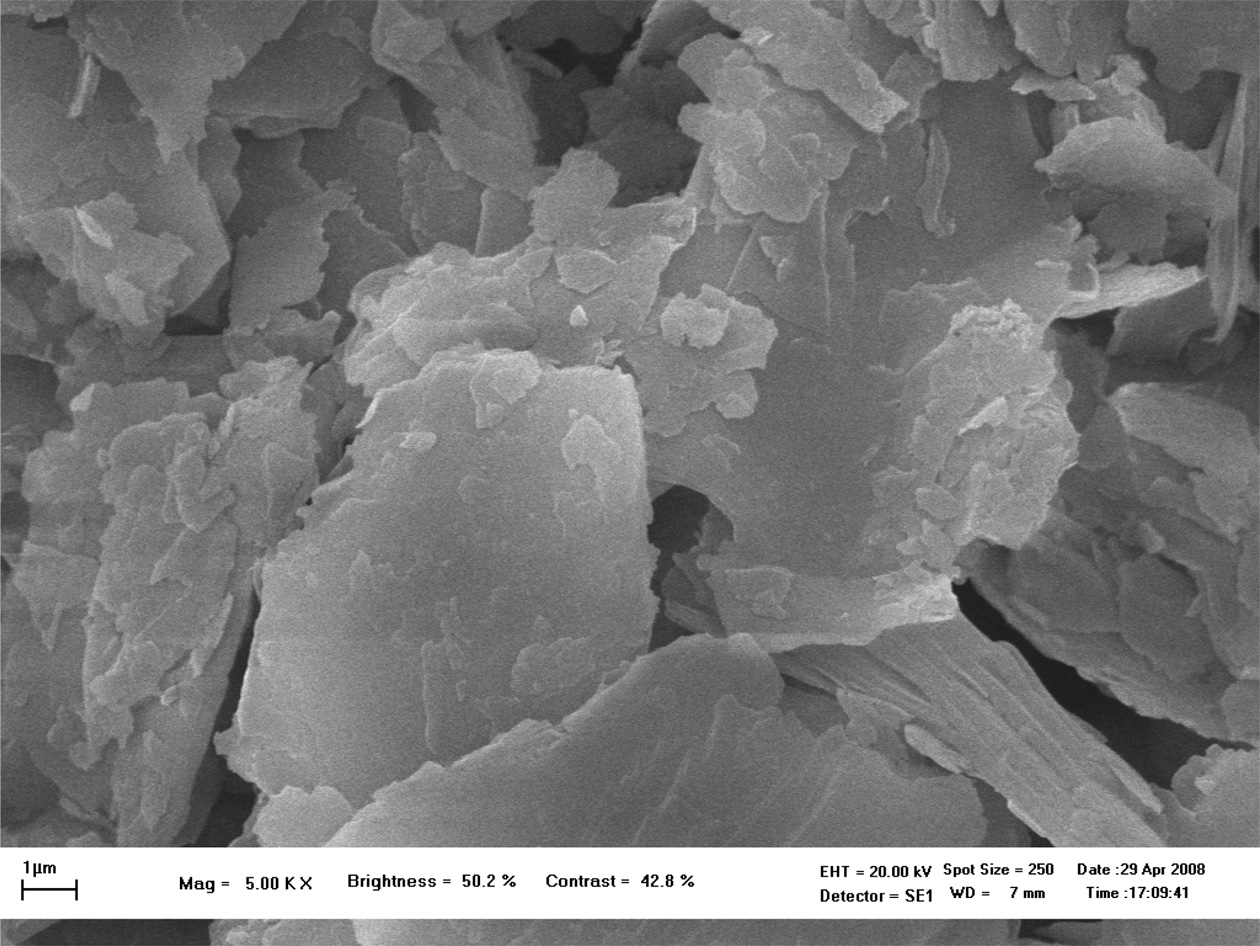

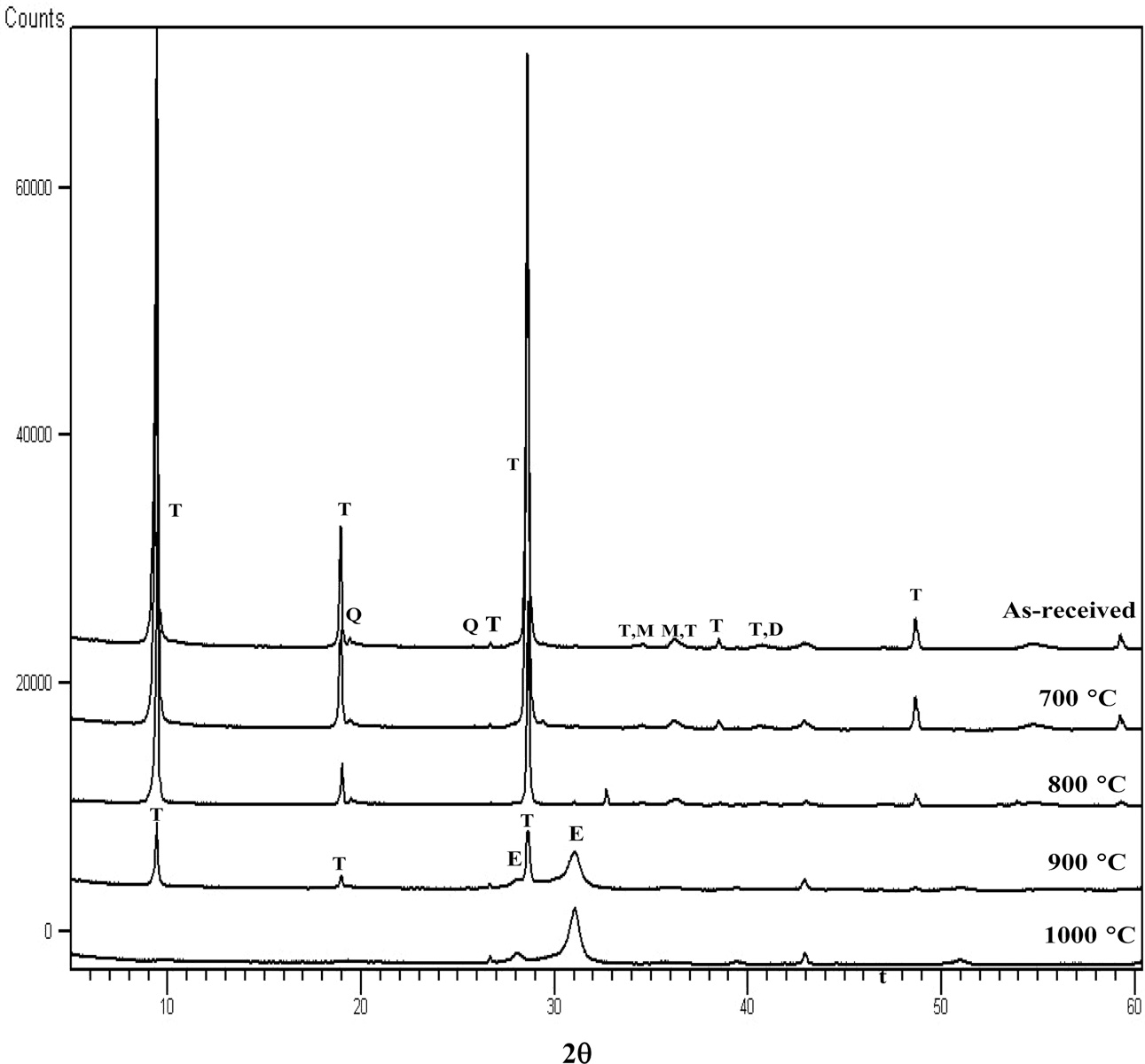

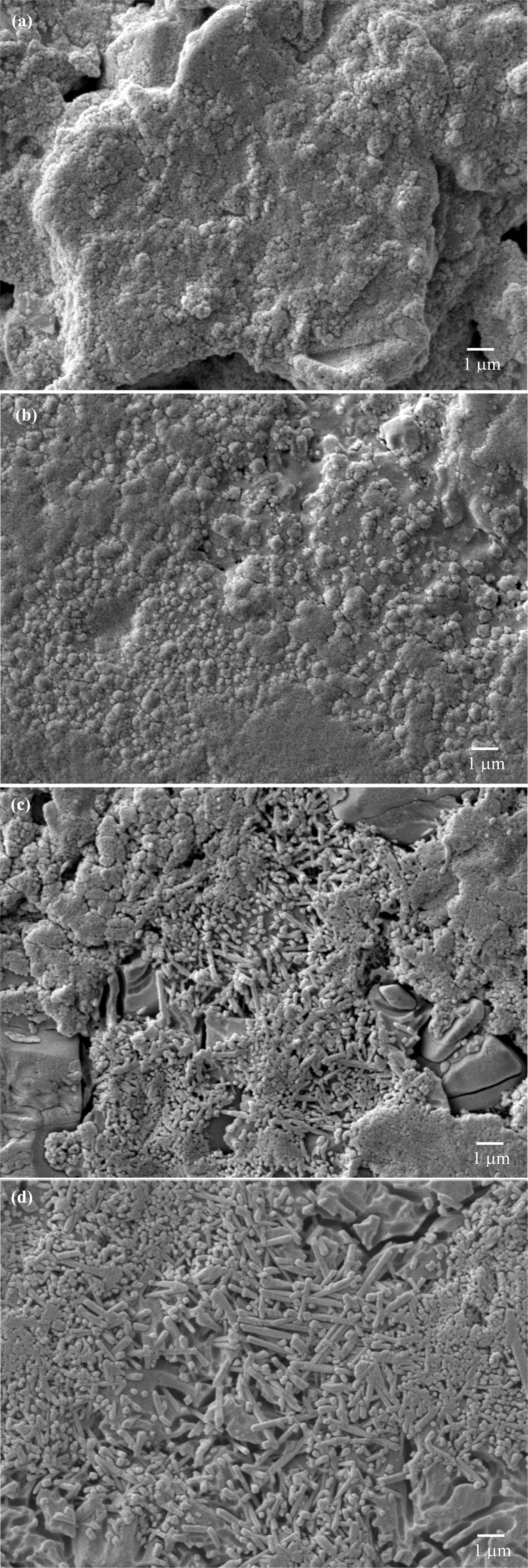

Analysis of phase changes, chemical contents and particle

size of clay and illite were reported elsewhere [20]

so only analysis of

talc is addressed in this paper. Lateral size of the talc was calculated according

to Eq. (1) was 2.19 mm. Morphological observation using an SEM of the talc used

in this study is shown in Fig. 1. X-ray diffraction (XRD) analysis (Fig. 2)

shows that talc mainly contained talc mineral with a small amount of quartz and

magnesite (MgCO3) as well as a small trace of dolomite (CaCO3·MgCO3).

Upon firing to 800 oC, talc reflections started to diminish.

Reflections of enstatite (MgSiO3) started to appear around 900 oC.

This result was in good agreement with the report by Sabouang et al. [29].

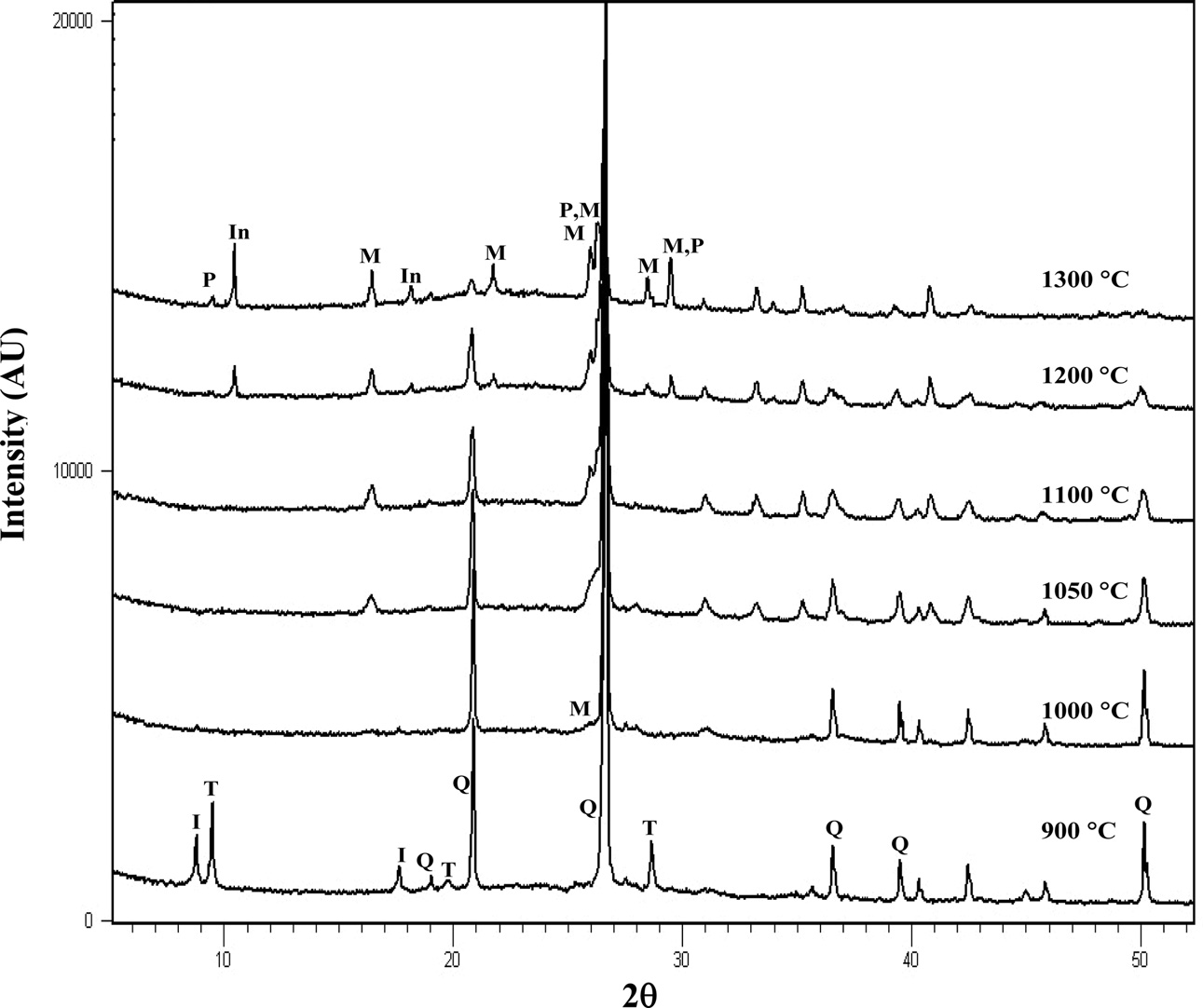

XRD spectra of the fired sample bars are displayed in Fig.

3. Only those with 5% talc are shown since the samples with less percentage of

talc had relatively similar reactions upon firing but with lesser extensity of

the phase compositions due to the lesser content of talc. At

900 oC, reflections belonging to quartz, illite and talc

existed. It was noted that the reflections belonging to enstatite, which

appeared when pure talc was fired, were not observed in the spectra. At

1,000 oC, talc and illite reflections disappeared while mullite

started to emerge and got stronger in intensity with the increase of firing

temperatures. Primary mullite content was reported to

slightly increase with increased sintering temperature through

transformation mullitization process of kaolinite [28]

. At 1,200-1,300 oC, two types of other

aluminosilicate minerals, indialite and pyrophyllite, appeared.

Indialite (Mg2Al4Si5O18), with a

chemical formula similar to cordierite, had a hexagonal structure so it was

once thought to be cordierite appeared at these temperatures. However, the work

done by Miyashiro showed that cordierite had a triplet around 29-30 o2q, while indialite only showed a

single reflection at this region [30].

Some recent literatures, however, stated that

indialite is a high temperature form of cordierite [31, 32].

The reflection at 9.5 o2q could be indexed as pyrophyllite (Al2Si4O4(OH)2)

or talc (X’pert High Score Plus: reference number

00-003-0170 and 00-003-0881 respectively) due to the close peak positions of

these two compounds at this angle. Pyrophyllite is a 2:1 clay mineral without

interlayer cation similar to talc [33]

. If this reflection truly belonged to talc, it would be

puzzling as to how it reappeared. Re-examination on another sample gave the

same result, suggesting that this observation was reliable. Neither enstatite

nor dehydrated talc, which appeared in the heat-treated pure talc sample, was

observed in this set of samples. It is noted that indialite and pyrophyllite

(or talc) reflections were not observed in the IT0 samples.

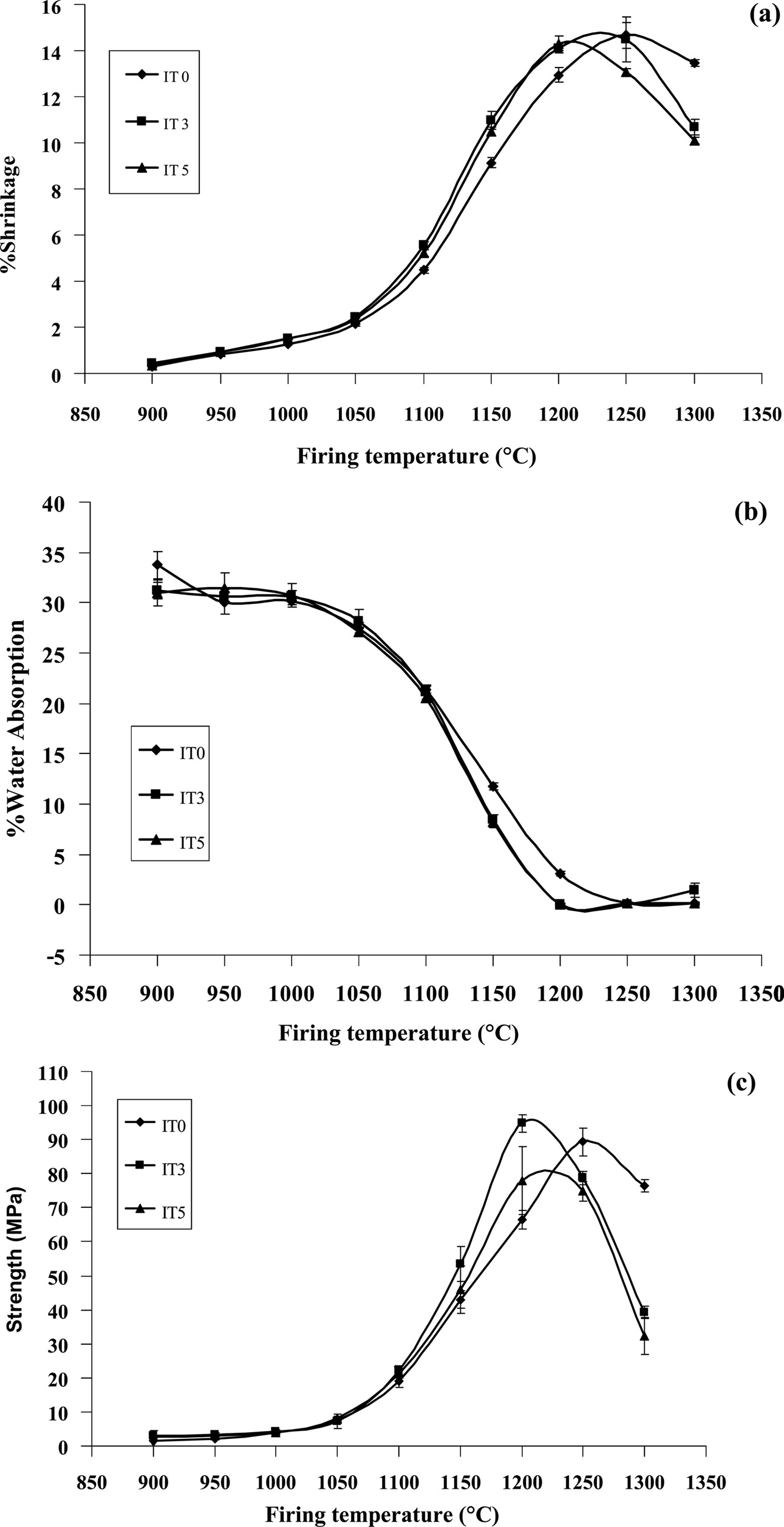

Key physical properties of the samples such as firing

shrinkage and water absorption as well as mechanical properties

are shown in Fig. 4. The IT0 samples showed the greatest

shrinkage at 1250 oC while the IT3 and IT5 samples

showed the greatest shrinkage at around 1,200-1,250 oC and

1,200 oC respectively (Fig. 4(a)). All the samples showed

expansion due to expansion of trapped gas (bloating) after reaching

the greatest shrinkage. Trapped air in a ceramic body could be caused

by arise due to over firing, too rapid firing, or the increase in the content

of volatile materials such as manganese oxide and iron ochre [34].

In our present study, it was believed that over firing

was the reason for bloating as also suggested by the finding by López and

Rodríguez [35].

Water absorption was also smallest when the shrinkage

was highest but slightly increased when bloating occurred (Fig. 4(b)). Flexural

strength for the IT0 sample was greatest after firing at 1,250 oC.

Improvement of strength was found in the IT3 sample with the reduction

of optimum temperature to 1,200 oC. Deterioration of the

strength was observed in the IT5 sample primarily due to bloating (Fig.

4(c)).

SEM micrographs for the specimens with 3% talc heat treated

at 1,000-1,300 oC are shown in Fig. 5. At 1,000 oC.

The surface was fully covered with nanocrystals and early

stage of densification was also observed (Fig. 5(a)). In the sample with 0%

talc, these crystals were suggested to be mullite formed by

decomposition of illite because primary mullite was not normally observable

at this temperature [20].

Increasing the firing temperature

to 1,100 oC, the nanocrystalline mullite did not appreciably

grow while progressive densification could be observed (Fig. 5(b)). At 1,200 oC, elongated

mullite of up to 1 mm long (as estimated using the SEM scale) appeared while

cubical mullite was still generally observed (Fig. 5(c)). It was noted that

this elongated mullite was laterally larger than needle shaped

mullite typically observed in a standard porcelain body. In a typical porcelain

body where feldspar was used as a single flux, the outer rim of the feldspar

relict showed a clear boundary to the clay relict. Needle shaped-mullite

crystals originated on this boundary and grew into the liquid pool relict. In

this experiment, however, such boundary and liquid pool relict were not so

visible due to the different source and location of the liquid former

being used. Morphology of the secondary mullite was thus

different as a result of the mentioned reason. At 1,300 oC

(Fig. 5(d)), both mullite types grew in size and covered almost all the areas.

|

Fig. 1 SEM micrograph of talc particles revealing their platy shape. |

|

Fig. 2 XRD spectra for talc fired at various temperatures (T: talc, Q: quartz: M: magnesite, D: dolomite). |

|

Fig. 3 XRD spectra for talc fired at various temperatures (T: talc, Q: quartz: M: magnesite, D: dolomite). |

|

Fig. 4 Variation of (a) firing shrinkage (b) water absorption and (c) flexural strength as a function of firing temperatures of the samples with different talc contents. |

|

Fig. 5 Microstructural development of the body with 3% talc addition after firing at (a) 1,000 oC, (b) 1,100 oC, (c) 1,200 oC and (d) 1,300 oC. |

This paper presents the use of talc as in auxiliary flux

to illite in a triaxial body. When it was incorporated in the recipe, phase

transformation up on firing of talc was found to be different from that found

in the pure form. his research showed that talc could be used as a supplemental

flux in the body containing illite as a primary flux

with improved body properties and reduction of the peak

firing temperature. However, the amount of talc contents should not exceed 3

weight % addition otherwise deterioration of the properties especially flexural

strength would be obtained due to bloating of the body.

The authors would like to thank Mae Fah Luang University,

Thailand for the financial and laboratory support.

- 1. A.N.N. Dowuona, A. Yaya, E. Nyankson, J.K. Efavi, L.N.W. Damoah, D. Dodoo-Arhin, V. Apalangya, E. Annan, E.K. Tiburu, B. Onwona-Agyeman, and B. Tomiczek, J. Ceram. Process. Res. 19[2] (2018) 95-100.

- 2. J. Choi, K. Hwang, U. Kim, K. Ryu, K. Shim, and S. Kang, J. Cearmic Process. Res. 20[4] (2019) 424-430.

- 3. R.H. and A.B.A. S. Natrah, Int. J. Autom. Mech. Eng. 16[2] (2019) 6649-6659.

- 4. D.U. Tulyaganov, S. Agathopoulos, H.R. Fernandes, and J.M.F. Ferreira, J. Eur. Ceram. Soc. 26[7] (2006) 1131-1139.

-

- 5. Y.U. and S.Ö.A. Karaa, K. Kayacic, and A.S. Küçükerc, V. Bozkurtd, Ind. Ceram. 29[2] (2009) 71-81.

- 6. L.A. Carús, F. de Souza, and S.R. Bragança, ISRN Ceram. 2012 (2012) 1-7.

-

- 7. S.K. Das and K. Dana, Thermochim. Acta 406[1-2] (2003) 199-206.

-

- 8. K. Dana and S.K. Das, J. Eur. Ceram. Soc. 24[15-16] (2004) 3833-3839.

-

- 9. S.R. Bragança and C.P. Bergmann, J. Eur. Ceram. Soc. 24[8] (2004) 2383-2388.

-

- 10. P. Lima, A. Zocca, W. Acchar, and J. Günster, J. Eur. Ceram. Soc. 38[9] (2018) 3395-3400.

-

- 11. D.Y. Tunçel, M.K. Kara, and E. Özel, IOP Conf. Ser. Mater. Sci. Eng. 18[22] (2011) 222025.

-

- 12. W. Lerdprom, R.K. Chinnam, D.D. Jayaseelan, and W.E. Lee, J. Eur. Ceram. Soc. 36[16] (2016) 4319-4325.

-

- 13. W. Lerdprom, E. Zapata-Solvas, D.D. Jayaseelan, A. Borrell, M.D. Salvador, and W.E. Lee, Ceram. Int. 43[16] (2017) 13765-13771.

-

- 14. D. Wattanasiriwech, K. Srijan, and S. Wattanasiriwech, Appl. Clay Sci. 43[1] (2009) 57-62.

-

- 15. A. Aras, Appl. Clay Sci. 24[3-4] (2004) 257-269.

-

- 16. R. E. Grim and W. F. Bradley, J. Am. Ceram. Soc. 23[8] (1940) 242-248.

-

- 17. A. Khalfaoui, S. Kacim, and M. Hajjaji, J. Eur. Ceram. Soc. 26[1-2] (2006) 161-167.

-

- 18. G. Wang, H. Wang, and N. Zhang, Appl. Clay Sci. 146 (2017) 254-263.

-

- 19. S. Boussen, D. Sghaier, F. Chaabani, B. Jamoussi, and A. Bennour, Appl. Clay Sci. 123 (2016) 210-221.

-

- 20. D. Wattanasiriwech and S. Wattanasiriwech, J. Eur. Ceram. Soc. 31[8] (2011) 1371-1376.

-

- 21. S. Farrokhpay, B. Ndlovu, and D. Bradshaw, Appl. Clay Sci. 160 (2018) 270-275.

-

- 22. A. Dumas, F. Martin, E. Ferrage, P. Micoud, C. Le Roux, and S. Petit, Appl. Clay Sci. 85 (2013) 8-18.

-

- 23. M. Hojamberdiev, P. Arifov, K. Tadjiev, and Y. Xu, Min. Sci. Technol. 20[3] (2010) 415-420.

-

- 24. L. Esposito, A. Salem, A. Tucci, A. Gualtieri, and S.H. Jazayeri, Ceram. Int. 31[2] (2005) 233-240.

-

- 25. M.U. Taskiran, N. Demirkol, and A. Capoglu, J. Eur. Ceram. Soc. 25[4] (2005) 293-300.

-

- 26. M. Dondi, V. Biasini, G. Guarini, M. Raimondo, A. Argnani, and S. Di Primio, Key Eng. Mater. 206-213[II] (2001) 1795-1798.

-

- 27. L.A. Pérez-Maqueda, A. Duran, and J.L. Pérez-Rodríguez, Appl. Clay Sci. 28[1-4] (2005) 245-255.

-

- 28. F.O. Aramide, O.D. Adepoju, and A.P. Popoola, J. Ceram. Process. Res. 19[6] (2018) 483-491.

- 29. C.J. Ngally Sabouang, J.A. Mbey, F. Hatert, and D. Njopwouo, J. Asian Ceram. Soc. 3[3] (2015) 360-367.

-

- 30. T. Iiyama, Proc. Jpn. Acad. 31[3] (1955) 166-168.

-

- 31. N.N. Sampathkumar, A.M. Umarji, and B.K. Chandrasekhar, Mater. Res. Bull. 30[9] (1995) 1107-1114.

-

- 32. F.A.C. Oliveira, N. Shohoji, J.C. Fernandes, and L.G. Rosa, Sol. Energy 78[3] (2005) 351-361.

-

- 33. S.L. Correia, K.A.S. Curto, D. Hotza, and A.M. Segadães, Mater. Sci. Forum 498-499 (2009) 447-452.

-

- 34. D. Wattanasiriwech, C. Sangtong, and S. Wattanasiriwech, ScienceAsia 33[1] (2007) 125-130.

- 35. S.Y.R. López and J.S. Rodríguez, AZoJomo, 4[July] (2008) 1-7.

This Article

This Article

-

2019; 20(6): 643-648

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.643

- Received on Jul 19, 2019

- Revised on Oct 8, 2019

- Accepted on Oct 20, 2019

Services

Services

- Abstract

introduction

experiments

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Darunee Wattanasiriwech

-

aCenter of Innovative Materials for Sustainability, School of Science, Mae Fah Luang University, Thailand

bCircular Economy for Waste-free Thailand Research Group, Mae Fah Luang University, Thailand

Tel : +6653916263 Fax: +6653916776 - E-mail: darunee@mfu.ac.th

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.