- A study on the ball-milling effect of calcined Mg-Al hydrotalcite on the CO2 adsorption behavior

F. Granados-Correa*, J.L. Iturbe-García and J. Bonifacio-Martínez

Instituto Nacional de Investigaciones Nucleares, Departamento de Química, A.P. 18-1027, Col. Escandón, Delegación Miguel Hidalgo, C.P. 11801, Ciudad de México, México

We have investigated the

effect of ball-milling over calcined Mg-Al hydrotalcite, with regard to its CO2

adsorption capacity. The prepared materials were systematically characterized

by X-ray diffraction, scanning electron microscopy and N2

physisorption measurements. The results reveal an excellent adsorption capacity

of CO2 by calcined Mg-Al hydrotalcite; however, when this adsorbent

was treated by ball-milling for 2 h, a slight decrease in its CO2

adsorption capacity was observed, mainly attributable to the decreased surface

area, total pore volume, pore size and the formation of particle aggregates of

the aforementioned hydrotalcite. Therefore, alterations in structure, texture

and morphology of calcined Mg-Al hydrotalcite during the ball-milling treatment

do not optimize its CO2 adsorption capacity.

Keywords: CO2 adsorption, Calcined Mg-Al hydrotalcite, Co-precipitation synthesis, Ball-milling effect.

It is well-known that global warming is one of the main

environmental concerns around worldwide, and that CO2 is one of the

greenhouse gases that most notably contribute to this problem [1]. Currently,

it is an environmental issue of great importance that requires an immediate

solution to diminish the negative impacts of high CO2 atmospheric

concentrations to the environment and ecosystems [2]. In this framework, the

global scientific community has made great efforts to develop

new and advanced CO2-capture technologies as

technologically viable solutions for the reduction of atmospheric CO2

on a large scale. In this scenario, recently, one of the most promising

post-combustion CO2 capture technologies has been developed, which

carries out CO2 capture with solid adsorbents, made possible by its

high operating flexibility and low energy demand; thus, from this point of

view, the design of CO2 solid adsorbents is quite viable

[3, 4]. Many solid adsorbents have been actively researched and reported

in specialized literature for CO2 capture purposes [5-10]. Each one

of these studied materials has shown interesting results in

terms of CO2 adsorption capacity, under different

temperature and pressure conditions, but it is still necessary to find an

adsorbent that exhibits high selectivity and adsorption towards CO2;

besides, great effort has been made to improve CO2 capture. In

this regard, the key requirement for technological CO2

capture applications is the development of new

adsorbents that have a high CO2 working retention

capacity over a wide temperature range, from room temperature to 700 oC

[11]. Currently, and according to literature, hydrotalcites-type adsorbents,

with divalent and trivalent cations such as Mg2+ and Al3+,

have demonstrated exceptional CO2 capture due to their unique

characteristics, such as anion-exchange, high surface area

and a considerable layer-charge, significant with regard

to acidic gases, as in the case of CO2 [12-14]. Hydrotalcites can be

obtained commercially, as well as in a laboratory; they are

double-layered hydroxides with lamellar structure, formed by a

positively-charged brucite layer, with an interlayer space to accommodate water

molecules and CO32- anions. Also,

these materials have presented high stability during cycling operations,

which is crucial for the development of practical applications such as CO2

capture [15, 16]. It has been reported in the literature,

that the maximum CO2 capture capacity of

hydrotalcite compounds are generally found in the temperature range of

200-400 oC [17-19]. On the other hand,

it has also been confirmed that the adsorbent surface area

plays an important active role in CO2 adsorption, because it

translates to a greater number of active sites which, in turn,

represent greater adsorbance. To address this issue, different

strategies have been examined in recent years in order to improve adsorbent

activity [20-23]. In particular, the strategies that include reducing the

adsorbent particle-size to nanometric scale (<100 nm) have proved to be promising

methodologies for improving adsorbent activity, because the generated fine

nanoparticles have higher contact and reaction efficiencies than traditional

materials do [24]. It is well-known that the ball-milling mechanical activation

method provides an efficient route for preparing stabilized

nano-size adsorbents with improved structural, chemical

and textural characteristics that could be relevant for CO2 capture

[25]. The mechanical ball-milling method is an extensive method employed to obtain

nanostructured materials with several technological uses

[26-27]; this mechanical ball-milling treatment allows to activate dry solids

and specifically increase their surface area, as well as to improve their CO2

capture

properties [28]. Thus, it is considered to have a broader impact compared to

other conventional materials. With regards

to hydrotalcite-like compounds, the

recent interest in novel mechanochemical approaches is

devoted almost exclusively to the successful preparation and modification of these layered double

hydroxides using different starting materials, as well as preparing different nanocomposites [29-32]. From the

hydrotalcite synthesis viewpoint, the

mechanochemical activation method is

simple and versatile, reduces time consuming, and avoids heating

treatment, solvent use and production

of large amounts of waste, which are characteristics consequences of other

existing synthesis methods such as urea hydrolysis, sol-gel, hydrothermal,

combustion, sonication, microwave irradiation, steam activation and

solvothermal [33]. So far, however, significantly fewer studies have indicated

that the ball-milling process, as a nanoparticle generation method, enhances CO2

capture [11, 25].

With regard to this concern,

studies need to be conducted in order to determine the effect of ball milling over the CO2

adsorption behavior of hydrotalcites in order

to optimize this process. To the best of our knowledge, no study has been reported on CO2 adsorption behavior of calcined Mg-Al hydrotalcite after ball-milling. Therefore, new

results could contribute to a greater understanding of the

CO2 adsorption mechanism. For these reasons, the aim

of this study was to understand the effectiveness of the calcined Mg-Al

hydrotalcite, followed by ball-milling treatment for CO2 capture, as

a viable CO2 capture process, because of the expected formation of

aluminum and manganese oxide coatings over the Mg-Al calcined hydrotalcite

surface, which may provide different adsorption sites and a higher surface area

for enhanced CO2 adsorption due to its resultant nanostructured

nature.

The Mg-Al hydrotalcite used in this study was synthetized

by the co-precipitation method at constant pH, according to Sato et al.

[34]. This procedure is based on the mixing of solutions A and B;

solution A contains the cation precursors of hydrotalcite (Mg2+

and Al3+) in water and solution B consists of NaOH and NaCO3

compounds, which provides a basic medium of pH between 8-10, sufficient for

hydrotalcite formation and precipitation. These carbonates

participate in the stabilization of hydrotalcite structure as load

compensators, due to its large size, which facilitates the filtration

of the precipitate formed. Then, using a classic procedure,

1,000 mL of a solution of MgCl2·6H2O 0.75 M and AlCl3·6H2O

0.25 M were added, drop by drop, to 1000 mL of another solution, which

consisted of 0.5 M Na2CO3 and 2.5 M NaOH, under vigorous

agitation. Both aqueous solutions were previously heated to 60 oC

and kept at this temperature during vigorous agitation. Once the

hydrotalcite was obtained, it was separated by filtration and then washed with

enough distilled water until that the chloride ions were not detectable by

precipitation with silver nitrate in solution. The Mg-Al hydrotalcite

precipitate was dried at room temperature for 5 days, and then dried at

80 oC in a stove for three hours. The molar ratio value of

prepared hydrotalcite by this method was 0.25. Then, the calcined Mg-Al

hydrotalcite, denoted as CHT, was obtained by heating the previously-prepared

Mg-Al hydrotalcite to 500 oC for 5 hours in a muffle furnace;

the obtained powders were cooled to room temperature and grounded to a fine

powder in an agate mortar. Additionally, the CHT prepared via co-precipitation,

followed by calcination, was ball-milled for 2 hours under an argon atmosphere

by using a Spex 8000 high-energy mechanical mill with a 50 mL-capacity and a

ball-to-powder weight ratio of 6:1. This obtained material

(CHT-BM), together with the dry Mg-Al calcined hidrotalcite (CHT),

were employed for CO2 adsorption determinations.

CO2 adsorption experiments were carried out at

200 oC and 1 atmosphere of pressure using a Parr 4592

stainless-steel pressure reactor with a 50 mL-capacity, coupled to a

temperature-controlled system. Separately, 8 mg of Mg-Al hydrotalcite samples

were exposed to a high-purity (99.98%), ultra-dry CO2 gas flow for

15 minutes, as a fixed saturation time. Before the CO2 adsorption

tests, the samples were pretreated at 325°C under vacuum for 30 min in order

to remove the adsorbed environmental

impurities. CO2 adsorption capacities

were determined by thermogravimetric analysis using a TGA calorimeter analyzer (TA Instruments SDT Q600), coupled to

a mass spectrum analyzer (TA Instruments, LLC). In this analysis, approximately

6 mg of Mg-Al hydrotalcite samples were placed in a ceramic cell and heated

from 20°C to 850°C at a heating rate of 10 °C/min, under an inert atmosphere,

in which helium was used as the carrier gas (100 mL/min). The ratio m/e = 44 was used for CO2

quantification. The number of

millimoles of CO2 captured per gram of Mg-Al hydrotalcite (mmol/g) were

calculated from the TGA calcination profiles, based on the weight loss of CO2

that was adsorbed in the materials.

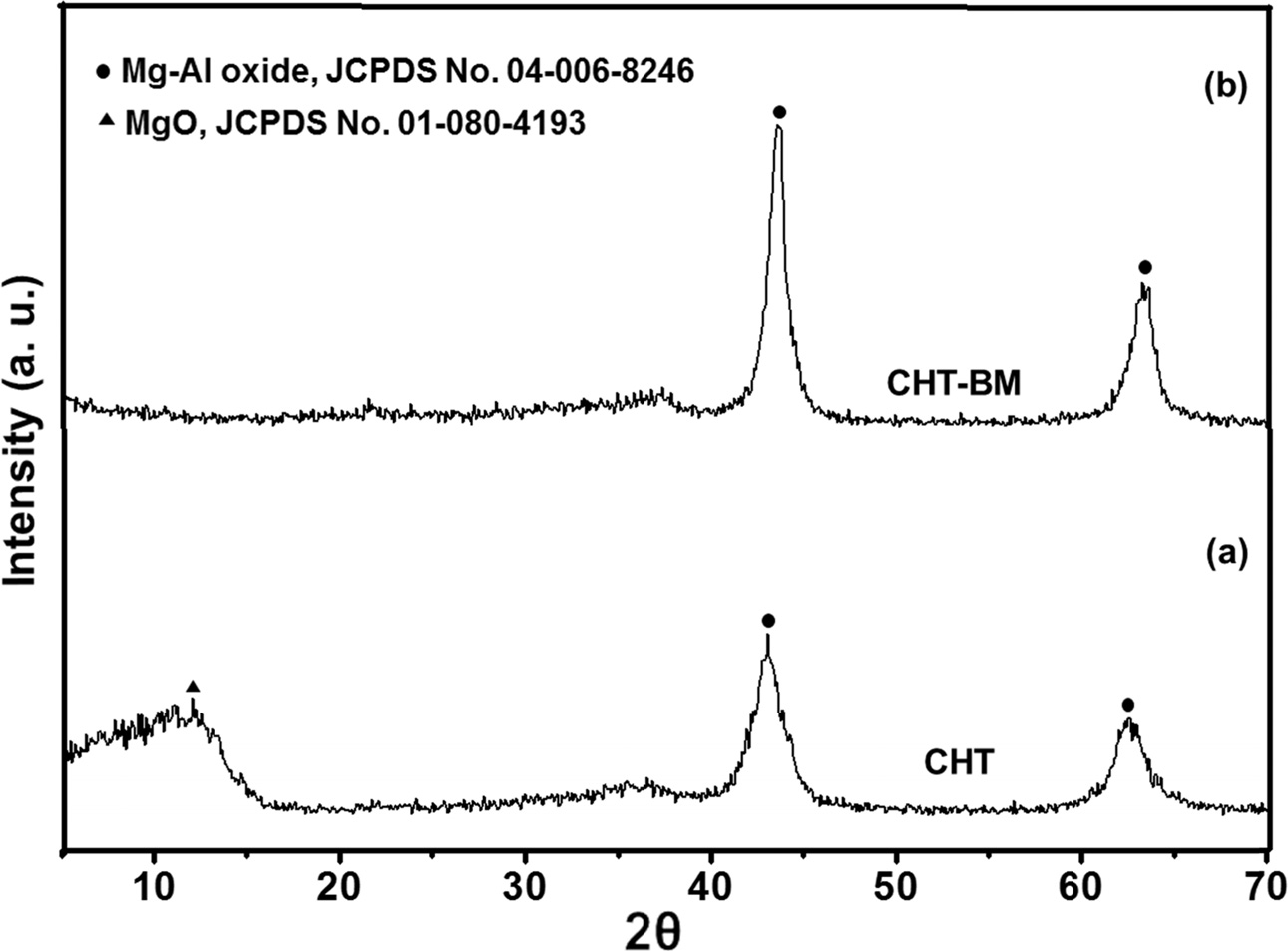

XRD

analysis

Fig. 1 shows the XRD patterns of the Mg-Al hydrotalcite powders prepared by the co-precipitation method

after calcination at 500 oC for 5 h (CHT), and the calcined

Mg-Al hydrotalcite powders after the ball-milling treatment for 2 hours

(CHT-BM). Granados and Serrano [35] reported that the hydrotalcite prepared by

co-precipitation before calcination showed a typical hydrotalcite pattern of

sharp and intense reflections at 11.7o, 23.2o, 60.6o

and 61.8o, at low values of 2θ angle, and less intense, asymmetric

reflections at higher angular values,

characteristic of a well-crystallized Mg-Al hydrotalcite compound, in agreement with the JCPDS card No. 41-1428,

of a double-layered material composed of a positively-charged brucite-like

layer and a negatively-charged interlayer, with the interlayer space typically occupied by water molecules and

anions for charge compensation. The

X-ray pattern of the Mg-Al

hydrotalcite calcined at 500 oC for 5 h (CHT) showed that its characteristic lamellar structure

disappeared, and that at this collapsed layer structure, only a well-dispersed

mixture of Mg and Al oxides was obtained with a high BET-specific surface area,

large total pore volume and a mesoporous diameter, as was revealed by N2

physisorption measurements (Table 1). It is well-know that, under calcination

at 400-500 oC, the Mg-Al hydrotalcite gradually loses interlaminar

water up to at approximately 200 oC; in the range of

200-500 oC, it is dehydroxylated

and decarbonated, allowing the formation of a well-dispersed mixture

of aluminum and magnesium oxides,

with a typical mixed oxide XRD trace obtained, where there are no peaks present

related to aluminium oxide, because aluminum oxide does not crystallize at the

relatively low temperature at which calcination is carried out.

Therefore, the X-ray diffraction pattern (Fig. 1) confirms

the formation of mixed oxides through calcination. When the calcined Mg-Al

hydrotalcite was ball-milled for 2 h, (labeled as the CHT-BM sample), the

presence of only a mixture of Mg and Al oxides was observed in this X-ray

pattern (Fig. 1), but with an increased cristallinity compared to

calcined hydrotalcite. The increased crystalline structure

can be attributed to the effect exerted on the adsorbent powders by the

ball-milling medium (stainless-steel balls), generating a nanostructured

material with a reduced particle size, which could improve the CO2 capture

[36]. It has been previously reported that smaller metal oxide particle sizes

provide a larger BET-specific surface area for exposure and, as a result, these

materials have a higher CO2 adsorption capacity.

Specifically, results have shown that both MgO and CaO-based

adsorbents prepared through solution-combustion synthesis and treated by

ball-milling, produced metal oxide particles with better textural and

structural properties for enhancing CO2 adsorption

capacity, proving that the mechanical process plays a

crucial role in CO2 adsorption behavior [20]. Thus, from this

stand-point, the nanostructured nature of the CHT-BM

sample should lead to greater reactivity and

increased adsorption effects, involving a large number of active

surface sites available for CO2 molecules.

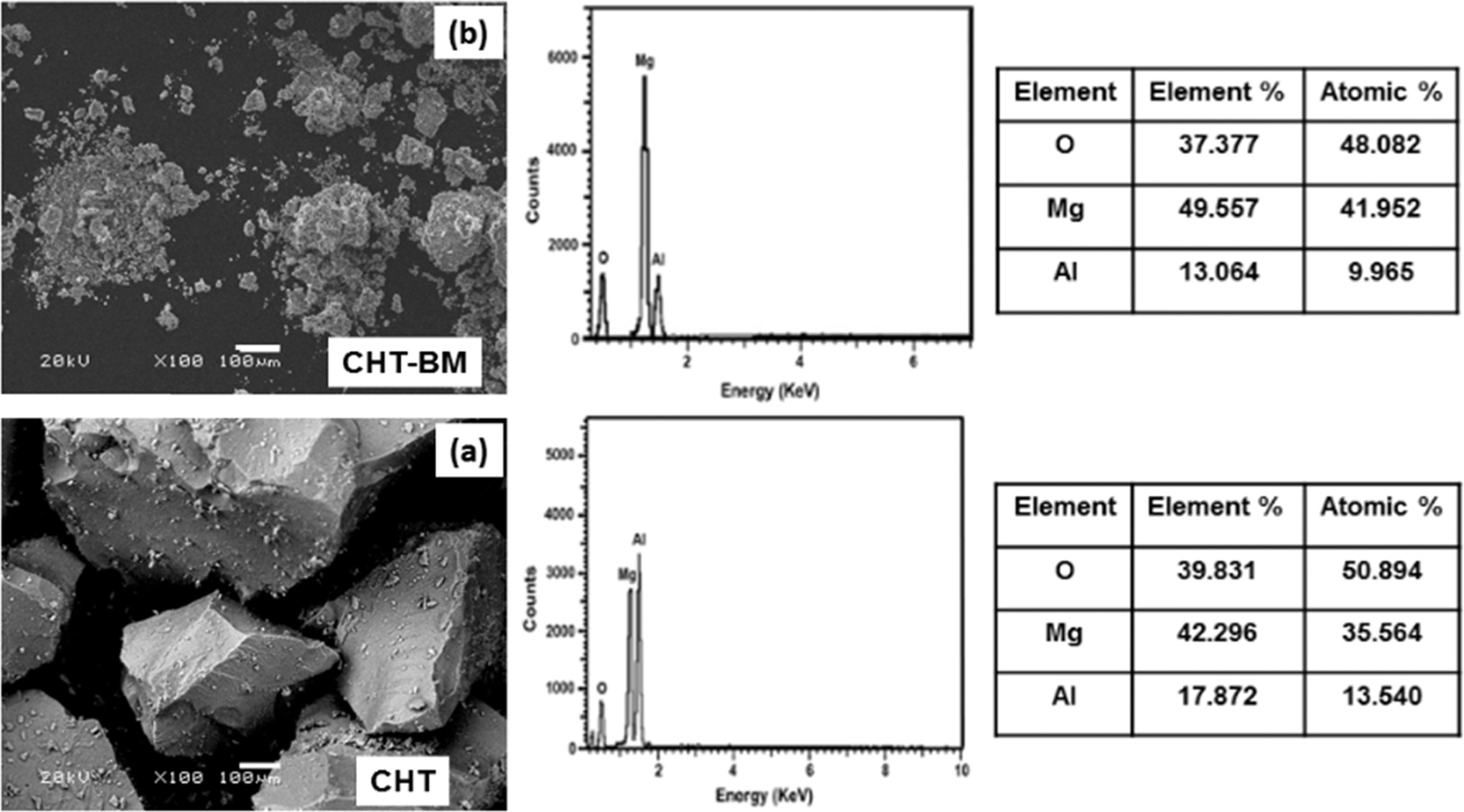

Morphology

and EDS analysis

According to Rossi et al. [15], the formed mixture

of alkali Mg and Al oxides after hydrotalcite calcination, are strongly related

to the basic sites for the adsorption of acidified CO2

molecules. Yang and Kim [18] reported that the

basicity of hydrotalcite also depends on chemical composition (cation

type, M2+/M3+ ratio, anion type existing in the

interlayer) and activation conditions such as the degree of impregnation with

alkali metal carbonates. In consequence, the aluminum content directly affected the hydrotalcite´s CO2 adsorption

capacity, because the increase in

adsorbent Al content decreased the number of basic sites [15]. Therefore, based

on the obtained M2+/M3+

ratio, determined by energy-dispersive

X-ray spectroscopy (EDS) analysis (Fig. 2), it is clear that the calcined Mg-Al

hydrotalcite, followed by ball-milling

for 2 hours, exhibited the best features, and it was to be expected that this

material present the maximum CO2

adsorption capacity. Furthermore, in this study, it was also observed (by

SEM images) that the CHT-BM sample (Fig. 2) resulted in particle agglomeration

after mechanical ball-milling, and that important alterations of the original morphology and textural properties,

along with a predominant formation of particle agglomerates after using the ball-milling treatment, had an inverse

effect on CO2 adsorption capacity.

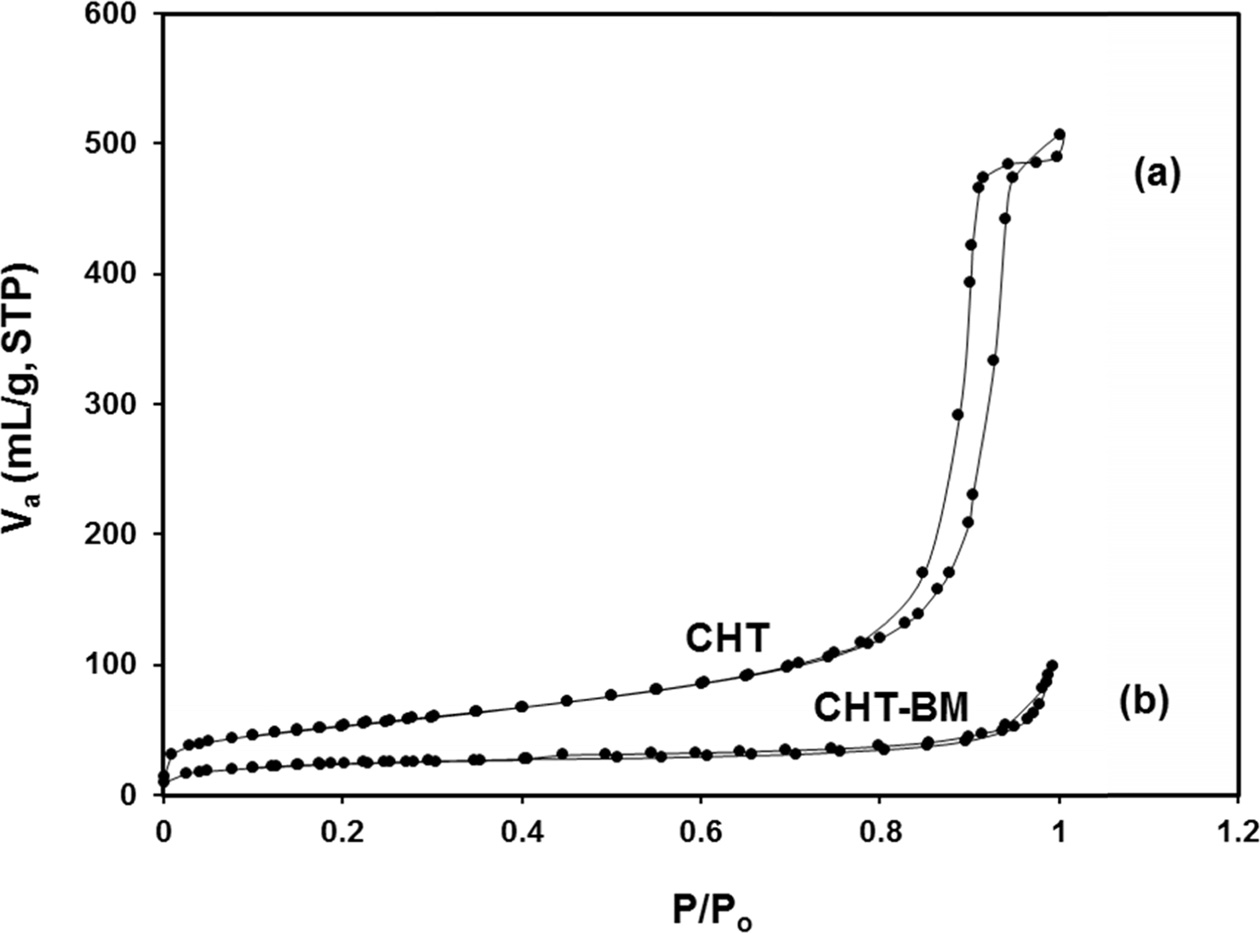

N2

adsorption-desorption isotherm analysis

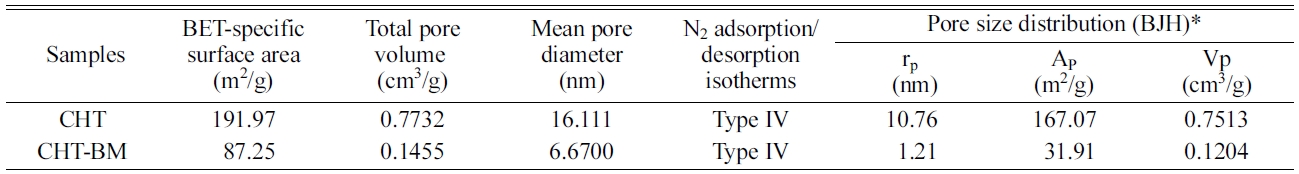

On

the other hand, the N2 adsorption-desorption isotherm results (Fig. 3), presented type IV isotherms of the studied samples, specifically for the CHT

sample, exhibited a marked low- adsorption hysteresis between the adsorption

and desorption curve, which, according to

the International Union of Pure and Applied Chemistry (IUPAC), is characteristic of mesoporous

materials. It is well-known that different adsorbent physicochemical characteristics such as BET-specific surface area, particle size, pore size, and pore volume, are

essential characteristics that play an

important role in CO2 adsorption

behavior, influencing the accessibility of CO2 in the pore structure

or adsorbent surface [36]; for example, adsorbents with a higher porosity have

a greater amount of pores, which determine a significant portion of the CO2

adsorption process, as well as physiadsorbents with small pores, which have

shown great potential as CO2

adsorbents. Indeed, CO2 adsorption increases as total pore volume increases, because a large pore volume

has more active sites for CO2, and experiences less diffusion resistance. According to

the main textural results (Table 1),

it can be seen that the Mg-Al

hydrotalcite, followed by ball-milling for 2 h (CHT-BM) does not have the most

significant physicochemical

characteristics, when compared to the calcined Mg-Al hydrotalcite sample (CHT)

without mechanical ball-milling treatment.

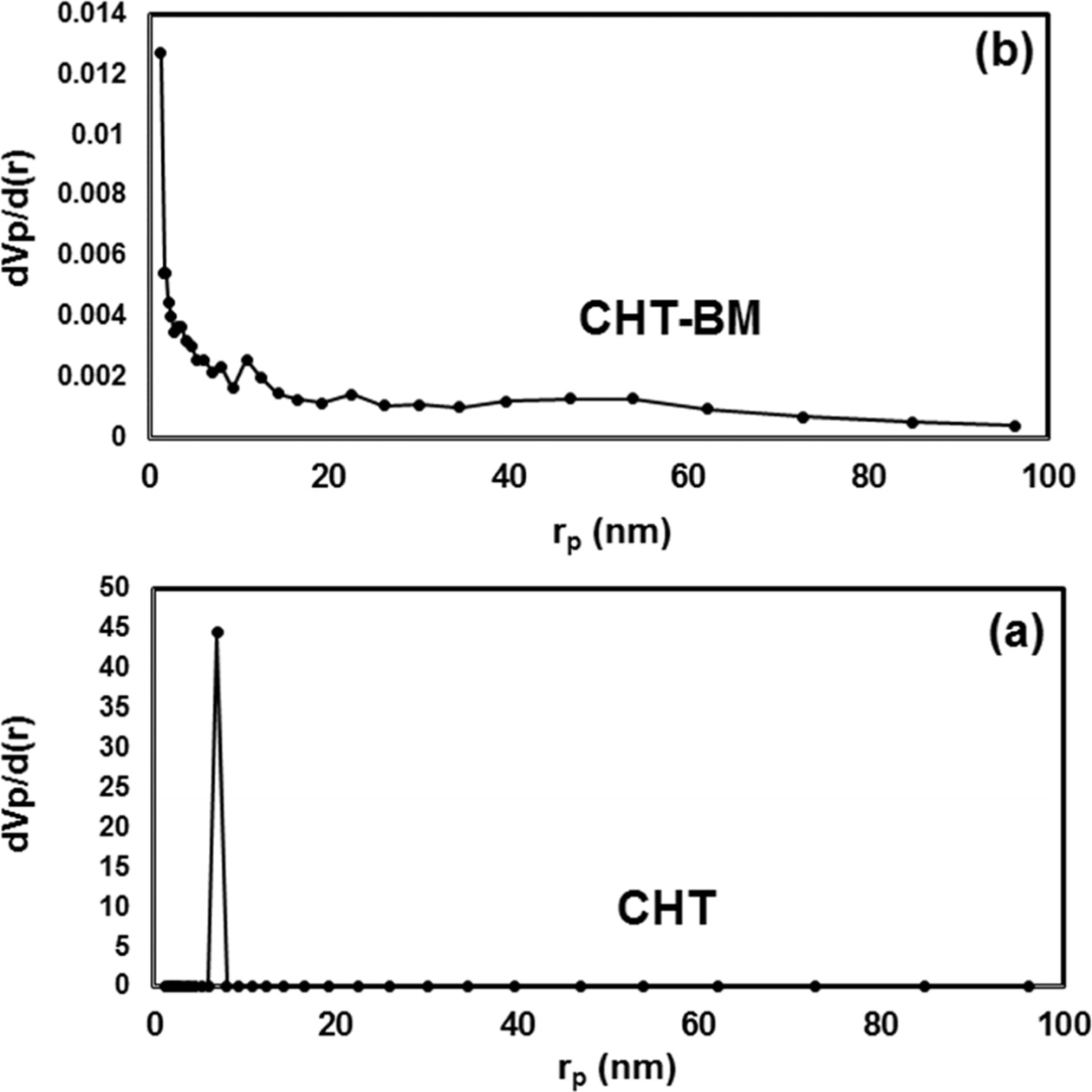

Pore

size distribution analysis

In addition, a significant reduction in pore size, from

10.76 nm to 1.21 nm, obtained by the Barrett-Joiner-Halenda (BJH) pore size distribution

method was also observed when the Mg-Al hydrotalcite was ball-milled (Fig. 4);

this sample showed a marked decrease in pore area (Ap) and total pore

volume (Vp) values (Table 1). It is known that the kinetic CO2

molecule diameter is 0.33 nm [37] and that the Mg-Al calcined hydrotalcite,

after ball-milling treatment, was drastically reduced in its pore diameter,

hence, the available pore space for CO2 did not lead to a better

diffusion of CO2 in the pore channels and decreased CO2

adsorption.

CO2

adsorption behavior

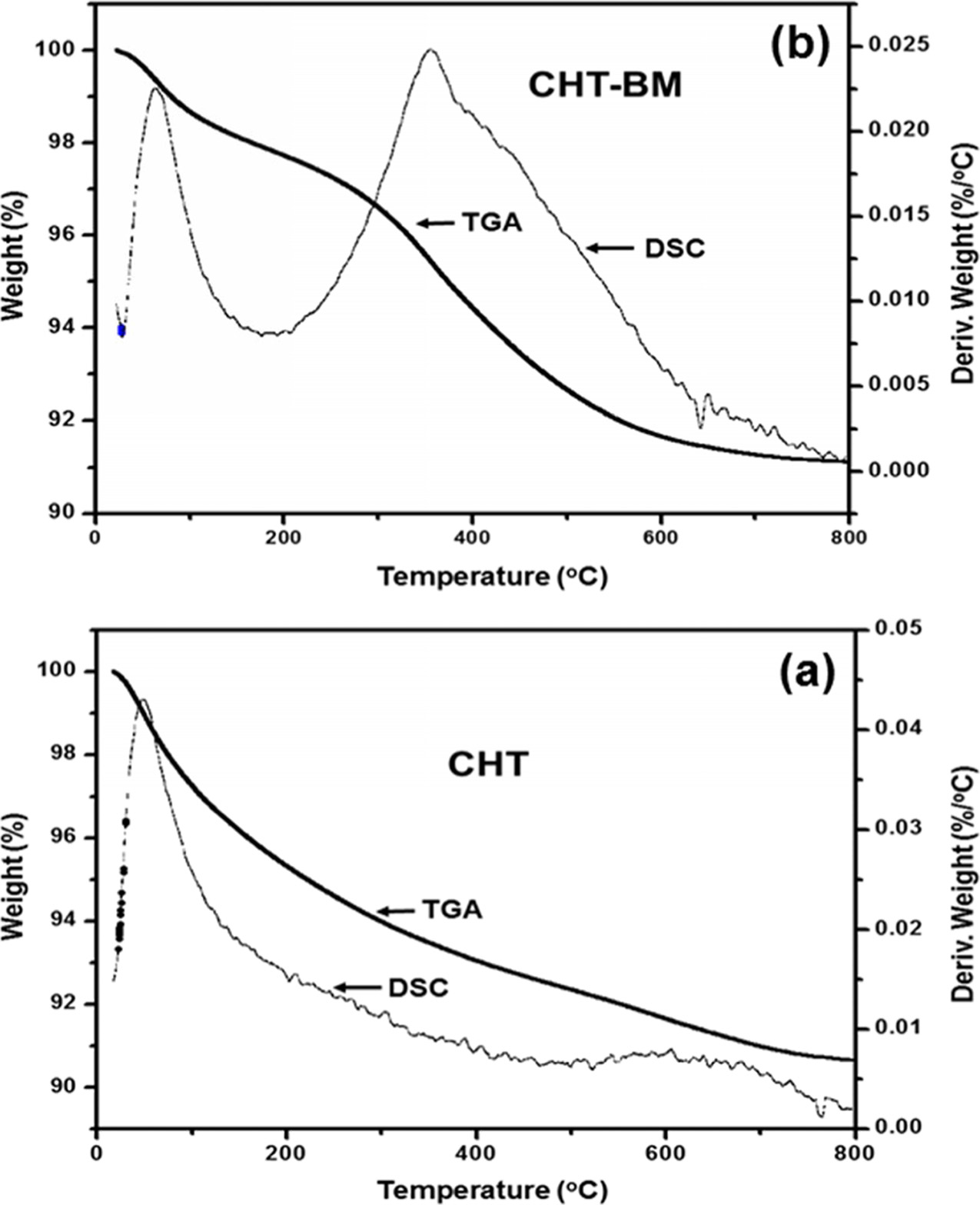

The CO2 adsorption behavior of CHT and CHT-BM samples

was examined. The obtained adsorption capacity values,

determined by thermogravimetric analysis and differential scanning calorimetry,

were different in both studied Mg-Al hydrotalcites. The TGA/DSC curves for CO2

desorbed from the studied hydrotalcite samples are shown in Fig. 5. It can be

observed that the CO2 adsorption capacity for CHT-BM was 2.018

mmol/g, which was 5.08% less than that observed value for CHT (2.126 mmol/g).

These obtained results are not consistent with those expected. The results

indicate that the ball-milling treatment negatively affects CO2

adsorption ability in the CHT-BM sample. It was expected that the

surface area would increase with mechanical ball-milling; however, it was

revealed that an important change occurred on the outer surface or inside the

CHT-BM sample. It is reasonable to expect that a mixed oxide derived from

calcined hydrotalcite, with considerable BET-surface area and high basicity,

would display an improved CO2 adsorption, and even more reasonable

to expect that the calcined Mg-Al hydrotalcite, treated by

ball milling (CHT-BM), would increase in its CO2 adsorption capacity

due to its nanometric scale and nature. Based on the above, the prepared CHT-BM

sample showed a decrease in its BET-surface area of 87.25 m2/g, in

comparison to the calcined Mg-Al hydrotalcite (191.97 m2/g), as well

as a decrease in its total pore volume, pore radius, as

can be seen in Table 1.

It can be clearly observed that the original small holes

and channels were blocked in the ball-milled calcined Mg-Al hydrotalcite

structure (CHT-BM). This alteration lead to a decrease in BET-surface area and

total pore volume, decreasing the effective reactive sites and reducing the

ability of the CHT-BM sample for CO2 capture. Also, it has been

widely reported that an appropriate pore size allows the diffusion of CO2

molecules inside of the adsorbent material; therefore, pore size can

inhibit or allow diffusion of CO2 molecules through the

hydrotalcite core, and certain pore sizes are ideal for CO2

adsorption. Consequently, an extended reduction in pore size can make the solid

adsorbent unsuitable for CO2 capture. In this regards, an average

particle-size reduction, resulting in the creation of fractures after

ball-milling, reduced the diffusion of CO2 molecules into the inner

framework of the CHT-BM and, as a consequence, the CO2

capacity of CHT-BM was decreased. In general, our results clearly

suggest that the agglomerate particle formation, a pore-size reduction,

decreased textural properties as a consequence of the

ball-milling treatment, which means that the treatment has negative effect over

the CO2 adsorption of calcined Mg-Al hydrotalcite. In that regard,

these significant results, demonstrate that CHT has the potential for CO2

capture, but that its efficiency is slightly decreased when this material is

ball-milled.

|

Fig. 1 XRD diffraction patterns of Mg-Al hydrotalcite samples prepared by the co-precipitation method; (a) no treatment (CHT) and (b) treatment with ball-milling for 2 h (CHT-BM). |

|

Fig. 2 SEM micrographs at 100X and EDS analysis of Mg-Al hydrotalcite samples prepared by the co-precipitation method; (a) no treatment (CHT) and (b) treated with ball-milling for 2 h (CHT-BM). |

|

Fig. 3 N2 adsorption-desorption isotherms of Mg-Al hydrotalcite samples prepared by the co-precipitation method; (a) no treatment (CHT), and (b) treated with ball milling for 2 h (CHT-BM). |

|

Fig. 4 Pore-size distributions by BJH method of Mg-Al hydrotalcite samples prepared by the co-precipitation method, with (a) no treatment (CHT) and (b) after treatment with ballmilling for 2 h (CHT-BM). |

|

Fig. 5 TGA-DSC curves of CO2 adsorption of Mg-Al hydrotalcite samples at 200 oC and 1 atmosphere: (a) calcined Mg-Al hydrotalcite (CHT) and (b) calcined Mg-Al hydrotalcite after ball-milling treatment for 2 h (CHT-BM). |

|

Table 1 Main textural properties of calcined Mg-Al hydrotalcite (CHT), and calcined Mg-Al hydrotalcite after ball-milling treatment for 2 h (CHT-BM). The samples were previously degassed with N2 at 300 oC for 2 h. |

*Barrette-Joyner-Halenda (BJH) method |

In this study, we investigated the effect of ball-milling

over the CO2 adsorption capacity of calcined Mg-Al hydrotalcite,

recognizing that this treatment is well-studied for the preparation of

nanostructured materials that should improve CO2

adsorption. However, in this work, it was demonstrated

that the ball-milling process is not considered a viable alternative for the

improvement of the CO2 absorption of calcined Mg-Al hydrotalcite,

due to its high particle aggregate formation, decreased

BET-surface area and pore size. Thus, based on all the aforementioned results,

it was concluded that the ball-milling process does not play a crucial role in

the obtainment of hydrotalcite compounds with better textural and structural

properties for enhancement of CO2 adsorption, and that

the calcined Mg-Al hydrotalcite treated by ball milling for 2 h does

not appear to be useful for large-scale CO2 capture technologies,

but certainly efficient when not treated by ball-milling.

This work was supported by the National Institute of

Nuclear Research (ININ), México, through research project CB-706, stages I to

III.

- 1. A. Yamasaki, J. Chem. Eng. Jpn. 36[4] (2003) 361-375.

-

- 2. D. Aaron and C. Tsouris, Sep. Sci. Technol. 40[1-3] (2005) 321-348.

-

- 3. S.Choi, J.H. Drese, and C.W. Jones, ChemSusChem 2[9] (2009) 796-854.

-

- 4. M.S. Shafeeyan, W.M.A.W. Daud, A. Houshmand, and A. Shamiri, J. Anal. Appl. Pyrol. 89[2] (2010) 143-151.

-

- 5. N. Chalal, H. Bouhali, H. Hamaizi, B. Lebeau, and A. Bengueddach, Micropor. Mesopor. Mat. 210 (2015) 32-38.

-

- 6. C. Chen, D. Park, and W. Ahn, Appl. Surf. Sci. 292 (2014) 63-67.

-

- 7. R. Dawson, A.I. Cooper, and D.I. Adams, Polym. Int. 62[3] (2013) 345-352.

-

- 8. H. Hedin, L. Andersson, L. Bergström, and J. Yan, Appl. Energy 104 (2013) 418-433.

-

- 9. N.A. Rashidi, S. Yusup, and A. Borhan, Procedia Eng. 148 (2016) 630-637.

-

- 10. K. Wang, X. Gou, P. Zhao, L. Zhang, and C. Zheng, Chem. Eng. J. 173 (2011) 158-163.

-

- 11. F. Granados-Correa, J. Bonifacio-Martínez, H. Hernández-Mendoza, and S. Bulbulian, J. Air Waste Manage. Assoc. 66[7] (2016) 643-654.

-

- 12. A. Miyata, Clays Clay Miner. 31[4] (1983) 305-311.

-

- 13. G. Mao, M. Tsuji, and Y. Tamaura, Clays Clay Miner. 41[6] (1993) 731-737.

-

- 14. F. Granados-Correa, J. Vilchis-Granados, M. Jiménez-Reyes, and L.A. Quiroz-Granados, J. Chem., 2013 Art. ID 751696, 1-9 pages.

-

- 15. T.M. Rossi, J.C. Campos, and M.M.V.M. Souza, Adsorption 22[2] (2016) 151-158.

-

- 16. F. Cavani, F. Trifiro, and A. Vaccari, Catal. Today 11[2] (1991) 173-301.

-

- 17. E.L.G. Oliveira, C.A. Grande, and A.E. Rodrigues, Sep. Purif. Technol. 62[1] (2008) 137-147.

-

- 18. J. Yang and N. Kim, Korean J. Chem. Eng. 23[1] (2006) 77-80.

-

- 19. M.H. Halabi, M.H.J.M. de Croon, V.D. Schaaf, P.D. Cobden, and J.C. Schouten, Int. J. Hydrogen Energy 37[5] (2012) 4516-4525.

-

- 20. E. Gutiérrez-Bonilla, F. Granados-Correa, V. Sánchez-Mendieta, and R.A. Morales-Luckie, J. Environ. Sci. 57 (2017) 418-428.

-

- 21. V. Manovic and E.J. Anthony, Int. J. Environ. Res. Public Health 7[8] (2010) 3129-3140.

-

- 22. F. Raganati, P. Ammendola, and R. Chirone, Powder Technol. 268 (2014) 347-356.

-

- 23. F.N. Ridha, V. Manovic, A. Macchi, and E.J. Anthony, Appl. Energy 140 (2015) 297-303.

-

- 24. E. Ordoñez-Regil, F. Granados-Correa, En. Ordoñez-Regil, and M.G. Almazán-Torrez, Environ. Technol. 36[2] (2015) 188-197.

-

- 25. J.M. Valverde, P.E. Sanchez-Jimenez, and L.A. Perez-Maqueda, Environ. Sci. Technol. 48[16] (2014) 9882-9889.

-

- 26. I.J. Son, K.I. Na, W. Kim, J.W. Lim, J.M. Doh, and J. Yoon, J. Ceram. Process. Res. 13 [16] (2012) 272-277.

- 27. L. Nikzerd, T. Ebadzadeh, M.R. Vaezi, and A. Tayebifard, J. Ceram. Process. Res. 13[5] (2012) 590-594.

- 28. W. Janusz, S. Khalameida, V. Sydorchuk, E. Skwarek, V. Zazhigalov, and Z.J. Skubiszewska, Adsorption 16[4-5] (2010) 333-341.

-

- 29. J. Qu, L. Sha, C. Wu, and Q. Zhang, Nanomaterials 9[1] (2019) 80.

-

- 30. L.N. Stepanova, O.B. Belskaya, O.N. Baklanova, A.V. Vasilevich, and V.A. Likholobov, Procedia Eng. 152 (2016) 672-680.

-

- 31. J. Qu, Q. Zhang, X. Li, X. He, and S. Song, Appl. Clay Sci. 119 (2016) 185-192.

-

- 32. J. Mi, X. Chen, Q. Zhang, Y. Zheng, Y. Xiao, F. Liu, C. Au, and L. Jiang, Chem. Commun. 55[63] (2019) 9375-9378.

-

- 33. M.R. Othman, Z.H. Martunus, and W.J.N. Fernando, Appl. Organomet. Chem. 23[9] (2009) 335-346.

-

- 34. T. Sato, H. Fujita, T. Endo, and M. Shimada, J. React. Solids 5[2-3] (1998) 218-219.

-

- 35. F. Granados Correa and J. Serrano Gómez, J. Radianal. Nucl. Chem. 268[1] (2006) 95-101.

-

- 36. F. Granados-Correa, J. Bonifacio-Martínez, and H. Hernández-Mendoza, Water Air Soil Pollut. 226[9] (2015) 1-10.

-

- 37. X. Xu, X. Zhao, L. Sun and X. Liu, J. Nat. Gas Chem. 18[2] (2009) 167-172.

-

This Article

This Article

-

2019; 20(6): 597-602

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.597

- Received on Jul 19, 2019

- Revised on Oct 4, 2019

- Accepted on Oct 7, 2019

Services

Services

- Abstract

experimental procedure

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- F. Granados-Correa

-

Instituto Nacional de Investigaciones Nucleares, Departamento de Química, A.P. 18-1027, Col. Escandón, Delegación Miguel Hidalgo, C.P. 11801, Ciudad de México, México

Tel : + 55-53297200 Fax: + 55-53297301 - E-mail: francisco.granados@inin.gob.mx

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.