- Effect of B2O3 addition on the Sintering of BaTiO3-CaTiO3 Composite Materials

T. Bezzia,*, A. Chennia, F. Sellama, K. Sahraouib and S.E. Baramab

aNational Center For Biotechnology Research, Ali Mejli Nouvelle Ville, UV03 Bp E73, Constantine, Algeria

bCeramics Laboratory, Fréres Mentouri University of Constantine 1, Algeria

The effects of B2O3

addition on the sintering behaviour of BaTiO3-CaTiO3 (BCT)

materials were investigated. (1-x) BaTiO3-x CaTiO3-y B2O3

(where x is 3 or 7 % mol. and 0 ≤ y ≤ 3 mol.% respectively). Pellets were

prepared from BaTiO3 (BT) and CaTiO3 (CT) powders mixture

and sintered at 1,200, 1,250, 1,300 and 1,350 oC, gradually in

air for 3 h. The relative density of BCT samples with 1 mol. % B2O3

sintered at 1,200 oC were as good as those of undoped BCT

sintered at 1,350 oC. When > 2 mol. % B2O3

was added to BCT, the over doped B2O3 did not form a

liquid phase or volatilize, it remained in the samples and formed a secondary

phase that lowered the sintering behaviour of the BCT. The X-Ray diffraction

analysis carried out on both kind of pellets (x = 0.3 and

x = 0.7) revealed the presence of BT and CT solutions together in an

unidentified secondary phase.

Keywords: BaTiO3, CaTiO3, B2O3, Sintering, Relative density, X-Rays diffraction

The nonlinear properties of ferroelectrics materials have,

recently, became the subject of intense research activity both in the

fundamental and practical domains. These materials, are currently used in

manufacturing of various microwave devices, such as voltage-controlled

oscillators (VCO), tenable filters, phase shifters and varactors

[1-3]. For such application, the basic requirements are;

high dielectric tenability defined as the mean variation

of the relative permittivity with field intensity, low dielectric

loss tan δ, appropriate level of dielectric constant and a feeble

temperature dependence of permittivity. In general, Strontium Titanate (ST)

based materials are used for devices operation at low temperature while (Ba,

Sr) TiO3 (BST) based materials are used for devices operating

at room temperature [4, 5]. Ferroelectric based materials

present two major inconvenient, relatively high dielectric loss and larger

temperature dependence of their relative permittivity. An efficient way is to

dope oxides that have low dielectric loss into the ferroelectric materials. Additionally,

the introduction of oxides would also be able to modulate the dielectric

properties of these materials for specific applications. CaTiO3

is a typical depressor in BaTiO3 ceramics, which

conduces to a significant decrease both in dielectric

loss and in temperature coefficient of dielectric constant.

Furthermore, CaTiO3 introduces only slight change of Curie point

when Ca2+ substitute Ba2+ in the A sites [6] but

causes an important shift to lower temperature when Ca2+

substitute Ti4+ in B sites [7]. In this latter case, it would be

possible to obtain like diffuse phase structure conferring good dielectric and

relaxer properties to these materials. Consequently, (Ba, Ca) TiO3

systems are expected to be alternative candidates for tunable microwave dielectric

materials with low dielectric loss and small temperature dependence [8].

BT or BCT ceramics usually

require sintering tempera- ture of

> 1,300 oC. Such temperatures are, unfortunately, too high for industrial

manufacturing. The principal objective of the present investigation was to

decrease the sintering temperature of BCT based materials by introducing B2O3

with different proportion in the initial powder mixture. B2O3

is well known as a compound with low melting point, that would react with CaO and

BaO to form glass phase, which

enhance the liquid sintering process and consequently increase the densification

of the sintered materials.

The BaTiO3 (BT) powder used in this

investigation was reagent commercial type manufactured by FLUKA while the used

CaTiO3 (CT) powder was prepared in laboratory following the

conventional procedure of milling and calcination. The starting raw materials

used for CT preparation were high purity commercial anatase

TiO2 powder (also made by FLUKA) and local CaCO3 powder

(extracted out from Khroub locality in Algeria). The

starting powders were weighed and mixed in a stoichiometric proportion. The

mixtures were then ball-milled for 6h using alumina balls in methanol alcohol.

The obtained slurry was dried at 70 oC in electrical furnace

and calcined in air at 1,100 oC for 8 h. XRD analysis was

carried out on calcined powders to control the formation of CT phase. (1-x)

BaTiO3-x CaTiO3-y B2O3 (where x is

3 or 7% mol. respectively and 0 ≤ y ≤ 3 mol.%) mixtures pellets were prepared

from BaTiO3 (BT), CaTiO3 (CT) and B2O3 powders

and re-milled by the same route. 1 mm high and 13 mm diameter pellets were

obtained by uniaxial cold pressing under 70 MPa. The pellets were then sintered

at 1,200-1,350 oC

temperature range. The sintered samples were characterised in terms of apparent

density by direct measure of mass and

volume. X-Ray diffraction analysis

was carried out on different sintered samples to follow the microstructure

evolution.

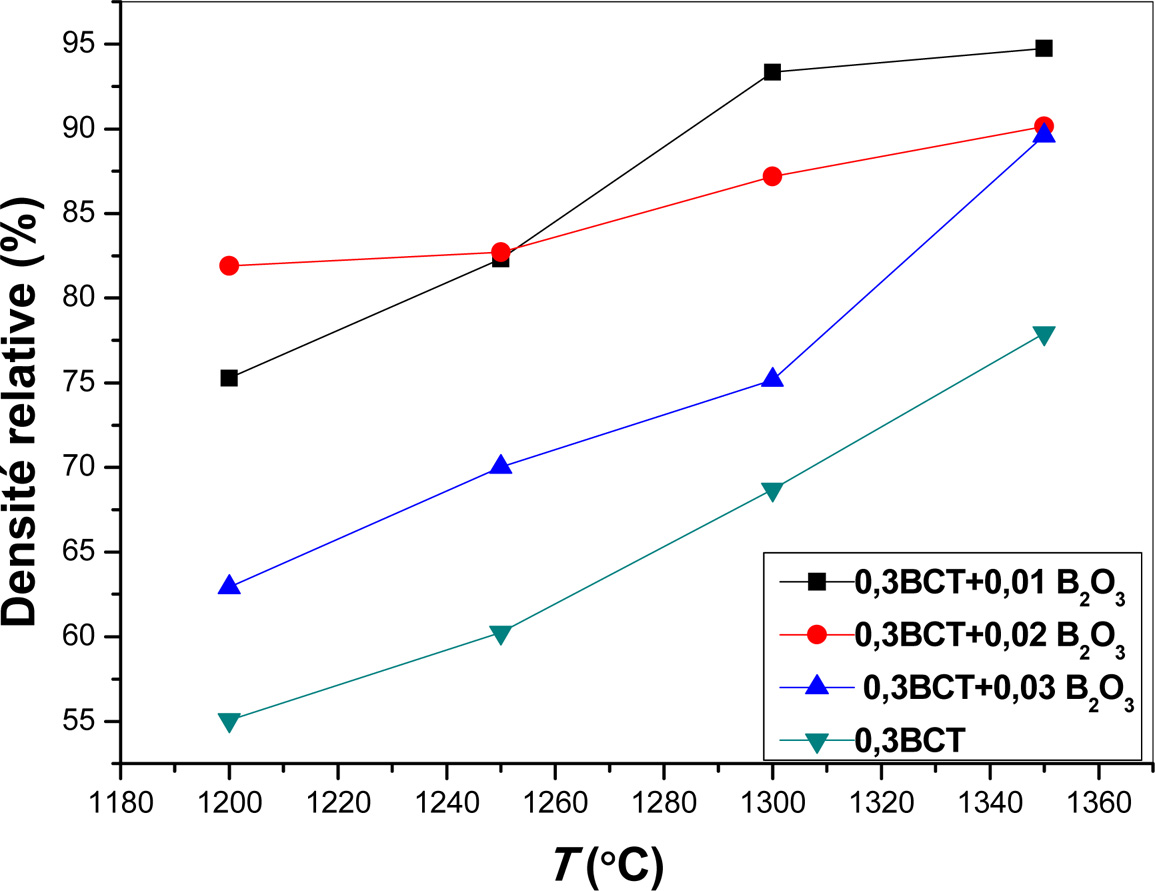

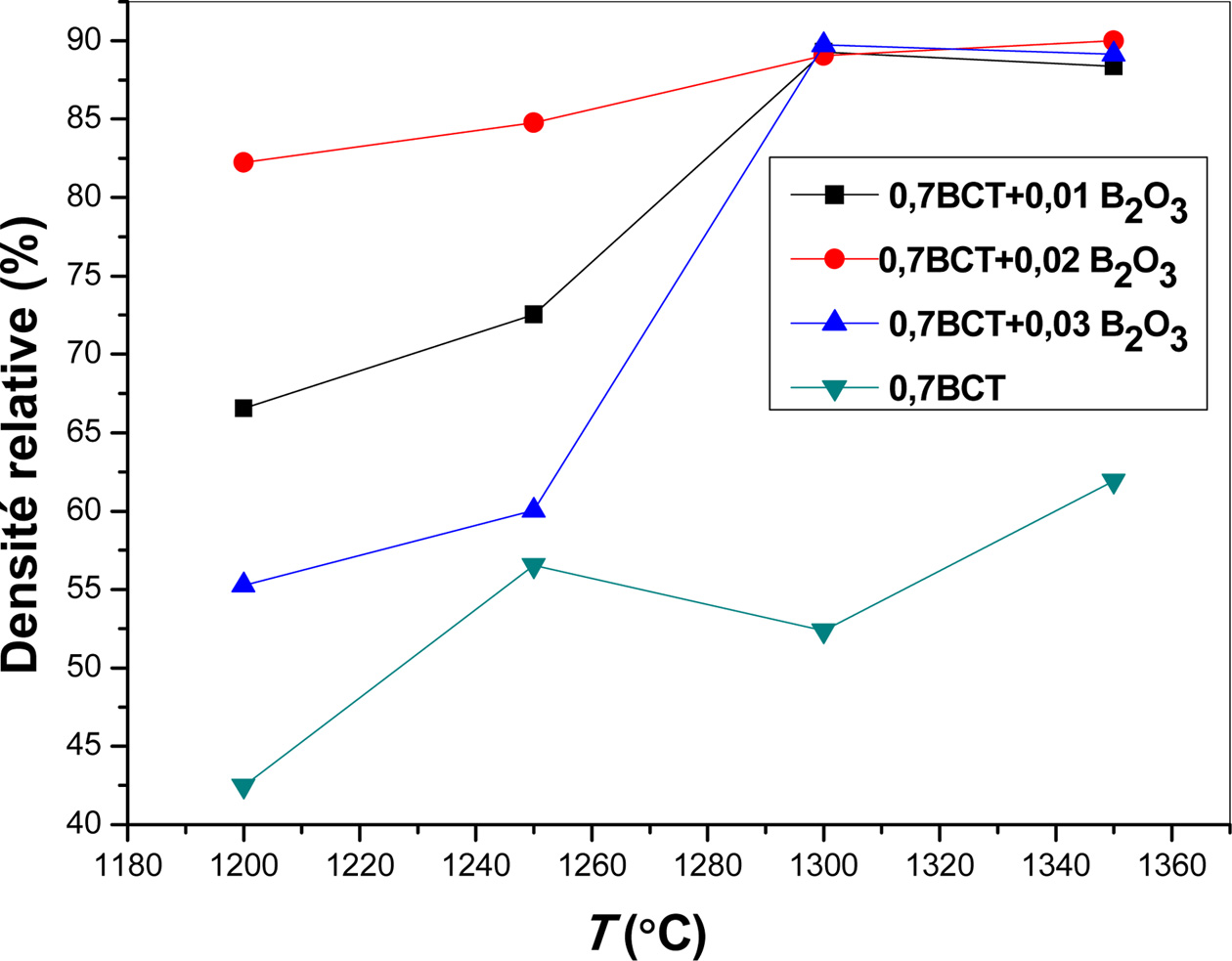

Study

of sample containing 70% of BT

The relative densities of samples sintered for 3 h at

different temperatures are reported in Fig. 1. The obtained

curves reveal identical evolution of the relative density as a

function of the sintering temperature for all considered B2O3 proportion

in the initial mixture. We noticed as well that the increase in the relative

density is, in all cases, about 17 to 20% per 150 oC. This

result, probably, reveals identical densification mechanisms of pellets in this

range of temperature.

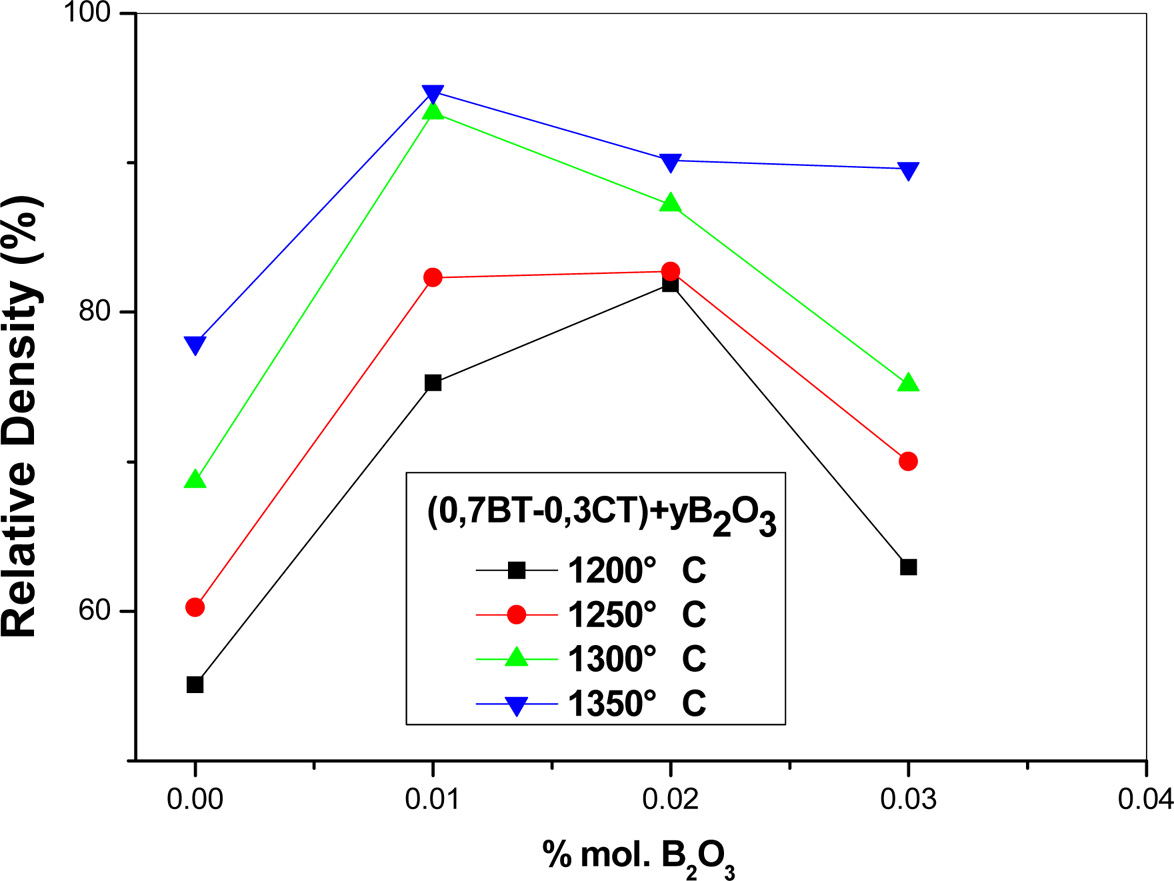

On the other hand, the obtained findings show (Fig. 2) an important

increase in the relative density as a function of B2O3

additions up to 1% mol. At the opposite, the

relative density of pellets decreases beyond such a percentage. Moreover, It can be noticed that the decrease in the

relative density is the more important that the sintering temperature is lower.

This evolution is probably due to the formation of liquid phase, which enhances

the densification for moderate proportion of B2O3 by

developing liquid sintering process. When the proportion of liquid phase became

so important (for Higher B2O3 proportion), the apparition

of secondary porosity (Fig. 2) inhibits the sintering, consequently the pellet

density decreases.

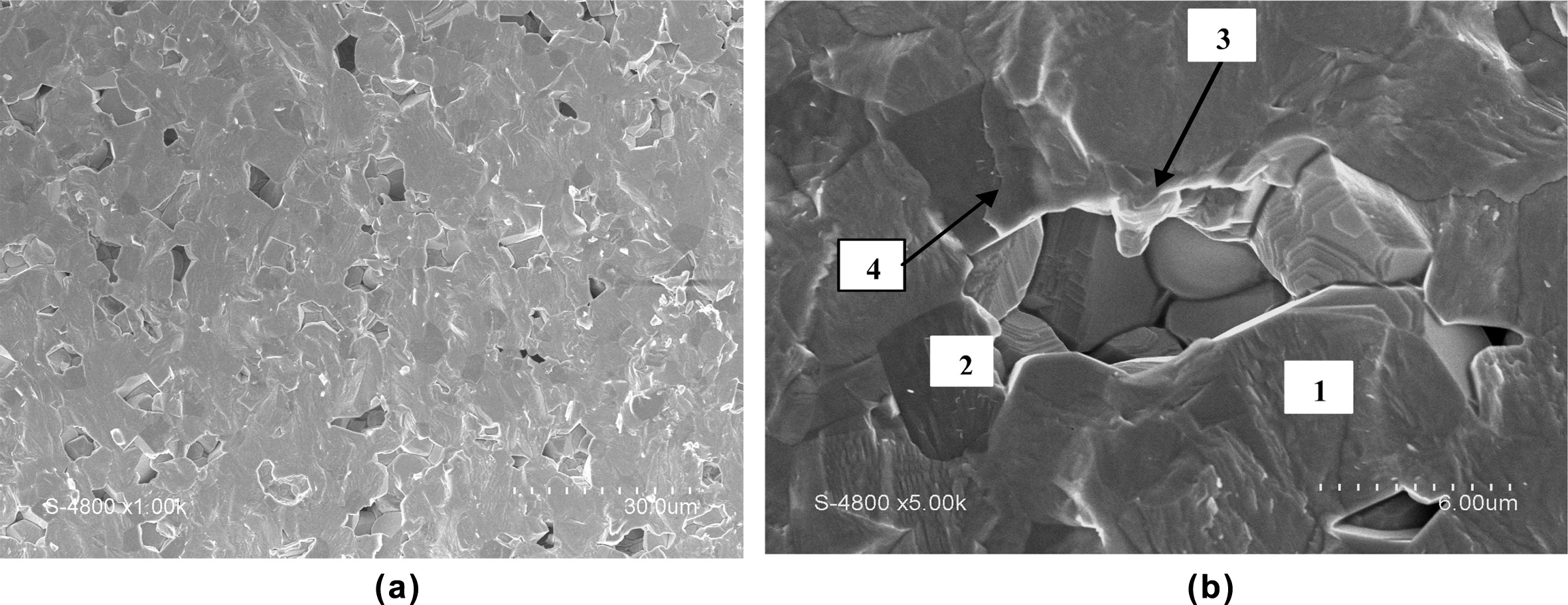

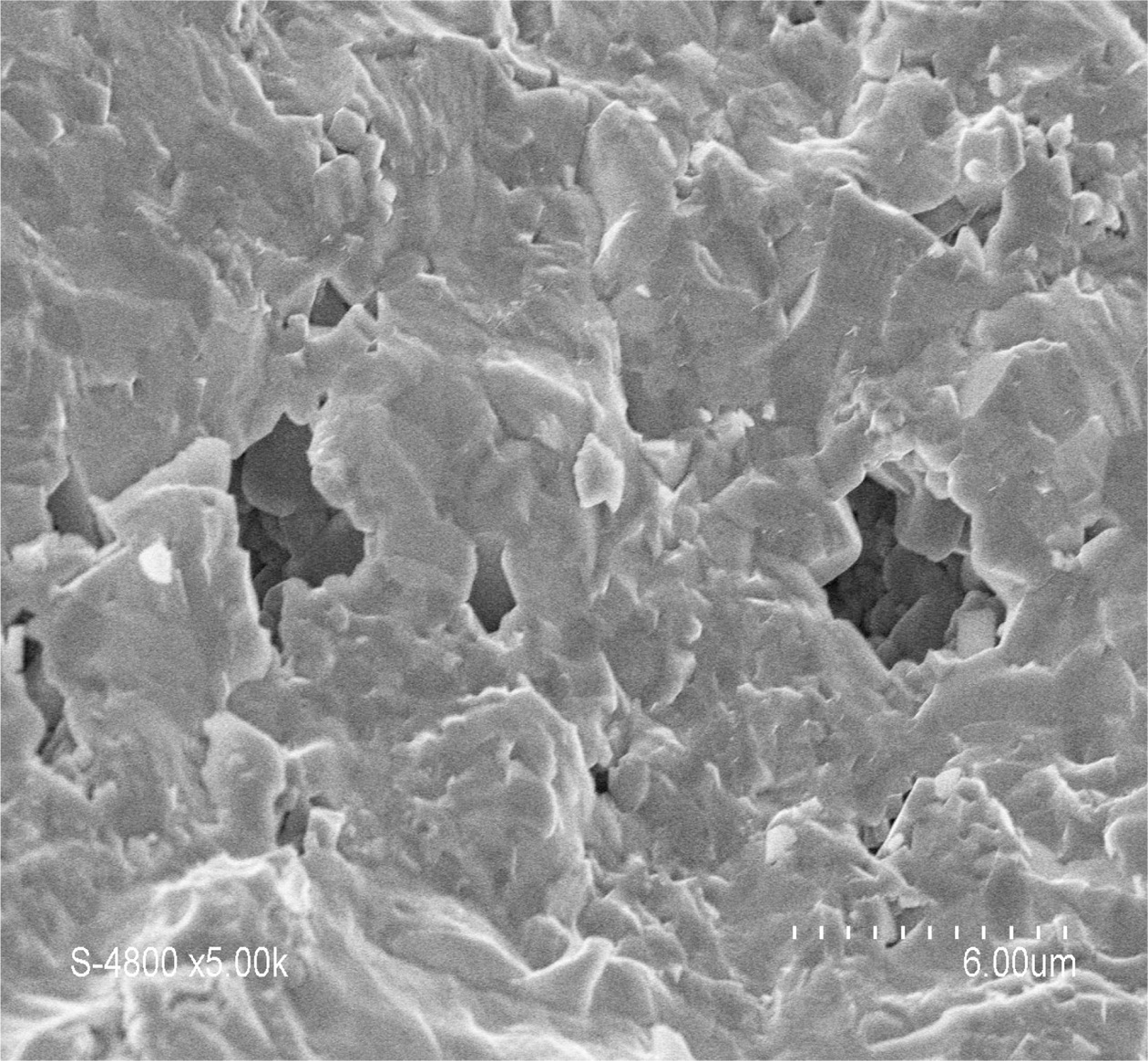

Higher B2O3 proportion), the

apparition of secondary porosity (Fig. 3(a)) inhibits the sintering,

consequently the pellet density decreases.

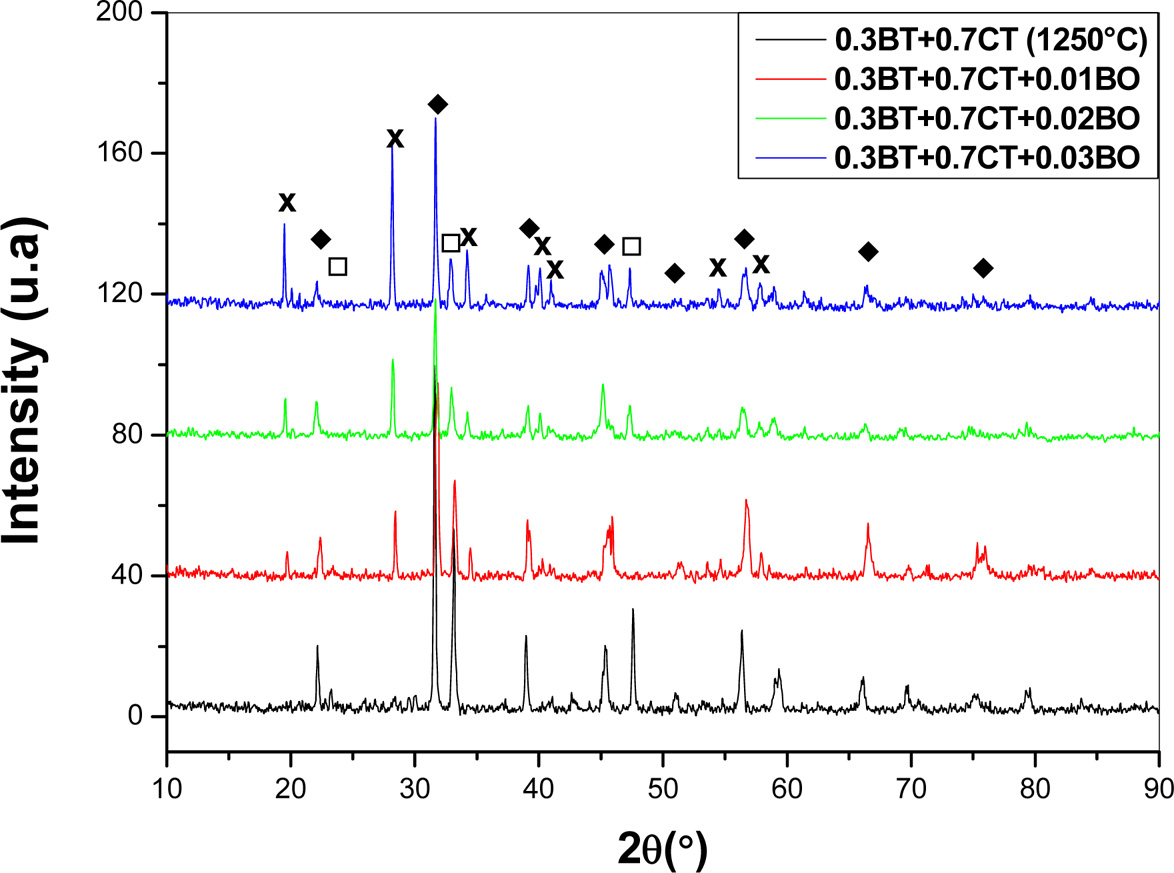

The formation of liquid phase is probably the con- sequence of the reaction between BT, CT

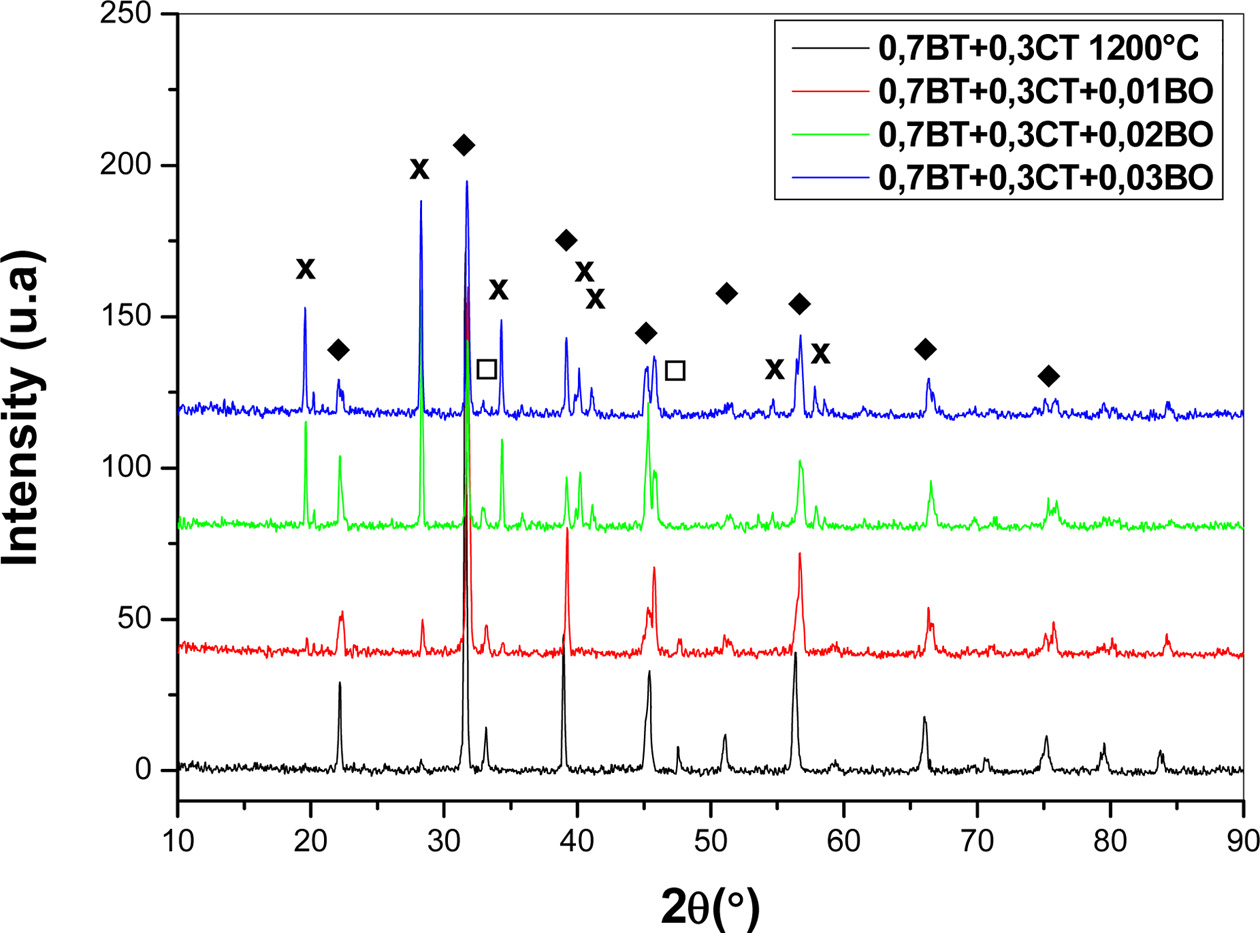

and B2O3 at lower temperature. X-Ray diffraction spectra

recorded from different pellets effectively put in evidence the formation of BT and CT

solution together an un-identified secondary

phase for all considered sintering temperatures (Fig. 4). Furthermore, the

obtained results reveal a decrease in

proportions of BT and CT solutions

respectively as function of added B2O3, while, the

pro- portion of the unidentified phase increases. Consequently, the unidentified phase probably corresponds to

liquid phase formed before than 1,200 oC.

Fig. 3(b) reveals the presence of 3 phases; the BT solid

solution major phase (1), a minor dark phase (2) corresponding

to CT solid solution and a glass-ceramics phase (3)

designated by an arrow. Furthermore, it can be seen that the melting phase

wraps a great area of a CT grain in zone (4)

and is neighboured by secondary porosity

which probably appears because of the shrinkage of the liquid phase during pellet cooling. Hence it must be concluded

that the formation of secondary liquid phase

enhances the densification of pellets for moderate proportion

of B2O3 by developing liquid sintering process. Contrariwise, when liquid phase content

increases, the proportion of the

secondary porosity, induced by the liquid phase shrinkage, increases too and

leads to a diminution of pellets density.

Study

of sample containing 70% of CT

The relative densities of samples containing 70% mol. of

CT and sintered during 3 h at different temperatures

are reported in Fig. 5.

As it can be observed, the evolution of the relative

density is quiet different from that obtained in the case of sample containing

30% mol. of CT. Hence, the relative density increases between 1,200 and

1,300 oC and reaches a maximum of about 90% at 1,350 oC

for all considered B2O3 percentages. At the same time,

the precedent curves reveal an important effect of B2O3

addition on the relative density. This fact is more apparent as we report the

evolution of the relative density as a function of added B2O3

percentage. In the case of pellets sintered at 1,200 or 1,250 oC,

the obtained curves (Fig. 6) firstly reveal an important

increase in the relative density with added percentage of B2O3 up

to 2% mol. For example, the relative density in pellets sintered

at 1,200 oC pass from 42.3% in undoped sample

to 82.3% in sample containing 2 mol.% of B2O3.

This corresponds to an augmentation of 100 per 100 in the

relative density. Over 2% mol of added B2O3, the relative

density decreases again probably owing to the formation of an important liquid

phase proportion leading to the apparition of secondary porosity (Fig. 7) which

restrain the densification in this range of temperature.

As in the case of pellets containing 30% of CT, the liquid

phase probably corresponds to the unidentified phase revealed by X-Ray

diffraction spectra recorded from different samples (Fig. 8). The spectra put

in evidence the presence of BT solid solution, CT solid solution and

unidentified phase whose proportion increases with added percentage of B2O3.

Nonetheless, it is important to remark that the pro- portion of BT solid solution seems not be

affected by B2O3 addition, while, CT

proportion manifestly diminishes as mol.% of B2O3

is increased. Therefore, we can say that the unidentified phase

principally forms by reaction between CT and B2O3.

In the case of pellets sintered at 1,300 or 1,350 oC,

the corresponding curves reveal, at the beginning, an increase in the relative

density with added B2O3 then the relative density

achieves a maximum of about 90% as B2O3 addition exceeds

1% mol.

|

Fig. 1 Relative density of different ((1 - y)(0.7 BaTiO3 + 0.3 CaTiO3) + yB2O3 pellets as function of sintering temperature. |

|

Fig. 2 Relative density of different ((1 - y)(0.7 BaTiO3 + 0.3 CaTiO3) + yB2O3 pellets as function of proportion of added B2O3. |

|

Fig. 3 (a) MEB micrograph of BT-0.3 CT + 3% B2O3 pellet sintered at 1250 oC for 3 h and (b) SEM micrograph of 0.7BT-0.3 CT + 3% B2O3 pellet sintered at 1,250 oC for 3 h. |

|

Fig. 4 X-Ray diffraction spectra recorded from different ((1 - y) (0.7 BaTiO3 + 0.3 CaTiO3) + yB2O3 pellets sintered at 1,200 oC from 3 h; BT, CT, X unidentified phase. |

|

Fig. 5 Relative density of different ((1 - y) (0.3 BaTiO3 + 0.7 CaTiO3) + yB2O3 pellets as function of sintering temperature. |

|

Fig. 6 Relative density of different ((1 - y)(0.3 BaTiO3 + 0.7 CaTiO3) + yB2O3 pellets as function of proportion of added B2O3. |

|

Fig. 7 MEB micrograph of BT-0.7 CT + 3% B2O3 pellet sintered at 1,200 oC for 3 h. |

|

Fig. 8 X-Ray diffraction spectra recorded from different ((1 - y) (0.3 BaTiO3 + 0.7 CaTiO3) + yB2O3 pellets sintered at 1,250 oC from 3 h; BT, CT, X unidentified phase. |

The relative density of (1-x) BaTiO3-x CaTiO3-y

B2O3 (where x is 3 or 7% mol.

respectively and 0 ≤ y ≤ 3 mol.%) composite materials depends on both chemical

composition of the initial mixtures and sintering conditions.

The reaction between BT, CT and BO powder conduces

to the formation of liquid phase which enhances the densification

of pellets, since its proportion is moderate. Inversely,

the liquid phase inhibits the densification when its proportion became so

important.

In the case of pellets containing 30% of CT, the obtained

results reveal an increase in the relative density of about 20% corresponding

to an increase of 150 oC in the sintering temperature. A

maximum of densification (~95%) is obtained in pellet containing 1% mol. of B2O3

and sintered at 1,300 oC.

The addition of 1% mol. of B2O3

provokes an increase of about 20% in the relative density for all considered

sintering temperature. At the opposite, the relative density decreases for

higher percentage of B2O3 addition.

In the case of pellets containing 70% of CT, the obtained

results also reveal an increase in the relative density with sintering

temperature of about 20% corresponding to an increase of 150 oC.

Like in the case of pellets containing 30% CT, the addition

of B2O3, up to 2% mol, enhance the densification,

but the relative density decreases over this percentage in the case of pellets

sintered at 1,200 or 1,250 oC. For higher

sintering temperature, the relative density reaches a maximum of

about 90% as B2O3 addition exceeds 1% mol.

- 1. A.B. Kozyrev, T.B. Samoilova, A.A. Golovkov, E.K. Hollmann, D.A. Kalinikos, V.E. Loginov, A.M. Prudan, O.I. Soldatenkov, D. Galt, C.H. Mueller, T.V. Rivkin, and G.A. Koepf, J. Appl. Phys. 84[6] (1998) 3326-3332.

-

- 2. C.L. Chen, H.H. Feng, Z. Zhang, A. Brazdeikis, Z.J. Huang, W.K. Chu, C.W. Chu, F.A. Miranda, F.W. Van Keuls, R.R. Romanofsky, and Y. Liou, Appl. Phys. Lett. 75[3] (1999) 412-414.

-

- 3. X.X. Xi, H.C. Li, W.D. Si, A.A. Sirenko, I.A. Akimov, J.R. Fox, A.M. Clark, and J.H. Hao, J., Electroceram. 4[2/3] (2000) 393-405.

- 4. L.B. Kong, S. Li, T.S. Zhang, J.W. Zhai, F.Y.C. Boey, and J. Ma, Progress in Materials Science 55[8] (2010) 840-893.

- 5. W.T. Chang and L. Sengupta, J. Appl. Phys. 92[7] (2002) 3941-3946.

- 6. M.S. Yoon and S.C. Ur, Ceram. Int. 34[8] (2008) 1941-1948.

- 7. J.G. Park, T.S. Oh, and Y.H. Kim, J Mater Sci. 27[11] (1992) 5713–5719.

-

- 8. X.M. Chen, T. Wang, and J. Li, Mat, Sci. and Eng. B 113[2] (2004) 117-120.

- 9. R.C. Devries and R. Roy, J. Am. Ceram. Soc. 38[4] (1955) 142-146.

-

This Article

This Article

-

2019; 20(6): 617-620

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.617

- Received on May 31, 2019

- Revised on Oct 8, 2019

- Accepted on Oct 20, 2019

Services

Services

Shared

Correspondence to

Correspondence to

- T. Bezzi

-

National Center For Biotechnology Research, Ali Mejli Nouvelle Ville, UV03 Bp E73, Constantine, Algeria

Tel : +213 (31) 77 50 37/39 Fax: +213 (31) 77 50 44 - E-mail: t.bezzi@crbt.dz

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.