- Effect of MgO addition on physico-chemical, mechanical and thermal behaviour of Al/Si3N4 composite material developed via hybrid casting technique

Shashi Prakash Dwivedia,*, Ashok Kumar Mishrab and V. R. Mishraa

aG. L. Bajaj Institute of Technology & Management, Greater Noida, Gautam Buddha Nagar, U.P., India

bMechanical Engineering Department, SRM University, Sonipat, Haryana, India

In the present investigation,

aluminium based composite material developed by using Si3N4 as

primary reinforcement material and MgO as secondary reinforcement material by

hybrid casting techniques. The microstructure of composite developed by hybrid

casting technique showed a uniform distribution of Si3N4

and MgO particles in the AA2024 aluminium alloy. Maximum tensile strength and

hardness were found to be 214.5

MPa and 78 BHN for heat-treated AA2024/7.5% Si3N4/5%

MgO composite material. Minimum thermal expansion was also found for

AA2024/7.5% Si3N4/5% MgO composite material. However,

minimum corrosion loss was found for AA2024/10% Si3N4/2.5%

MgO composite material. Though, toughness and ductility were reduced by adding

the Si3N4 and MgO particles in AA2024 aluminium alloy.

XRD analysis of AA2024/7.5% Si3N4/5% MgO composite

material was also observed to see the effect of Si3N4 and

MgO particles addition in AA2024 aluminium alloy.

Keywords: Wettability; XRD; Thermal expansion; Corrosion loss; Si3N4, MgO

Aluminium based metal matrix composites are used in various industrial application where high specific strength

and low corrosion rate materials are required. Its demand in aircraft

industries and automobile industries is mainly due to its low cost

of processing and a broad range of properties [1]. Aluminium based metal matrix

composite (AMC) has been used in the design of specific aerospace

and automotive components such as ventral fins, fuel excess

door covers, rotating blades sleeves, gear parts, crankshafts, and suspension

arms [2]. Among all aluminium alloys, AA2024 alloy is broadly used in aircraft

industries in making wing and fuselage structure under simple tension because

of its high fatigue, and tensile strength. The major component of AA2024

aluminium alloy is copper. The copper provides substantial increases in

strength and facilitates precipitation hardening. The introduction of copper to

aluminium also reduces corrosion resistance. The

susceptibility to solidification cracking of aluminium-copper

alloys is increased [3].

Magnesia or magnesium oxide (MgO) is an alkaline earth

metal oxide. It is obtained from the calcination of naturally occurring minerals.

Other important sources of magnesium oxide are seawater,

underground deposits of brine and deep salt beds where

magnesium hydroxide [Mg(OH)2] is processed [4]. Magnesium

is the eighth-most abundant element and equals about two per cent of the

earth's crust and typically 0.12% of seawater. Both MgCO3 and Mg(OH)2

are converted to MgO by calcinations [5]. It has an empirical

formula of MgO and consists of a lattice of Mg2+

ions and O2− ions held together by ionic bonding. Magnesium

hydroxide forms in the presence of water (MgO + H2O

→ Mg(OH)2), but it can be reversed by heating it to

separate moisture [6]. Silicon nitride (Si3N4) is a

chemical compound of the elements silicon and nitrogen. It is

the most thermo- dynamically stable of

the silicon nitrides. Si3N4 is prepared by heating

powdered silicon between 1,300 oC

and 1,400 oC in a nitrogen environment by chemical reaction (3Si+2 N2

→ Si3N4). Si3N4 contains silicon

(Si) [7]. The addition of silicon (present in Si3N4) to aluminium during casting reduces melting

temperature and improves fluidity. Si3N4 alone in

aluminium produces a non-heat-treatable aluminium based composite

material; however, in combination

with MgO enhanced precipitation hardening of aluminium based composite

material. The addition of MgO and Si3N4 to aluminium

produces the compound magnesium-silicide (Mg2Si) [8]. The formation

of this compound enhanced the heat treatable

property of aluminium based composite material.

In conventional development of composite material by the

mechanical stir casting technique, some porosity developed inside the solidified

composite. While, during the development of metal matrix composite via electromagnetic stir casting technique, most of

the ceramic particles settled down at

the bottom of the solidified composite. Resulting, agglomeration of

reinforcement particles was observed.

However, in the electromagnetic stir

casting process, very less amount of porosity developed

inside the composite. Keeping these facts in the mind, In the present

investigation, an attempt was made to develop the Si3N4

and MgO reinforced composite via hybrid casting techniques to avoid agglomeration of reinforcement particles and

minimize the porosity. In the hybrid casting process, composite material

developed by stir casting process, then in mushy zone transferred to

electromagnetic stir casting process

to obtain final composite. Wettability of composite materials

refers to the interaction between reinforcement particles and matrix material. Good interfacial reaction layer between

the matrix material and reinforcement particles

indicates proper wettability [9]. Proper wettability between reinforcement and matrix material always

play a significant role in enhancing

the mechanical properties. It was observed

from the literature that by using MgO powder as reinforcement material in

aluminium base matrix, mechanical properties such as tensile strength and

hardness were much improved [10]. MgO powder also enhanced the wettability of

aluminium based composite material

with reinforcement particles. Keeping

these facts in the mind, in this study, MgO powder is used as a secondary

reinforcement material with Si3N4 in development of

aluminium based composite material [11].

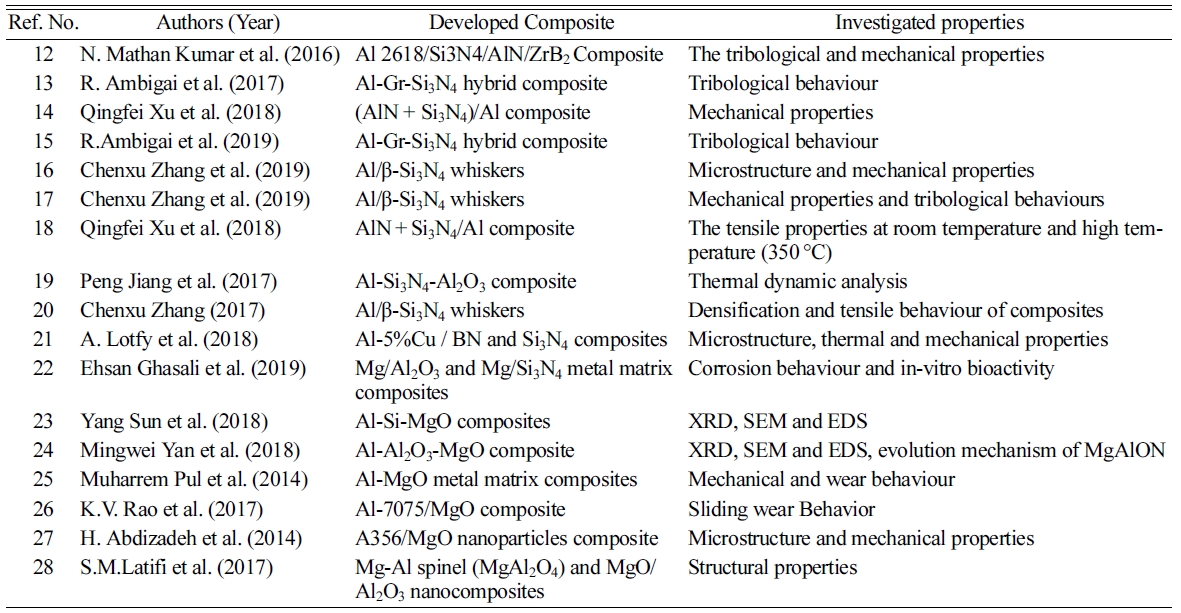

Table 1 shows the summary of composite material developed

by MgO and Si3N4 reinforcement particles. Some

researchers (Table 1) developed aluminium based hybrid

composite material by using Si3N4 as primary

reinforcement material and ceramic particles such as Gr, AlN, ZrB2, Al2O3

etc. as secondary reinforcement material. In the same way, some

researchers (Table 1) developed aluminium based hybrid composite material by using MgO

as primary reinforcement material and ceramic

particles such as Al2O3 as secondary reinforce- ment material. But, from archival literature,

it was observed that no researcher used MgO powder and Si3N4 particles together in

the development of aluminium-based

hybrid composite material by hybrid casting technique. Keeping these facts in

the mind; in the present investigation, MgO powder was added as a supplementary

reinforcement in Al/Si3N4 composite to enhance

wettability property. Properties such as tensile strength, hardness, toughness, ductility, thermal expansion and corrosion test were carried out to observe the MgO addition effect in Al/Si3N4

composite material. Heat treatment of

composite material was carried out to enhance

further mechanical properties of the composite.

Experimental

procedure

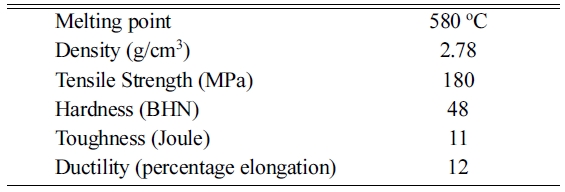

In this study, AA2024 is considered as a matrix material.

Measured mechanical properties of AA2024 alloy are shown in Table 2. Silicon

Nitride (Si3N4) is considered as a primary reinforcement

material. Silicon nitride (Si3N4) attributes an excellent

combination of various properties. It is almost light as silicon carbide (SiC),

but it gives excellent thermal shock resistance to material [12]. Fracture

toughness of traditional ceramic particles such as SiC, Al2O3

and B4C is very low. Fracture toughness of silicon nitride (Si3N4)

is high as compared to SiC, Al2O3 and B4C.

Magnesium oxide (MgO) particles were considered as a secondary reinforcement

material to enhance further mechanical properties of composites.

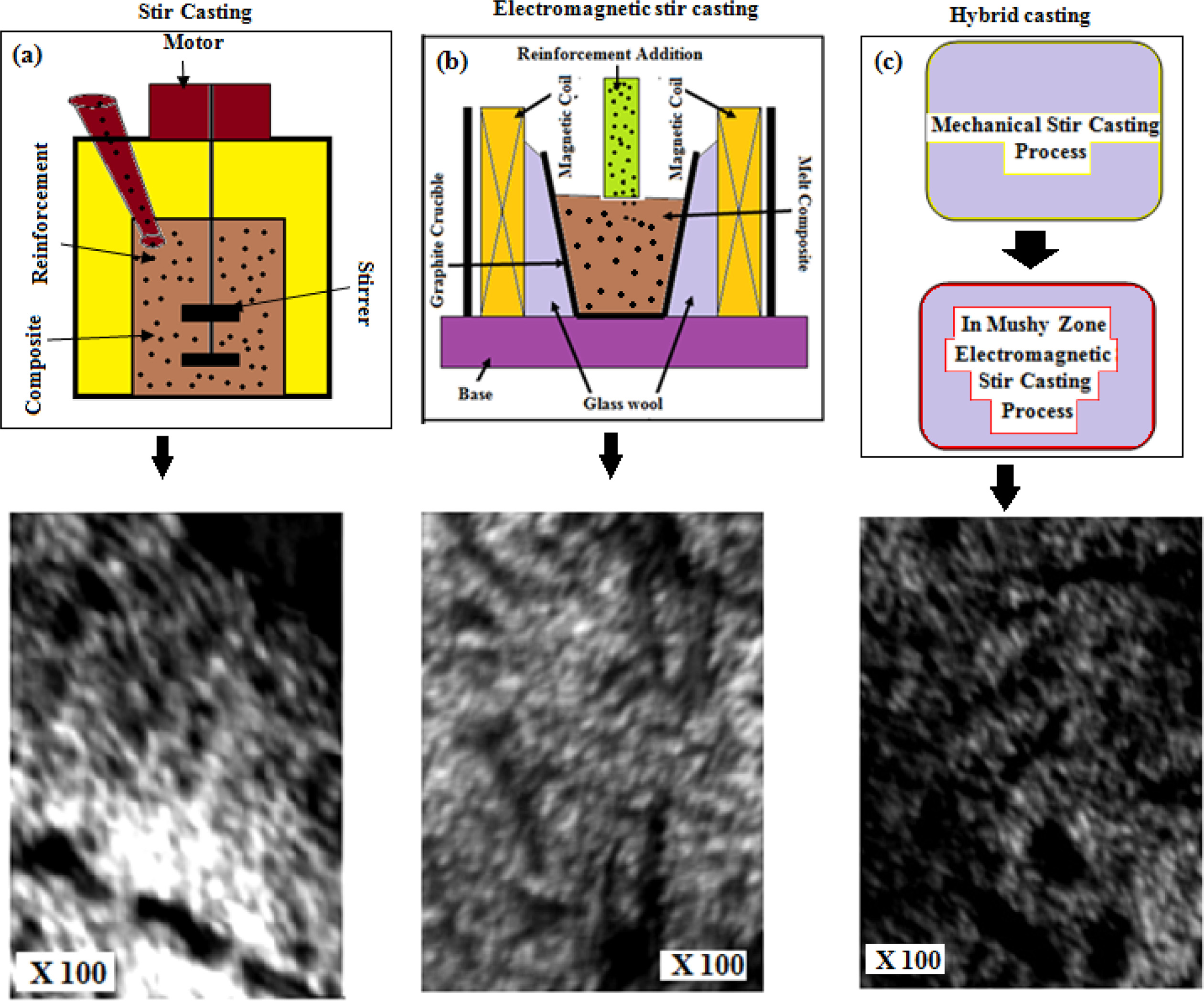

Fig. 1(a) shows a schematic diagram of the stir casting

technique. Matrix material was heated in muffle furnace up to 750 oC.

Preheated reinforcement particles (Si3N4 and MgO) were

added in matrix material at the temperature 700 oC.

Stir casting process involves stirring of melt composite material,

in which the melt matrix material with reinforcement particles is stirred which

exposes the melt composite material surface to the atmosphere which tends to

continuous oxidation of aluminium melt. Resulting, the wettability of the reinforcement particles with aluminium reduces and

the reinforcement particles remain unmixed. Therefore adding wetting

agents such as TiK2F6, borax and magnesium in the melt is an alternate solution of this problem and widely used for the fabrication of

aluminium based composite material.

In this study, MgO was added in Al/Si3N4 composite

material. Fig. 1(a) shows the microstructure of composite material obtained

from stir casting technique. Non-uniform distribution of reinforcement

particles in matrix material was observed by using stir casting technique.

Fig. 1(b) shows a schematic diagram of the electro- magnetic stir casting technique. AA2024

aluminium alloy was heated in muffle furnace above its liquidus temperature

(650 oC). Si3N4 and MgO reinforcement

particles were also preheated before mixing to avoid wettability problem. Melt

AA2024 matrix material was poured into a graphite crucible for stirring by the

electromagnetic field of the motor. The traditional EMS (electromagnetic

stirring) process mainly works in the mushy zone of the alloy, i.e.,

supercooled + EMS. There are two

hypotheses to explain the formation mechanism of

non-dendrites, that is, mechanical fragmentation and the root remelting of the

dendrite arms [29]. The homogenization of the temperature and constituents

caused by the forced convection during stirring can prompt the nucleation of

the primary α-Al phase and restrain the growth of dendrites. The

argon gas was used during the mixing of reinforcement particles in the melt of

AA2024 alloy. Fig. 1(b) shows the microstructure of composite

developed by electromagnetic stir casting technique. Less amount of porosity

was observed. However, some agglomeration of reinforcement

particles was also identified [30].

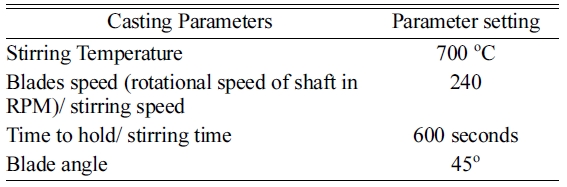

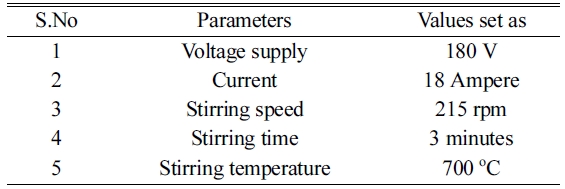

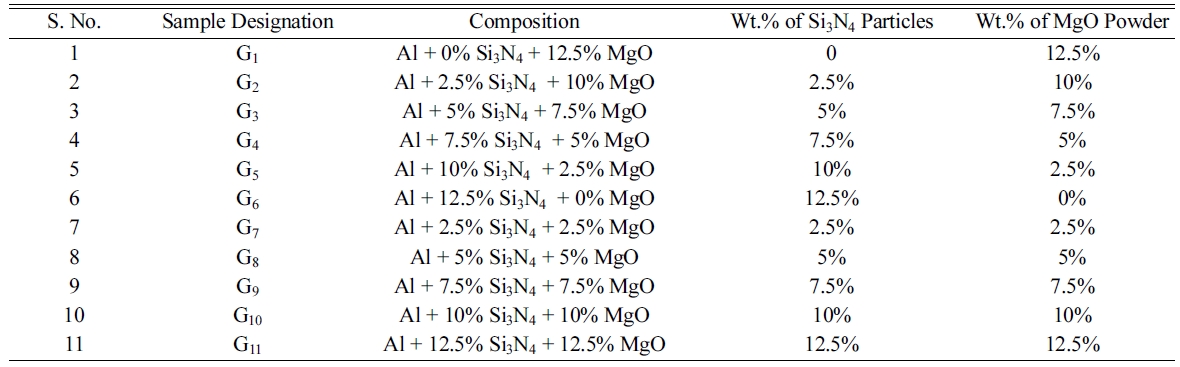

Fig. 1(c) shows the hybrid casting technique. Firstly,

preheated reinforcement particles were mixed in the stir casting process at

parameters shown in Table 3. After mixing the reinforcement particles in

mechanical stir casting, composite in the mushy zone was transferred

to electromagnetic stir casting route. Here, a mixed composite material in the

mushy zone was stirred by the electromagnetic field [31]. Table 4 shows the

parameters at which hybrid composite material was prepared. Uniform

microstructure with less porosity was obtained by the development of hybrid

casting technique process. Hence, the entire composite for this study was

prepared by the hybrid casting technique as shown in Table 5.

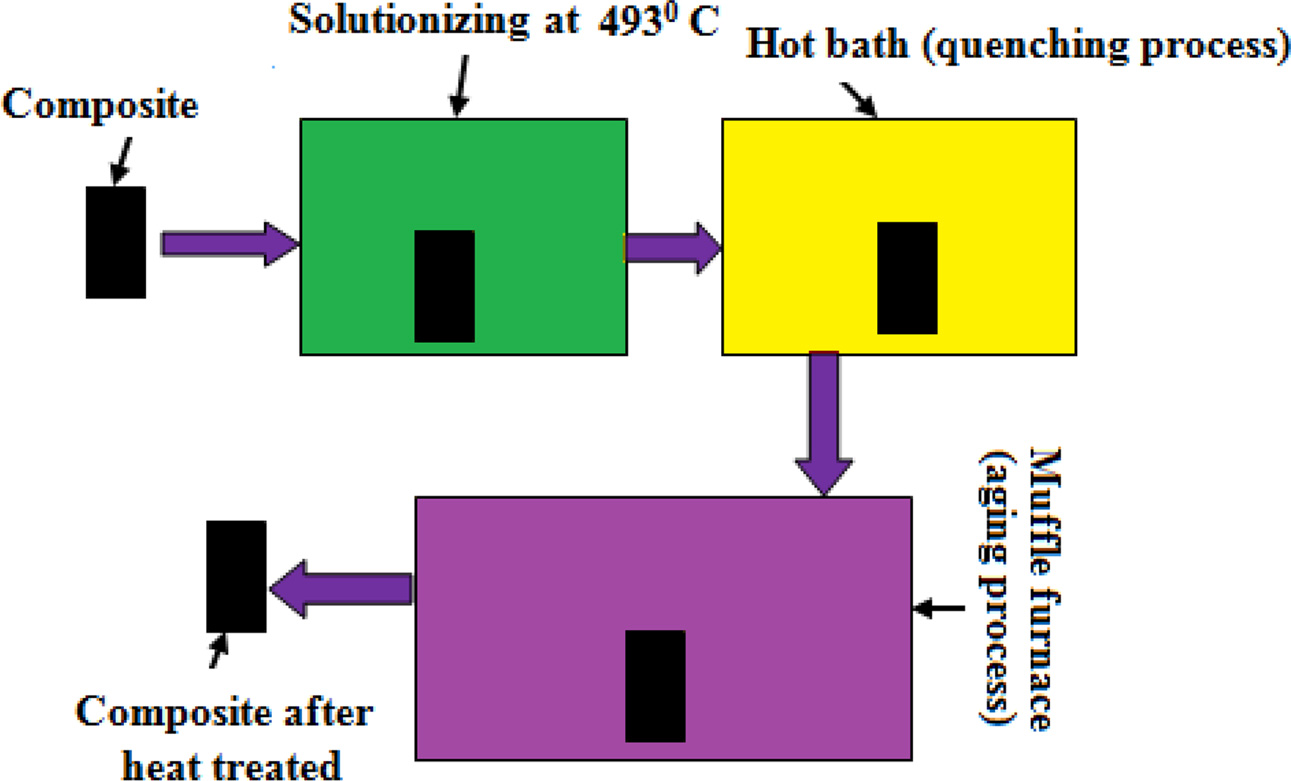

Precipitations

hardening process

The precipitations hardening process is used to improve

the yield strength of composite as well as other properties such as hardness

and fatigue strength. Schematic diagram of the

precipitation-hardening process is shown in Fig. 4. Precipitation

hardening process was carried out in three different phases. Firstly, the

solutionizing process was done at a temperature of 530 oC for

4.5 hours and then quenched in a hot bath at temperature 70 oC.

In muffle furnace ageing process was carried out for 13.5 hours [32].

Mechanical

characterizations and sample preparation

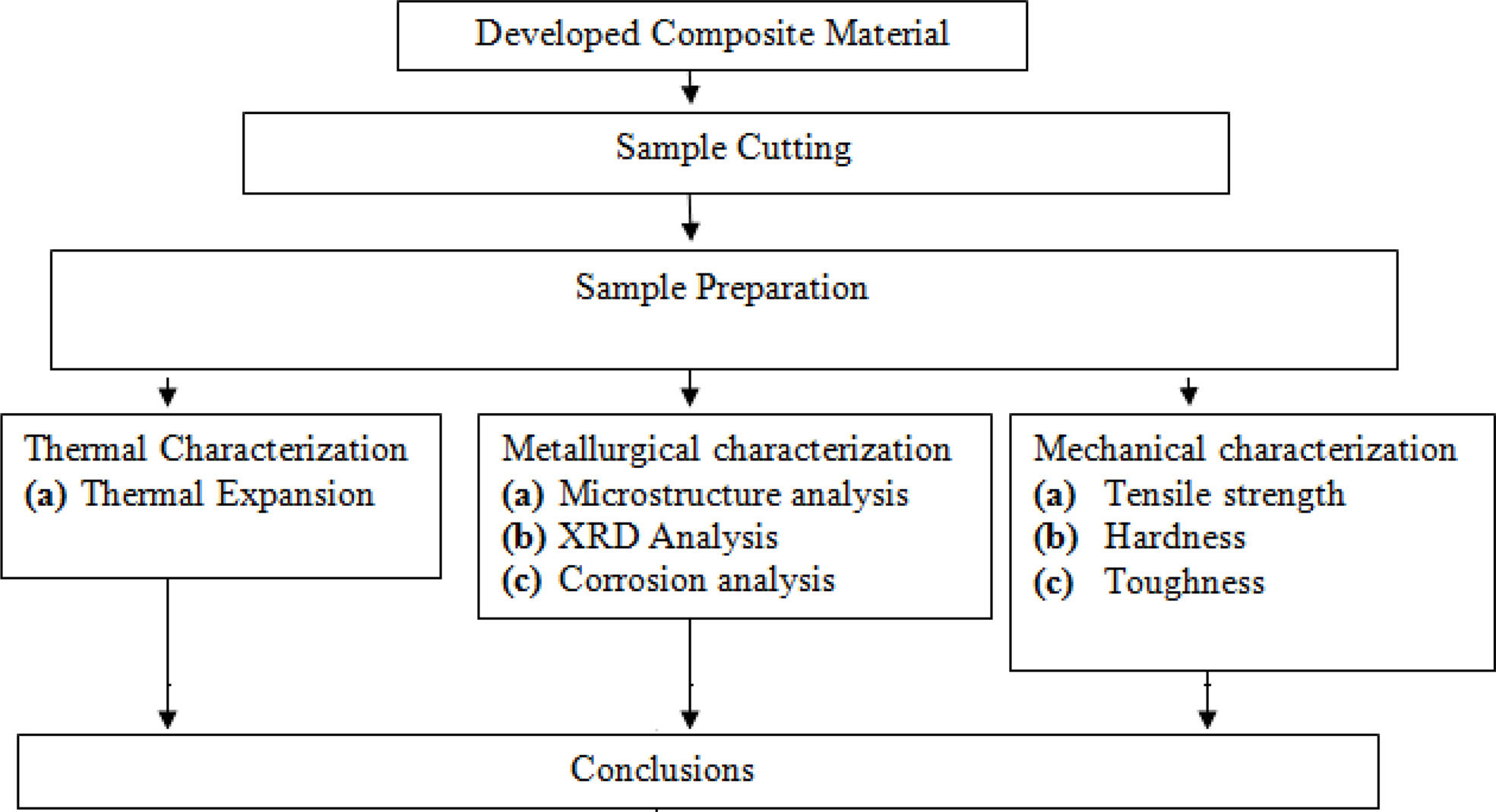

The developed composites were characterized in terms of

microstructure, tensile strength, hardness (10 mm x 10 mm x 25 mm),

toughness (10 mm x 10 mm x 55 mm with

45o V notch at center of 2 mm depth according to ASTM A370

standard), thermal expansion and corrosion loss and XRD of composite. The

tensile sample was prepared on a lathe machine. The tensile samples were tested

at room temperature. Tensile samples were prepared according to ASTM B557

standard (Test methods for tension testing wrought and cast aluminium and

magnesium-alloy products). The diameter of the sample prepared was 6 mm and the

gauge length was 36 mm. Flow chart of experimental techniques followed for the

present study is shown in Fig. 3.

Fig. 2

|

Fig. 1 Development of composite by; (a) Stir casting technique, (b) Electromagnetic stir casting technique, (c) Hybrid casting technique. |

|

Fig. 2 Heat treatment process of composites [32]. |

|

Fig. 3 Flow chart of experimental techniques followed. |

|

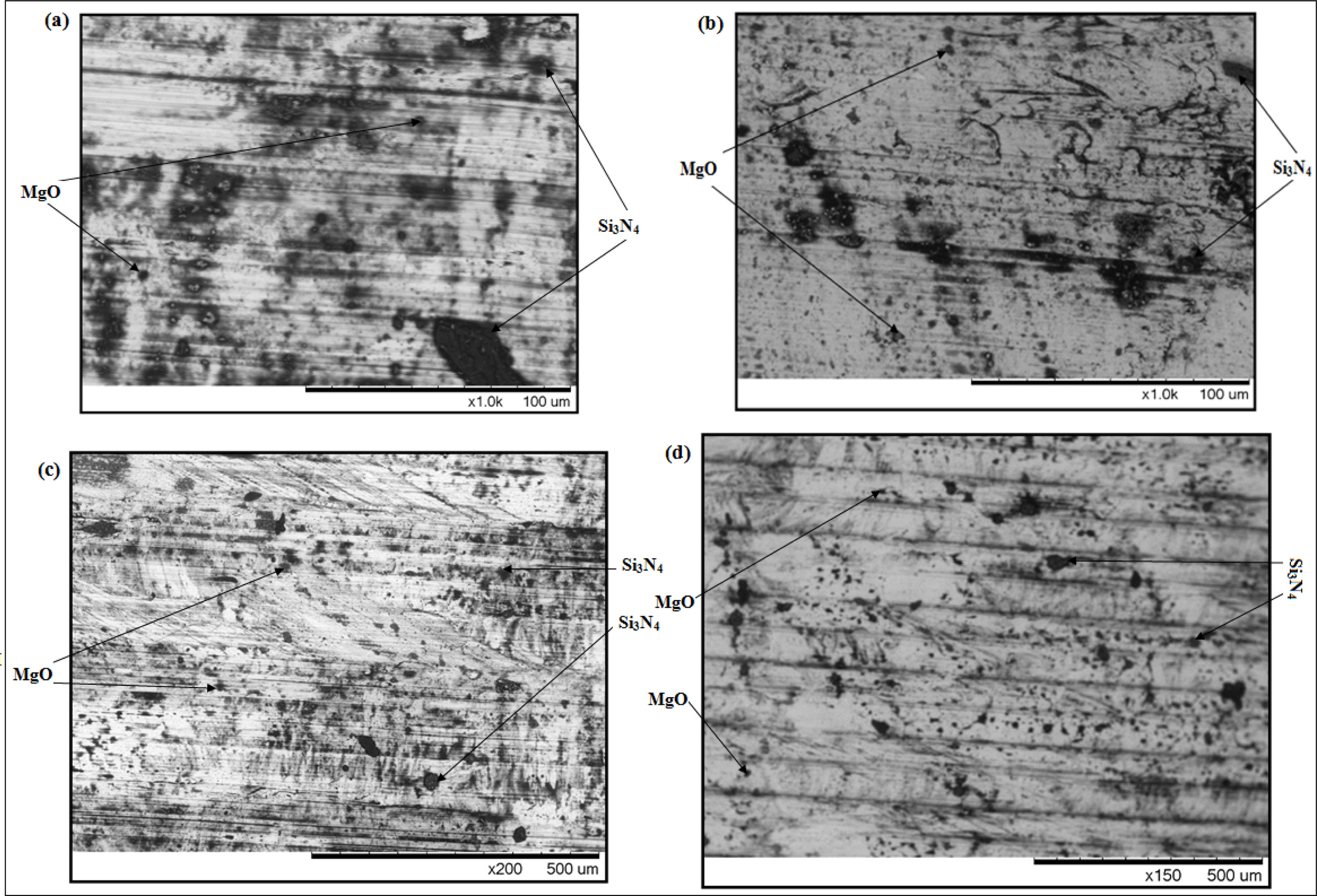

Fig. 4 SEM image of upper surface composite developed by; (a) mechanical stir casting technique, (b) electromagnetic stir casting technique, (c) hybrid stir casting technique, (d) hybrid stir casting technique after heat treatment. |

Microstructure

analysis

Microstructure analysis was carried out to identify the

distribution of reinforcement particles in the matrix material. MgO powder was

used to enhance wettability property of aluminium based composite with Si3N4

reinforcement particles. However, MgO was also responsible to improve tensile

strength and hardness of composites. Scanning electron microscopy (SEM) is used

to observe the distribution of reinforcement particles. Fig. 4(a) shows the

microstructure of composite (upper layer) developed by stir

casting technique. It can be observed that most of the reinforcement particles

are settled down at the bottom. Porosity and cracks can be seen

inside the composite developed through mechanical stir

casting technique. Fig. 4(b) shows the microstructure of the

composite developed by the electromagnetic stir casting process. However, less

amount of porosity and cracks were observed in composites developed via electromagnetic

stir casting process. But, in this process also most of

the ceramic particles were settled down at the bottom. Fig. 4(c) shows the

microstructure of composite developed through hybrid casting

technique. In this technique; firstly, reinforcement materials were

mixed in melt matrix material by mechanical stir casting technique. When

reinforcement particles were mixed properly by a stirrer, then

composite with crucible in the mushy

zone was transferred to the electromagnetic stir casting

process. Composite material began to rotate in the mushy

zone by the electromagnetic force produced developed

from magnetic flux. The obtained composite material

showed the proper distribution of reinforcement because in

mushy zone reinforcement materials were not able to settle down at the bottom.

Further, the grain structure of composite material was also improved as shown

in Fig. 4(c). In this study, MgO powder was used as a secondary reinforcement material.

MgO powder is also responsible in minimization of

porosity and inclusion inside the composite. Fig. 4(d) shows that the grain

structure of the composite more refined after the heat-treatment process. Microstructure

image showed that the hybrid casting technique showed better results as

compared to other technique. Hence, for further study, the hybrid casting

technique is used to develop aluminium based composite material reinforced with

MgO powder Si3N4 ceramic particles.

Tensile

strength analysis

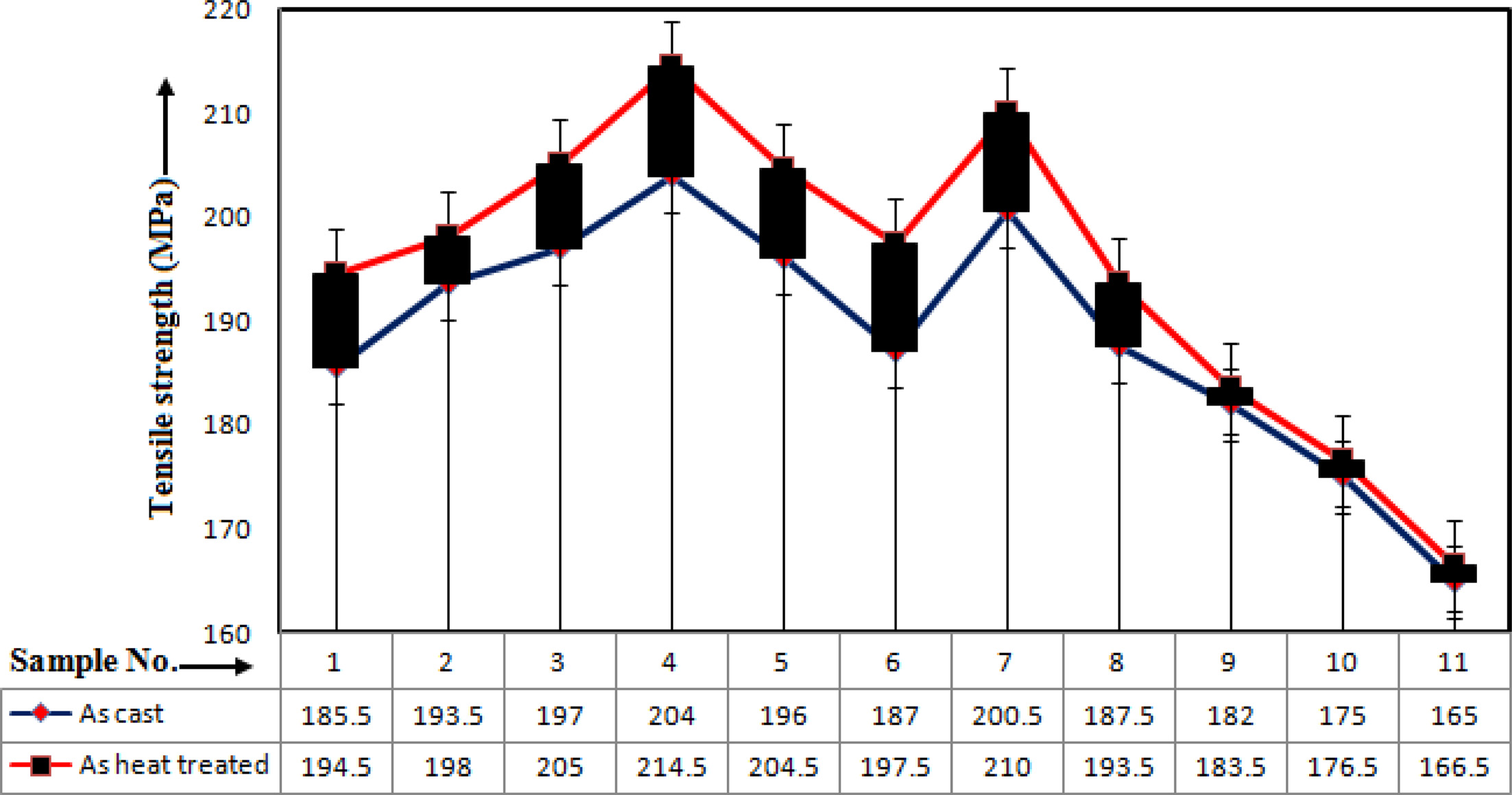

Fig. 5 shows the tensile strength of Si3N4

and MgO reinforced AA2024 aluminium-based hybrid metal matrix composite

developed through hybrid casting technique. It was observed that by increasing

the percentage of Si3N4 in AA2024/MgO composite tensile

strength is continuously increases. The addition of magnesium oxide (MgO) to

AA2024/Si3N4 composite increases strength through solid

solution strengthening and improves their strain hardening ability. But, much

higher content of MgO is not the dominant mechanism for densification. It is

likely that the extra MgO is located in the grain boundaries and acts as a

grain growth inhibitor [13]. Hence, beyond the 5% of MgO addition in AA2024/Si3N4

composite, tensile strength began to decreases. Maximum tensile strength was

found to be 204 MPa for AA2024/7.5 wt% Si3N4/5 wt% MgO

hybrid metal matrix composite. AA2024 is a good heat treatable material.

Keeping this fact in the mind, heat treatment of composite material was also

carried out in this study. It was observed that the tensile strength of

composite significantly improved after the heat treatment process. Tensile

strength was further improved after the heat treatment process of AA2024/7.5

wt% Si3N4/5 wt% MgO composite material. In this study,

MgO powder was used to enhance the wettability of Si3N4

with AA2014 aluminium alloy.

N. Mathan Kumar et al. [12] mixed Si3N4

(Silicon Nitride), AlN (Aluminium Nitride) & Zrb2 (Zirconium

Boride) with wt.% of (0,2,4,6,8) in Al 2618 aluminium alloy. Ultimate tensile

strength of Al 2618 was 440 MPa. Ultimate tensile strength of Al 2618 with 8

wt.% reinforcement was 493 MPa. Results showed that 12.045%

tensile strength improved. While in the present study, after

the addition of 7.5% Si3N4 and 5% MgO in AA2024

aluminium alloy, about 13.33% tensile strength was improved

with respect to the base metal. It was also notified that after the heat

treatment of AA2024/7.5% Si3N4/5% MgO, about 19.16%

tensile strength was improved. MgO has adequate atmospheric

resistance and moderate strength. Magnesium (Mg) also enhanced the

castability of the composite. MgO powder addition in aluminium has also

improved the wettability of reinforcement particles with the

aluminium matrix material.

Hardness

analysis

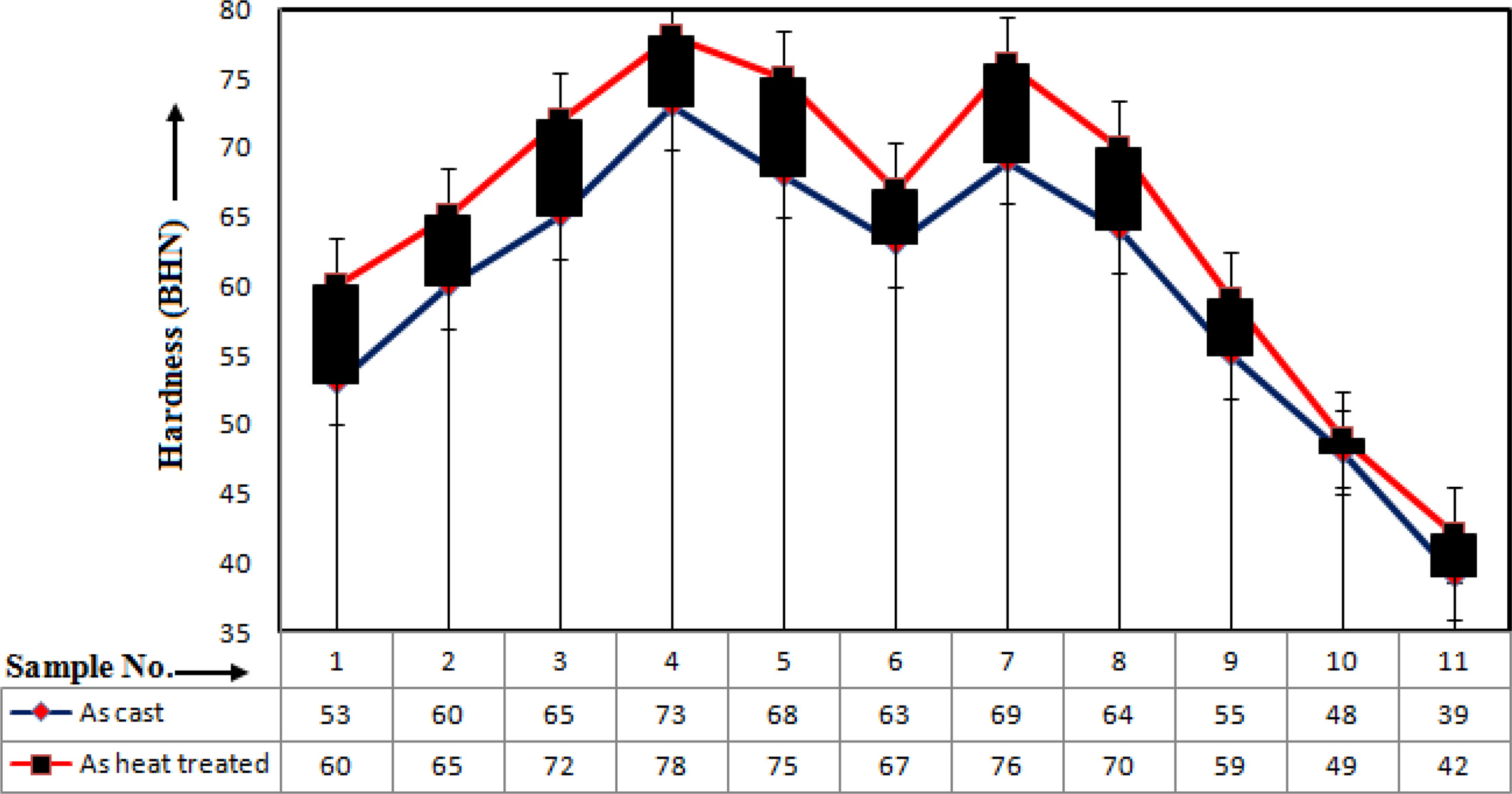

Fig. 6 shows the hardness of AA2024/Si3N4/MgO

hybrid metal matrix composite before and after heat treatment developed by

hybrid casting technique. Hardness is increased by increasing the weight

percent of MgO powder up to 5% in AA2024/7.5% Si3N4

composite. XRD results (Fig. 11) shows the presence of hard phases such as Si3N4,

Fe2O3 and MgO in AA2024/7.5% Si3N4/5%

MgO composite material. Presence of these phases was responsible for enhancing

the hardness of the composite. Proper wettability and uniform distribution of

reinforcement particles in a matrix material were also played a significant

role in enhancing the hardness of the composite. When Si3N4

and MgO particles increase beyond 7.5% and 5% respectively

in AA2024 alloy, hardness began to decreases. Air is

interrupted inside the composite material with reinforcement particles when

weight percent of reinforcement increases (beyond 7.5% for Si3N4

and 5% for MgO). Maximum hardness was found to be 73 BHN of AA2024/7.5%

Si3N4/5% MgO hybrid metal matrix composite.

N. Mathan Kumar et al. [12] showed that by using Si3N4

with AlN and Zrb2 as reinforcement in Al 2618 aluminium alloy, about

48.33% hardness increased. The present study showed that about 37.73% hardness enhanced

by using 7.5% Si3N4 and 5% MgO in AA2024 alloy.

The hardness of the composite was further improved after

the heat treatment process. After the heat treatment process,

about 62.5% hardness was improved with respect to the base metal.

Toughness

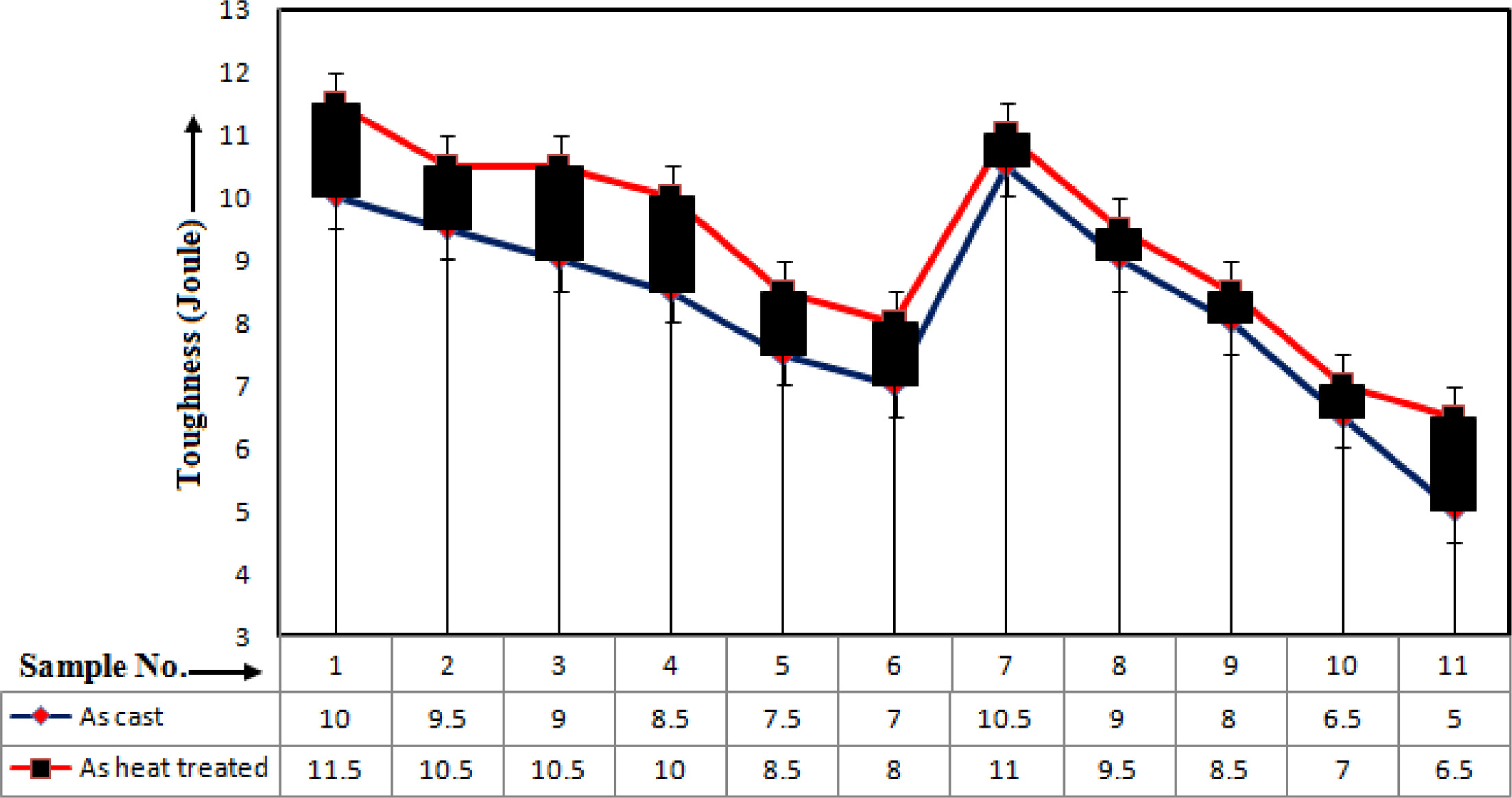

Results show that MgO addition in AA2024/Si3N4

composite enhanced the tensile strength and hardness of composite hybrid

casting technique. So, samples developed by the hybrid casting technique were

considered for further study. Fig. 7 shows the impact strength of AA2024/Si3N4/MgO

hybrid metal matrix composite. Silicon nitride (Si3N4) is

a material with high fracture toughness and excellent thermal shock resistance.

MgO powder addition in AA2024/ /Si3N4 composite

influence the grain boundary mobility, surface diffusivity

along with higher pore mobility of grains and grain boundary anisotropy of

composite material. However, It can be observed from the analysis that

toughness is continuously decreased by increasing the percentage of Si3N4

in AA2024/MgO composite [13]. The toughness of all the compositions was

improved after the heat treatment process.

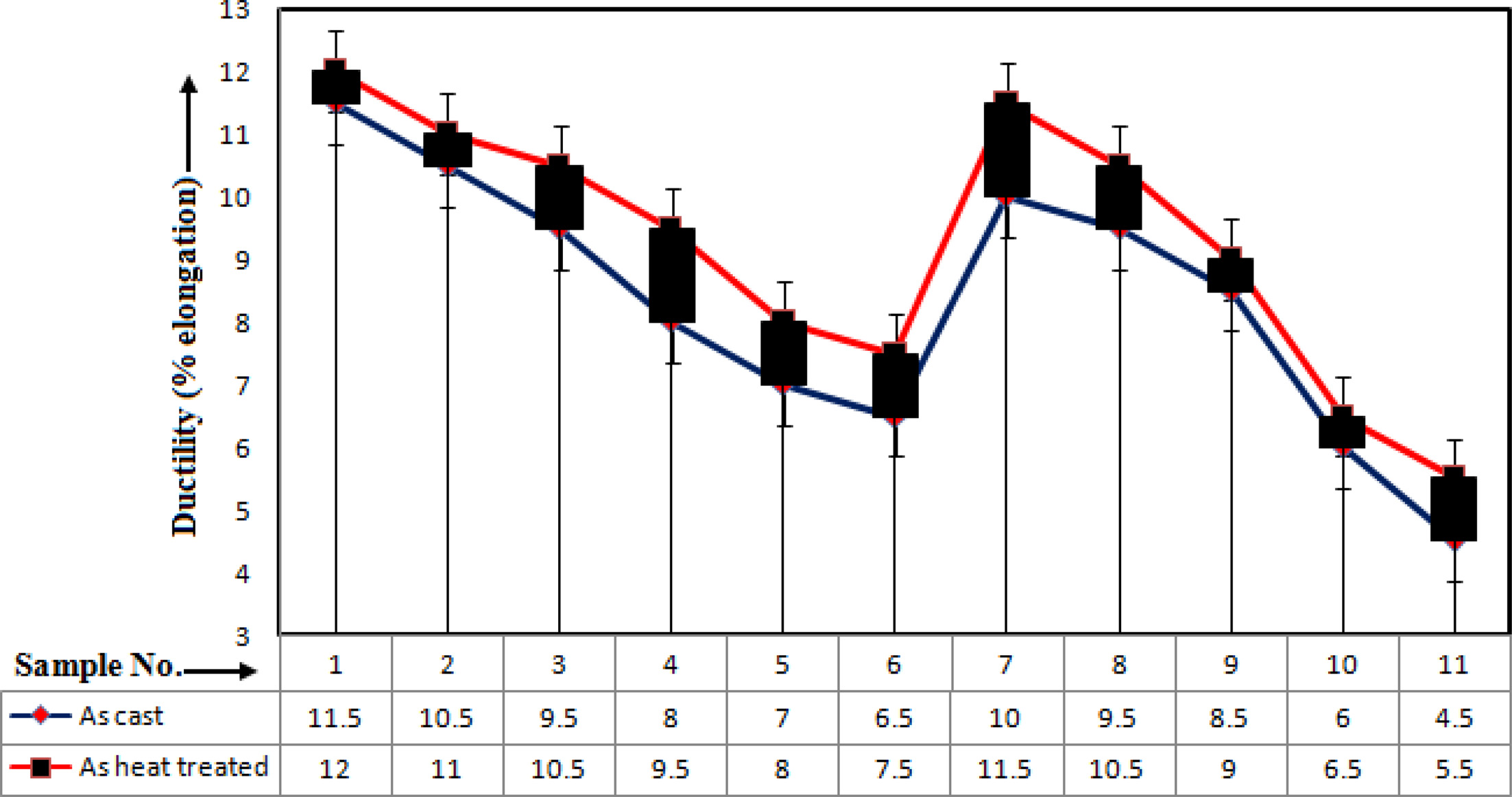

Ductility

Ductility of hybrid metal matrix composite was also

observed to the find out the percentage elongation of the composite. Percentage

elongation was calculated on extensometer during tensile testing.

ASTM B557 standard was used to prepare the tensile samples. Magnesium

oxide (MgO) has low ductility. It also shows unusual behaviour, such as a

regime of increasing strength with increasing temperature, which is the

opposite of most metals. Fig. 8 shows the ductility of AA2024/Si3N4/MgO

hybrid metal matrix composite. Results showed that the ductility of the hybrid

composite was also decreased by increasing the percentage of Si3N4

in AA2024/MgO composite material. The heat treatment effect was

also observed in the ductility samples. Purple deviation

bars show the enhancement of ductility after the heat treatment process.

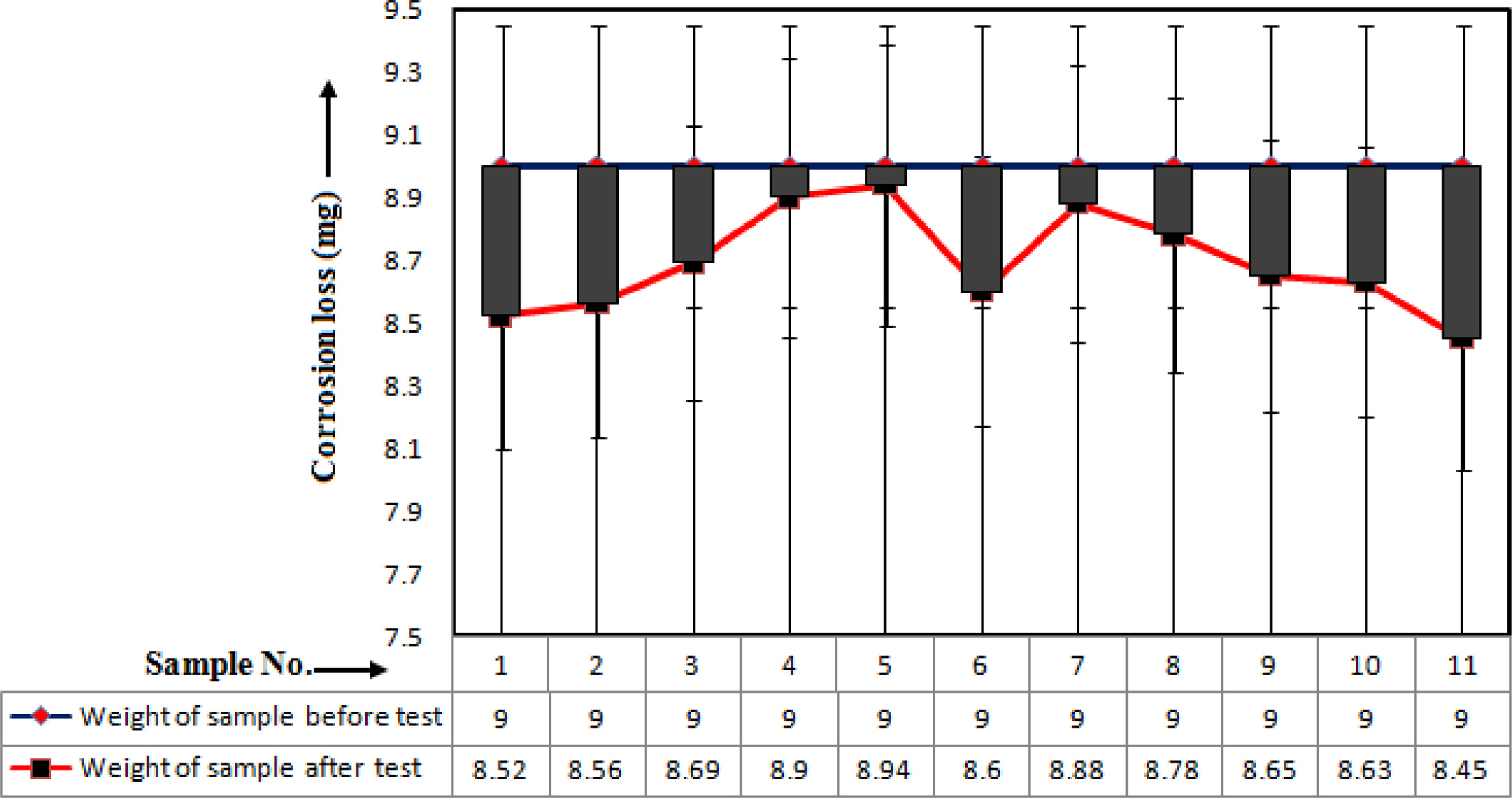

Corrosion

behaviour

Tensile strength and hardness results showed that MgO

addition in AA2024/Si3N4 composite provides better

results as compared to without addition of MgO in AA2024/Si3N4

composite. Hence, in this study, the corrosion behaviour of AA2024/Si3N4/MgO

hybrid composite was observed. Corrosion test of all the samples was carried

out in 3.5 wt.% NaCl for 120 hours. Weight of each sample was taken 9 mg to

make uniformity for the corrosion test. Fig. 9 shows the corrosion

weight loss of hybrid metal matrix composite. Minimum

corrosion loss was found to be 0.06 mg for AA2024/10% Si3N4/2.5%

MgO composite material.

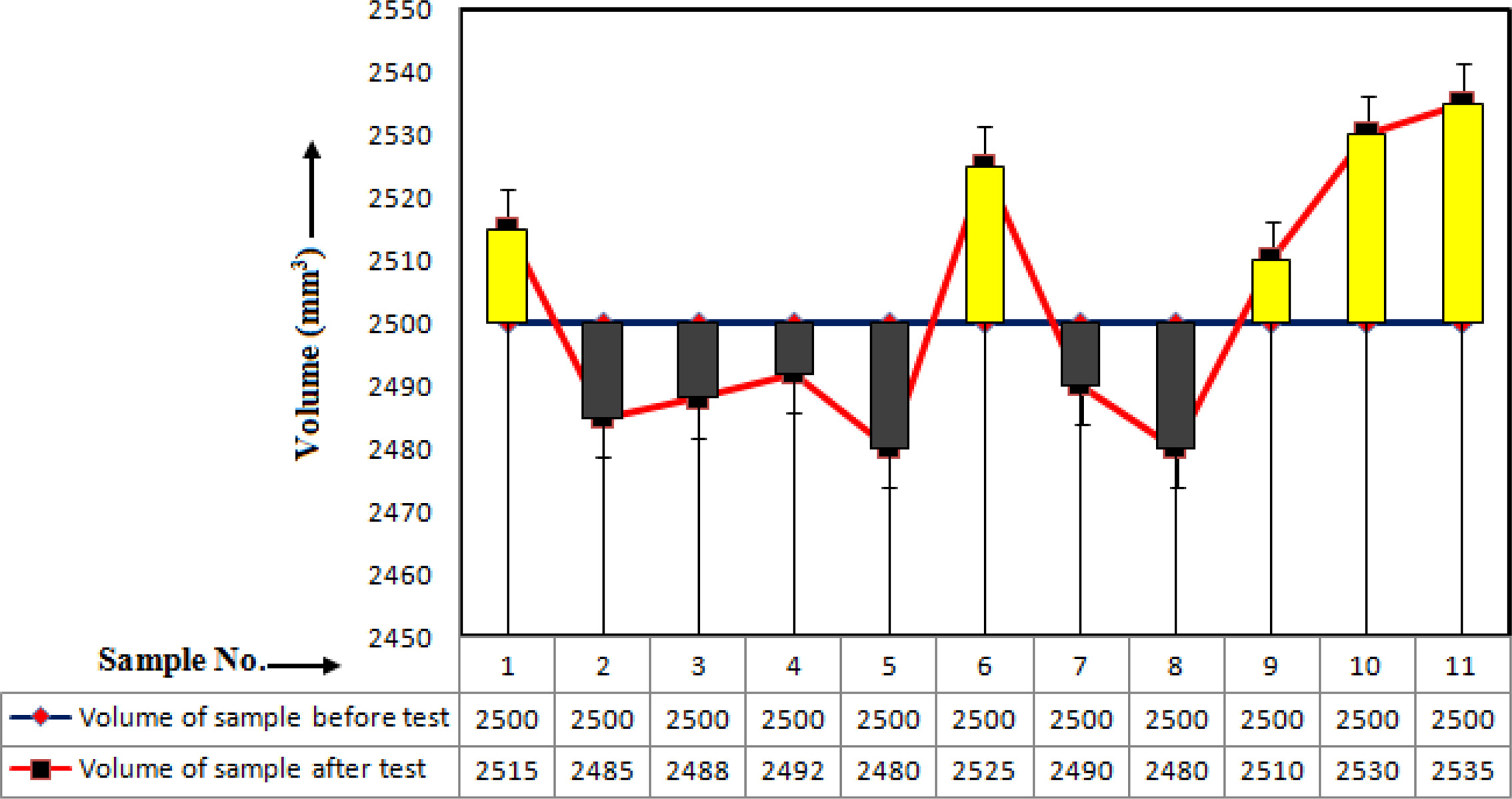

Thermal

expansion behaviour

Thermal expansion property of each green composite

material was identified to observe the appropriateness of material

in a high-temperature environment. Dimension (Volume:

2,500 mm3 (25 ´

10 ´ 10)) of each

sample was kept constant. Thermal expansion test was carried out for

72 hours at 450 oC in a muffle furnace. Thermal

expansion behaviour of AA2024/Si3N4/MgO hybrid composite

was observed. Fig. 10 shows the thermal expansion result of hybrid metal matrix

composite. Minimum volume difference was found to be 8 mm3 for

AA2024/7.5% Si3N4/5% MgO hybrid composite material. Si3N4

exhibits an unusually low coefficient of thermal expansion, which is a useful

property for designers working with high-temperature applications.

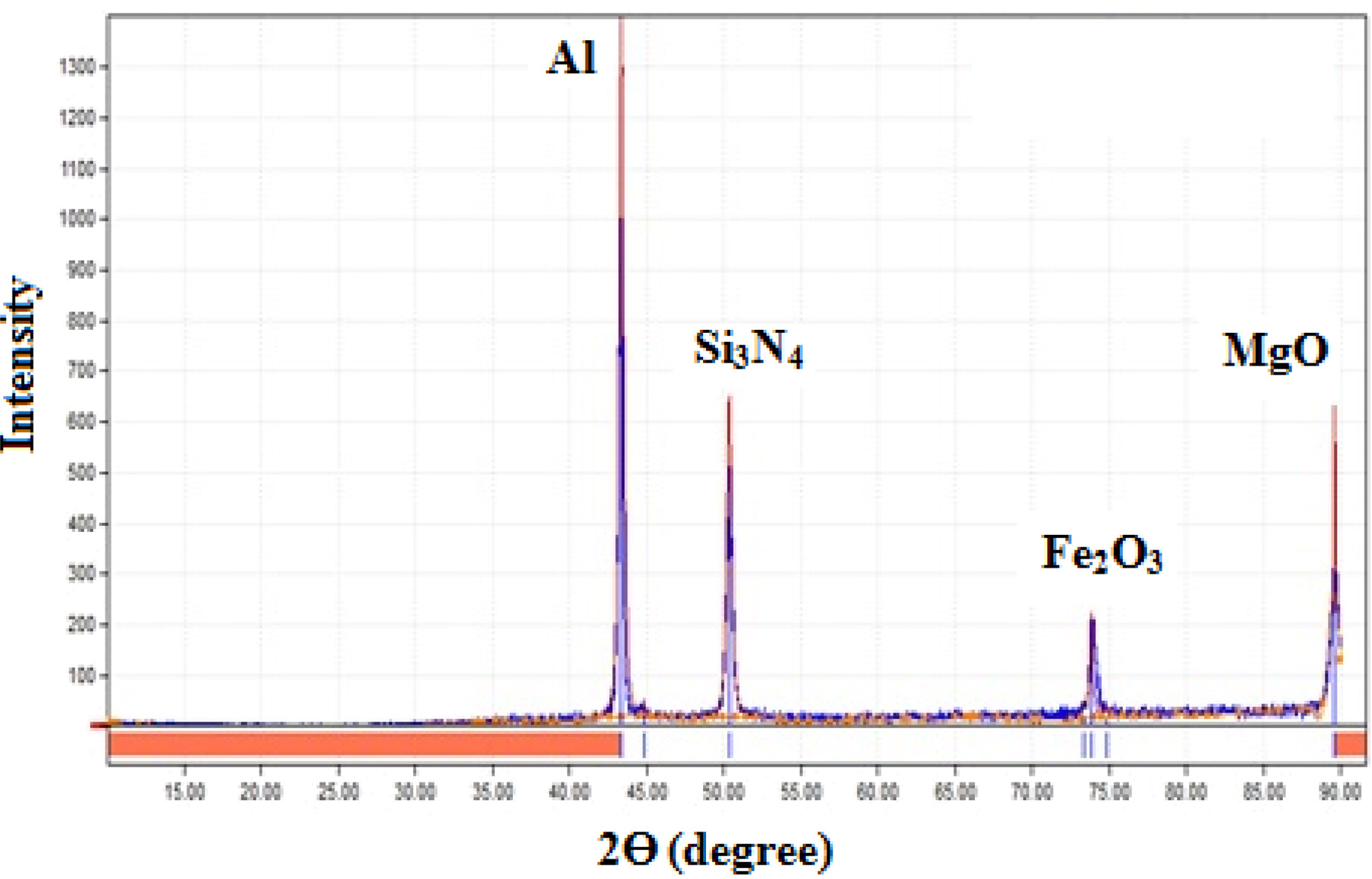

XRD

Analysis

XRD of AA2024/7.5% Si3N4/5%

MgO hybrid metal matrix composite was observed to identify the various phases

form during the development of composite material. Phases such as Al, Si3N4,

Fe2O3 and MgO were found at angles (2ϴ degree) 44o,

50o, 75o and 90o respectively as shown in Fig.

11. Formation of these phases may be responsible for increasing the tensile

strength and hardness of AA2024/7.5% Si3N4/5% MgO hybrid

metal matrix composite material.

|

Fig. 5 Tensile strength of composite materials. |

|

Fig. 6 Hardness of composite materials. |

|

Fig. 7 Toughness of hybrid composite. |

|

Fig. 8 Ductility of hybrid composite. |

|

Fig. 9 Corrosion weight loss of hybrid composite. |

|

Fig. 10 Thermal expansion of hybrid composite. |

|

Fig. 11 XRD Analysis of AA2024/7.5% Si3N4/5% MgO hybrid metal matrix composite. |

Following conclusions can be drawn from the analysis.

1. AA2024 aluminium base composite material

successfully developed by using Si3N4 as primary

reinforcement material and MgO as a secondary reinforcement material by hybrid

casting technique.

2. Microstructure results showed the

uniform distribution and proper wettability of Si3N4

ceramic particles in AA2024 aluminium alloy by adding MgO particles in

composite material.

3. Maximum tensile strength and hardness were

found to be 204.5 MPa and 72 BHN for AA2024/7.5% Si3N4/5%

MgO composite material. Results showed that tensile strength and hardness

increased about 19.16% and 62.5% with respect to base metal AA2024 aluminium

alloy after the heat-treatment process.

4. Toughness and Ductility were continuously

decreased by adding the Si3N4 and MgO

particles in AA2024 aluminium alloy.

5. Minimum corrosion loss was found to be 0.06 mg for

AA2024/10% Si3N4/2.5% MgO composite material.

Similarly, Minimum volume difference was found to be 8 mm3 for

AA2024/7.5% Si3N4/5% MgO hybrid composite material.

6. XRD of AA2024/7.5% Si3N4/5%

MgO hybrid metal matrix composite showed the formation of Al, Si3N4,

Fe2O3 and MgO phases at angles (2ϴ degree) 44o,

50o, 75o and 90o respectively.

- 1. C.-D. Lee, Materials Science and Engineering: A 559 (2013) 496-505.

-

- 2. S. Shekhar, R. Sarkar, S.K. Kar, and A. Bhattacharjee, Materials & Design 66 (2015) 596-510.

-

- 3. S.K. Patel, B. Kuriachen, N. Kumar, and R. Nateriya, Ceramics International 44 (2018) 6426-6432.

-

- 4. B. Fan, S. Zhu, H. Ding, Y. Bai, Y. Luo, and P. Di, Materials Chemistry and Physics 238 (2019) 121907.

-

- 5. H. Liu, L. Chen, and L. Ji, Journal of Hazardous Materials 376 (2019) 125-132.

-

- 6. S. Wang, M. Li, S. Zhang, S. Fang, and D. Wang, Journal of Magnetism and Magnetic Materials 479 (2019) 121-125.

-

- 7. M. Li, L. Cheng, R. Mo, F. Ye, and X. Yin, Journal of Alloys and Compounds 798 (2019) 280-289.

-

- 8. C. Yu, J. Ding, C. Deng, H. Zhu, and N. Peng, Ceramics International 44 (2018) 1104-1109.

-

- 9. J. H. Li, J. Barrirero, G. Sha, H. Aboulfadl, F. Mücklich, and P. Schumacher, Acta Materialia 108 (2016) 207-218.

-

- 10. R. Chen, Q. Xu, Z. Jia, and B. Liu, Materials & Design 90 (2016) 1059-1068.

-

- 11. M. G. Mueller, M. Fornabaio, and A. Mortensen, Journal of Material Science 52 (2017) 858-868.

-

- 12. N. M. Kumar, S. S. Kumaran, and L.A. Kumaraswamidhas, Journal of Alloys and Compounds 672 (2016) 238-250.

-

- 13. R. Ambigai and S. Prabhu, Transactions of Nonferrous Metals Society of China 27 (2017) 986-997.

-

- 14. Q. Xu, X. Ma, K. Hu, T. Gao, and X. Liu, Materials Science and Engineering: A 726 (2018) 113-119.

-

- 15. R. Ambigai and S. Prabhu, Measurement 146 (2019) 736-748.

-

- 16. C. Zhang, Y.-P. Zeng, D. Yao, J. Yin, K. Zuo, Y. Xia, and H. Liang, Journal of Materials Science & Technology 35 (2019) 1345-1353.

-

- 17. C. Zhang, D. Yao, J. Yin, K. Zuo, Y. Xia, H. Liang, and Y.-P. Zeng, Wear 430-431 (2019) 145-156.

-

- 18. Q. Xu, K. Hu, X. Ma, T. Gao, and X. Liu, Materials Science and Engineering: A 733 (2018) 211-219.

-

- 19. P. Jiang, X. Wu, W. Xue, J. Chen, W. Wang, and Y. Li, Ceramics International 43 (2017) 1335-1340.

-

- 20. C. Zhang, J. Yin, D. Yao, K. Zuo, Y. Xia, H. Liang, and Y. Zeng, Composites Part A: Applied Science and Manufacturing 102 (2017) 145-153.

-

- 21. A. Lotfy, A.V. Pozdniakov, V.S. Zolotorevskiy, M.T. Abou El-khair, A. Daoud, and A.G. Mochugovskiy, Materials Characterization 136 (2018) 144-151.

-

- 22. E. Ghasali, A. Bordbar-Khiabani, M. Alizadeh, M. Mozafari, M. Niazmand, H. Kazemzadeh, and T. Ebadzadeh, Materials Chemistry and Physics 225 (2019) 331-339.

-

- 23. Y. Sun, Y. Li, H. Li, M. Yan, S. Tong, and J. Sun, Ceramics International 44 (2018) 3987-3992.

-

- 24. M. Yan, Y. Li, H. Li, Y. Sun, H. Chen, C. Ma, and J. Sun, Ceramics International 44 (2018) 3856-3861.

-

- 25. M. Pul, R. Çalin, and F. Gül, Materials Research Bulletin 60 (2014) 634-639.

-

- 26. K.V. Sreenivasa Rao, and Govindaraju, Materials Today: Proceedings 4 (2017) 11096-11101.

-

- 27. H. Abdizadeh, R. Ebrahimifard, and M. A. Baghchesara, Composites Part B: Engineering 56 (2014) 217-221.

-

- 28. S.M. Latifi, J. Bakhshi Azghandi, A. Salehirad, and M. Parvini, Chinese Journal of Chemical Engineering 25 (2017) 1329-1334.

-

- 29. R. Mohammadi Badizi, M. Askari-Paykani, A. Parizad, and H.R. Shahverdi, Inter Metalcast 12 (2018) 565-573.

-

- 30. G. Eisaabadi and A. Nouri, Inter Metalcast, 12 (2018) 292-297.

-

- 31. S. Ordóñez, O. Bustos, and R. Colás, Inter, Inter Metalcast, 3 (2009) 37-41. https://doi.org/10.1007/BF03355451.

-

- 32. S.P. Dwivedi, S. Sharma, and R.K. Mishra, Journal of Composite Materials 51 (2017) 4261-4271.

-

- 33. S. P. Dwivedi, S. Sharma, and R. K. Mishra, Journal of the Brazilian Society of Mechanical Sciences and Engineering 37 (2015) 57-67.

-

This Article

This Article

-

2019; 20(6): 632-642

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.632

- Received on May 31, 2019

- Revised on Aug 12, 2019

- Accepted on Sep 26, 2019

Services

Services

Shared

Correspondence to

Correspondence to

- Shashi Prakash Dwivedi

-

G. L. Bajaj Institute of Technology & Management, Greater Noida, Gautam Buddha Nagar, U.P., India

Tel : +91120-3272515 Fax: +91120-2323817 - E-mail: spdglb@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.