- Thermoelectric properties of FeVSb1-xTex half-heusler alloys fabricated via mechanical alloying process

Rahidul Hasan and Soon-Chul Ur*

Department of Materials Science and Engineering/ReSEM, Korea National University of Transportation, 50 Daehak-ro, Chungju, Chungbuk 27469, Korea

FeVSb1-xTex (0.02 ≤ x ≤ 0.10)

half-Heusler alloys were fabricated by mechanical alloying process and

subsequent vacuum hot pressing. Near single half-Heusler phases are formed in

vacuum hot pressed samples but a second phase of FeSb2 couldn’t be

avoided. After doping, the lattice thermal conductivity in the system was shown

to decrease with increasing Te concentration and with increasing temperature.

The lowest thermal conductivity was achieved for FeVSb0.94Te0.06

sample at about 657 K. This considerable reduction of thermal

conductivities is attributed to the increased phonon scattering enhanced by

defect structure, which is formed by doping of Te at Sb site. The phonon

scattering might also increase at grain boundaries due to the formation of fine

grain structure. The Seebeck coefficient increased considerably as well,

consequently optimizing the thermoelectric figure of merit to a peak value of

~0.24 for FeVSb0.94Te0.06. Thermoelectric properties of

various Te concentrations were investigated in the temperature range of around

300~973 K.

Keywords: Thermoelectric, Thermal conductivity, Seebeck coefficient, Thermolectric figure of merit

Fossil fuel, the main source of energy today, is finishing

up very quickly. Thus, the energy scientists are giving priority to alternative

energy sources before the fossil fuels deposit run out. Moreover, fossil fuels

are spreading various greenhouse gases, which are the main cause of global

warming. A sustainable supply of clean energy is now in demand for

future energy solution. It is noted that, a lot of energy

is wasted in the form of heat during energy utilization process. Thermoelectric

(TE) power generators could be a possible solution because this can transform

the waste heat into useful electrical energy [1-3]. The

efficiency of a thermoelectric material is calculated by the

dimensionless figure of merit, ZT = S2sT/(kl + ke),

where S is the Seebeck coefficient, σ is the

electrical conductivity, T is the temperature, kl is the

lattice thermal conductivity, and ke is the thermal

conductivity due to electrons.

FeVSb half-Heusler (HH) materials are getting considerable

interest as potential TE materials due to its high power of conversion

efficiency and low cost of the elements [4]. In recent times, Fu et al. [5] and

Zou et al. [6] reported that FeVSb HH matrix can exhibit both n- and p-type TE

properties. Their studies suggest that large power factors could be achieved,

though high thermal conductivity limits the TE figure of merit. They proposed

that one of the effective ways to get high TE efficiency would be

nanostructuring. Nano-structuring produced ZT > 1.2 for n-type

MNiSn1-xSbx [7-9] and ZT = 0.9~1.0 for p-type

MCoSb1-xSnx [10, 11], where M = Ti, Zr and Hf.

TE figure of merit also can be upgraded by isoelectronic alloying, which is

capable of initiating phonon scattering [12]. There is strong evidence which

shows that increasing phonon scattering lowers the thermal conductivity

considerably [13, 14]. Solubility limits of the forming systems can also

be a factor which may bring ‘natural’ nanostructuring into the

crystal system. This nanostructuring is also capable of lowering the thermal

conductivity [9, 11]. TE efficiency can also be optimized by chemical

substitution, which may further improve the power factor

of the material system. Doping with electron donating or accepting elements

might help to optimize the carrier concentration [15].

Generally, doping establishes point defects in the host matrix,

which is innate in any material system. Doping elements act here as an exchange

corner between the distant reservoir and the host matrix

which could minimize the formation energy of

defect into the matrix by controlling the doping limits.

Mechanical alloying process is a well-known high energy

milling technique that can produce ultrafine microstructures [16]. It has

advantages over other traditional processes such as casting and forging [17,

18]. It may help to produce alloys which are difficult to produce

applying conventional metallurgical techniques. MA produces

fine-grained particles which improves the TE conversion efficiency by the

reduction of lattice thermal conductivity [19]. Fine-grained particles also

help to lower the diffusion path to enhance phase transformation

and homogenization. The high temperature process

such as arc-melting and levitation-melting were avoided to get rid of

evaporation of high vapor pressure elements (i.e., Sb, Sn) during processing.

In this study, TE performance of Te-doped FeVSb HH alloys

were described as a function of temperature at around 300~973 K. A group of

FeVSb1-xTex (0.02 £

x £ 0.10)

HH materials was synthesized by mechanical alloying (MA)

process followed by vacuum hot pressing (VHP). TE

properties were examined in the forms of Seebeck coefficient, electrical conductivity

and thermal conductivity. Transport properties were also

investigated in terms of Hall mobility, Hall coefficient and

carrier concentration.

For the synthesis of FeVSb1-xTex

(0.02 £ x £ 0.10) HH alloys, elemental powder

mixtures of Fe (99.9%, 63 µm), V (99.9%, 75 µm), Te (99.9%, 53 µm)

and Sb (99.9%, 45 µm) were used. A zirconia vial was used to carry out the

MA process using a high-energy vibrator mill (KMTech TMM 70, Korea) for 16 h.

The milling speed was kept constant at 1,080 rpm in this

experiment. 5 mm zirconia balls were used in this process, keeping

the ball-to-powder mixture ratio at 10꞉1. Consolidation of the powders was done

in VHP for 2 h under the pressure and temperature of 80 MPa and 1,073 K. A 10

mm graphite die was used in VHP for consolidation of powders.

Contamination during handling and processing of samples

throughout the process was avoided using Ar atmosphere.

A particle size analyzer (PSA) (Horriba LA-950, Japan) was

utilized to measure the particle size. X-ray diffraction

(XRD; Bruker AXS Advance D-8, Germany) of the MAed

and VHPed samples were carried out using Cu (Kα)

radiation. The microstructure was investigated using a scanning electron

microscopy (SEM) (FEI Quanta-400, Netherland). The Seebeck coefficient and

electrical conductivity were measured using ZEM3 (Ulvac-Riko, Japan) by 4-probe

method. 3×3×10 mm3 VHPed samples were used for the Seebeck

coefficient and electrical conductivity measurements and 10Φ × 1 mm

samples were used for thermal conductivity measurement.

Thermal diffusivity was captured using TC-9000H

(Ulvac-Riko, Japan) by a laser flash method. Density calculation was

done by the Archimedes principle. The Van

der Pauw method (modified Keithley

7065, USA) was applied to measure Hall measurement.

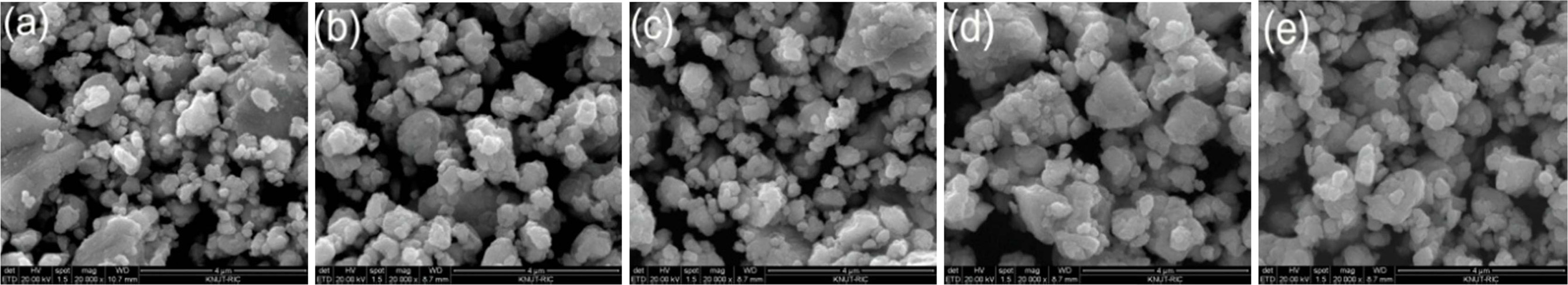

As-MAed powders are shown to be near spherical shape as in

typical MA process, and approximated particle sizes are of less than 10 µm as

shown in Fig. 1. Average particle sizes were measured using PSA are 7.0 µm, 6.2

µm, 5.9 µm, 5.3 µm and 5.2 µm for doping concentration,

x = 0.02~0.10, respectively. Particle size seems to

decrease with increasing doping concentration. The

collision of balls to the powder mixture might introduce lattice distortions

which could limit the particle size [20].

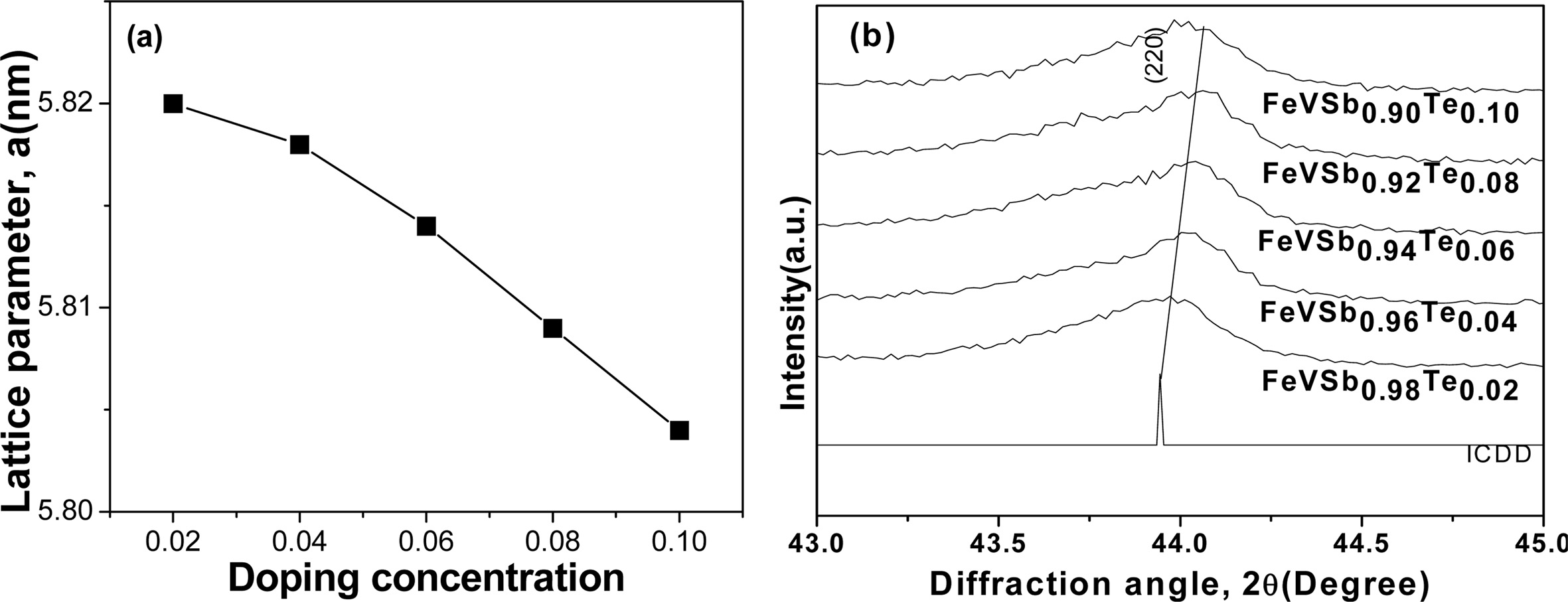

The lattice parameter decreased with increasing doping

elements according to Vegard’s law, which stated that lattice parameter varies

linearly with the atomic radii of the doping elements [21], as shown in Fig.

2(a). As the atomic size of the dopant decreased, the size of the lattice

also decreased. This decrease in lattice parameter might shift

the diffraction peak to the longer diffraction angle, which is represented by

(220) peak in Fig. 2(b). It is perhaps due to the replacement of larger Sb (atomic

radius = 1.45 Å) by smaller Te (atomic radius = 1.35 Å) atom shifts

the peak to the longer diffraction angle [22].

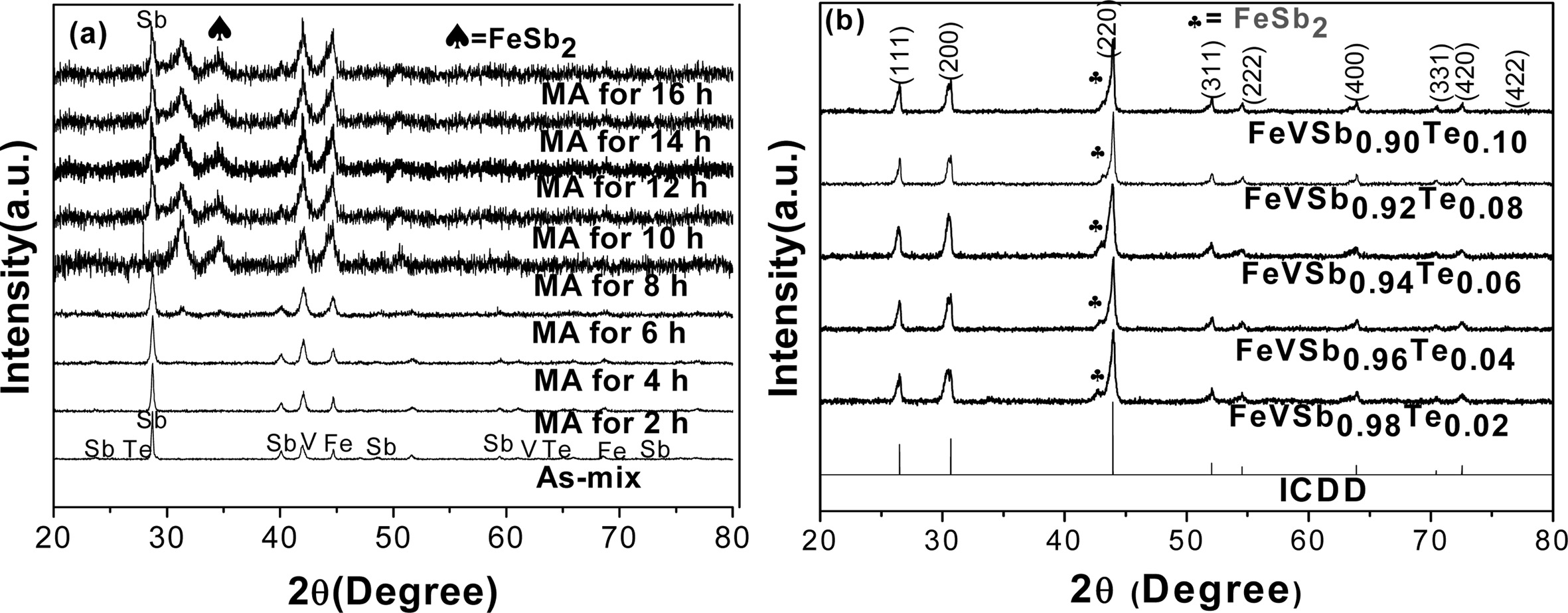

XRD patterns of the as-MAed powders are plotted in Fig.

3(a). The XRD patterns indicated that substitution of Sb by Te took place

slowly in FeVSb1-xTex and the HH phase formation

progressed during milling. Second phases of FeSb2and elemental Sb

were formed in the as-milled powder. The elemental peak of Sb is

completely disappeared but a trace of FeSb2 is still

remained after VHP, which is shown by Fig. 3(b). All the VHPed samples

contained HH phases as a dominant phase.

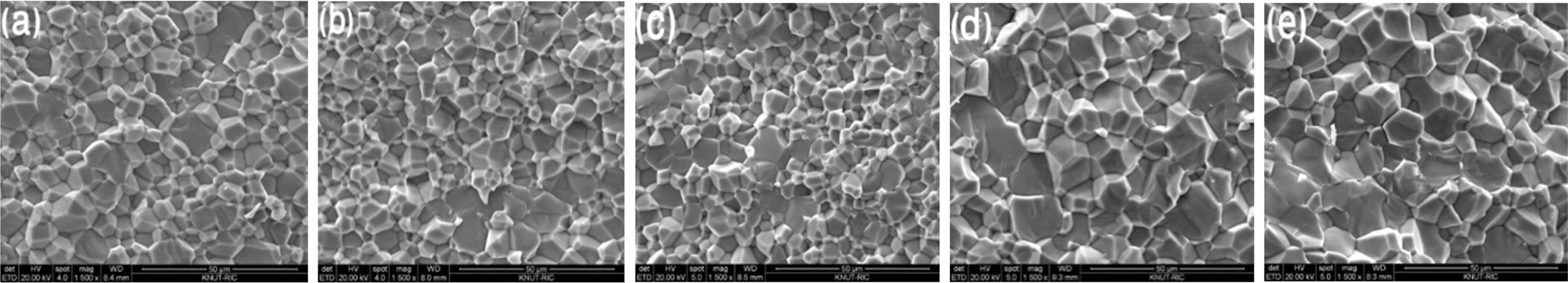

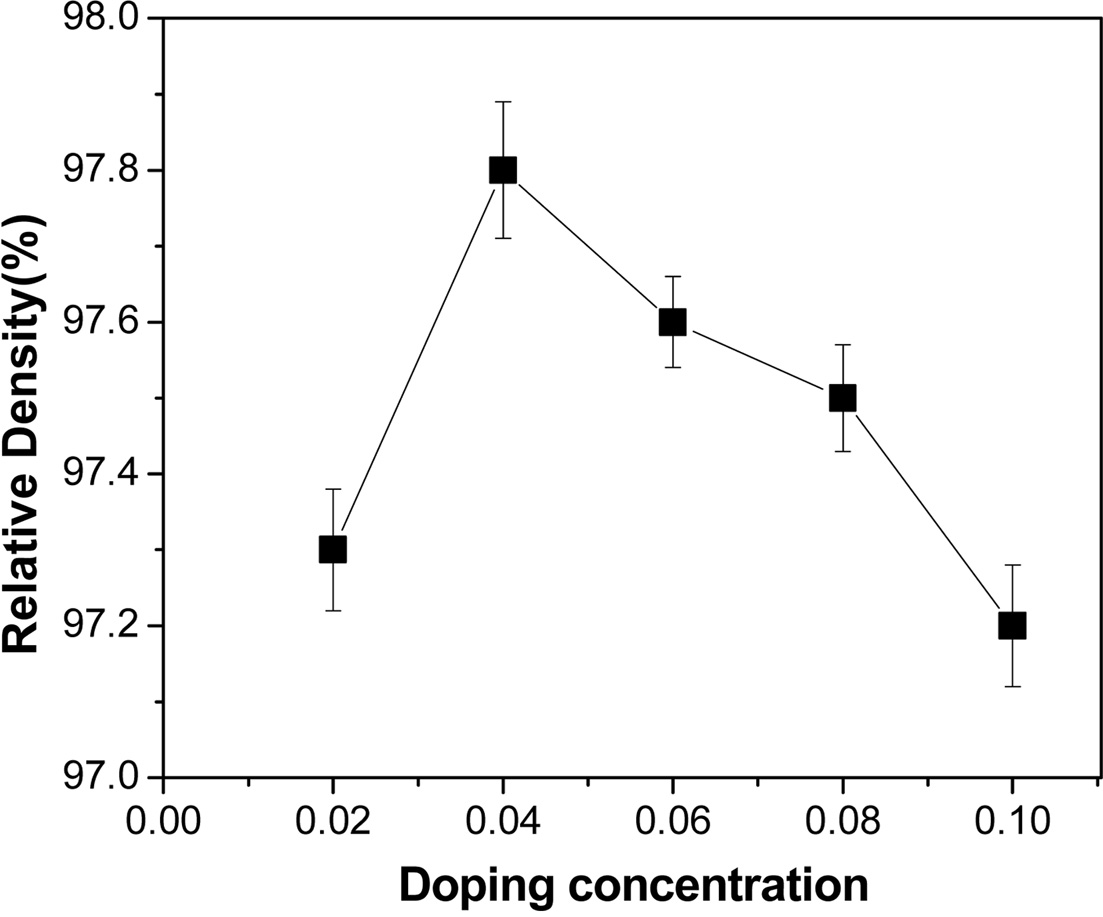

Fig. 4. shows the SEM images of the VHPed samples.

Relative density of the VHPed samples is found to be around 98% (Fig. 5.). The

grains seem to be densely packed, which could be induced from the relatively

high density of VHPed samples. The grain size of the sample measured was found

to be less than 10 µm.

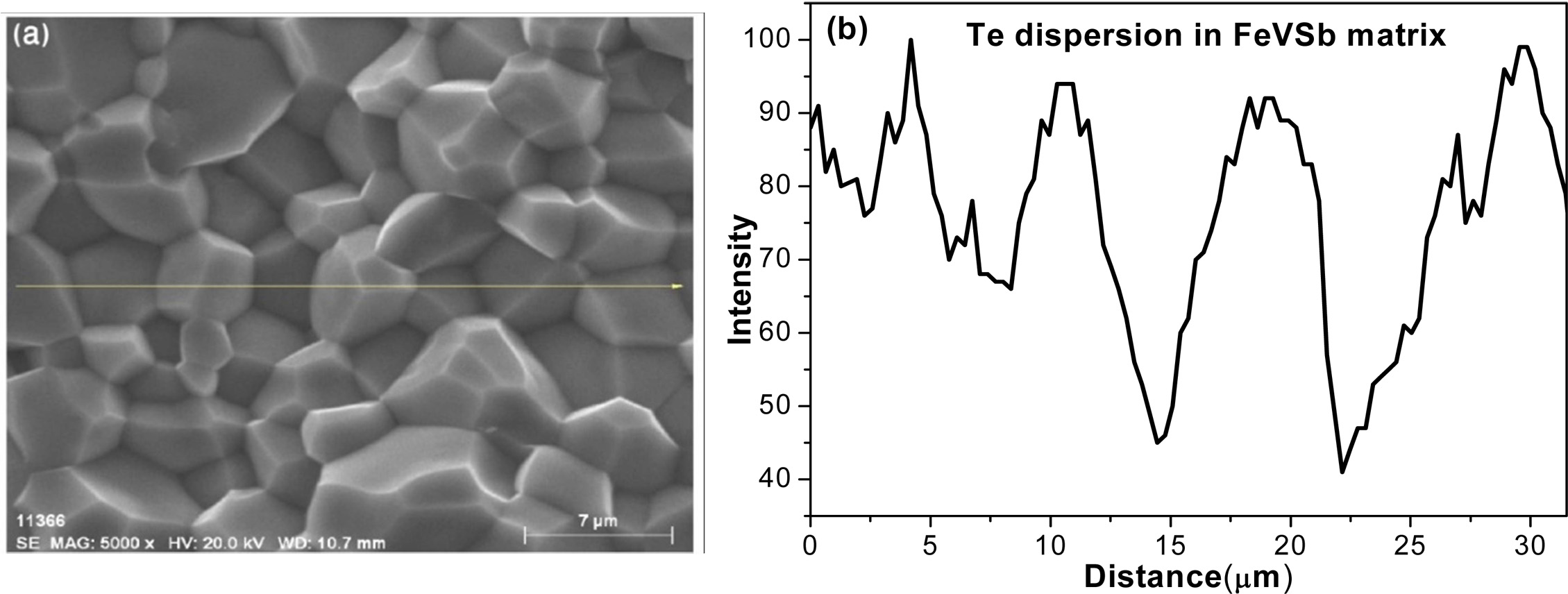

Te is a low melting point element (meltingpoint-723 K,

boiling point-1261 K). It could be sublimated during VHP process over the melting point

temperature. However, sublimation was not

much in this measurement. EDS line

mapping was performed to find out the traces of Te after VHP. The EDS line

mapping of the sample showed that Te

was homogeneously dispersed throughout

the HH matrix (Fig. 6).

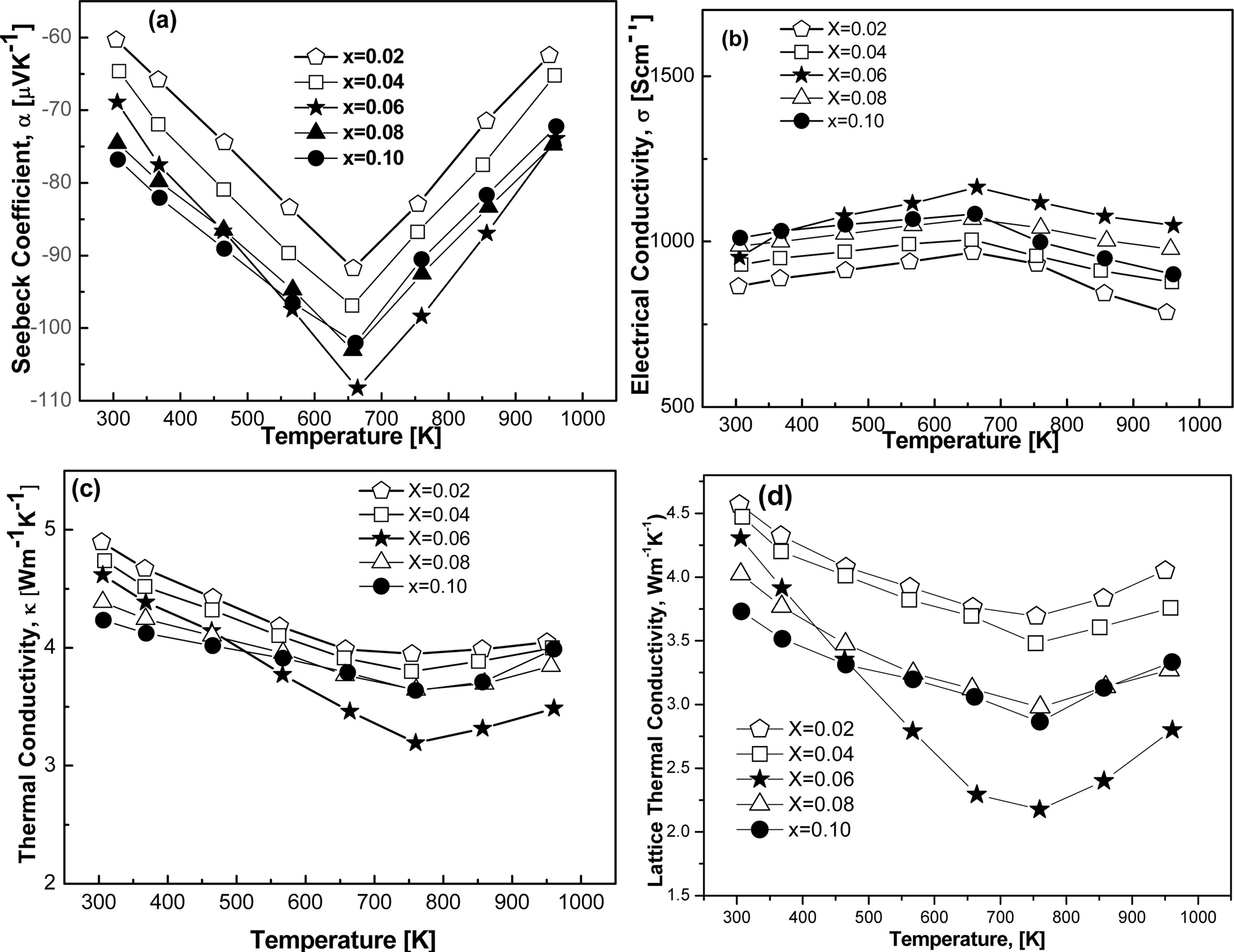

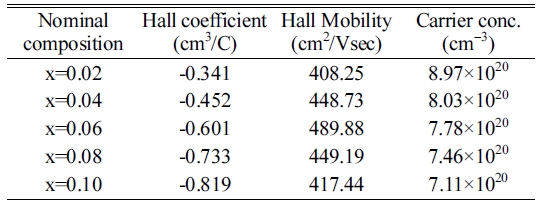

Fig. 7(a~d) shows the temperature dependence of Seebeck

coefficient, electrical conductivity, lattice thermal conductivity

and thermal conductivity, respectively. Fig. 7(a) reveals that Seebeck coefficient

is strongly dependent on Te concentration as it is varied with increasing

or decreasing temperature. The charge carriers for the

current system turned out to be electrons because the sign of the Seebeck

coefficient was found to be negative as can be seen in Fig. 7(a). The absolute

value of the Seebeck coefficient slightly increases with increasing Te

concentration at room temperature, reaching a maximum value of 77 µVK-1 for x = 0.06. The absolute

value of Seebeck coefficient is increased with the rise of temperature up to

650 K. This gradual increase of absolute Seebeck coefficient could be due to

the increase of effective mass of the charge carriers. As it is established

that Seebeck coefficient is directly proportional to the carriers effective mass

(S∞m*). Moreover, carrier concentration slightly decreased with the increasing

concentration of Te contents as shown in Table 2, which also enhances the

Seebeck coefficient as well. FeVSb0.94Te0.06 showed

strong temperature dependence of the Seebeck coefficient. A maximum value of

absolute Seebeck coefficient was found to be 107 µVK-1 for

x = 0.06 at 658 K. This suggests that the composition, FeVSb0.94Te0.06

holds great promise for enhanced figure of merit as the Seebeck

coefficient and electrical conductivity can be further increased via the

optimization of appropriate elemental doping at the Fe/V sites in the system

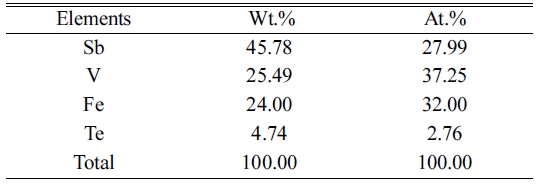

[23]. No incorporation of trace elements during milling was found which is

visualized in Table 1.

Temperature dependence of electrical conductivities in

FeVSb1-xTex HH samples are demonstrated by the Fig. 7(b).

At room temperature, electrical conductivity of all the samples climbed owing

to the semi-metallic behavior, which was resulted by the narrow band gap semiconductor

[24, 25]. Electrical conductivity increased again

for all the samples with the increasing temperature, which

indicated metallic behavior. This dependence of the

electrical conductivity on increasing Te concentration might be due

to the change of carrier concentration and mobility as a function of Te

concentration. The highest electrical conductivity of 1,164 Scm-1

was observed for the sample x=0.06, which also showed the considerable TE

efficiency as TE efficiency is directly proportional to electrical

conductivity and the degeneracy of electron band. This

increase in electrical conductivity could also be due to the easy

transformation of Fermi band to the higher conduction band by thermal elevation

of electrons within the band gap [26]. Eventually, electrical

conductivity slightly decreased at higher temperature range of around 660~973

K. It can be considered that all the samples displayed bipolar electrical

behavior over the temperature range of 300~973 K. Although a significant

improvement of the electrical conductivity of FeVSb1-xTex

alloys could be achieved by optimizing the Te concentration, the observed

values are still low for the expectation in TE material. Generally, to be used

in a device, ZT of a TE material should be ~1. However, the prospect of further

enhancement of the electrical conductivity of this family of compounds is

expected to be high through doping on Fe or V sites [26].

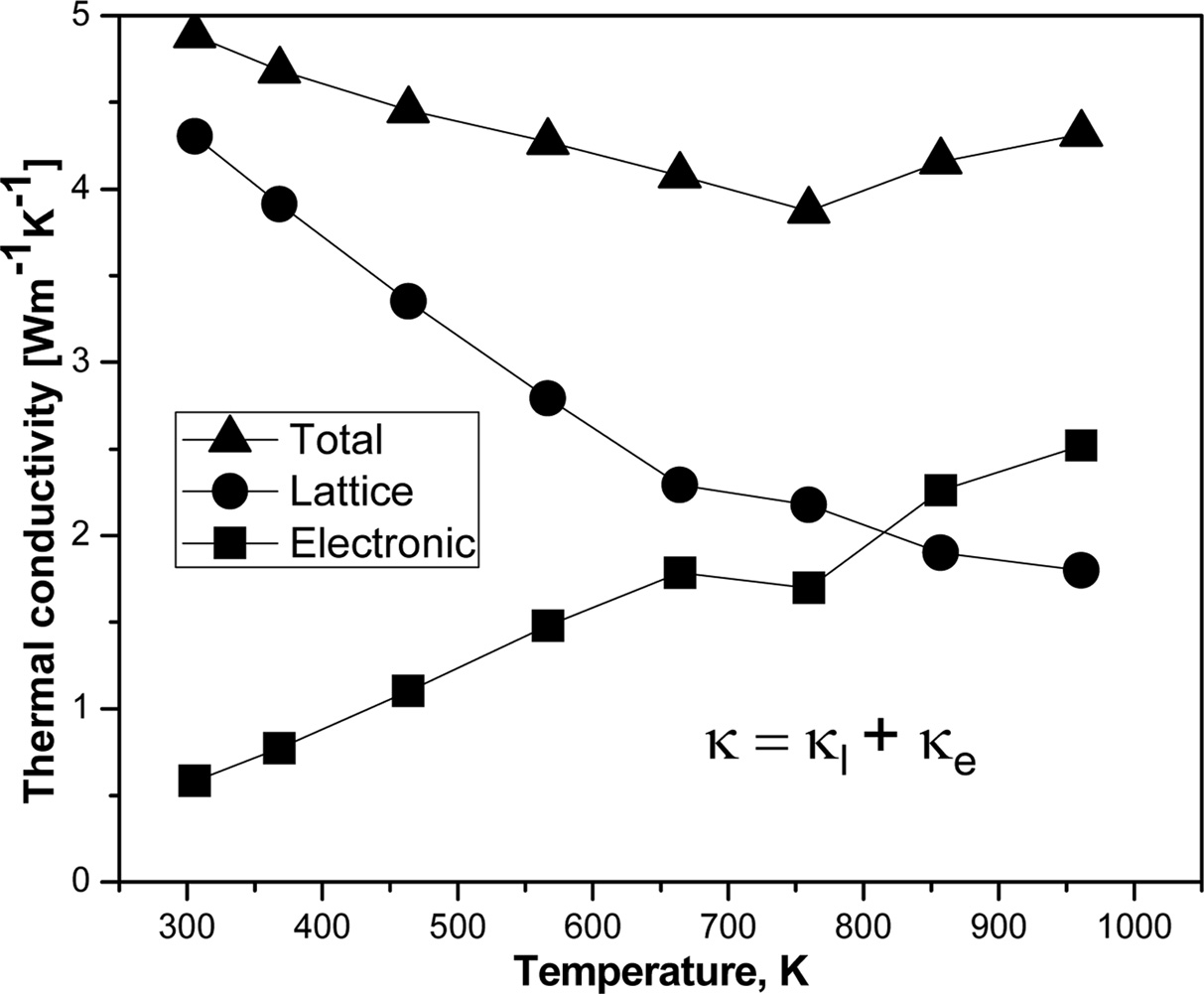

Temperature

dependence of thermal conductivity and lattice thermal conductivity are shown

in Fig. 7(c, d). Both of them markedly decreased at room temperature after

adding increasing order of dopants. The lattice thermal conductivity of FeVSb1-xTex

decreased considerably with increasing Te

contents. It could be due to the enhanced phonon scattering. Possibly,

effective hybridization of 5p orbitals of both the Sb and Te optimized the

carrier concentration [27]. This optimized concentration increased the

effective mass of the carriers, which took part in effective phonon scattering

process. In addition, because of the expected small grain size (≤10 μm) of the

synthesized FeVSb1-xTexHH materials, a high density of

grain boundaries might form. This

translates enhanced phonon scattering

at grain boundaries which may contribute significantly to the reduction of the

lattice thermal conductivity as well. Regardless of the composition, the

lattice thermal conductivity decreases considerably with rising temperature

(Fig. 7(d)) and lattice thermal conductivity as low as 2.22 Wm-1K-1

was achieved at 773 K for composition with x = 0.06. A similar trend

was observed for the total thermal conductivity of all FeVSb1-xTex

compounds (Fig. 7(c)). There is a marginal difference

between the total thermal conductivity and the lattice contribution and is

observed for all the compositions due to the very low electronic thermal

conductivity of FeVSb1-xTex alloys (Fig. 8). No foreign

elements effect on thermal conductivity was observed, which was

confirmed by EDS analysis given in Table 1. The

electronic thermal conductivity is found considerably low;

however, it cannot be ignored for good TE devices. The maximum

thermal conductivity is found to be ~5 Wm-1K-1.

This thermal conductivity is considerably low compared to other material

system, and it is practically noticeable. Second phase could also be

responsible for this decreasing of thermal conductivity. Electronic thermal

conductivity can be calculated using the equation, κe = LσT,

where L is the Lorenz number (2×10-8 WΩK-2).

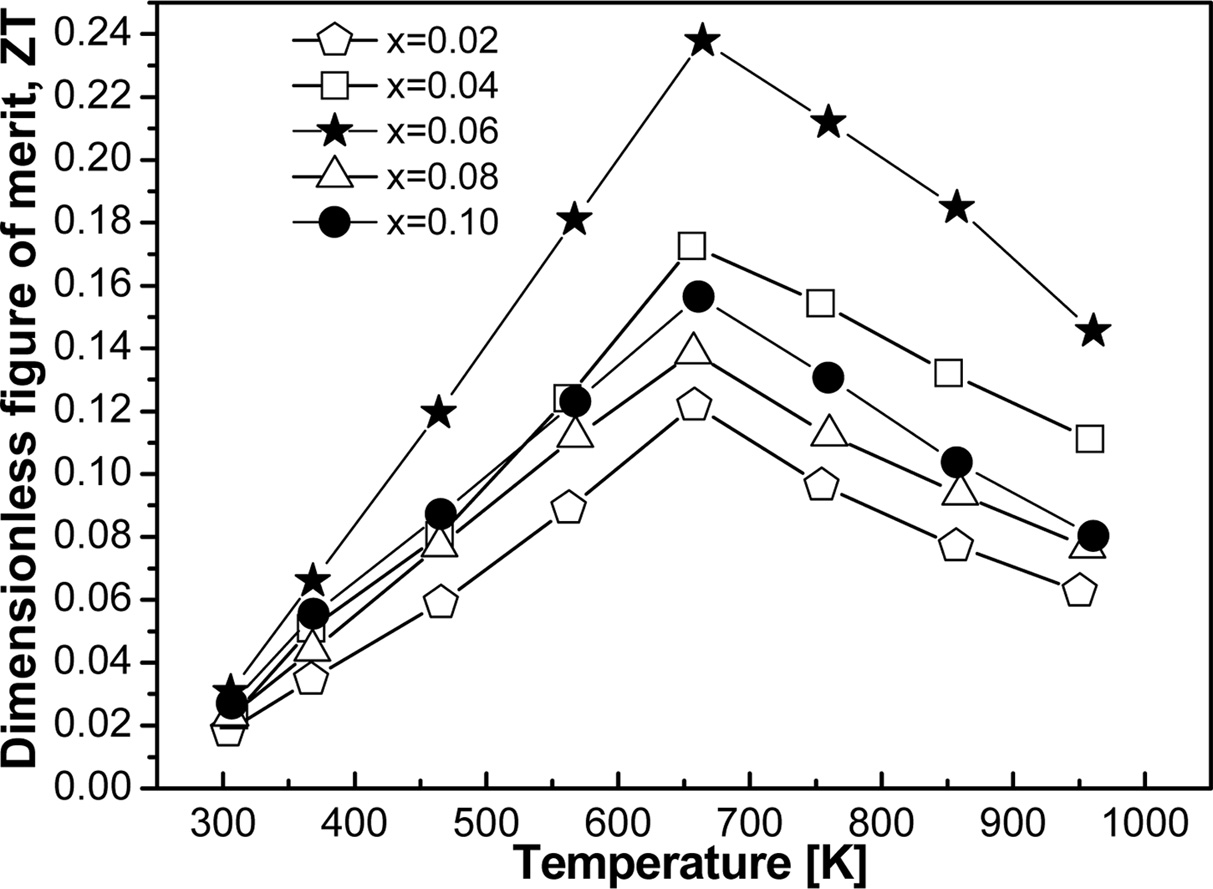

The dimensionless figure of merit (ZT) was calculated

from TE properties and shown in Fig. 9 as a function of temperature. The

maximum value of ZT is achieved for the sample x = 0.06 at 657 K.

This moderate value of ZT could not be enough to be used in a practical TE

device. Generally, denser material produced maximum ZT which is

evident in this experiment for FeVSb0.94Te0.06.

The resultant maximum ZT of 0.24 was found due to the impurities free material

formation and relatively low thermal conductivity with relatively high Seebeck

coefficient. This suggests that careful tuning of the appropriate dopant might

produce higher ZT than current experiment. Another way that might be fruitful

to improve ZT is multi-doping which could decrease the thermal conductivity to

a large fraction and enhance ZT significantly [28].

|

Fig. 1 Average particle size of as-MAed powders for 16 h; (a) x=0.02, (b) x=0.04, (c) x=0.06, (d) x=0.08, and (e) x=0.10. |

|

Fig. 2 Crystal structure variations of VHPed samples; (a) lattice parameter as a function of doping elements, and (b) peak shifting to lower diffraction angle for FeVSb1-xTex (x=0.02~0.10). |

|

Fig. 3 X-ray diffraction patterns of; (a) MAed powder samples which represent progress of milling, and (b) HH phase formation with a fraction of secondary phase. |

|

Fig. 4 SEM images of the VHPed samples of FeVSb1-xTex; (a) x=0.02, (b) x=0.04, (c) x=0.06, (d) x=0.08, and (e) x=0.10. |

|

Fig. 5 Relative density against the doping concentration. |

|

Fig. 6 EDS line mapping image of Te in VHPed FeVSb1-xTex HH phases as a representative. |

|

Fig. 7 Temperature dependent thermoelectric properties in the form of; (a) Seebeck coefficient, (b) electrical conductivity, (c) thermal conductivity, and (d) lattice thermal conductivity. |

|

Fig. 8 Temperature dependence of total thermal conductivity in the form of lattice thermal conductivity and electronic thermal conductivity. |

|

Fig. 9 Calculated temperature dependent ZT as a function of doping element. |

FeVSb1-xTex (0.02 ≤ x ≤ 0.10)

HH alloys synthesized by MA process and subsequent VHP were studied in the

temperature range of around 300 to 973 K. It was found that with the increase

of Te concentration, the lattice thermal conductivity decreased considerably.

The lowest value of lattice thermal conductivity is found to be 2.22 Wm-1K-1

at 773 K, which is relatively low for HH compounds. The lowest

thermal conductivity was obtained for the composition FeVSb0.94Te0.06.

This considerable reduction of the lattice thermal conductivity

of the FeVSb0.94Te0.06 HH alloys might be due to the enhanced phonon

scattering, increased effective mass of carriers and second phase interaction

by Te substitution at the Sb site in FeVSb matrix. The Seebeck coefficient and

electrical conductivity were found to be very sensitive to the Te concentration

throughout the process. Te substitution at the Sb site enhanced the ZT of FeVSb1-xTexHH

alloys and the maximum ZT was found to be 0.24 at 657 K for FeVSb0.94Te0.06.

Although the observed highest ZT value is relatively moderate to apply in a TE

device, further improvement maybe possible through enhancement of the electrical conductivity and Seebeck

coefficient via optimization of appropriate doping at the Fe/V sites and

formation of pure single phase.

This work was supported by the Regional Innovation Center

(RIC) Program, which was conducted by the Ministry of SMEs and Startups of the

Korean Government, and the Korea Basic Science Institute grant funded by the

Ministry of Education (grant no. 2019R1A6C1010047).

- 1. J.B. Neaton, Nature Nanotechnology. 9 (2014) 876-877.

-

- 2. X.F. Zheng, C.X. Liu, Y.Y. Yan, and Q. Wang, Renewable and Sustainable Energy Reviews. 32 (2014) 486-503.

-

- 3. G.J. Snyder and E.S. Toberer, Nature Materials. 7 (2008) 105-114.

-

- 4. K. Delime-Codrin, T. Yamada, A. Yamamoto, R. Sobota, M. Matsunami, and T. Takeuchi, Jpn. J. Appl. Phys. 56 (2017) 111202.

-

- 5. C. Fu, H. Xie, T. Zhu, J. Xie, and B.X. Zhao, J. Appl. Phys. 112 (2012) 124915.

-

- 6. M. Zou, J.F. Li, T. Kita, Sol. Stat. Chem. 198 (2013) 125-130

-

- 7. S. Sakurada and N. Shutoh, Appl. Phys. Lett. 86 (2005) 082105.

-

- 8. S. Populoh, M. Aguirre, O. Brunko, K. Galazka, Y. Lu, andA. Weidenkaff, Materials, 6 (2013) 1326-1332.

-

- 9. M. Schwalland B. Balke, Phys. Chem. Chem. Phys. 15 (2013) 1868-1872.

-

- 10. X. Yan, W. Liu, H. Wang, S. Chen, J. Shiomi, K. Esfarjani, H. Wang, D. Wang, G. Chen, and Z. Ren, Energy Environ. Sci., 5 (2012) 7543-7548.

-

- 11. E. Rausch, B. Balke, S. Ouardi, andC. Felser, Phys. Chem. Chem. Phys. 16 (2014) 25258-25262.

-

- 12. P. Qiu, X. Huang, X. Chen, andL. Chen, J. Appl. Phys. 106 (2009) 103703.

-

- 13. Z. Aksamijaand I. Knezevic, Phys. Rev. B. 88 (2013) 155318.

-

- 14. K. Kothariand M. Maldovan, Nanoscale and Microscale Thermophysical Engineering. 22 (2018) 1-15.

-

- 15. R. Stern, B. Dongre, andG.K.H. Madsen, Nanotechnology. 27 (2016) 334002.

-

- 16. S.-C. Ur, H. Choo, D. B. Lee, and P. Nash, Metals and Materials, 6 (2000) 435.

-

- 17. E.P. DeGarmo, J.T. Black, and R.A. Kohser, Solution Manuals to Accompany-Materials and Process in Manufacturing (9th Ed.), John Wiley and Sons Ltd, New York (2003).

- 18. M. Blair and T.L. Stevens, Steel Castings Handbook, ASM International, Ohio (1995).

- 19. D.M. Rowe and V.S. Shukla, J. Appl. Phys. 52 (1981) 7421.

-

- 20. W. Qin, T. Nagase, Y. Umakoshi, andJ.A. Szpunar, J. Phys.: Condens. Matter. 19 (2007) 236217.

-

- 21. A.R. Dentonand N.W. Ashcroft, Phys. Rev. A. 43 (1991) 3161-3164.

-

- 22. E. Atkins, Phys. Bull. 29 (1978) 572.

-

- 23. T. Sekimoto, K. Kurosaki, H. Muta, andS. Yamanaka, 24th International Conference on Thermoelectrics (ICT 2005).

-

- 24. G. S. Nolas, J. Sharp, andJ. Goldsmid, Thermoelectrics: Basic Principles and New Materials Development, Springer, USA, 2001.

-

- 25. P. Maji, N.J. Takas, D.K. Misra, H. Gabrisch, K. Stokes, and P.F.P. Poudeu, Solid State Chem. 183 (2010) 1120-1126.

-

- 26. C. Uher, J. Yang, S. Hu, D.T. Morelli, and G.P. Meisner, Phys. Rev. B. 59 (1999) 8615-8621.

-

- 27. J. Cui, G. Cai, and W. Ren, RSC Adv. 8 (2018) 21637-21643.

-

- 28. R. Hasan and S.-C. Ur, Trans. Electr. Electron. Mater. 19 (2018) 106-111.

-

This Article

This Article

-

2019; 20(6): 582-588

Published on Dec 31, 2019

- 10.36410/jcpr.2019.20.6.58

- Received on Mar 8, 2019

- Revised on Aug 21, 2019

- Accepted on Sep 26, 2019

Services

Services

- Abstract

introduction

experiments

results and discussions

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Rahidul Hasan and Soon-Chul Ur

-

Department of Materials Science and Engineering/ReSEM, Korea National University of Transportation, 50 Daehak-ro, Chungju, Chungbuk 27469, Korea

Tel : +82-43-841-5385 - E-mail: scur@ut.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.